Search results for: 'hard'

- Related search terms

- hardwired level 2 charger

- hard wire io box

- harden 4

- hard cap hat

- hardness testing machine

-

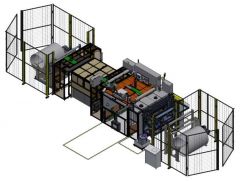

NANOSPIDER - ELECTROSPINREFERENCE NUMBER: A-2510 NANOSPIDER - ELECTROSPIN FIRST – (ROUNDED TANKS) NEW GENERATION NS PRODUCTION LINE ALLOWS NANOFIBERS TO BE PRODUCED ON A FULLY-INDUSTRIAL SCALE FOR A NUMBER OF APPLICATIONS FEATURES: • CONSTRUCTION USING SELF - EXTINGUISHING MATERIALS • VENTILATED SPINNING CHAMBER, PREVENTING THE ESCAPE OF SOLVENT FUMES • GROUNDING ROD FOR CHARGE DISSIPATION AND AUTOMATIC GROUNDING SYSTEM • FOUR EMERGENCY - STOP BUTTONS ARE PLACED ON THE CORNERS OF THE UNIT • ONE EMERGENCY - STOP BUTTON IS PLACED ON THE SERVICE CONTROL PANEL • THE TWO UPWARD SLIDING DOORS ARE EQUIPPED WITH AUTOMATIC DOOR LOCKS WITH LIMIT SWITCHES TO PREVENT ACCIDENTAL OPENING AND WILL ALSO SHUT DOWN THE UNIT IF A SLIDING DOOR IS ACCIDENTALLY OPENED • THE FOUR LOWER SWING OPEN DOORS HAVE LIMIT SWITCHES THAT WILL SHUT DOWN THE UNIT IF THE DOOR IS ACCIDENTALLY OPENED • FIRE SUPPRESSION SYSTEM FOR THE SPINNING CHAMBER WITH MANUAL ACTIVATION VIA BUTTON ON THE CONTROL PANELS • THE EQUIPMENT IS PRODUCED ACCORDING TO CE STANDARDS • RECOMMENDED ROOM LAYOUT: THE LAYOUT WILL BE OPTIMIZED ACCORDING TO BUYER NEEDS • LIGHTS ON THE FRONT AND BACK OF MACHINE SPECIFICATIONS: POLYMER (PROCESS) TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • CYLINDRICAL TANKS ON WHEELS, ONE FOR FRESH POLYMER • CYLINDRICAL TANKS ON WHEELS, ONE FOR WASTE • MIXING CAPABILITY (PNEUMATIC MIXTURE) FOR IN AND OUT TANKS - PNEUMATIC DRIVEN AGITATOR • CLEANING SHOWER FOR BOTH IN AND OUT TANK • TWO CYLINDRICAL SHAPED TANKS ON THE WHEELS IN ONE TUB • BURST DISK FOR EACH TANK • QUICK COUPLINGS STÄUBLI HCB 08 WORKING VOLUME OF TANKS IS 60 LITERS FOR EACH TANK CLEANING TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • TANK WITH VOLUME OF 60 LITERS WILL BE DIVIDED INTO TWO SECTIONS: 30 L FOR CLEAN,30 L USED CLEANING SOLUTION • CYLINDRICAL TANK ON WHEELS - SIZE ROUGHLY HALF OF THE PROCESS TANKS • BURST DISK FOR EACH TANK VOLUME 30 + 30 LITERS WILL BE POSSIBLE TO USE MULTIPLE TIMES FOR CLEANING SITE PREPARATION / CONNECTION REQUIREMENTS ALL POWER SUPPLY IS REALIZED FOR FULL LINE INCLUDING PERIPHERAL PARTS. IT IS JUST NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ AND 50/60Hz, MAIN CIRCUIT BREAKER 32 A POWER CONSUMPTION: UP TO 12 KW PRESSURE AIR: 5 TO 8 BAR, CONNECTION POINT CAPACITY 1000 L/min INERT GAS: 0.5 BAR, CONNECTION POINT CAPACITY 200 L/min PROCESS AIR INLET/OUTLET: UP TO 1000 M3/H PRODUCT SIZE AND WEIGHT LENGTH: APPROX. 2800 mm WIDTH: APPROX. 3300 mm HEIGHT: APPROX. 3000 mm WEIGHT: APPROX. 2500 KG SCOPE OF SUPPLY SPINNING CHAMBER • WITH WIRE COLLECTING ELECTRODE • LIFTING MECHANISM OF CART CAPABLE OF ADJUSTING THE DISTANCE BETWEEN THE COLLECTING AND SPINNING ELECTRODE BETWEEN 150 AND 250 mm VIA THE CONTROL PANEL • HV PROTECTING COVERS • SLIDING DOORS WITH ILLUMINATION • AIR INLET AND OUTLET WITH HOMOGENIZER AND FANS EXTINGUISHING SYSTEM • SWITCHBOARD SPINNING CART • 2 X PROCESS DOUBLE - TANKS (ONE CART ON WHEEL, EACH WITH IN AND OUT TANK) • CDS – CHEMICAL DISTRIBUTION SYSTEM • SEPARATE SPINNING MODULE EACH WITH MOVABLE CARRIAGE WITH SPINNING HEAD, ENERGY CHAIN • HV COVERS • WIRE SPINNING MECHANISM • WIRE ALIGNMENT MECHANISM • SET OF WIRE SPOOL 0.2 mm AND 0.3 mm MAIN OPERATOR PANEL – CONTROL SYSTEM HV POWER SUPPLIES SYSTEM (MAXIMUM AVAILABLE RATINGS + 80 KV DC / - 60 KV DC) SET OF SPINNING NOTCHES – FOR ROR 1 X CLEANING TANKS SERVICE OPERATION PANEL AUTOMATIC DISCHARGER R & D MODE ENABLE ELECTRO SPINNING FROM 4 WIRES ONLY – ONE MODULE PREPARATION FOR DRIVEN ENDLESS BELT COLLECTING ELECTRODE NOT IN SCOPE OF SUPPLY • SPARE WIRE FOR SPINNING • SPARE POLYMER CONTACT COMPONENT: CDS (PUMPS, VALVES, HOSES), SPINNING CARRIAGES WITH SPINNING HEADS, ENERGY CHAINS WITH POLYMER HOSES • SET OF SPINNING NOTCHES – NOT NECESSARY FOR ROR • ENDLESS BELT COLLECTING ELECTRODE REWINDING 1600 mm FULL THE NS LINE ALLOWS THE PRODUCTION OF NANOFIBERS ON A SUBSTRATE MATERIAL ONLY. THE SUBSTRATE MATERIAL MUST BE PRESENT IN THE SPINNING UNIT DURING THE SPINNING PROCESS. MOST NANOFIBER PRODUCTS USE TEXTILE, PAPER, OR FOIL SHEETS IN ROLLS AS A SUBSTRATE MATERIAL. UNWIND AND REWIND EQUIPMENT ALLOWS BIDIRECTIONAL REWINDING OF THE SUBSTRATE MATERIAL. THE ROLL GOODS EXCHANGE AND INSERTION IS MANUAL. MANIPULATION TOOLS ARE USUALLY NECESSARY BOTH UNWIND AND REWIND CONTAINS STEEL FRAMES WITH MOTORS, WHICH DRIVE THE UNWINDING AND WINDING PNEUMATIC SHAFTS SPEED IS CONTROLLED BY A SPECIAL RUBBER CYLINDER. THE PNEUMATIC SHAFTS ARE INFLATABLE AND SUITABLE FOR USE WITH PAPER CORES FEATURES: MAIN ROLL UNWINDER • THE SIDE-WALLS OF UNWINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE RUNNING ROLLERS ARE MACHINED • THE UNWINDER IS EQUIPPED SWINGING SPLICING TABLE. MAT SPLICING IS SOLVED BY THE CUSTOMER (E.G. DOUBLE STICKY TAPE) • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE UNWINDER. ON THE UNWINDER THERE IS PLACED STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE WINDER • THE SIDE-WALLS OF WINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE-RUNNING ROLLERS ARE MACHINED • COMPENSATOR SPLITS THE WINDING TENSION FROM PRODUCTION LINE AND THE WINDER. TO INCREASE THE FRICTION COEFFICIENT AND THUS TO PREVENT SLIDING OF THE WOUND MATERIAL, COMPENSATOR ROLLER SURFACE IS FINISHED WITH A GLUED TEXTILE STRAP WITH A LAYER OF THE RUBBER. THE WOUND MATERIAL CONTACTS THE OPPOSITE SIDE TO THAT ONE WITH NANOFIBERS • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE WINDER • ON THE WINDER THERE IS PLACED THE STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE BANANA ROLL • ROLL IS PLACED TO ADJUSTABLE BEARINGS FOR EASY SETTING OF CORRECT SPREADING EFFECT. ROLL SURFACE IS RUBBER COATED. THE BANANA ROLL IS DRIVEN TO SECURE ITS ROTATION AT LOW WINDING TENSIONS LONGITUDINAL CUTTING • INDIVIDUAL CUTTING HEADS CAN BE MANUALLY ADJUSTED TO THE DESIRED WIDTH. CUTTING IS CARRIED OUT BY PRESSURE AGAINST THE HARDENED CYLINDER - SHREDDER. CUTTING QUALITY IS RECOMMENDED TO TEST THE MATERIAL IN ADVANCE. THE EDGE TRIMS SLIDES ALLOW TO REDIRECT TRIMS TO CUSTOMER BIN OR TRIM WINDER WINDER EDGE GUIDING • THE EDGE GUIDING EQUIPMENT CONSIST OF WINDER BASE FRAME WITH TRANSVERSAL RAILS, ROLLERS MOUNTED ON WINDER MOVING FRAME, LINEAR ACTUATOR AND EDGE SENSOR INSTALLED ON ADJUSTABLE ARM. THE SENSOR MONITORS MATERIAL EDGE AND IN CASE OF EDGE POSITION DEVIATION THE WINDER FRAME IS MOVED RIGHT OR LEFT TO COMPENSATE THE MATERIAL PATH DEVIATION CONTROL SYSTEM • USER CONTROLS OF THE REWINDING IS SOLVED FROM THE MAIN CONTROL PANEL (HMI) OF NANOSPIDER LINE. SERVICE INTERVENTIONS ARE PERFORMED FROM THE SERVICE PANEL LOCATED ON THE DEVICE SPECIFICATIONS: WORKING WIDTH: 1650 mm SPEED: 0.4 TO 40 M/min +/- 1% CORES, INNER DIAMETER: 76 mm (3'') MAX. WINDING FORCE: 2000 N @ 90 mm MIN. WINDING FORCE: 80 N MAX. UNWINDING FORCE: 700 N MIN. UNWINDING FORCE: 40 N MAXIMUM DIAMETER OF ROLL: 1200 mm SAFETY FENCING • SAFETY FENCING IS NEEDED TO AVOID MECHANICAL HAZARDS IN THE CASE OF A RUNNING WINDING. FIRST THREATING OF THE SUBSTRATE IS PERFORMED WITH THE ENGINE DISCONNECTED, IE WITHOUT THE DANGER. ACCURATE FENCING DESIGN FOR COMPLETE SOS (SCOPE OF SUPPLY). VERY OFTEN IS IN SAFETY FENCING PLACE AIR PERMEABILITY TESTER OR OTHER EQUIPMENT BEFORE REWINDING. PROVIDED SAFETY FENCING COMPLIES WITH THE CURRENT MACHINERY DIRECTIVE 2006/42/EC HEIGHT: 1900 mm SAFETY DISTANCE: 120 mm PILLARS: 50 X 50 mm OR 70 X 70 mm MESH SIZE: 50 X 30 mm NUMBER OF DOORS: 1 X UNWINDER 2 X REWINDER SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THOUGHT NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASE OF ELECTRICAL POWER, SPACE AND PRESSURE AIR POWER: 10 KW VOLTAGE: 220 VOLTZ AND 50/60 Hz COMPRESSED AIR: 6 TO 8 BAR (CONNECTION POINT 60 L/min) PRODUCT SIZE AND WEIGHT UNWINDER - WITHOUT ROLL: 2800 X 2100 X 2300 mm WINDER - WITHOUT ROLL 2600 X 2200 X 1400 mm WEIGH – TOTAL 1000 KG (UNWINDER), 1800 KG (WINDER) SCOPE OF SUPPLY • RW SYSTEM • EDGE GUIDE CONTROL • BANANA ROLLER • SLITTING SYSTEM MECHANISM • 1 SLITTING KNIFE SYSTEM • SAFETY FENCING NOT IN SCOPE OF SUPPLY • SPARE PNEUMATIC SHAFT - 3" OR 6" • THE WAY OF MAT STICKING IS SOLVED BY THE BUYER AND IS NOT A PART OF DELIVERY • MACHINE FOUNDATIONS • FIRE PROTECTION • ROLL + SHAFT HANDLING • SUCTION SYSTEM FOR TRIMMED EDGES • THE LINE SPEED MEASURING DEVICE • LASER SENSOR FOR MEASURING OF PACKAGE DIAMETER FOR SIGNIFICANT INCREASING OF THE UN/WINDER CONTROL SENSITIVITY • COMPACTER ROLL ON THE WINDER • WASTE MATERIAL DISPOSAL ADHESION MODULE NS AM 1600 (WITH SHOWER) ADHESION MODULE IS DESIGNED TO ENSURE THAT THE NANOFIBER LAYER DEPOSITED ON A SUBSTRATE MATERIAL ADHERES PROPERLY TO IT WITHOUT ANY DELAMINATING FAILURES. THE EQUIPMENT IS INTENDED FOR APPLICATION OF LIQUID DISPERSION GLUES OR SIMILAR LIQUIDS ONTO THE SURFACE OF DIFFERENT SUBSTRATE MATERIALS WITH SMOOTH OR SLIGHTLY STRUCTURED SURFACES AS E.G. PAPER (FLAT AND CORRUGATED), PLASTIC FILMS, WOVEN OR NON-WOVEN TEXTILES ETC THE GLUE IS DEPOSITED ON A SUBSTRATE IN CONTACT WAY. A STEEL CYLINDER ROTATES IN A TUB FILLED WITH GLUE. GLUE IN THE TUB IS KEPT AT A CERTAIN LEVEL BY THE PERISTALTIC PUMP, WHICH ALSO KEEPS ITS CIRCULATION IN A CLOSED LOOP SPECIFICATION: WORKING WIDTH: ADJUSTABLE FROM 800 TO 1640 mm SUBSTRATE MATERIAL WIDTH UP TO 1700 mm SPEED: 1 TO 40 M/min (LIMIT DEPENDS ON THE TYPE OF SUBSTRATE AND WINDING SYSTEM PARAMETERS AND TYPE OF HOT AIR DRYER). COATING (DRY MASS): 0.5 TO 1.5 GSM (CHANGE BY 0.5 GSM PROVIDES A SIGNIFICANT CHANGE IN ADHESION) FEATURES: THE ADHESIVE MODULE CAN WORK IN TWO MODES • MODE 1 - STEEL CYLINDER IS IN CONTACT WITH A SOFT ROLLER AND THIS FOAM ROLLER COATS THE SUBSTRATE WITH A THIN LAYER OF GLUE – USED MAINLY FOR COATING OF CORRUGATED MEDIA. SOFT ROLLER IS A CONSUMABLE PART • MODE 2 - SUBSTRATE IS IN DIRECT CONTACT WITH STEEL CYLINDER, ADHESIVE IS TRANSFERRED DIRECTLY ONTO SUBSTRATE • SPEED IS THE CRUCIAL PARAMETER OF THE QUALITY OF THE ADHESION TREATMENT. OPERATING SPEED RANGE MUST BE TESTED WITH THE REQUIRED SUBSTRATE MATERIAL AND OPTIMIZED. AT TOO LOW SPEED THE ADHESIVE USUALLY DRIES OUT BEFORE IT REACHES THE SPINNING CHAMBER. ON THE OTHER HAND, TOO HIGH-SPEED LEADS TO INHOMOGENEOUS COATING. • THE HOT AIR DRYER IS USED IN COMBINATION WITH ADHESIVE MODULE. • ADHESION MODULE IS INTEGRATED TO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR THE OPERATION. SETTING OF ADHESION MODULE STRICTLY DEPENDS ON RECIPE OF RECORD, ADHESION MODULE DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF GLUE. • THE INSIDE OF THE MACHINE IS EQUIPPED WITH A TAP WITH INLET AND DRAINAGE FOR CLEANING. THE WATER IS HEATED IN THE MACHINE FOR BETTER DISSOLUTION OF THE ADHESIVE RESIDUE. THE DEVICE CONTAINS DRAIN PUMP FOR USED WATER. • BETWEEN THE ADHESION MODULE AND THE NANOSPIDER LINE IS A COVERED SINGLE-CYLINDER VENTILATED PORTER FOR BETTER MATERIAL GUIDANCE IN THE TECHNOLOGY. SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASED ELECTRICAL POWER, SPACE AND PRESSURE AIR • POWER: 7.5 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 6 TO 8 BARS (CONSUMPTION 100 L/min) • TAP WATER: G THREAD ½” TO CAPACITY 20 LITERS/min • DRAIN: WASTE WATER PUMP: ½“ HOSE. • MAXIMUM HOSE LENGTH 10000 mm MAX. RECOMMENDED HEAD 3000 mm PRODUCT SIZE AND WEIGHT DIMENSIONS: 2675 X 2430 X 1470 mm + 800 mm COVERS WEIGHT: 1300 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 2 MOTORS FOR MAIN AND SOFT ROLLERS • COVERS FOR SPACE BETWEEN NANOSPIDER UNIT AND ADHESION MODULE – TENT • CONTROL SYSTEM – SWITCHBOARD – OPERATOR PANEL IS USED FROM NS LINE • MECHANISM FOR WIPING THE ADHESIVE FROM THE MAIN CYLINDER • INITIAL SET OF SOFT ROLLERS (4X) • EXPANSION SHAFT FOR MOHAIR ROLLER WITH SAFETY CLAMPS • TANK WITH PNEUMATIC MIXER (75L) – NOISE APPROX. 75DB • MEASUREMENT OF THE AMOUNT OF COATING – WEIGHT PLATFORM/SCALE • AUTOMATIC LOCK FOR SLIDING DOOR WITH SWITCH LIMIT TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • THREE SWITCH LIMITS ON DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • TWO EMERGENCY-STOP BUTTONS ON THE CORNERS OF THE MODULE WATER HEATER • SHOWER • DRAIN NOT IN SCOPE OF SUPPLY • SPARE SOFT ROLLERS – CONSUMABLE PARTS • GLUE • OPERATORS PANEL (USE PANEL FROM LINE) • GLUE PREPARATION STATION • ANY OTHER EQUIPMENT OF CLEAN SOFT ROLLER • WATER AND DRAIN CONNECTION – PIPING OPERATION DESCRIPTION GLUE PREPARATION TYPICALITY IS GLUE DELIVERY FROM SUPPLIER IN CONCENTRATION APPROX. 50%. FOR ADHESION MODULE IS USED TYPICALLY CONCENTRATION VALUE BETWEEN 20-30%. IF NO GLUE WEIGHT STATION IS USED, THE FOLLOWING METHOD OF GLUE PREPARATION IS RECOMMENDED • FILL ORIGINAL CONCENTRATION OF GLUE TO GLUE TANK – FOR EXAMPLE MEASURING BY LABORATORY SCALE • FILL (HOT) WATER FOR DILUTING GLUE – MEASURED BY VOLUME (HOT WATER IS RECOMMENDED FOR FASTER MIXING) • MOVE TANK TO COMPRESS AIR SUPPLY AND MIX THE GLUE SOLUTION FOR 10-30 MINUTES BY INTEGRAL MIXER WE RECOMMEND PREPARING ONLY SUCH AMOUNT OF GLUE WHICH IS NECESSARY FOR PRODUCTION – AS APPROX. AFTER 3 DAYS THERE IS RISK OF BIODEGRADATION OF THE PREPARED UNUSED GLUE GLUE DEPOSITION MEASURING (CHECK) – SCALE METHOD TANK WITH GLUE IS PLACED ON WEIGHT PLATFORM (SCALE) AND MEASURE DECREASING OF MASS IN TIME = DEPOSITION ON SUBSTRATE. MEASURING IN TIME LONGER THAN 5 MINUTES IS REQUIRED – DEPENDS ON WEIGHT PLATFORM RESOLUTION AND SETTING OF ADHESION MODULE HOT AIR DRYER HAD 1600/2000 – FIRST FEATURES: • THE HOT AIR DRYER EQUIPMENT PROVIDES ADDITIONAL DRYING OF FINAL PRODUCT. NANOFIBER LAYERS WILL LEAVE THE SPINNING UNIT WITH SOME RESIDUAL HUMIDITY (OR SOLVENT CONTENT) AND THE LAYER MUST BE DRIED BEFORE WINDING. THE HOT AIR DRYER IS NEEDED, WHENEVER THE ADHESION MODULE (APPLYING WATER-BASED GLUES) IS IN OPERATION OR THICKER NANOFIBER LAYERS ARE PRODUCED OF LOW VOLATILE SOLVENT SYSTEMS ARE GENERATED. THE DRYER ALSO REDUCES THE POLLUTION OF THE AMBIENT AIR AS IT IS VENTILATED • THE HOT AIR DRYER MAY NOT PROVIDE COMPLETE DRYING OF PRODUCED NANOFIBER LAYER IF THEY ARE TOO THICK, DENSE OR THE SPEED OF THE LINE IS TOO HIGH, THEREFORE ITS PERFORMANCE MUST BE TESTED ON PARTICULAR NANOFIBER PRODUCTS • THE EQUIPMENT IS PLACED BEHIND THE SPINNING UNIT. THE DRYER CAN USE ADDITIONAL HEATING TO SPEED UP THE DRYING PROCESS. AIR FLOW RATE AND HEATING TEMPERATURE CAN BE SET DIRECTLY FROM THE CONTROL SYSTEM AS REQUIRED BASED ON THE POLYMER SOLUTION AND AMOUNT OF ADHESIVE USED AND ON THE SPEED OF THE WHOLE NS LINE • THE HOT AIR DRYER INCLUDES A CHAMBER WITH NOZZLES, EXHAUST FAN AND RECOVERY FAN AND HEATERS. THE PROCESS AIR IS SUCKED FROM THE ROOM, PARTIALLY RECIRCULATED INSIDE THE CHAMBER AND THEN EXHAUSTED • HOT AIR DRYER IS INTEGRATED INTO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR ITS OPERATION. SETTING OF HOT AIR DRYER IS STRICTLY DEPENDENT ON RECIPE OF RECORD, ESPECIALLY ON SETTING OF ADHESION MODULE AND TYPE OF SUBSTRATE MATERIAL. EQUIPMENT DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF RESIDUAL WATER • HOT AIR DRYER CONTAINS SUPPORTING ROLLERS. GEOMETRICAL SHAPE OF THIS ROLLER IS SIMILAR TO LETTER “OMEGA”. PURPOSE OF OMEGA CYLINDER IS REDUCTION OF UNSUPPORTED LENGTH OF MATERIAL. SUPPORT OF THE MATERIAL IS TYPICALLY NEEDED EACH 2 TO 3 METERS. IF MATERIAL IS NOT SUPPORTED BY OTHER EQUIPMENT (LIKE REWINDING ADHESION MODULE) IT IS NECESSARY TO USE THESE 3 CYLINDERS. CYLINDER WHICH IS IN CONTACT WITH NANOFIBERS HAS PTFE COATING. CYLINDER IN STANDARD IS NOT DRIVEN (DRIVEN ONE IS ON THE REQUEST FOR SOFT MATERIAL – CAN BE ASSEMBLED AFTER INSTALLATION) • PURPOSE OF USAGE OF TENT AROUND OMEGA CYLINDERS IS DRIVEN BY MECHANICAL SAFETY AND WITH AMBIENT ATMOSPHERE AROUND TECHNOLOGY (REDUCED ODORS, IMPROVED STABILITY OF AMBIENT ATMOSPHERE IN SPINNING CHAMBER). SPECIFICATION: WORKING WIDTH: 1600 mm SUBSTRATE MATERIAL WIDTH: UP TO 1700 mm HEATING TEMPERATURE: UP TO 80 °C POWER HEATING: UP TO 15 KW NOMINAL LENGTH OF DRYING: 2000 mm AIR CHANGE/EXHAUST: MAXIMUM UP TO 500M3/H SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ 50/60 Hz 24 KW EXHAUST: UP TO 500 M3/H (DN 160) PRODUCT SIZE AND WEIGHT DIMENSIONS: 2200 X 1800 X 2700 mm + 900 mm FOR SUPPORTING ROLLER WEIGHT: 1500 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 1 PROCESS FAN, INLET AND OUTLET FAN • CONTROL SYSTEM – SWITCHBOARD • TENT WITH NONDRIVEN SUPPORTING ROLLERS • TWO EMERGENCY - STOP BUTTONS (ONE ON FRONT, ONE ON BACK OF HAD) • SIX SWITCH LIMITS ON THE DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED NOT IN SCOPE OF SUPPLY • OPERATORS PANEL (USE MAIN PANEL FROM LINE) DATA STORAGE AND REMOTE ACCESS FEATURES: THIS SYSTEM IS PERIODICALLY SAVING SPECIFIC PROCESS DATA AND SETTINGS FROM THE MACHINE. NO DATA STORAGE FROM WINDING SYSTEM. DATA IS ACCESSIBLE BY HTTP PROTOCOL IN LOCAL NETWORK. THIS UNIT ALSO REALIZES REMOTE ACCESS (PRIVATE AND SECURED VPN). WE ARE RECOMMENDING PERMANENT INTERNET CONNECTION FOR BETTER SERVICE CAPABILITY. ALL COMPONENTS ARE PLACED IN 19” RACK FLAT BOX – 9 UNIT TYPE. FOR RIGHT FUNCTION IS NECESSARY PERMANENT POWER SUPPLY 230V/10/16A – STANDARD PLUG. REMOTE CONTROL ENABLES DIAGNOSIS OF MOTOR FUNCTIONS, UPLOADING NEW SOFTWARE VERSIONS, ONLINE DIAGNOSIS OF THE TECHNOLOGY PARAMETERS. FURTHERMORE, THE ONLINE TROUBLESHOOTING WILL BE POSSIBLE TO SPEED UP AND MINIMIZE DOWNTIME IN THE CASE OF BREAKAGE OR MISUSE. ETHERNET COMMUNICATION IS BASED ON: SPECIFICATION: RACK: 19” RACK FLAT BOX COMPUTER: SIEMENS INDUSTRIAL PC OPERATION SYSTEM: WINDOWS + WEB ACCESS (TOSI BOX) SITE PREPARATION / CONNECTION REQUIREMENTS POWER CONSUMPTION: UP TO 1.5 KW VOLTAGE: 230V/10/16A TO STANDARD PLUG CEE7 TO PERMANENTLY CONNECT INTERNET CONNECTION: CONNECTED TO THE BUYER`S INTERNAL NETWORK OR, IF SECURITY IS CONCERN, BUYER`S DMZ (DE-MILITARIZED ZONE) IN ORDER TO GET CONNECTIVITY TO THE INTERNET NETWORK. THE RECOMMENDED SPEED IS AT LEAST 512 KBPS / 512 KBPS. PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 1000 X 1000 mm (19” RACK FLAT BOX) WEIGHT: 50 KG SCOPE OF SUPPLY • 19” RACK FLAT BOX (OR PLACE IN SWITCHBOARD OF MACHINE) • VPN ROUTER • DATA STORAGE MEMORY • WEB ACCESS TO DOWNLOAD DATA NOT IN SCOPE OF SUPPLY • CONNECTION TO INTERNET • OTHER TOSI BOX KEY PMS 60 L– PELLETS ONLY • THE POLYMER MIX STATION (PMS) IS DESIGNED TO PREPARE POLYMER SOLUTIONS SUITABLE FOR FURTHER USE IN THE SPINNING UNIT. THE MIX STATION CONSISTS OF THE MIXER, STAIRS, SWITCHBOARD CABINET, WITH HEATING AND COOLING UNIT, STORAGE TANK AND CONNECTION POINT • THE MIXER IS A DOUBLE WALL VESSEL, WHERE A PREPARED SOLUTION IS STIRRED AND CAN BE HEATED OR COOLED DURING PREPARATION. THE MIXER IS PLACED ON A WEIGHING PLATFORM - SCALE. THE SOLVENTS ARE DELIVERED VIA FIXED PIPING FROM EXTERNAL DRUMS, BARRELS OR CANISTERS, SOLID POLYMERS ARE FILLED IN THROUGH A FUNNEL • THE OPERATION IS ALMOST FULLY AUTOMATED, SO THAT THE OPERATOR NEEDS TO ENTER ONLY A POLYMER SOLUTION RECIPE INTO THE CONTROL SYSTEM VIA A TOUCH SCREEN. SINCE THE MIXING PROCESS IS INITIATED, THE SOLVENTS ARE DOSED AUTOMATICALLY. THE SOLID POLYMER MUST BE ADDED THROUGH A FUNNEL MANUALLY • CONTACT OF OPERATORS AND CHEMICALS USED IS ELIMINATED, AS THE POLYMER MIX STATION AND THE FILLING AND CLEANING STATION ARE CONNECTED STEADILY AND FOR ANY CHANGES IN CONFIGURATION ONLY SAFETY QUICK COUPLINGS NEED TO BE DISCONNECTED AND CONNECTED • THE SPINNING SOLUTION USED IN THE ELECTROSPINNING PROCESS CAN BE REUSED FOR PREPARATION OF A NEW BATCH OF THE SPINNING SOLUTION BY UTILIZING THE STORAGE TANK. THE DEVICE IS DESIGNED FOR OPERATION IN EX ENVIRONMENT AND COMPLIES WITH ATEX DIRECTIVE 2014/34/EU. INSIDE THE MIXING VESSEL IS ZONE 0, ABOVE THE MIXING VESSEL IS ZONE 1, AND WITHIN A 1.5 M RADIUS (SHOWN AS CIRCLE IN ABOVE DRAWING) FROM THE OUTER SURFACE (BODY) OF THE MIXING VESSEL IS ZONE • THE POLYMER MIX STATION SHOULD BE ALWAYS PLACED INTO A SEPARATE EXHAUSTED ROOM EQUIPPED WITH EMERGENCY VENTILATION, AS IT WORKS WITH HIGHER AMOUNT OF CHEMICALS. THE VENTILATION SHOULD BE DESIGNED ACCORDING TO THE LOCAL LEGISLATION REQUIREMENTS, ESPECIALLY TO THE AMOUNT AND TYPE OF CHEMICALS SUPPOSED TO BE USED. DESIGN OF THE ROOMS FOR ATEX COMPLIANCE AND VENTILATING SYSTEM IS NOT INCLUDED IN THE SCOPE OF SUPPLY SPECIFICATION: WORKING VOLUME: 60 LITERS OPERATING TEMPERATURE: 20 TO 80°C MAXIMUM VISCOSITY OF FINAL SOLUTION OF POLYMER: 1000 MPAS MAXIMUM VISCOSITY OF SOURCE COMPONENTS – LIQUIDS: 500 MPAS ACCURACY OF AUTOMATIC DOSING SOURCE CHEMICALS: ± 0.100 KG FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS ROOM - SIZE DEFINED IN LAYOUT (ROUGHLY 40 M2) - VENTILATION OF ROOM RECOMMENDED 6X PER HOUR (ACCORDING TO LOCAL REGULATION) - SPACE AROUND MIXING VESSEL (1.5 M) IS IN EX ZONE • POWER: 15 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 5 TO 8 BAR (CONSUMPTION 600 L/min) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 2000 X 1000 mm INCL. WEIGHING PLATFORM DIMENSIONS - STAIRS: 1150 X 2000 X 1150 mm DIMENSIONS - CABINET: 1150 X 2050 X 1050 mm INCL. THE BUILT - IN HEATING / COOLING UNIT DIMENSIONS - STORAGE TANK: 800 X 1000 X 1000 mm WEIGHT MIXER AND STAIRS: 1000 KG WEIGHT - CABINET: 400 KG SCOPE OF SUPPLY MIXING VESSEL • INLET FOR PELLETS • 3X INLET FOR LIQUID (SOLVENTS OR USED POLYMER SOLUTION) • LIGHT AND SIGHT GLASS IN LID • MATERIAL IN CONTACT WITH POLYMER SOLUTION – AISI 316L CONTROL PANEL STORAGE TANK – 60 L STAIRS ARE COMPLIANT WITH EN131 FILLING AND CLEANING STATION ALL CONNECTIONS AND PIPING FOR MANIPULATION OF POLYMER SOLUTION AND SOLVENTS BETWEEN SELLER PROVIDED EQUIPMENT NOT IN SCOPE OF SUPPLY PIPING CONNECTION TO CHILLER (PRODUCTION OF COLD WATER) BARRELS FOR FRESH AND WASTE CHEMICALS VENTILATION OF ROOM FIRE EXTINGUISHER CAPABILITY FOR POLYMERS IN POWDER FORM FILLING AND CLEANING STATION + SWITCHBOARD FILLING AND CLEANING STATION IS DESIGNED TO REDUCE CONTACT OF OPERATORS WITH ANY CHEMICALS DURING PROCESSES OF FILLING AND CLEANING. THE EQUIPMENT HAS THE FOLLOWING FUNCTIONS • FILL THE RESERVOIR TANKS WITH A FRESH SPINNING SOLUTION FOR FURTHER USE IN THE SPINNING UNIT • DRAIN THE RESERVOIR TANKS AND REMOVE THE SPINNING SOLUTION AFTER BEING USED IN THE SPINNING UNIT • CLEAN THE RESERVOIR TANKS • CLEAN THE SPINNING CARRIAGE THE FILLING AND CLEANING STATION CONSISTS OF THE EXHAUSTED CHAMBER WITH A TUB FOR CLEANING CHEMICALS FOR MANUAL CLEANING OF SPINNING CARRIAGES AND A SET OF PUMPS. A SCALE FOR MIXING VESSEL IS USED FOR CONTROL OF PRECISE FILLING OF THE RESERVOIR TANKS. OTHER OPERATIONS CAN BE CONTROLLED BY TIMERS. THE EQUIPMENT MUST BE CONNECTED TO AN EXHAUST DESIGN OF FILLING AND CLEANING STATION VARY ACCORDING TO SUPPLIED NANOSPIDER LINE CONFIGURATION DIMENSIONS: 650 (EXCLUDING RAMP) X 2650 X 800 mm WEIGHT: UP TO 400 KG AIR CONDITIONING UNIT • THE ATMOSPHERE IN THE SPINNING CHAMBER IS ONE OF THE MOST IMPORTANT FACTORS, INFLUENCING BOTH FIBER MORPHOLOGY AND PROCESS THROUGHPUT. THE RELATIVE HUMIDITY IN THE RANGE 20 TO 50% AND TEMPERATURE IN THE RANGE 18 TO 30°C IS TARGET FOR MOST POLYMER SOLUTION RECIPES. THE OPTIMAL RELATIVE HUMIDITY AND TEMPERATURE OF THE AMBIENT AIR DIFFER FOR EACH POLYMER SYSTEM AND BOTH FACTORS ARE OPTIMIZED EMPIRICALLY. WHILE FOR ONE POLYMER SYSTEM, THE MOST SUITABLE RH CAN BE 20%, FOR ANOTHER ONE, 35% CAN BE MUCH BETTER. USUALLY, EVEN IF THE ROOMS THE LINE IS INSTALLED IN ARE AIR CONDITIONED, THE PRECISE CONTROL IS NOT EASY AND IS USUALLY TOO EXPENSIVE. THEREFORE, IT IS NECESSARY TO HAVE THE HUMIDITY CONTROL EQUIPMENT CONNECTED DIRECTLY TO THE SPINNING UNIT TO CONTROL RELATIVE HUMIDITY (AND TEMPERATURE) INSIDE THE SPINNING CHAMBER • THE AIR CONDITIONING UNIT IS DESIGNED TO PROVIDE PRECISE CONTROL OF TEMPERATURE AND RELATIVE HUMIDITY OF THE SPINNING UNIT INLET AIR. IT IS POSSIBLE TO SET UP TEMPERATURE AND HUMIDITY INDEPENDENTLY AND KEEP BOTH OUTPUT VALUES IN QUITE NARROW RANGE • THERE ARE TWO MAIN TECHNOLOGICAL COMPONENTS OF THE A/C UNIT: DEHUMIDIFIER AND HUMIDIFIER. THE AIR THAT SHOULD BE DEHUMIDIFIED (PROCESS AIR) ENTERS THE ROTOR. THE WATER MOLECULES ARE ADSORBED IN THE SILICA GEL ROTOR. THE ROTOR IS REACTIVATED THROUGH ANOTHER AIR STREAM WHICH IS HEATED UP TO 100 TO 120 °C. THE MOISTURE LEAVES THE A/C AS WARM WET AIR • THE A/C UNIT IS ABLE TO COVER VERY LOW HUMIDITY AND IS SUBSTANTIALLY MORE EFFECTIVE THAN STANDARD DEHUMIDIFIER WORKING ON CONDENSATION PRINCIPLE. THE A/C UNIT USES CROSS FLOW RECUPERATOR OF WASTE HEAT DURING THE DEHUMIDIFYING PROCESS. IN CASE OF REMOTE ACCESS, WE OFFER REAL-TIME SERVICE SCAN OF THE A/C UNIT AT CUSTOMER’S SITE SPECIFICATION: PROCESS SIDE • PROCESS AIR FLOW (FRESH AIR): (VPA)1000 M3/H • MIN. INLET TEMPERATURE: (TIMIN) 8 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • OUTLET TEMPERATURE: (TO) 20 TO 25 °C • MIN. OUTLET HUMIDITY: (ABSHOMIN) 2 G / KG • MAX. OUTLET HUMIDITY: (ABSHOMAX) 9 G / KG • HUMIDITY ACCURACY: (ΔRH) + / - 3,0 % • TEMPERATURE ACCURACY: (ΔT) + / - 1,0 °C • EXTERNAL PRESSURE: (PEXT) 250 PA REGENERATION SIDE • PROCESS AIR FLOW (FRESH AIR): (VRA) 400 M3 / H • MIN. INLET TEMPERATURE: (TIMIN) 18 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • EXTERNAL PRESSURE: (PEXT) 150 PA • REACTIVATION HEATER: (QHEL) 10 KW FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS VOLTAGE: 3 / N / PE 3 X 400 V 50 HZ, 57A COMPRESSED AIR: N/A WATER CONNECTION: TAP WATER, 1 TO 8 BAR, 10 L/HOUR AIR DUCT CONNECTION: PROCESS AIR DN200 – SEE PARAMETERS ABOVE (PROCESS SIDE) WASTE AIR DN160 (< 60°C, <90% RH) COOLING WATER CONNECTION: WATER / GLYCOL MIXTURE RECOMMENDED (MEG 30%), IN / OUT G 1 1/2” WASTEWATER CONNECTION: DN32 (PVC PIPING) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1400 X 2000 X 6000 mm WEIGHT: 2000 KG SCOPE OF SUPPLY MAIN AIR CONDITIONING UNIT TECHNICAL GUIDE CHILLED WATER ACCUMULATOR 400 L (INCLUDED) CIRCULATION PUMP (INCLUDED) REVERSE OSMOSIS SYSTEM (INCLUDED) WATER DRAIN PUMP (INCLUDED) NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL 30% (-15°C) - APPROX. 1000 L DUCTING BETWEEN THE AC AND NS LINE PIPING BETWEEN AC UNIT AND CHILLER (OR OTHER COOLING SYSTEM) - SEE HYDRAULIC FLOW PLAN BELOW CHILLER (CAN BE OFFERED) OPTIONAL EQUIPMENT AND PARTS REQUIRED FOR THE OPERATION OF NS AC1000 CHILLER – NECESSARY EQUIPMENT IF BUYER DOES NOT HAVE ANOTHER USABLE COOLING SYSTEM ALREADY INSTALLED! • TEMPERATURE STABILITY (± 2°C BY THE SET POINT) • COOLING CAPACITY MIN 20 KW • TEMPERATURE SET POINT OUT 2,0/ IN 5,0 °C ETHYLENE GLYCOL 30% (-15°C) ADDITIONAL SUPPORTIVE VENTILATOR (ACCORDING TO LOCAL NEEDS) SELLER IS NOT RESPONSIBLE FOR SUPPLY OF ANY EXTRA PARTS, WHICH ARE NOT INCLUDED IN THE SCOPE OF SUPPLY, AND WHICH DEPENDS ON EXACT PLACEMENT OF EACH PERIPHERAL PARTS NEEDED FOR THE INSTALLATION ROOM CONDITIONS INTENDED SCOPE OF POLYMERS TO BE USED, RH AND TEMPERATURE OF AMBIENT AIR ARE AMONG THE MOST IMPORTANT ASPECTS. PRIOR TO PURCHASE OF THE UNIT BY THE SELLER THE CUSTOMER MUST AGREE AND SIGN A PROTOCOL CONFIRMING THAT ALL REQUIREMENTS THAT NEED TO BE MET BY THE BUYER WILL BE FULFILLED PRIOR TO INSTALLATION. IF THE REQUIREMENTS ARE NOT MET PRIOR TO INSTALLATION, THE SELLER CANNOT GUARANTEE MEETING THE PROCESS PARAMETERS CHILLER CHILLER IS A MACHINE TO PRODUCE CHILLED WATER, WHICH IS USED FOR TAKING OUT THE HEAT DEVELOPED IN VARIOUS INDUSTRIAL PROCESSES IN NS TECHNOLOGY, CHILLED WATER IS DISTRIBUTED INTO HEAT EXCHANGERS IN NS AC UNIT AND THEN THE WATER IS RE-CIRCULATED BACK TO THE CHILLER TO BE COOLED AGAIN. THE FIRST HEAT EXCHANGER IS USED TO COOL AND DEHUMIDIFY THE INLET AIR (1ST DEHUMIDIFYING STEP) AND THE SECOND HEAT EXCHANGER IS USED FOR FINAL ADJUSTMENT OF THE REQUIRED OUTPUT TEMPERATURE OF THE AIR. DUE TO THE AIR-COOLING PRINCIPLE, THE CHILLER IS PRIMARILY INTENDED FOR OUTDOOR INSTALLATION AND OPERATION. CHILLER MIGHT BE INSTALLED ALSO INSIDE OF BUILDINGS WHERE IT BECOMES THE SOURCE OF NON-NEGLIGIBLE AMOUNT OF WASTE HEAT SPECIFICATION: COOLING CAPACITY: (QC) 25.69 KW AMBIENT TEMPERATURE MAX: 46.0 °C OUTLET / INLET WATER TEMPERATURE: (TO/TI) 2.0/5.0 °C CHILLED WATER ACCUMULATOR TANK: 100 L FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 11.18 KW (400V/ 3 PH / 50HZ) SURROUNDINGS: OUTSIDE PRODUCT SIZE AND WEIGHT DIMENSIONS: 75 X 1450 X 1750 mm (THE CHILLER NEEDS A FREE SPACE OF ABOUT 1.5 M FROM ALL SIDES FOR PROPER OPERATION) NET WEIGHT: 293 KG SCOPE OF SUPPLY MAIN UNIT EC FANS NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL - 30% (-15°C) PIPING BETWEEN AC UNIT AND CHILLER REGENERATIVE CATALYTIC OXIDIZER 3000-GAS EMISSION LIMITS IN MOST REGIONS DO NOT ALLOW DISCHARGE OF THESE CONCENTRATIONS DIRECTLY INTO THE ATMOSPHERE. COMBUSTION IS CHOSEN AS A UNIVERSAL WASTE AIR TREATMENT METHOD. THE EQUIPMENT SHOULD ALWAYS BE CHOSEN WITH RESPECT TO: PROCESS PARAMETERS • FLOW RATE • CONCENTRATION LOCAL REGULATIONS • EMISSION LIMITS • OTHER CONDITION FINAL FACTORY INSTALLATION • AVAILABLE ENERGY • SPACE – INSIDE OUTSIDE THIS TECHNICAL EQUIPMENT IS ONE OF POSSIBLE SOLUTION, FOR FINAL OFFER WE RECOMMENDED SPECIFIED MORE PRECISELY CATALYTIC OXIDATION WITH REGENERATION / RECUPERATION OF WASTE HEAT (RCO/CO) IN THE CASE OF EXACT PRE-DEFINED CONDITIONS AND CHARACTERISTICS OF THE WASTE GAS, IT IS POSSIBLE TO SUPPLEMENT THE RTO AND TO TECHNOLOGIES WITH CATALYST. THANKS TO THIS CATALYST, OXIDATION OF VOCS OCCURS AT LOWER TEMPERATURES, WHICH REDUCES OPERATING COSTS. TECHNOLOGIES WITH CATALYST REACH AUTOTHERMAL OPERATION AT LOWER CONCENTRATIONS OF VOCS IN THE WASTE GAS. THERMAL OXIDIZER (WITH HEAT RECUPERATION) (TO) THE TECHNOLOGY OF DIRECT COMBUSTION IS ESPECIALLY SUITABLE FOR WASTE GASES WITH HIGHER CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS. IN ORDER TO REDUCE FUEL CONSUMPTION, A TUBULAR HEAT EXCHANGER FOR PREHEATING THE WASTE AND COMBUSTION AIR IS ADDED. REGENERATIVE THERMAL OXIDIZER (RTO) RTO SYSTEMS UTILIZE THE TECHNOLOGY OF REGENERATION OF WASTE HEAT CONTAINED IN THE EXHAUST CLEANED OFF-GAS. THERMAL EFFICIENCY OF UP TO 95 % TRANSLATES INTO LOW CONSUMPTION OF AUXILIARY FUEL EVEN FOR RELATIVELY LOW CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS IN THE OFF-GAS. RTO TECHNOLOGIES ARE DISTINGUISHED BY THE FOLLOWING CHARACTERISTICS: • LOW CONSUMPTION OF AUXILIARY ENERGY • WIDE TURNDOWN RATIO • OPTIONAL AUTOTHERMAL OPERATION (WITHOUT CONSUMPTION OF AUXILIARY ENERGY) • LONG LIFETIME OF CERAMIC LINING • EASY OPERATION AND MAINTENANCE SPECIFICATIONS: PROCESS AIR VOLUME MAXIMUM: 3000 NM3/H MINIMUM: 1500 NM3/H PRINCIPLE: REGENERATIVE CATALYTIC OXIDIZER ENERGY FOR HEATING: NATURAL GAS 70 KW LOCATION INSIDE (FROM +3°C TO 30°C) ESTIMATED CONSUMPTION: 3000 M3 / H CONCENTRATION: 0 MG TOC / NM3 48 KW CONCENTRATION: 0.5 G / NM3 - DMAC 42 KW EMISSION TOC <20 MG / NM3 CO <100 MG/NM3 NOX <100 MG / NM3 FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 10 KW (400V @ 50HZ) PRESSURE AIR: DEW POINT +3°C (OUTSIDE -40°C) 6 BAR 4 NM3 / H NATURAL GAS: 150 MBAR CALORIFIC / HEATING / ENERGY VALUE: 10.2 KWH/NM3 70KW PRODUCT SIZE AND WEIGHT DIMENSIONS: 3300 mm X 3300 mm X 3400 mm (LOCATION OUTSIDE OR INSIDE) EXTERNAL SWITCHBOARD (APPROX. 1200 X 500 X 2000 mm) NET WEIGHT: 7500 KG SCOPE OF SUPPLY PROCESS CENTRIFUGAL FAN AND MOTOR COMBUSTION CHAMBER WITH CATALYTIC DAMPER SYSTEM – TO CHANGE PROSS AND REGENERATION CATALYTIC HEATER SUPPORTING STEEL STRUCTURE STACK / CHIMNEY Ø300M - 7M – FREE STANDING EXTERNAL SWITCHBOARD + CABLE UP TO 1000 mm NOT IN SCOPE OF SUPPLY CIVIL WORKS AND ANCHORING CONNECTION DUCTWORKS BETWEEN PRODUCTION NANOSPIDER LINE AND WAT CONNECTION TO UTILITIES UP TO THE BATTERY LIMITS PROCESS FLUIDS (FUEL, COMPRESSED AIR) WASTE DISPOSAL LIFTING EQUIPMENT • START-UP EMISSION ANALYSIS CONTINUOUS ANALYZER EMISSION. CABLE TRACE FOR CONNECTION BURNING UNIT AND SWITCHBOARD Learn More

NANOSPIDER - ELECTROSPINREFERENCE NUMBER: A-2510 NANOSPIDER - ELECTROSPIN FIRST – (ROUNDED TANKS) NEW GENERATION NS PRODUCTION LINE ALLOWS NANOFIBERS TO BE PRODUCED ON A FULLY-INDUSTRIAL SCALE FOR A NUMBER OF APPLICATIONS FEATURES: • CONSTRUCTION USING SELF - EXTINGUISHING MATERIALS • VENTILATED SPINNING CHAMBER, PREVENTING THE ESCAPE OF SOLVENT FUMES • GROUNDING ROD FOR CHARGE DISSIPATION AND AUTOMATIC GROUNDING SYSTEM • FOUR EMERGENCY - STOP BUTTONS ARE PLACED ON THE CORNERS OF THE UNIT • ONE EMERGENCY - STOP BUTTON IS PLACED ON THE SERVICE CONTROL PANEL • THE TWO UPWARD SLIDING DOORS ARE EQUIPPED WITH AUTOMATIC DOOR LOCKS WITH LIMIT SWITCHES TO PREVENT ACCIDENTAL OPENING AND WILL ALSO SHUT DOWN THE UNIT IF A SLIDING DOOR IS ACCIDENTALLY OPENED • THE FOUR LOWER SWING OPEN DOORS HAVE LIMIT SWITCHES THAT WILL SHUT DOWN THE UNIT IF THE DOOR IS ACCIDENTALLY OPENED • FIRE SUPPRESSION SYSTEM FOR THE SPINNING CHAMBER WITH MANUAL ACTIVATION VIA BUTTON ON THE CONTROL PANELS • THE EQUIPMENT IS PRODUCED ACCORDING TO CE STANDARDS • RECOMMENDED ROOM LAYOUT: THE LAYOUT WILL BE OPTIMIZED ACCORDING TO BUYER NEEDS • LIGHTS ON THE FRONT AND BACK OF MACHINE SPECIFICATIONS: POLYMER (PROCESS) TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • CYLINDRICAL TANKS ON WHEELS, ONE FOR FRESH POLYMER • CYLINDRICAL TANKS ON WHEELS, ONE FOR WASTE • MIXING CAPABILITY (PNEUMATIC MIXTURE) FOR IN AND OUT TANKS - PNEUMATIC DRIVEN AGITATOR • CLEANING SHOWER FOR BOTH IN AND OUT TANK • TWO CYLINDRICAL SHAPED TANKS ON THE WHEELS IN ONE TUB • BURST DISK FOR EACH TANK • QUICK COUPLINGS STÄUBLI HCB 08 WORKING VOLUME OF TANKS IS 60 LITERS FOR EACH TANK CLEANING TANKS COMPONENT IS CONSISTING FROM FOLLOWING PARTS • TANK WITH VOLUME OF 60 LITERS WILL BE DIVIDED INTO TWO SECTIONS: 30 L FOR CLEAN,30 L USED CLEANING SOLUTION • CYLINDRICAL TANK ON WHEELS - SIZE ROUGHLY HALF OF THE PROCESS TANKS • BURST DISK FOR EACH TANK VOLUME 30 + 30 LITERS WILL BE POSSIBLE TO USE MULTIPLE TIMES FOR CLEANING SITE PREPARATION / CONNECTION REQUIREMENTS ALL POWER SUPPLY IS REALIZED FOR FULL LINE INCLUDING PERIPHERAL PARTS. IT IS JUST NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ AND 50/60Hz, MAIN CIRCUIT BREAKER 32 A POWER CONSUMPTION: UP TO 12 KW PRESSURE AIR: 5 TO 8 BAR, CONNECTION POINT CAPACITY 1000 L/min INERT GAS: 0.5 BAR, CONNECTION POINT CAPACITY 200 L/min PROCESS AIR INLET/OUTLET: UP TO 1000 M3/H PRODUCT SIZE AND WEIGHT LENGTH: APPROX. 2800 mm WIDTH: APPROX. 3300 mm HEIGHT: APPROX. 3000 mm WEIGHT: APPROX. 2500 KG SCOPE OF SUPPLY SPINNING CHAMBER • WITH WIRE COLLECTING ELECTRODE • LIFTING MECHANISM OF CART CAPABLE OF ADJUSTING THE DISTANCE BETWEEN THE COLLECTING AND SPINNING ELECTRODE BETWEEN 150 AND 250 mm VIA THE CONTROL PANEL • HV PROTECTING COVERS • SLIDING DOORS WITH ILLUMINATION • AIR INLET AND OUTLET WITH HOMOGENIZER AND FANS EXTINGUISHING SYSTEM • SWITCHBOARD SPINNING CART • 2 X PROCESS DOUBLE - TANKS (ONE CART ON WHEEL, EACH WITH IN AND OUT TANK) • CDS – CHEMICAL DISTRIBUTION SYSTEM • SEPARATE SPINNING MODULE EACH WITH MOVABLE CARRIAGE WITH SPINNING HEAD, ENERGY CHAIN • HV COVERS • WIRE SPINNING MECHANISM • WIRE ALIGNMENT MECHANISM • SET OF WIRE SPOOL 0.2 mm AND 0.3 mm MAIN OPERATOR PANEL – CONTROL SYSTEM HV POWER SUPPLIES SYSTEM (MAXIMUM AVAILABLE RATINGS + 80 KV DC / - 60 KV DC) SET OF SPINNING NOTCHES – FOR ROR 1 X CLEANING TANKS SERVICE OPERATION PANEL AUTOMATIC DISCHARGER R & D MODE ENABLE ELECTRO SPINNING FROM 4 WIRES ONLY – ONE MODULE PREPARATION FOR DRIVEN ENDLESS BELT COLLECTING ELECTRODE NOT IN SCOPE OF SUPPLY • SPARE WIRE FOR SPINNING • SPARE POLYMER CONTACT COMPONENT: CDS (PUMPS, VALVES, HOSES), SPINNING CARRIAGES WITH SPINNING HEADS, ENERGY CHAINS WITH POLYMER HOSES • SET OF SPINNING NOTCHES – NOT NECESSARY FOR ROR • ENDLESS BELT COLLECTING ELECTRODE REWINDING 1600 mm FULL THE NS LINE ALLOWS THE PRODUCTION OF NANOFIBERS ON A SUBSTRATE MATERIAL ONLY. THE SUBSTRATE MATERIAL MUST BE PRESENT IN THE SPINNING UNIT DURING THE SPINNING PROCESS. MOST NANOFIBER PRODUCTS USE TEXTILE, PAPER, OR FOIL SHEETS IN ROLLS AS A SUBSTRATE MATERIAL. UNWIND AND REWIND EQUIPMENT ALLOWS BIDIRECTIONAL REWINDING OF THE SUBSTRATE MATERIAL. THE ROLL GOODS EXCHANGE AND INSERTION IS MANUAL. MANIPULATION TOOLS ARE USUALLY NECESSARY BOTH UNWIND AND REWIND CONTAINS STEEL FRAMES WITH MOTORS, WHICH DRIVE THE UNWINDING AND WINDING PNEUMATIC SHAFTS SPEED IS CONTROLLED BY A SPECIAL RUBBER CYLINDER. THE PNEUMATIC SHAFTS ARE INFLATABLE AND SUITABLE FOR USE WITH PAPER CORES FEATURES: MAIN ROLL UNWINDER • THE SIDE-WALLS OF UNWINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE RUNNING ROLLERS ARE MACHINED • THE UNWINDER IS EQUIPPED SWINGING SPLICING TABLE. MAT SPLICING IS SOLVED BY THE CUSTOMER (E.G. DOUBLE STICKY TAPE) • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE UNWINDER. ON THE UNWINDER THERE IS PLACED STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE WINDER • THE SIDE-WALLS OF WINDER ARE CONNECTED BY WELDED CROSS-BEAMS WHICH ENSURE RELATIVE POSITION OF THE SIDE-WALLS AND STABILITY OF THE MACHINE. THE BEAMS CAN ALSO BE USED TO HANDLE THIS PART OF THE MACHINE. THERE ARE MACHINED MOUNTING AREAS ON INNER SURFACES OF THE SIDE-WALLS FOR THE WINDING SHAFT SAFETY CHUCKS, WINDING SHAFT DRIVE AND BEARING BODIES OF THE BALANCED STAINLESS STEEL FREE-RUNNING ROLLERS. THE SURFACES OF THE STAINLESS STEEL FREE-RUNNING ROLLERS ARE MACHINED • COMPENSATOR SPLITS THE WINDING TENSION FROM PRODUCTION LINE AND THE WINDER. TO INCREASE THE FRICTION COEFFICIENT AND THUS TO PREVENT SLIDING OF THE WOUND MATERIAL, COMPENSATOR ROLLER SURFACE IS FINISHED WITH A GLUED TEXTILE STRAP WITH A LAYER OF THE RUBBER. THE WOUND MATERIAL CONTACTS THE OPPOSITE SIDE TO THAT ONE WITH NANOFIBERS • THE POSITION OF THE DANCER IS MONITORED IN CONTACTLESS MANNER BY MEANS OF A CAM AND AN ANALOGUE SENSOR. INFORMATION FROM DANCER SERVES FOR THE RIGHT FUNCTION OF THE WINDER • ON THE WINDER THERE IS PLACED THE STOP BAR, WHICH FIXES THE MATERIAL AGAINST MOVEMENT WHEN THE LINE IS STOPPED. THE STOP BAR WILL BE PLACED ACCORDING TO TECHNICAL POSSIBILITIES TO THE NEAREST ROLL OF UNWINDING AXE BANANA ROLL • ROLL IS PLACED TO ADJUSTABLE BEARINGS FOR EASY SETTING OF CORRECT SPREADING EFFECT. ROLL SURFACE IS RUBBER COATED. THE BANANA ROLL IS DRIVEN TO SECURE ITS ROTATION AT LOW WINDING TENSIONS LONGITUDINAL CUTTING • INDIVIDUAL CUTTING HEADS CAN BE MANUALLY ADJUSTED TO THE DESIRED WIDTH. CUTTING IS CARRIED OUT BY PRESSURE AGAINST THE HARDENED CYLINDER - SHREDDER. CUTTING QUALITY IS RECOMMENDED TO TEST THE MATERIAL IN ADVANCE. THE EDGE TRIMS SLIDES ALLOW TO REDIRECT TRIMS TO CUSTOMER BIN OR TRIM WINDER WINDER EDGE GUIDING • THE EDGE GUIDING EQUIPMENT CONSIST OF WINDER BASE FRAME WITH TRANSVERSAL RAILS, ROLLERS MOUNTED ON WINDER MOVING FRAME, LINEAR ACTUATOR AND EDGE SENSOR INSTALLED ON ADJUSTABLE ARM. THE SENSOR MONITORS MATERIAL EDGE AND IN CASE OF EDGE POSITION DEVIATION THE WINDER FRAME IS MOVED RIGHT OR LEFT TO COMPENSATE THE MATERIAL PATH DEVIATION CONTROL SYSTEM • USER CONTROLS OF THE REWINDING IS SOLVED FROM THE MAIN CONTROL PANEL (HMI) OF NANOSPIDER LINE. SERVICE INTERVENTIONS ARE PERFORMED FROM THE SERVICE PANEL LOCATED ON THE DEVICE SPECIFICATIONS: WORKING WIDTH: 1650 mm SPEED: 0.4 TO 40 M/min +/- 1% CORES, INNER DIAMETER: 76 mm (3'') MAX. WINDING FORCE: 2000 N @ 90 mm MIN. WINDING FORCE: 80 N MAX. UNWINDING FORCE: 700 N MIN. UNWINDING FORCE: 40 N MAXIMUM DIAMETER OF ROLL: 1200 mm SAFETY FENCING • SAFETY FENCING IS NEEDED TO AVOID MECHANICAL HAZARDS IN THE CASE OF A RUNNING WINDING. FIRST THREATING OF THE SUBSTRATE IS PERFORMED WITH THE ENGINE DISCONNECTED, IE WITHOUT THE DANGER. ACCURATE FENCING DESIGN FOR COMPLETE SOS (SCOPE OF SUPPLY). VERY OFTEN IS IN SAFETY FENCING PLACE AIR PERMEABILITY TESTER OR OTHER EQUIPMENT BEFORE REWINDING. PROVIDED SAFETY FENCING COMPLIES WITH THE CURRENT MACHINERY DIRECTIVE 2006/42/EC HEIGHT: 1900 mm SAFETY DISTANCE: 120 mm PILLARS: 50 X 50 mm OR 70 X 70 mm MESH SIZE: 50 X 30 mm NUMBER OF DOORS: 1 X UNWINDER 2 X REWINDER SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THOUGHT NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASE OF ELECTRICAL POWER, SPACE AND PRESSURE AIR POWER: 10 KW VOLTAGE: 220 VOLTZ AND 50/60 Hz COMPRESSED AIR: 6 TO 8 BAR (CONNECTION POINT 60 L/min) PRODUCT SIZE AND WEIGHT UNWINDER - WITHOUT ROLL: 2800 X 2100 X 2300 mm WINDER - WITHOUT ROLL 2600 X 2200 X 1400 mm WEIGH – TOTAL 1000 KG (UNWINDER), 1800 KG (WINDER) SCOPE OF SUPPLY • RW SYSTEM • EDGE GUIDE CONTROL • BANANA ROLLER • SLITTING SYSTEM MECHANISM • 1 SLITTING KNIFE SYSTEM • SAFETY FENCING NOT IN SCOPE OF SUPPLY • SPARE PNEUMATIC SHAFT - 3" OR 6" • THE WAY OF MAT STICKING IS SOLVED BY THE BUYER AND IS NOT A PART OF DELIVERY • MACHINE FOUNDATIONS • FIRE PROTECTION • ROLL + SHAFT HANDLING • SUCTION SYSTEM FOR TRIMMED EDGES • THE LINE SPEED MEASURING DEVICE • LASER SENSOR FOR MEASURING OF PACKAGE DIAMETER FOR SIGNIFICANT INCREASING OF THE UN/WINDER CONTROL SENSITIVITY • COMPACTER ROLL ON THE WINDER • WASTE MATERIAL DISPOSAL ADHESION MODULE NS AM 1600 (WITH SHOWER) ADHESION MODULE IS DESIGNED TO ENSURE THAT THE NANOFIBER LAYER DEPOSITED ON A SUBSTRATE MATERIAL ADHERES PROPERLY TO IT WITHOUT ANY DELAMINATING FAILURES. THE EQUIPMENT IS INTENDED FOR APPLICATION OF LIQUID DISPERSION GLUES OR SIMILAR LIQUIDS ONTO THE SURFACE OF DIFFERENT SUBSTRATE MATERIALS WITH SMOOTH OR SLIGHTLY STRUCTURED SURFACES AS E.G. PAPER (FLAT AND CORRUGATED), PLASTIC FILMS, WOVEN OR NON-WOVEN TEXTILES ETC THE GLUE IS DEPOSITED ON A SUBSTRATE IN CONTACT WAY. A STEEL CYLINDER ROTATES IN A TUB FILLED WITH GLUE. GLUE IN THE TUB IS KEPT AT A CERTAIN LEVEL BY THE PERISTALTIC PUMP, WHICH ALSO KEEPS ITS CIRCULATION IN A CLOSED LOOP SPECIFICATION: WORKING WIDTH: ADJUSTABLE FROM 800 TO 1640 mm SUBSTRATE MATERIAL WIDTH UP TO 1700 mm SPEED: 1 TO 40 M/min (LIMIT DEPENDS ON THE TYPE OF SUBSTRATE AND WINDING SYSTEM PARAMETERS AND TYPE OF HOT AIR DRYER). COATING (DRY MASS): 0.5 TO 1.5 GSM (CHANGE BY 0.5 GSM PROVIDES A SIGNIFICANT CHANGE IN ADHESION) FEATURES: THE ADHESIVE MODULE CAN WORK IN TWO MODES • MODE 1 - STEEL CYLINDER IS IN CONTACT WITH A SOFT ROLLER AND THIS FOAM ROLLER COATS THE SUBSTRATE WITH A THIN LAYER OF GLUE – USED MAINLY FOR COATING OF CORRUGATED MEDIA. SOFT ROLLER IS A CONSUMABLE PART • MODE 2 - SUBSTRATE IS IN DIRECT CONTACT WITH STEEL CYLINDER, ADHESIVE IS TRANSFERRED DIRECTLY ONTO SUBSTRATE • SPEED IS THE CRUCIAL PARAMETER OF THE QUALITY OF THE ADHESION TREATMENT. OPERATING SPEED RANGE MUST BE TESTED WITH THE REQUIRED SUBSTRATE MATERIAL AND OPTIMIZED. AT TOO LOW SPEED THE ADHESIVE USUALLY DRIES OUT BEFORE IT REACHES THE SPINNING CHAMBER. ON THE OTHER HAND, TOO HIGH-SPEED LEADS TO INHOMOGENEOUS COATING. • THE HOT AIR DRYER IS USED IN COMBINATION WITH ADHESIVE MODULE. • ADHESION MODULE IS INTEGRATED TO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR THE OPERATION. SETTING OF ADHESION MODULE STRICTLY DEPENDS ON RECIPE OF RECORD, ADHESION MODULE DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF GLUE. • THE INSIDE OF THE MACHINE IS EQUIPPED WITH A TAP WITH INLET AND DRAINAGE FOR CLEANING. THE WATER IS HEATED IN THE MACHINE FOR BETTER DISSOLUTION OF THE ADHESIVE RESIDUE. THE DEVICE CONTAINS DRAIN PUMP FOR USED WATER. • BETWEEN THE ADHESION MODULE AND THE NANOSPIDER LINE IS A COVERED SINGLE-CYLINDER VENTILATED PORTER FOR BETTER MATERIAL GUIDANCE IN THE TECHNOLOGY. SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE WITH INCREASED ELECTRICAL POWER, SPACE AND PRESSURE AIR • POWER: 7.5 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 6 TO 8 BARS (CONSUMPTION 100 L/min) • TAP WATER: G THREAD ½” TO CAPACITY 20 LITERS/min • DRAIN: WASTE WATER PUMP: ½“ HOSE. • MAXIMUM HOSE LENGTH 10000 mm MAX. RECOMMENDED HEAD 3000 mm PRODUCT SIZE AND WEIGHT DIMENSIONS: 2675 X 2430 X 1470 mm + 800 mm COVERS WEIGHT: 1300 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 2 MOTORS FOR MAIN AND SOFT ROLLERS • COVERS FOR SPACE BETWEEN NANOSPIDER UNIT AND ADHESION MODULE – TENT • CONTROL SYSTEM – SWITCHBOARD – OPERATOR PANEL IS USED FROM NS LINE • MECHANISM FOR WIPING THE ADHESIVE FROM THE MAIN CYLINDER • INITIAL SET OF SOFT ROLLERS (4X) • EXPANSION SHAFT FOR MOHAIR ROLLER WITH SAFETY CLAMPS • TANK WITH PNEUMATIC MIXER (75L) – NOISE APPROX. 75DB • MEASUREMENT OF THE AMOUNT OF COATING – WEIGHT PLATFORM/SCALE • AUTOMATIC LOCK FOR SLIDING DOOR WITH SWITCH LIMIT TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • THREE SWITCH LIMITS ON DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED • TWO EMERGENCY-STOP BUTTONS ON THE CORNERS OF THE MODULE WATER HEATER • SHOWER • DRAIN NOT IN SCOPE OF SUPPLY • SPARE SOFT ROLLERS – CONSUMABLE PARTS • GLUE • OPERATORS PANEL (USE PANEL FROM LINE) • GLUE PREPARATION STATION • ANY OTHER EQUIPMENT OF CLEAN SOFT ROLLER • WATER AND DRAIN CONNECTION – PIPING OPERATION DESCRIPTION GLUE PREPARATION TYPICALITY IS GLUE DELIVERY FROM SUPPLIER IN CONCENTRATION APPROX. 50%. FOR ADHESION MODULE IS USED TYPICALLY CONCENTRATION VALUE BETWEEN 20-30%. IF NO GLUE WEIGHT STATION IS USED, THE FOLLOWING METHOD OF GLUE PREPARATION IS RECOMMENDED • FILL ORIGINAL CONCENTRATION OF GLUE TO GLUE TANK – FOR EXAMPLE MEASURING BY LABORATORY SCALE • FILL (HOT) WATER FOR DILUTING GLUE – MEASURED BY VOLUME (HOT WATER IS RECOMMENDED FOR FASTER MIXING) • MOVE TANK TO COMPRESS AIR SUPPLY AND MIX THE GLUE SOLUTION FOR 10-30 MINUTES BY INTEGRAL MIXER WE RECOMMEND PREPARING ONLY SUCH AMOUNT OF GLUE WHICH IS NECESSARY FOR PRODUCTION – AS APPROX. AFTER 3 DAYS THERE IS RISK OF BIODEGRADATION OF THE PREPARED UNUSED GLUE GLUE DEPOSITION MEASURING (CHECK) – SCALE METHOD TANK WITH GLUE IS PLACED ON WEIGHT PLATFORM (SCALE) AND MEASURE DECREASING OF MASS IN TIME = DEPOSITION ON SUBSTRATE. MEASURING IN TIME LONGER THAN 5 MINUTES IS REQUIRED – DEPENDS ON WEIGHT PLATFORM RESOLUTION AND SETTING OF ADHESION MODULE HOT AIR DRYER HAD 1600/2000 – FIRST FEATURES: • THE HOT AIR DRYER EQUIPMENT PROVIDES ADDITIONAL DRYING OF FINAL PRODUCT. NANOFIBER LAYERS WILL LEAVE THE SPINNING UNIT WITH SOME RESIDUAL HUMIDITY (OR SOLVENT CONTENT) AND THE LAYER MUST BE DRIED BEFORE WINDING. THE HOT AIR DRYER IS NEEDED, WHENEVER THE ADHESION MODULE (APPLYING WATER-BASED GLUES) IS IN OPERATION OR THICKER NANOFIBER LAYERS ARE PRODUCED OF LOW VOLATILE SOLVENT SYSTEMS ARE GENERATED. THE DRYER ALSO REDUCES THE POLLUTION OF THE AMBIENT AIR AS IT IS VENTILATED • THE HOT AIR DRYER MAY NOT PROVIDE COMPLETE DRYING OF PRODUCED NANOFIBER LAYER IF THEY ARE TOO THICK, DENSE OR THE SPEED OF THE LINE IS TOO HIGH, THEREFORE ITS PERFORMANCE MUST BE TESTED ON PARTICULAR NANOFIBER PRODUCTS • THE EQUIPMENT IS PLACED BEHIND THE SPINNING UNIT. THE DRYER CAN USE ADDITIONAL HEATING TO SPEED UP THE DRYING PROCESS. AIR FLOW RATE AND HEATING TEMPERATURE CAN BE SET DIRECTLY FROM THE CONTROL SYSTEM AS REQUIRED BASED ON THE POLYMER SOLUTION AND AMOUNT OF ADHESIVE USED AND ON THE SPEED OF THE WHOLE NS LINE • THE HOT AIR DRYER INCLUDES A CHAMBER WITH NOZZLES, EXHAUST FAN AND RECOVERY FAN AND HEATERS. THE PROCESS AIR IS SUCKED FROM THE ROOM, PARTIALLY RECIRCULATED INSIDE THE CHAMBER AND THEN EXHAUSTED • HOT AIR DRYER IS INTEGRATED INTO NANOSPIDER PRODUCTION LINE, MAIN CONTROL PANEL IS USED FOR ITS OPERATION. SETTING OF HOT AIR DRYER IS STRICTLY DEPENDENT ON RECIPE OF RECORD, ESPECIALLY ON SETTING OF ADHESION MODULE AND TYPE OF SUBSTRATE MATERIAL. EQUIPMENT DOESN´T CONTAIN ANY MEASUREMENT OF AMOUNT OF RESIDUAL WATER • HOT AIR DRYER CONTAINS SUPPORTING ROLLERS. GEOMETRICAL SHAPE OF THIS ROLLER IS SIMILAR TO LETTER “OMEGA”. PURPOSE OF OMEGA CYLINDER IS REDUCTION OF UNSUPPORTED LENGTH OF MATERIAL. SUPPORT OF THE MATERIAL IS TYPICALLY NEEDED EACH 2 TO 3 METERS. IF MATERIAL IS NOT SUPPORTED BY OTHER EQUIPMENT (LIKE REWINDING ADHESION MODULE) IT IS NECESSARY TO USE THESE 3 CYLINDERS. CYLINDER WHICH IS IN CONTACT WITH NANOFIBERS HAS PTFE COATING. CYLINDER IN STANDARD IS NOT DRIVEN (DRIVEN ONE IS ON THE REQUEST FOR SOFT MATERIAL – CAN BE ASSEMBLED AFTER INSTALLATION) • PURPOSE OF USAGE OF TENT AROUND OMEGA CYLINDERS IS DRIVEN BY MECHANICAL SAFETY AND WITH AMBIENT ATMOSPHERE AROUND TECHNOLOGY (REDUCED ODORS, IMPROVED STABILITY OF AMBIENT ATMOSPHERE IN SPINNING CHAMBER). SPECIFICATION: WORKING WIDTH: 1600 mm SUBSTRATE MATERIAL WIDTH: UP TO 1700 mm HEATING TEMPERATURE: UP TO 80 °C POWER HEATING: UP TO 15 KW NOMINAL LENGTH OF DRYING: 2000 mm AIR CHANGE/EXHAUST: MAXIMUM UP TO 500M3/H SITE PREPARATION / CONNECTION REQUIREMENTS • ALL POWER SUPPLY IS REALIZED THROUGH NANOSPIDER PRODUCTION LINE. IT IS NECESSARY TO CALCULATE INCREASE OF ELECTRICAL POWER, SPACE AND AIR FLOW VOLTAGE: 220 VOLTZ 50/60 Hz 24 KW EXHAUST: UP TO 500 M3/H (DN 160) PRODUCT SIZE AND WEIGHT DIMENSIONS: 2200 X 1800 X 2700 mm + 900 mm FOR SUPPORTING ROLLER WEIGHT: 1500 KG SCOPE OF SUPPLY • MAIN EQUIPMENT, 1 PROCESS FAN, INLET AND OUTLET FAN • CONTROL SYSTEM – SWITCHBOARD • TENT WITH NONDRIVEN SUPPORTING ROLLERS • TWO EMERGENCY - STOP BUTTONS (ONE ON FRONT, ONE ON BACK OF HAD) • SIX SWITCH LIMITS ON THE DOORS WITH DIRAC KEY ACCESS TO SHUT DOWN THE LINE IF THE DOOR IS ACCIDENTALLY OPENED NOT IN SCOPE OF SUPPLY • OPERATORS PANEL (USE MAIN PANEL FROM LINE) DATA STORAGE AND REMOTE ACCESS FEATURES: THIS SYSTEM IS PERIODICALLY SAVING SPECIFIC PROCESS DATA AND SETTINGS FROM THE MACHINE. NO DATA STORAGE FROM WINDING SYSTEM. DATA IS ACCESSIBLE BY HTTP PROTOCOL IN LOCAL NETWORK. THIS UNIT ALSO REALIZES REMOTE ACCESS (PRIVATE AND SECURED VPN). WE ARE RECOMMENDING PERMANENT INTERNET CONNECTION FOR BETTER SERVICE CAPABILITY. ALL COMPONENTS ARE PLACED IN 19” RACK FLAT BOX – 9 UNIT TYPE. FOR RIGHT FUNCTION IS NECESSARY PERMANENT POWER SUPPLY 230V/10/16A – STANDARD PLUG. REMOTE CONTROL ENABLES DIAGNOSIS OF MOTOR FUNCTIONS, UPLOADING NEW SOFTWARE VERSIONS, ONLINE DIAGNOSIS OF THE TECHNOLOGY PARAMETERS. FURTHERMORE, THE ONLINE TROUBLESHOOTING WILL BE POSSIBLE TO SPEED UP AND MINIMIZE DOWNTIME IN THE CASE OF BREAKAGE OR MISUSE. ETHERNET COMMUNICATION IS BASED ON: SPECIFICATION: RACK: 19” RACK FLAT BOX COMPUTER: SIEMENS INDUSTRIAL PC OPERATION SYSTEM: WINDOWS + WEB ACCESS (TOSI BOX) SITE PREPARATION / CONNECTION REQUIREMENTS POWER CONSUMPTION: UP TO 1.5 KW VOLTAGE: 230V/10/16A TO STANDARD PLUG CEE7 TO PERMANENTLY CONNECT INTERNET CONNECTION: CONNECTED TO THE BUYER`S INTERNAL NETWORK OR, IF SECURITY IS CONCERN, BUYER`S DMZ (DE-MILITARIZED ZONE) IN ORDER TO GET CONNECTIVITY TO THE INTERNET NETWORK. THE RECOMMENDED SPEED IS AT LEAST 512 KBPS / 512 KBPS. PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 1000 X 1000 mm (19” RACK FLAT BOX) WEIGHT: 50 KG SCOPE OF SUPPLY • 19” RACK FLAT BOX (OR PLACE IN SWITCHBOARD OF MACHINE) • VPN ROUTER • DATA STORAGE MEMORY • WEB ACCESS TO DOWNLOAD DATA NOT IN SCOPE OF SUPPLY • CONNECTION TO INTERNET • OTHER TOSI BOX KEY PMS 60 L– PELLETS ONLY • THE POLYMER MIX STATION (PMS) IS DESIGNED TO PREPARE POLYMER SOLUTIONS SUITABLE FOR FURTHER USE IN THE SPINNING UNIT. THE MIX STATION CONSISTS OF THE MIXER, STAIRS, SWITCHBOARD CABINET, WITH HEATING AND COOLING UNIT, STORAGE TANK AND CONNECTION POINT • THE MIXER IS A DOUBLE WALL VESSEL, WHERE A PREPARED SOLUTION IS STIRRED AND CAN BE HEATED OR COOLED DURING PREPARATION. THE MIXER IS PLACED ON A WEIGHING PLATFORM - SCALE. THE SOLVENTS ARE DELIVERED VIA FIXED PIPING FROM EXTERNAL DRUMS, BARRELS OR CANISTERS, SOLID POLYMERS ARE FILLED IN THROUGH A FUNNEL • THE OPERATION IS ALMOST FULLY AUTOMATED, SO THAT THE OPERATOR NEEDS TO ENTER ONLY A POLYMER SOLUTION RECIPE INTO THE CONTROL SYSTEM VIA A TOUCH SCREEN. SINCE THE MIXING PROCESS IS INITIATED, THE SOLVENTS ARE DOSED AUTOMATICALLY. THE SOLID POLYMER MUST BE ADDED THROUGH A FUNNEL MANUALLY • CONTACT OF OPERATORS AND CHEMICALS USED IS ELIMINATED, AS THE POLYMER MIX STATION AND THE FILLING AND CLEANING STATION ARE CONNECTED STEADILY AND FOR ANY CHANGES IN CONFIGURATION ONLY SAFETY QUICK COUPLINGS NEED TO BE DISCONNECTED AND CONNECTED • THE SPINNING SOLUTION USED IN THE ELECTROSPINNING PROCESS CAN BE REUSED FOR PREPARATION OF A NEW BATCH OF THE SPINNING SOLUTION BY UTILIZING THE STORAGE TANK. THE DEVICE IS DESIGNED FOR OPERATION IN EX ENVIRONMENT AND COMPLIES WITH ATEX DIRECTIVE 2014/34/EU. INSIDE THE MIXING VESSEL IS ZONE 0, ABOVE THE MIXING VESSEL IS ZONE 1, AND WITHIN A 1.5 M RADIUS (SHOWN AS CIRCLE IN ABOVE DRAWING) FROM THE OUTER SURFACE (BODY) OF THE MIXING VESSEL IS ZONE • THE POLYMER MIX STATION SHOULD BE ALWAYS PLACED INTO A SEPARATE EXHAUSTED ROOM EQUIPPED WITH EMERGENCY VENTILATION, AS IT WORKS WITH HIGHER AMOUNT OF CHEMICALS. THE VENTILATION SHOULD BE DESIGNED ACCORDING TO THE LOCAL LEGISLATION REQUIREMENTS, ESPECIALLY TO THE AMOUNT AND TYPE OF CHEMICALS SUPPOSED TO BE USED. DESIGN OF THE ROOMS FOR ATEX COMPLIANCE AND VENTILATING SYSTEM IS NOT INCLUDED IN THE SCOPE OF SUPPLY SPECIFICATION: WORKING VOLUME: 60 LITERS OPERATING TEMPERATURE: 20 TO 80°C MAXIMUM VISCOSITY OF FINAL SOLUTION OF POLYMER: 1000 MPAS MAXIMUM VISCOSITY OF SOURCE COMPONENTS – LIQUIDS: 500 MPAS ACCURACY OF AUTOMATIC DOSING SOURCE CHEMICALS: ± 0.100 KG FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS ROOM - SIZE DEFINED IN LAYOUT (ROUGHLY 40 M2) - VENTILATION OF ROOM RECOMMENDED 6X PER HOUR (ACCORDING TO LOCAL REGULATION) - SPACE AROUND MIXING VESSEL (1.5 M) IS IN EX ZONE • POWER: 15 KW • VOLTAGE: 220 VOLTZ AND 50/60 Hz • COMPRESSED AIR: 5 TO 8 BAR (CONSUMPTION 600 L/min) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1000 X 2000 X 1000 mm INCL. WEIGHING PLATFORM DIMENSIONS - STAIRS: 1150 X 2000 X 1150 mm DIMENSIONS - CABINET: 1150 X 2050 X 1050 mm INCL. THE BUILT - IN HEATING / COOLING UNIT DIMENSIONS - STORAGE TANK: 800 X 1000 X 1000 mm WEIGHT MIXER AND STAIRS: 1000 KG WEIGHT - CABINET: 400 KG SCOPE OF SUPPLY MIXING VESSEL • INLET FOR PELLETS • 3X INLET FOR LIQUID (SOLVENTS OR USED POLYMER SOLUTION) • LIGHT AND SIGHT GLASS IN LID • MATERIAL IN CONTACT WITH POLYMER SOLUTION – AISI 316L CONTROL PANEL STORAGE TANK – 60 L STAIRS ARE COMPLIANT WITH EN131 FILLING AND CLEANING STATION ALL CONNECTIONS AND PIPING FOR MANIPULATION OF POLYMER SOLUTION AND SOLVENTS BETWEEN SELLER PROVIDED EQUIPMENT NOT IN SCOPE OF SUPPLY PIPING CONNECTION TO CHILLER (PRODUCTION OF COLD WATER) BARRELS FOR FRESH AND WASTE CHEMICALS VENTILATION OF ROOM FIRE EXTINGUISHER CAPABILITY FOR POLYMERS IN POWDER FORM FILLING AND CLEANING STATION + SWITCHBOARD FILLING AND CLEANING STATION IS DESIGNED TO REDUCE CONTACT OF OPERATORS WITH ANY CHEMICALS DURING PROCESSES OF FILLING AND CLEANING. THE EQUIPMENT HAS THE FOLLOWING FUNCTIONS • FILL THE RESERVOIR TANKS WITH A FRESH SPINNING SOLUTION FOR FURTHER USE IN THE SPINNING UNIT • DRAIN THE RESERVOIR TANKS AND REMOVE THE SPINNING SOLUTION AFTER BEING USED IN THE SPINNING UNIT • CLEAN THE RESERVOIR TANKS • CLEAN THE SPINNING CARRIAGE THE FILLING AND CLEANING STATION CONSISTS OF THE EXHAUSTED CHAMBER WITH A TUB FOR CLEANING CHEMICALS FOR MANUAL CLEANING OF SPINNING CARRIAGES AND A SET OF PUMPS. A SCALE FOR MIXING VESSEL IS USED FOR CONTROL OF PRECISE FILLING OF THE RESERVOIR TANKS. OTHER OPERATIONS CAN BE CONTROLLED BY TIMERS. THE EQUIPMENT MUST BE CONNECTED TO AN EXHAUST DESIGN OF FILLING AND CLEANING STATION VARY ACCORDING TO SUPPLIED NANOSPIDER LINE CONFIGURATION DIMENSIONS: 650 (EXCLUDING RAMP) X 2650 X 800 mm WEIGHT: UP TO 400 KG AIR CONDITIONING UNIT • THE ATMOSPHERE IN THE SPINNING CHAMBER IS ONE OF THE MOST IMPORTANT FACTORS, INFLUENCING BOTH FIBER MORPHOLOGY AND PROCESS THROUGHPUT. THE RELATIVE HUMIDITY IN THE RANGE 20 TO 50% AND TEMPERATURE IN THE RANGE 18 TO 30°C IS TARGET FOR MOST POLYMER SOLUTION RECIPES. THE OPTIMAL RELATIVE HUMIDITY AND TEMPERATURE OF THE AMBIENT AIR DIFFER FOR EACH POLYMER SYSTEM AND BOTH FACTORS ARE OPTIMIZED EMPIRICALLY. WHILE FOR ONE POLYMER SYSTEM, THE MOST SUITABLE RH CAN BE 20%, FOR ANOTHER ONE, 35% CAN BE MUCH BETTER. USUALLY, EVEN IF THE ROOMS THE LINE IS INSTALLED IN ARE AIR CONDITIONED, THE PRECISE CONTROL IS NOT EASY AND IS USUALLY TOO EXPENSIVE. THEREFORE, IT IS NECESSARY TO HAVE THE HUMIDITY CONTROL EQUIPMENT CONNECTED DIRECTLY TO THE SPINNING UNIT TO CONTROL RELATIVE HUMIDITY (AND TEMPERATURE) INSIDE THE SPINNING CHAMBER • THE AIR CONDITIONING UNIT IS DESIGNED TO PROVIDE PRECISE CONTROL OF TEMPERATURE AND RELATIVE HUMIDITY OF THE SPINNING UNIT INLET AIR. IT IS POSSIBLE TO SET UP TEMPERATURE AND HUMIDITY INDEPENDENTLY AND KEEP BOTH OUTPUT VALUES IN QUITE NARROW RANGE • THERE ARE TWO MAIN TECHNOLOGICAL COMPONENTS OF THE A/C UNIT: DEHUMIDIFIER AND HUMIDIFIER. THE AIR THAT SHOULD BE DEHUMIDIFIED (PROCESS AIR) ENTERS THE ROTOR. THE WATER MOLECULES ARE ADSORBED IN THE SILICA GEL ROTOR. THE ROTOR IS REACTIVATED THROUGH ANOTHER AIR STREAM WHICH IS HEATED UP TO 100 TO 120 °C. THE MOISTURE LEAVES THE A/C AS WARM WET AIR • THE A/C UNIT IS ABLE TO COVER VERY LOW HUMIDITY AND IS SUBSTANTIALLY MORE EFFECTIVE THAN STANDARD DEHUMIDIFIER WORKING ON CONDENSATION PRINCIPLE. THE A/C UNIT USES CROSS FLOW RECUPERATOR OF WASTE HEAT DURING THE DEHUMIDIFYING PROCESS. IN CASE OF REMOTE ACCESS, WE OFFER REAL-TIME SERVICE SCAN OF THE A/C UNIT AT CUSTOMER’S SITE SPECIFICATION: PROCESS SIDE • PROCESS AIR FLOW (FRESH AIR): (VPA)1000 M3/H • MIN. INLET TEMPERATURE: (TIMIN) 8 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • OUTLET TEMPERATURE: (TO) 20 TO 25 °C • MIN. OUTLET HUMIDITY: (ABSHOMIN) 2 G / KG • MAX. OUTLET HUMIDITY: (ABSHOMAX) 9 G / KG • HUMIDITY ACCURACY: (ΔRH) + / - 3,0 % • TEMPERATURE ACCURACY: (ΔT) + / - 1,0 °C • EXTERNAL PRESSURE: (PEXT) 250 PA REGENERATION SIDE • PROCESS AIR FLOW (FRESH AIR): (VRA) 400 M3 / H • MIN. INLET TEMPERATURE: (TIMIN) 18 °C • MAX. INLET TEMPERATURE: (TIMAX) 30 °C • MIN. INLET HUMIDITY: (ABSHIMIN) 1.5 G / KG • MAX. INLET HUMIDITY: (ABSHIMAX) 13 G / KG • EXTERNAL PRESSURE: (PEXT) 150 PA • REACTIVATION HEATER: (QHEL) 10 KW FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS VOLTAGE: 3 / N / PE 3 X 400 V 50 HZ, 57A COMPRESSED AIR: N/A WATER CONNECTION: TAP WATER, 1 TO 8 BAR, 10 L/HOUR AIR DUCT CONNECTION: PROCESS AIR DN200 – SEE PARAMETERS ABOVE (PROCESS SIDE) WASTE AIR DN160 (< 60°C, <90% RH) COOLING WATER CONNECTION: WATER / GLYCOL MIXTURE RECOMMENDED (MEG 30%), IN / OUT G 1 1/2” WASTEWATER CONNECTION: DN32 (PVC PIPING) PRODUCT SIZE AND WEIGHT DIMENSIONS: 1400 X 2000 X 6000 mm WEIGHT: 2000 KG SCOPE OF SUPPLY MAIN AIR CONDITIONING UNIT TECHNICAL GUIDE CHILLED WATER ACCUMULATOR 400 L (INCLUDED) CIRCULATION PUMP (INCLUDED) REVERSE OSMOSIS SYSTEM (INCLUDED) WATER DRAIN PUMP (INCLUDED) NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL 30% (-15°C) - APPROX. 1000 L DUCTING BETWEEN THE AC AND NS LINE PIPING BETWEEN AC UNIT AND CHILLER (OR OTHER COOLING SYSTEM) - SEE HYDRAULIC FLOW PLAN BELOW CHILLER (CAN BE OFFERED) OPTIONAL EQUIPMENT AND PARTS REQUIRED FOR THE OPERATION OF NS AC1000 CHILLER – NECESSARY EQUIPMENT IF BUYER DOES NOT HAVE ANOTHER USABLE COOLING SYSTEM ALREADY INSTALLED! • TEMPERATURE STABILITY (± 2°C BY THE SET POINT) • COOLING CAPACITY MIN 20 KW • TEMPERATURE SET POINT OUT 2,0/ IN 5,0 °C ETHYLENE GLYCOL 30% (-15°C) ADDITIONAL SUPPORTIVE VENTILATOR (ACCORDING TO LOCAL NEEDS) SELLER IS NOT RESPONSIBLE FOR SUPPLY OF ANY EXTRA PARTS, WHICH ARE NOT INCLUDED IN THE SCOPE OF SUPPLY, AND WHICH DEPENDS ON EXACT PLACEMENT OF EACH PERIPHERAL PARTS NEEDED FOR THE INSTALLATION ROOM CONDITIONS INTENDED SCOPE OF POLYMERS TO BE USED, RH AND TEMPERATURE OF AMBIENT AIR ARE AMONG THE MOST IMPORTANT ASPECTS. PRIOR TO PURCHASE OF THE UNIT BY THE SELLER THE CUSTOMER MUST AGREE AND SIGN A PROTOCOL CONFIRMING THAT ALL REQUIREMENTS THAT NEED TO BE MET BY THE BUYER WILL BE FULFILLED PRIOR TO INSTALLATION. IF THE REQUIREMENTS ARE NOT MET PRIOR TO INSTALLATION, THE SELLER CANNOT GUARANTEE MEETING THE PROCESS PARAMETERS CHILLER CHILLER IS A MACHINE TO PRODUCE CHILLED WATER, WHICH IS USED FOR TAKING OUT THE HEAT DEVELOPED IN VARIOUS INDUSTRIAL PROCESSES IN NS TECHNOLOGY, CHILLED WATER IS DISTRIBUTED INTO HEAT EXCHANGERS IN NS AC UNIT AND THEN THE WATER IS RE-CIRCULATED BACK TO THE CHILLER TO BE COOLED AGAIN. THE FIRST HEAT EXCHANGER IS USED TO COOL AND DEHUMIDIFY THE INLET AIR (1ST DEHUMIDIFYING STEP) AND THE SECOND HEAT EXCHANGER IS USED FOR FINAL ADJUSTMENT OF THE REQUIRED OUTPUT TEMPERATURE OF THE AIR. DUE TO THE AIR-COOLING PRINCIPLE, THE CHILLER IS PRIMARILY INTENDED FOR OUTDOOR INSTALLATION AND OPERATION. CHILLER MIGHT BE INSTALLED ALSO INSIDE OF BUILDINGS WHERE IT BECOMES THE SOURCE OF NON-NEGLIGIBLE AMOUNT OF WASTE HEAT SPECIFICATION: COOLING CAPACITY: (QC) 25.69 KW AMBIENT TEMPERATURE MAX: 46.0 °C OUTLET / INLET WATER TEMPERATURE: (TO/TI) 2.0/5.0 °C CHILLED WATER ACCUMULATOR TANK: 100 L FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 11.18 KW (400V/ 3 PH / 50HZ) SURROUNDINGS: OUTSIDE PRODUCT SIZE AND WEIGHT DIMENSIONS: 75 X 1450 X 1750 mm (THE CHILLER NEEDS A FREE SPACE OF ABOUT 1.5 M FROM ALL SIDES FOR PROPER OPERATION) NET WEIGHT: 293 KG SCOPE OF SUPPLY MAIN UNIT EC FANS NOT IN SCOPE OF SUPPLY ETHYLENE GLYCOL - 30% (-15°C) PIPING BETWEEN AC UNIT AND CHILLER REGENERATIVE CATALYTIC OXIDIZER 3000-GAS EMISSION LIMITS IN MOST REGIONS DO NOT ALLOW DISCHARGE OF THESE CONCENTRATIONS DIRECTLY INTO THE ATMOSPHERE. COMBUSTION IS CHOSEN AS A UNIVERSAL WASTE AIR TREATMENT METHOD. THE EQUIPMENT SHOULD ALWAYS BE CHOSEN WITH RESPECT TO: PROCESS PARAMETERS • FLOW RATE • CONCENTRATION LOCAL REGULATIONS • EMISSION LIMITS • OTHER CONDITION FINAL FACTORY INSTALLATION • AVAILABLE ENERGY • SPACE – INSIDE OUTSIDE THIS TECHNICAL EQUIPMENT IS ONE OF POSSIBLE SOLUTION, FOR FINAL OFFER WE RECOMMENDED SPECIFIED MORE PRECISELY CATALYTIC OXIDATION WITH REGENERATION / RECUPERATION OF WASTE HEAT (RCO/CO) IN THE CASE OF EXACT PRE-DEFINED CONDITIONS AND CHARACTERISTICS OF THE WASTE GAS, IT IS POSSIBLE TO SUPPLEMENT THE RTO AND TO TECHNOLOGIES WITH CATALYST. THANKS TO THIS CATALYST, OXIDATION OF VOCS OCCURS AT LOWER TEMPERATURES, WHICH REDUCES OPERATING COSTS. TECHNOLOGIES WITH CATALYST REACH AUTOTHERMAL OPERATION AT LOWER CONCENTRATIONS OF VOCS IN THE WASTE GAS. THERMAL OXIDIZER (WITH HEAT RECUPERATION) (TO) THE TECHNOLOGY OF DIRECT COMBUSTION IS ESPECIALLY SUITABLE FOR WASTE GASES WITH HIGHER CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS. IN ORDER TO REDUCE FUEL CONSUMPTION, A TUBULAR HEAT EXCHANGER FOR PREHEATING THE WASTE AND COMBUSTION AIR IS ADDED. REGENERATIVE THERMAL OXIDIZER (RTO) RTO SYSTEMS UTILIZE THE TECHNOLOGY OF REGENERATION OF WASTE HEAT CONTAINED IN THE EXHAUST CLEANED OFF-GAS. THERMAL EFFICIENCY OF UP TO 95 % TRANSLATES INTO LOW CONSUMPTION OF AUXILIARY FUEL EVEN FOR RELATIVELY LOW CONCENTRATIONS OF VOLATILE ORGANIC COMPOUNDS IN THE OFF-GAS. RTO TECHNOLOGIES ARE DISTINGUISHED BY THE FOLLOWING CHARACTERISTICS: • LOW CONSUMPTION OF AUXILIARY ENERGY • WIDE TURNDOWN RATIO • OPTIONAL AUTOTHERMAL OPERATION (WITHOUT CONSUMPTION OF AUXILIARY ENERGY) • LONG LIFETIME OF CERAMIC LINING • EASY OPERATION AND MAINTENANCE SPECIFICATIONS: PROCESS AIR VOLUME MAXIMUM: 3000 NM3/H MINIMUM: 1500 NM3/H PRINCIPLE: REGENERATIVE CATALYTIC OXIDIZER ENERGY FOR HEATING: NATURAL GAS 70 KW LOCATION INSIDE (FROM +3°C TO 30°C) ESTIMATED CONSUMPTION: 3000 M3 / H CONCENTRATION: 0 MG TOC / NM3 48 KW CONCENTRATION: 0.5 G / NM3 - DMAC 42 KW EMISSION TOC <20 MG / NM3 CO <100 MG/NM3 NOX <100 MG / NM3 FEATURES: SITE PREPARATION / CONNECTION REQUIREMENTS TOTAL INPUT POWER: 10 KW (400V @ 50HZ) PRESSURE AIR: DEW POINT +3°C (OUTSIDE -40°C) 6 BAR 4 NM3 / H NATURAL GAS: 150 MBAR CALORIFIC / HEATING / ENERGY VALUE: 10.2 KWH/NM3 70KW PRODUCT SIZE AND WEIGHT DIMENSIONS: 3300 mm X 3300 mm X 3400 mm (LOCATION OUTSIDE OR INSIDE) EXTERNAL SWITCHBOARD (APPROX. 1200 X 500 X 2000 mm) NET WEIGHT: 7500 KG SCOPE OF SUPPLY PROCESS CENTRIFUGAL FAN AND MOTOR COMBUSTION CHAMBER WITH CATALYTIC DAMPER SYSTEM – TO CHANGE PROSS AND REGENERATION CATALYTIC HEATER SUPPORTING STEEL STRUCTURE STACK / CHIMNEY Ø300M - 7M – FREE STANDING EXTERNAL SWITCHBOARD + CABLE UP TO 1000 mm NOT IN SCOPE OF SUPPLY CIVIL WORKS AND ANCHORING CONNECTION DUCTWORKS BETWEEN PRODUCTION NANOSPIDER LINE AND WAT CONNECTION TO UTILITIES UP TO THE BATTERY LIMITS PROCESS FLUIDS (FUEL, COMPRESSED AIR) WASTE DISPOSAL LIFTING EQUIPMENT • START-UP EMISSION ANALYSIS CONTINUOUS ANALYZER EMISSION. CABLE TRACE FOR CONNECTION BURNING UNIT AND SWITCHBOARD Learn More -

J-2786 VERTICAL MODULE FOR TEMPERATURE MEASUREMENT & FACE RECOGNITION

J-2786 VERTICAL MODULE FOR TEMPERATURE MEASUREMENT & FACE RECOGNITIONUSES ROCKCHIP RK3288 / RK 3399 / QUALCOMM MSM8953 HIGH-PERFORMANCE HARDWARE PLATFORM, EQUIPPED WITH INDUSTRIAL GRADE BINOCULAR CAMERA, LIVE FACIAL RECOGNITION SOFTWARE AND INFRARED THERMAL IMAGING MODULE TO SUPPORT FACE-WITH-MASK INDEITIFICATION.

SUPPORTS EXPANSION OF VARIOUS PERIPHERALS SUCH AS ID CARD READERS, FINGERPRINT READERS, ETC WHICH CAN BE APPLIED TO GATE PASSAGES AND ATTENDANCE SYSTEM TO ACHIEVE SAFE AND EFFICIENT ACCESS CONTROL FOR PERSONNEL

CAN BE USED WITH ACCESS GATES & ATTENDANCE FOR COMMUNITIES, OFFICES, SCHOOLS, HOTELS, PUBLIC VENUES, TRANSPORTATION HUBS AND PUBLIC SERVICE PLACES

FEATURES:

8 INCH IPS FULL-VIEW LCD DISPLAY

INDUSTRIAL APPEARANCE, WATERPROOF AND SUNPROOF DESIGN

STABLE AND RELIABLE

SUPPORTS A DATABASE OF 30,000 FACES

THE 1:1 COMPARISON RECOGNITION RATE IS MORE THAN 99.7%

THE 1:N COMPARISON RECOGNITION RATE IS MORE THAN 96.7% @ 0.1% MISRECOGNITION RATE

LIVE DETECTION ACCURACY RATE: 98.3% @ 1% MISRECOGNITION RATE

FACE RECOGNITION PASS SPEED IS LESS THAN 1 SECOND

SUPPORTS ACCURATE FACE RECOGNITION AND COMPARISON WHILE WEARING A MASK

USES INDUSTRIAL GRADE BINOCULAR WIDE DYNAMIC CAMERA, NIGHT INFRARED AND LED DUAL PHOTO FLOOD LAMP

ROCKCHIP RK3288 QUAD-CORE PROCESSOR, ROCKCHIP RK3399 SIX-CORE PROCESSOR, AND QUALCOMM MSM8953 OCTA-CORE PROCESSOR

SUPPORTS HUMAN BODY TEMPERATURE DETECTION AND DISPLAY (BEST TEMPERATURE DETECTION DISTANCE IS 0.5 METERS, MAXIMUM IS 1 METER), MEASUREMENT ERROR +/- 0.5 °C

TEMPERATURE CAN BE READ IN ONLY A FEW SECONDS AND THE DEVICE AUTOMATICALLY SOUNDS AN ALARM FOR ABNORMALITIES

ATTENDANCE TEMPERATURE MEASUREMENT DATA EXPORTED IN REAL TIME

VARIOUS PERIPHERALS AVAILABLE FOR ID CARD READING, FINGERPRINT READING, IC CARD READING, 2-DIMENSIONAL CODE READING, ETC.

WITH COMPLETE DOCUMENTATION AND SUPPORT FOR SECONDARY DEVELOPMENT

SUPPORTS SYSTEM LEVEL, APP OFFLINE LEVEL, APP AND BACKGROUND NETWORK LEVEL MULTIPLE API DOCKINGCAMERA

RESOLUTION 2 MILLION PIXELS

TYPE BINOCULAR WIDE DYNAMIC CAMERA

APERTURE F2.4

FOCUSING DISTANCE 50-150CM

WHITE BALANCE AUTO

PHOTO FLOOD LIGHT LED AND IR DUAL PHOTO FLOOD LIGHTSCREEN

SIZE 8.0 INCH IPS LCD SCREEN

RESOLUTION 800×1280

TOUCH NOT SUPPORTED (OPTIONAL SUPPORT)PROCESSOR

CPU RK3288 QUAD-CORE (OPTIONAL RK3399 SIX-CORE, MSM8953

EIGHT-CORE)

STORAGE EMMC 8GINTERFACE

NETWORK MODULE ETHERNET AND WIRELESS (WIFI)

AUDIO 2.5W / 4R SPEAKERS

USB 1 USB OTG, 1 USB HOST STANDARD A PORT

SERIAL COMMUNICATION 1 RS232 SERIAL PORT

RELAY OUTPUT 1 DOOR OPEN SIGNAL OUTPUT

WIEGAND ONE WIEGAND 26/34 OUTPUT, ONE WIEGAND 26/34 INPUT

UPGRADE BUTTON SUPPORT UBOOT UPGRADE BUTTON

WIRED NETWORK 1 RJ45 ETHERNET SOCKETFUNCTION

CREDIT CARD READER NONE (OPTIONAL IC CARD READER, ID CARD, ID CARD)

FACE DETECTION SUPPORTS DETECTION AND TRACKING OF MULTIPLE PEOPLE AT THE SAME

TIME

FACE LIBRARY UP TO 30,000

1: N FACE RECOGNITION SUPPORT

1: 1 FACE COMPARISON SUPPORT

STRANGER DETECTION SUPPORT

IDENTIFY DISTANCE

CONFIGURATION

SUPPORT

UI INTERFACE CONFIGURATION SUPPORT

UPGRADE REMOTELY SUPPORT

INTERFACE INTERFACES INCLUDE DEVICE MANAGEMENT, PERSONNEL / PHOTO

MANAGEMENT, RECORD QUERY, ETC.

DEPLOYMENT METHOD SUPPORT PUBLIC CLOUD DEPLOYMENT, PRIVATIZED DEPLOYMENT, LAN

USE, STAND-ALONE USEINFRARED THERMAL IMAGING MODULE

TEMPERATURE DETECTION SUPPORT

TEMPERATURE DETECTION 1 METER (OPTIMAL DISTANCE 0.5 METER)

DISTANCE

TEMPERATURE

MEASUREMENT ACCURACY

≤ ±0.5℃

TEMPERATURE

MEASUREMENT RANGE

10℃~42℃

THERMAL FIELD OF VIEW 32 X 32℃

VISITORS' TEMPERATURE IS

NORMAL AND RELEASED

DIRECTLY

SUPPORT

ABNORMAL TEMPERATURE

ALARM

SUPPORT (TEMPERATURE ALARM VALUE CAN BE SET)GENERAL PARAMETERS

POWER DC12V(±10%)

OPERATING TEMPERATURE 0℃~60℃

STORAGE TEMPERATURE -20℃~60℃

POWER CONSUMPTION 13.5W(MAX)

INSTALLATION METHOD GATE BRACKET INSTALLATION

SIZE : STANDARD:274.24*128*21.48(MM); IC CARD / ID CARD:296.18*132.88*25(MM)PACKING LIST

Learn More

MACHINE * 1, POWER ADAPTER * 1, MANUAL * 1, CERTIFICATE OF CONFORMITY * 1 -

D-2388 What’s the Best Material for a Mask?

D-2388 What’s the Best Material for a Mask?Federal health officials have now recommended that we cover our faces with fabric during the coronavirus pandemic. But what material offers the most protection?

The Centers for Disease Control and Prevention has posted a no-sew mask pattern using a bandanna and a coffee filter as well as a video on making masks using rubber bands and folded fabrics found at home.

While a simple face covering can reduce the spread of coronavirus by blocking outgoing germs from coughs or sneezes of an infected person, experts say there is more variation in how much homemade masks might protect the wearer from incoming germs, depending on the fit and quality of the material used.

Scientists around the country have taken it upon themselves to identify everyday materials that do a better job of filtering microscopic particles. In recent tests, HEPA furnace filters scored well, as did vacuum cleaner bags, layers of 600-count pillowcases and fabric similar to flannel pajamas. Stacked coffee filters had medium scores. Scarves and bandanna material had the lowest scores, but still captured a small percentage of particles.

If you don’t have any of the materials that were tested, a simple light test can help you decide whether a fabric is a good candidate for a mask.

“Hold it up to a bright light,” said Dr. Scott Segal, chairman of anesthesiology at Wake Forest Baptist Health who recently studied homemade masks. “If light passes really easily through the fibers and you can almost see the fibers, it’s not a good fabric. If it’s a denser weave of thicker material and light doesn’t pass through it as much, that’s the material you want to use.”

Researchers say it’s important to remember that lab studies are conducted under perfect conditions with no leaks or gaps in the mask, but the test methods give us a way to compare materials. And while the degree of filtration for some homemade masks seems low, most of us — who are staying home and practicing social distancing in public — don’t need the high level of protection required for medical workers. More important, any face covering is better than none, especially if worn by a person who has the virus but doesn’t know it.

The biggest challenge of choosing a homemade mask material is to find a fabric that is dense enough to capture viral particles, but breathable enough that we can actually wear it. Some items being touted online promise high filtration scores, but the material would be unwearable.

Dressing Up for Work … at Home

Yang Wang, an assistant professor of environmental engineering at Missouri University of Science and Technology, worked with his graduate students to study various combinations of layered materials — including both air filters and fabric. “You need something that is efficient for removing particles, but you also need to breathe,” said Dr. Wang, who last fall won an international award for aerosol research.To test everyday materials, scientists are using methods similar to those used to test medical masks, which everybody agrees should be saved for medical workers who are exposed to high doses of virus from seeing infected patients. The best medical mask — called the N95 respirator — filters out at least 95 percent of particles as small as 0.3 microns. By comparison, a typical surgical mask — made using a rectangular piece of pleated fabric with elastic ear loops — has a filtration efficiency ranging from 60 to 80 percent.

Dr. Wang’s group tested two types of air filters. An allergy-reduction HVAC filter worked the best, capturing 89 percent of particles with one layer and 94 percent with two layers. A furnace filter captured 75 percent with two layers, but required six layers to achieve 95 percent. To find a filter similar to those tested, look for a minimum efficiency reporting value (MERV) rating of 12 or higher or a microparticle performance rating of 1900 or higher.

The problem with air filters is that they potentially could shed small fibers that would be risky to inhale. So if you want to use a filter, you need to sandwich the filter between two layers of cotton fabric. Dr. Wang said one of his grad students made his own mask by following the instructions in the C.D.C. video, but adding several layers of filter material inside a bandanna.

Dr. Wang’s group also found that when certain common fabrics were used, two layers offered far less protection than four layers. A 600 thread count pillow case captured just 22 percent of particles when doubled, but four layers captured nearly 60 percent. A thick woolen yarn scarf filtered 21 percent of particles in two layers, and 48.8 percent in four layers. A 100 percent cotton bandanna did the worst, capturing only 18.2 percent when doubled, and just 19.5 percent in four layers.

The group also tested Brew Rite and Natural Brew basket-style coffee filters, which, when stacked in three layers, showed 40 to 50 percent filtration efficiency — but they were less breathable than other options.

If you are lucky enough to know a quilter, ask them to make you a mask. Tests performed at the Wake Forest Institute for Regenerative Medicine in Winston-Salem, N.C., showed good results for homemade masks using quilting fabric. Dr. Segal, of Wake Forest Baptist Health, who led the study, noted that quilters tend to use high-quality, high-thread count cotton. The best homemade masks in his study were as good as surgical masks or slightly better, testing in the range of 70 to 79 percent filtration. Homemade masks that used flimsier fabric tested as low as 1 percent filtration, Dr. Segal said.

The best-performing designs were a mask constructed of two layers of high-quality, heavyweight “quilter’s cotton,” a two-layer mask made with thick batik fabric, and a double-layer mask with an inner layer of flannel and outer layer of cotton.

Bonnie Browning, executive show director for the American Quilter’s Society, said that quilters prefer tightly woven cottons and batik fabrics that stand up over time. Ms. Browning said most sewing machines can handle only two layers of fabric when making a pleated mask, but someone who wanted four layers of protection could wear two masks at a time.

Ms. Browning said she recently reached out to quilters on Facebook and heard from 71 people who have made a combined total of nearly 15,000 masks. “We quilters are very much in the thick of what’s going on with this,” said Ms. Browning, who lives in Paducah, Ky. “One thing most of us have is a stash of fabric.”

People who don’t sew could try a folded origami mask, created by Jiangmei Wu, assistant professor of interior design at Indiana University. Ms. Wu, who is known for her breathtaking folded artwork, said she began designing a folded mask out of a medical and building material called Tyvek, as well as vacuum bags, after her brother in Hong Kong, where mask wearing is common, suggested it. (DuPont, the maker of Tyvek, said in a statement that Tyvek is intended for medical apparel, not masks.) The folded mask pattern is free online, as is a video demonstrating the folding process. In tests at Missouri University and University of Virginia, scientists found that vacuum bags removed between 60 percent and 87 percent of particles. But some brands of vacuum bags may contain fiberglass or are harder to breathe through than other materials, and shouldn’t be used. Ms. Wu used a bag by EnviroCare Technologies, which has said it does not use fiberglass in its paper and synthetic cloth bags.

“I wanted to create an alternative for people who don’t sew,” said Ms. Wu, who said she is talking to various groups to find other materials that will be effective in a folded mask. “Given the shortage of all kinds of materials, even vacuum bags might run out.”

The scientists who conducted the tests used a standard of 0.3 microns because that is the measure used by the National Institute for Occupational Safety and Health for medical masks.

Linsey Marr, a Virginia Tech aerosol scientist and an expert in the transmission of viruses, said the certification method for respirators and HEPA filters focuses on 0.3 microns because particles around that size are the hardest to catch. While it seems counterintuitive, particles smaller than 0.1 microns are actually easier to catch because they have a lot of random motion that makes them bump into the filter fibers, she said.

“Even though coronavirus is around 0.1 microns, it floats around in a wide range of sizes, from around 0.2 to several hundred microns, because people shed the virus in respiratory fluid droplets that also contain lots of salts and proteins and other things,” said Dr. Marr. “Even if the water in the droplets fully evaporates, there’s still a lot of salt and proteins and other gunk that stays behind as solid or gel-like material. I think 0.3 microns is still useful for guidance because the minimum filtration efficiency will be somewhere around this size, and it’s what NIOSH uses.”

Learn More -

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm