Search results for: 'process+equipment'

-

TT-1059 SML COEX CAST FILM EXTRUSION LINE, YEAR 2011, 2230 KG PER HOURTT-1059 SML COEX CAST FILM EXTRUSION LINE, YEAR 2011, 2230 KG PER HOUR MAIN LINE COMPONENTS MANUFACTURERS: SML: EXTRUDER; CHAIR, ROLLERS, WINDING DEVICE GWK: COOLING EXTRUDER KREYENBORG: SCREEN CHANGER CLOEREN: FEED BLOCK, SLOT DIE PIOVAN: DRYER, DOSING DEVICE SERVE: EDGE BAND CUTTING DEVICE MATHO: SUCTION RAPID: EDGE STRIP SHREDDER KONGSHILDE: RECYLING EDGE STRIPS, START ROLLERS INFSTAUB: FILLING STATION SMK: CHILLERS SIEMENS: CONTROL OCS: CAMERA SYSTEM SEMET: LABELING SYSTEM AFS: CORONA SATION BETA CONTROLL: RADIOMETRIC THICKNESS MEASUREMENT SML: AUTOM. FYLING SPLICE WINDING UNIT, BECKOFF CONTROL SIMCO: ANTISTATIC ALTEK: AUTOMATIC ROLL MANIPULATOR (TRANSFER CARRIAGE) QUANTITY: 1 Learn More

TT-1059 SML COEX CAST FILM EXTRUSION LINE, YEAR 2011, 2230 KG PER HOURTT-1059 SML COEX CAST FILM EXTRUSION LINE, YEAR 2011, 2230 KG PER HOUR MAIN LINE COMPONENTS MANUFACTURERS: SML: EXTRUDER; CHAIR, ROLLERS, WINDING DEVICE GWK: COOLING EXTRUDER KREYENBORG: SCREEN CHANGER CLOEREN: FEED BLOCK, SLOT DIE PIOVAN: DRYER, DOSING DEVICE SERVE: EDGE BAND CUTTING DEVICE MATHO: SUCTION RAPID: EDGE STRIP SHREDDER KONGSHILDE: RECYLING EDGE STRIPS, START ROLLERS INFSTAUB: FILLING STATION SMK: CHILLERS SIEMENS: CONTROL OCS: CAMERA SYSTEM SEMET: LABELING SYSTEM AFS: CORONA SATION BETA CONTROLL: RADIOMETRIC THICKNESS MEASUREMENT SML: AUTOM. FYLING SPLICE WINDING UNIT, BECKOFF CONTROL SIMCO: ANTISTATIC ALTEK: AUTOMATIC ROLL MANIPULATOR (TRANSFER CARRIAGE) QUANTITY: 1 Learn More -

TT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLESTT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLES TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS NEW TATHAM BLOWFILL FIBRE OPENING AND FILLING LINE HOPPER 900mm WIDTH CARD OPENER FOR FIBRE 900mm WIDTH TWIN PNEUMATIC PILLOW FILLING POSITIONS PRODUCTION 250KG PER HOUR QUANTITY: 1 Learn More

TT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLESTT-1018 TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS, 2 NOZZLES TATHAM BLOW FILLING PRODUCTION LINE FOR PILLOW/CUSHIONS NEW TATHAM BLOWFILL FIBRE OPENING AND FILLING LINE HOPPER 900mm WIDTH CARD OPENER FOR FIBRE 900mm WIDTH TWIN PNEUMATIC PILLOW FILLING POSITIONS PRODUCTION 250KG PER HOUR QUANTITY: 1 Learn More -

YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98%YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98% DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS CORE COMPONENTS: BEARING APPLICATION: TEXTILE/ FIBER /WOOL/ CASHMERE AUTOMATIC GRADE: AUTOMATIC PRODUCTION EFFICIENCY: 98% POWER: 3.0 KW DIMENSIONS (L X W X H): 4450 X 2400 X 1550 mm WEIGHT: 4500 KG NAME: OPENING MACHINE MACHINE TYPE: RIGHT HAND FEEDING TYPE: PHOTOELECTRIC CONTROL AUTOMATIC FEEDING QUANTITY: 1 Learn More

YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98%YY-2050 SHEEP WOOL OPENING MACHINE, PRODUCTION EFFICIENCY 98% DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS CORE COMPONENTS: BEARING APPLICATION: TEXTILE/ FIBER /WOOL/ CASHMERE AUTOMATIC GRADE: AUTOMATIC PRODUCTION EFFICIENCY: 98% POWER: 3.0 KW DIMENSIONS (L X W X H): 4450 X 2400 X 1550 mm WEIGHT: 4500 KG NAME: OPENING MACHINE MACHINE TYPE: RIGHT HAND FEEDING TYPE: PHOTOELECTRIC CONTROL AUTOMATIC FEEDING QUANTITY: 1 Learn More -

T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020 CROSS TEAR PERFORATING UNIT YEAR 2020 WORKING WIDTH 1600mm WORKS WITH PLASTIC FILM, FOIL OR PAPER AND SOME NONWOVENS CROSS WEB TEAR LINE PERFORATING UNIT CAN BE CONVERTED TO PIN PERFORATOR IF REQUIRED PRODUCES EASY TEAR LINES FOR BAGS EASY TEAR LINES FOR HYGIENIC WIPES ETC. CREASE LINES FOR EASY CREASING ADJUSTABLE SLIT LENGTH AND REPEAT LENGTHS WEB DRIVEN MACHINE IS AVAILABLE IMMEDIATELY VERY NICE CONDITION QUANTITY: 1 Learn More

T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020 CROSS TEAR PERFORATING UNIT YEAR 2020 WORKING WIDTH 1600mm WORKS WITH PLASTIC FILM, FOIL OR PAPER AND SOME NONWOVENS CROSS WEB TEAR LINE PERFORATING UNIT CAN BE CONVERTED TO PIN PERFORATOR IF REQUIRED PRODUCES EASY TEAR LINES FOR BAGS EASY TEAR LINES FOR HYGIENIC WIPES ETC. CREASE LINES FOR EASY CREASING ADJUSTABLE SLIT LENGTH AND REPEAT LENGTHS WEB DRIVEN MACHINE IS AVAILABLE IMMEDIATELY VERY NICE CONDITION QUANTITY: 1 Learn More -

T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015 A8 OPEN END MACHINE YEAR 2015 552 ROTORS PER SET SAME TIME CAN PRODUCE 3 TYPE YARN 4 PCS ROBOTS COROLAB CLEANER T633BD ROTOR CUP BD174 COMBING ROLLER MOMENT SPINNING 20S COTTON YARN MACHINE WIDTH: 1547mm QUANTITY: 2 Learn More

T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015T-8176 A8 OPEN END MACHINE, 552 ROTORS, YEAR 2015 A8 OPEN END MACHINE YEAR 2015 552 ROTORS PER SET SAME TIME CAN PRODUCE 3 TYPE YARN 4 PCS ROBOTS COROLAB CLEANER T633BD ROTOR CUP BD174 COMBING ROLLER MOMENT SPINNING 20S COTTON YARN MACHINE WIDTH: 1547mm QUANTITY: 2 Learn More -

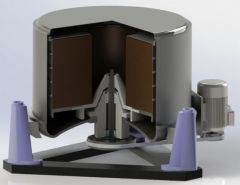

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More -

Z-1607 7200-D CANE SUGAR MILLZ-1607 7200-D CANE SUGAR MILL USED 7200-D CANE PROCESSING PLANT INCLUDING MAJOR EQUIPMENT Learn More

Z-1607 7200-D CANE SUGAR MILLZ-1607 7200-D CANE SUGAR MILL USED 7200-D CANE PROCESSING PLANT INCLUDING MAJOR EQUIPMENT Learn More -

USED 1500 TPD SUGAR REFINERY FROM RAW SUGARREFERENCE NUMBER: AJ-2089 USED 1500 TPD SUGAR REFINERY FROM RAW SUGAR THE PROCESS CONSIST OF: RAW SUGAR RECEPTION WITH 2 WAREHOUSES FOR STORAGE OF APPROX 14000 TON OF RAW SUGAR AFFINATION (FCB CONTI CENTRIFUGES) CARBONATION FILTRATION WITH DIASTAR AND PUTSCH FILTERS ION EXCHANGE 3 COLUMNS DECOLORIZATION WITH APPLEXION MEMBRANE FILTRATION EVAPORATION WITH 4 FALLING FILM EVAPORATORS JUICE AND SYRUP HEATING CRYSTALLIZATION WITH 9 VACUUM PANS AND VERTICAL CRYSTALLIZERS CURING (SUGAR CRYSTALS SEPARATION) WITH 6 FCB BATCH SUGAR CENTRIFUGES SCREENING AND DRYING SUGAR WITH 55 RPH MAGUIN REVOLVER TYPE SUGAR DRYER AND ADDITIONAL 12 TPH FLUID BED SUGAR DRYER PACKING AND PALLETIZING SUGAR 5 GRAM STICKS, 1 KG, 20 TO 50 KG, 1000 KG BAGS 50000 TON SUGAR SILO POWER PLANT WITH 120 TPH OF STEAM AND 11 MW ABB OR CKD TURBO GENERATOR WATER TREATMENT PLANT REPORTED THE PLANT WAS RUNNING UP TO 1600 TPD CAPACITY MAY BE INCREASED TO 2000 TPD WITH ADDITIONAL EQUIPMENT QUANTITY: 1 Learn More

USED 1500 TPD SUGAR REFINERY FROM RAW SUGARREFERENCE NUMBER: AJ-2089 USED 1500 TPD SUGAR REFINERY FROM RAW SUGAR THE PROCESS CONSIST OF: RAW SUGAR RECEPTION WITH 2 WAREHOUSES FOR STORAGE OF APPROX 14000 TON OF RAW SUGAR AFFINATION (FCB CONTI CENTRIFUGES) CARBONATION FILTRATION WITH DIASTAR AND PUTSCH FILTERS ION EXCHANGE 3 COLUMNS DECOLORIZATION WITH APPLEXION MEMBRANE FILTRATION EVAPORATION WITH 4 FALLING FILM EVAPORATORS JUICE AND SYRUP HEATING CRYSTALLIZATION WITH 9 VACUUM PANS AND VERTICAL CRYSTALLIZERS CURING (SUGAR CRYSTALS SEPARATION) WITH 6 FCB BATCH SUGAR CENTRIFUGES SCREENING AND DRYING SUGAR WITH 55 RPH MAGUIN REVOLVER TYPE SUGAR DRYER AND ADDITIONAL 12 TPH FLUID BED SUGAR DRYER PACKING AND PALLETIZING SUGAR 5 GRAM STICKS, 1 KG, 20 TO 50 KG, 1000 KG BAGS 50000 TON SUGAR SILO POWER PLANT WITH 120 TPH OF STEAM AND 11 MW ABB OR CKD TURBO GENERATOR WATER TREATMENT PLANT REPORTED THE PLANT WAS RUNNING UP TO 1600 TPD CAPACITY MAY BE INCREASED TO 2000 TPD WITH ADDITIONAL EQUIPMENT QUANTITY: 1 Learn More -

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More

INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: A-2490 INNER EARLOOP SURGICAL MASK PRODUCTION LINE 1+1 FULLY AUTOMATIC MASK MACHINE MACHINE WILL COMPLETE THE WHOLE PRODUCTION PROCESS FROM RAW MATERIAL ROLL TO FINISHED PRODUCT OF THE MASK. THE EQUIPMENT INCORPORATES ULTRASONIC WELDING MODE, SANITATION AND ENVIRONMENTAL PROTECTION. SPECIFICATIONS: MACHINE SIZE: 5000 X 2500 X 1900 mm NET WEIGHT: <= 2000 KGS GROUND BEARING ≤200 KG/M2 WORKING POWER: 220 VOLTS AND 50/60 Hz COMPRESSED AIR: 0.5 TO 0.7 MPA USAGE FLOW: 150 L/min USE ENVIRONMENT: TEMPERATURE 1O TO 35℃ HUMIDITY: 5 TO 55% HR, NO COMBUSTIBLE OR CORROSIVE GAS OR DUST NORMAL PRODUCTION: 60 TO 90 PCS/min FEATURES • INCORPORATING ULTRASONIC WELDING TECHNOLOGY, SANITARY AND ENVIRONMENTAL - FRIENDLY • WHOLE PRODUCTION LINE IS AUTOMATIC FROM FEEDING, NOSE STRAP INSERTING, EDGE SEALING AND CUTTING FINISHED PRODUCTS • THE FRAME STRUCTURE IS MADE OF ALUMINUM ALLOY AND THE KEY PARTS ARE MADE OF STAINLESS STEEL. • COMPUTER PLC PROGRAMMING CONTROL, STEP OR SERVO DRIVE, PARTIAL PNEUMATIC DRIVE, HIGH STABILITY, LOW FAILURE RATE, HIGH EFFICIENCY • FEEDING, WELDING AND BINDING OF EARBELT ARE DRIVEN BY STEP OR SERVO MOTOR • THE TENSION OF THE RAW MATERIALS HAS AUTOMATIC CONTROL TO ENSURE THE TENSION BALANCE OF RAW MATERIALS • PHOTOELECTRIC (OPTICAL FIBER) DETECTION OF RAW MATERIALS TO AVOID MISTAKES AND REDUCE MATERIAL WASTE Learn More