Search results for: 'Frame 500'

-

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More

TT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEWTT-1370 AUTOMATIC HIGH SPEED SLITTING REWINDING MACHINE, WIDTH 1900mm, NEW SUITABLE FOR ROLLS OF PLASTIC FILMS, LAMINATED FILMS, PAPER, ETC. SPEED: 0-400M/MIN SLITTING WIDTH: 30 TO 1900mm UNWINDING DIAMETER MAXIMUM ø1400mm WINDING DIAMETER: ø610mm MACHINE WEIGHT: 5000KG TOTAL MOTOR POWER: 31KW DIMENSIONS: W3500 X L3500 X H1900 (mm) PAPER CORE 3" (DIAMETER φ76mm DIAMETER φ92mm) OR 3.6” CORE ACCURACY: ≤ 0.30mm TENSION SETTING RANGE: 2 ~ 30KG WINDING MOTOR POWER: 11KW X 2 TRACTION MOTOR: 11KW MACHINE COLOR: STANDARD WHITE (OR AS REQUIRED) QUANTITY: 1 SET Learn More -

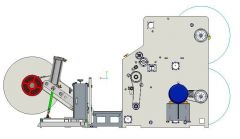

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More

YY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINEYY-2029 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: 1. BAG SIZE: BASED ON CUSTOMER'S REQUEST; 2. SPEED: 120 TO 180 BAGS/MIN; 3. PACKING MATERIALS: PAPER + PAPER, PAPER + PLASTIC, 4. PACKAGE MATERIAL DIAMETER Φ≤350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; 5. VOLTAGE: 3 PHASE 380V 50Hz OR 220V 50/60Hz; 6. MOTORS: a. SERVO MOTOR 1.5KW b. SERVO MOTOR: 1KW c. STEPPING MOTOR 110 d. STEPPING MOTOR VARIABLE FREQUENCY MOTOR 0.37KW 7. TOTAL OF 5 MOTORS IS 4KW 8. USES 28 VOLT FOR THE HEAT CIRCUIT, 2 HEATING PANELS, EACH PANEL WITH 8 HEATING TUBES, EACH TUBE IS 300 W, TOTAL 4.8 KW; 9. MACHINE WEIGHT: 800 KG; 10. MACHINE SIZE: LENGTH 5000 × WIDTH 1300 × HEIGHT 1600mm; 11. CRATE SHIPPING DATA: LENGTH 2600 × WIDTH 1900 × HEIGHT 1800mm. 12. TOTAL OF 5 MOTORS IS: 4KW QUANTITY: 1 Learn More -

T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020 CROSS TEAR PERFORATING UNIT YEAR 2020 WORKING WIDTH 1600mm WORKS WITH PLASTIC FILM, FOIL OR PAPER AND SOME NONWOVENS CROSS WEB TEAR LINE PERFORATING UNIT CAN BE CONVERTED TO PIN PERFORATOR IF REQUIRED PRODUCES EASY TEAR LINES FOR BAGS EASY TEAR LINES FOR HYGIENIC WIPES ETC. CREASE LINES FOR EASY CREASING ADJUSTABLE SLIT LENGTH AND REPEAT LENGTHS WEB DRIVEN MACHINE IS AVAILABLE IMMEDIATELY VERY NICE CONDITION QUANTITY: 1 Learn More

T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020T-9742 CROSS TEAR PERFORATING UNIT, WORKING WIDTH 1600mm, YEAR 2020 CROSS TEAR PERFORATING UNIT YEAR 2020 WORKING WIDTH 1600mm WORKS WITH PLASTIC FILM, FOIL OR PAPER AND SOME NONWOVENS CROSS WEB TEAR LINE PERFORATING UNIT CAN BE CONVERTED TO PIN PERFORATOR IF REQUIRED PRODUCES EASY TEAR LINES FOR BAGS EASY TEAR LINES FOR HYGIENIC WIPES ETC. CREASE LINES FOR EASY CREASING ADJUSTABLE SLIT LENGTH AND REPEAT LENGTHS WEB DRIVEN MACHINE IS AVAILABLE IMMEDIATELY VERY NICE CONDITION QUANTITY: 1 Learn More -

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More

V-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETERV-2005 WARPER AND CREEL FOR DENIM YARNS WITH 48 BEAMS; 1800mm WIDTH X 1400mm DIAMETER MAXIMUM WARPING SPEED: 1000 METERS PER MINUTE WARP DENSITY: 0.3 TO 0.65 G/cm3; BRAKE SYSTEM: PNEUMATIC-HYDRAULIC CLAMP-BRAKES ON GUIDE ROLLER, WARPING BEAM, PRESS ROLLER; BRAKING DISTANCE: ≤4M (AT SPEED OF 500 METERS PER MINUTE); LENGTH MEASURING: LENGTH MEASURING ON PRESSURE ROLLER WHEN WORKING, LENGTH MEASURING ON WARPING BEAM WHEN PRESS ROLLER BACKWARDS; LENGTH MEASURING ACCURACY: ±0.1%; PRESS METHOD: CYLINDER PUSHES PRESS ROLLER GIVING PARALLEL PRESSURE ALONG THE INCLINED LINEAR GUIDE, PNEUMATIC DISC OFFERS AUXILIARY DAMPING PRESSURE; EXPANSION REED TYPE: W SHAPE, MOVABLE UP AND DOWN, LEFT AND RIGHT; REED TRAVERSE RANGE: 0 TO 40mm ADJUSTABLE; REED TRAVERSE ADJUSTMENT: MANUALLY; REED TRAVERSE FREQUENCY: 24 CYCLES PER MINUTE; EXPANSION REED STRETCH METHOD: ELECTRICAL; REED CENTERING METHOD: ELECTRICAL; BEAM CLAMP: PNEUMATIC; PRESS ROLLER CENTERING: ELECTRICAL; WORKSTATION: TOUCH SCREEN, BUTTONS ON SAFETY BAR. QUANTITY: 1 SET SHIPPING NOTICE: 1 40FT CONTAINER FOR WARPER AND CREEL 1 40FT CONTAINER FOR 48 BEAMS TIME TO BUILD THE MACHINE: 100 DAYS Learn More -

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More -

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More

INDUSTRIAL ELECTROSPINNING MACHINEREFERENCE NUMBER: A-2471 INDUSTRIAL ELECTROSPINNING MACHINE A MASS PRODUCTION MACHINE OF ELECTROSPINNING. ALUMINUM FRAME STRUCTURE MAKES IT POSSIBLE FOR EXTENDING DIFFERENT FUNCTIONS. THE SPINNERET USED IS MULTI-NEEDLE ARRAYS, FROM 64 TO 384 NEEDLES ARE EQUIPPED. THE LENGTH AND WIDTH CAN BE MADE ACCORDING TO CUSTOMER'S REQUIREMENT. ROLL TO ROLL COLLECTOR AND CONTINUOUS COLLECTOR CAN BE USED BASED ON THE THICKNESS OF REQUIRED FIBER SHEET. FOR SOLUTIONS, A MULTI-CHANNEL PUMP WILL BE SUPPLIED FOR LONG TIME PRODUCTION OR NONE-STOP PRODUCTION. FEATURES: - EQUIPPED WITH BOTH POSITIVE & NEGATIVE HIGH VOLTAGE SUPPLY DEVICES - EQUIPPED WITH UNWINDING & WINDING MACHINES - CONTINUOUS ELECTROSPINNING & WINDING - ALUMINUM ALLOY FRAME STRUCTURE, MULTI-FUNCTIONS EXPANSIBLE - MULTI-NEEDLES IN ARRAYS. 16 NEEDLES X N ROWS, UP TO 384 NEEDLES - SPINNERET MOVING MACHINERY ENSURES EVEN FIBER SHEET - ONLINE AUTO-CLEAN DEVICE FOR NEEDLES - THICKNESS OF THE FIBER SHEET IS CONTROLLABLE - CE & FCC CERTIFICATE SPINNERET STANDARD:16 NEEDLES X 8 GROUPS =128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ADJUSTED FREELY ACCORDING TO THE REQUIREMENTS OF USE) X-Y-Z MOTION SYSTEM - THE NOZZLE CAN BE MOVED UP AND DOWN IN THE Z DIRECTION THROUGH THE TOUCH SCREEN CONTROL TO DETERMINE THE APPROPRIATE SPINNING DISTANCE. - THE NOZZLE CAN MOVE BACK AND FORTH ALONG THE YAXIS DIRECTION OF THE TANGENT DIRECTION OF THE RECEIVING FILM TO PREPARE A UNIFORM FIBER FILM. - THE NOZZLE AUTOMATIC ONLINE CLEANING DEVICE SCANS ALONG THE X-AXIS DIRECTION. COLLECTOR - STAINLESS STEEL PLATE / MESH SERVES AS A CARRIER FOR THE FIBER MEMBRANE SUBSTRATE. - CONNECTED WITH NEGATIVE HIGH VOLTAGE. - RECEIVER BOARD WIDTH: 500 mm - SPINNING DISTANCE: 80 TO 300 mm ADJUSTABLE WINDER AND UNWINDER - AUTOMATICALLY CALCULATE THE ROLL DIAMETER OF THE LOADED MATERIAL AND CONTROL THE TENSION BETWEEN THE UNWINDING AND SPINNING SECTIONS. - CONSTANT FEEDING SPEED. THE FEEDING SPEED RANGE IS 0 TO 5000 mm / min. - ONLINE HOT PRESSING FUNCTION MODULE. AFTER THE SPINNING IS COMPLETED, BEFORE THE WINDING, A TEMPERATURE-CONTROLLED HOT PRESSING DEVICE (ROOM TEMPERATURE TO 60 ° C) IS USED FOR HOT PRESSING. (OPTIONAL THIRD LAYER MATERIAL STICKING AND REWINDING DEVICE). - CAN BE OPERATED BY TOUCH SCREEN. - DO NOT USE METAL FILM AS THE RECEIVING CARRIER. SYRINGE PUMP - 200ML X 4N CHANNEL - FLOW RATE: 0.1ML / H TO 1280 ML / H - SPECIALLY DESIGNED FOR ELECTRO-SPINNING AND RESISTANT TO HIGH VOLTAGE. HIGH VOLTAGE DEVICE -0 TO 50KV, DIGITAL DISPLAY --50KV ~ 0 KV, DIGITAL DISPLAY -OUTPUT CURRENT: <1 MA -CONTINUOUSLY ADJUSTABLE CONTROL SYSTEM -PLC CONTROL SYSTEM, 7-INCH TOUCH SCREEN. -CONTROL THE MOVEMENT OF THE NOZZLE. -CONTROL THE NOZZLE TO MOVE UP AND DOWN. -YOU CAN SET THE MOVEMENT TIME, STROKE AND SPEED OF THE NOZZLE. -CONTROL THE FREQUENCY OF NOZZLE CLEANING. -SPINNING PROCESS PARAMETER RECORDS. ENVIRONMENTAL CONTROL SYSTEM -PROVIDE INTERFACE TO LET IN DRY AMBIENT HUMIDITY AIR. -AN EXTERNAL DEHUMIDIFIER CAN BE USED TO CONTROL THE AMBIENT HUMIDITY. THE EXTERNAL DEHUMIDIFIER NEEDS TO BE SELECTED ACCORDING TO THE SIZE OF THE WORKSHOP. THIS EQUIPMENT DOES NOT INCLUDE THIS DEHUMIDIFIER. EXHAUST SYSTEM -BOTTOM UP, AND FOUR FANS ARE PUMPED AT THE SAME TIME. -THE DISCHARGE VOLUME OF A SINGLE UNIT IS 5 TO 150 M3 / H, AND THE RATE IS ADJUSTABLE. THE COMBINED DISCHARGE VOLUME OF THE TWO EXHAUST FANS IS 10 TO 300M3 / H. THE EXTRACTOR IS DRAWN FROM THE MIDDLE. IN THIS WAY, THE HIGH-SPEED AIR VENTILATION MINIMIZES THE RELATIVE DISTURBANCE TO THE SPINNING. THE EXHAUST FAN IS A SILENT EXHAUST FAN. SAFETY -AUTOMATIC POWER-OFF DEVICE FOR OPENING THE DOOR. -RESIDUAL STATIC ELECTRICITY REMOVAL DEVICE. -EMERGENCY STOP SWITCH. -GROUND AT MULTIPLE POINTS. -ALARM DEVICE AFTER THE CONTROL PARAMETERS EXCEED THE LIMIT. CHAMBER -THE CHAMBER IS MADE OF ALUMINUM ALLOY FRAME. -THE FRONT AND SIDE WINDOWS OF THE CABINET ARE MADE OF TEMPERED GLASS. -MULTI-POINT TEMPERATURE AND HUMIDITY COLLECTION AND DISPLAY. -THE PROCESS CAN BE OBSERVED WITH THE NAKED EYE. -AIR INLET: HOT AND DRY AIR CAN BE INTRODUCED TO QUICKLY ADJUST THE HUMIDITY INSIDE THE CHAMBER. POWER SOURCE -220 VOLTS AND 50/60 Hz -TOTAL POWER: 10KW NUMBER OF NEEDLES: 128 NEEDLES (THE NUMBER OF NEEDLES CAN BE ARBITRARILY REDUCED ACCORDING TO THE SOLVENT USAGE) FLOW RATE OF EACH NEEDLE: (~ 3ML ± 50%) / HOUR TOTAL FLOW OF THE WHOLE MACHINE: ABOUT (400ML ± 50%) / HOUR SOLUTION CONCENTRATION: 10 TO 20% 8 HOURS SOLUTION PROCESSING CAPACITY: ABOUT (3L ± 50%) / 8 HOURS SOLID CONTENT (WEIGHT OF FIBER PRODUCED): (300G ± 50%) / 8 HOURS ACCORDING TO THE APPROXIMATE PRODUCTION OF FIBER MATERIAL WITH A GRAM WEIGHT OF 2GSM. WINDING AND UNWINDING SPEED: 50M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 25 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 200 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: 600 SQUARE METERS BASED ON THE PRODUCTION OF FIBER MATERIAL WITH A GRAMMAGE OF 0.02G / ㎡, APPROXIMATELY: WINDING AND UNWINDING SPEED: 5000M / H MATERIAL WIDTH: 0.5 METERS FABRIC AREA PRODUCED PER HOUR: 2500 SQUARE METERS FABRIC AREA PRODUCED IN 8 HOURS: 20,000 SQUARE METERS FABRIC AREA PRODUCED IN 24 HOURS: ABOUT 60,000 SQUARE METERS Learn More -

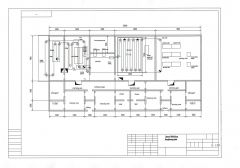

C-4127 RIETER RING SPINNING MILL WITH 24000 SPINDLES, YEAR 2003 TO 2008

C-4127 RIETER RING SPINNING MILL WITH 24000 SPINDLES, YEAR 2003 TO 2008C-4127 RIETER RING SPINNING MILL WITH 24000 SPINDLES, YEAR 2003 TO 2008

RIETER RING SPINNING MILL

24000 SPINDLES

YEAR: 2003 TO 2008CONSISTING OF:

OPENING LINE:

OFFER 001

UNIFLOC A11

WASTE OPENER

UNICLEAN

UNIMIX

UNIFLEX

JOSSI VISION SHIELD 2

QUANTITY: 1OFFER 002

CARDS:

C51

CHUTE FEED A70

IDF (INTEGRATED GRINDING SYSTEM)

CAN SIZE: 1000mm

QUANTITY: 18OFFER 003

DRAW FRAME:

4 X RSB SB-D15

CAN SIZE 600mm

5 X RSB D35

CAN SIZE 500mm

QUANTITY: 9OFFER 004

LAP WINDER:

E32

QUANTITY: 2OFFER 005

COMBER:

5 X E62

6 X E65

QUANTITY: 11OFFER 006

ROVING:

6 X F11

120 SPINDLES

6 X 16"

QUANTITY: 12OFFER 007

RING FRAME:

G33

1200 SPINDLES

38mm RING DIA. (10)

40mm RING DIA. (10)

GAUGE: 70mm

QUANTITY: 20OFFER 008

WINDER:

MURATA 21C

60 POSITIONS

57

YARN CLEARER LÖPFE TK940F

WAXING

QUANTITY: 8QUANTITY: 1 MILL

Learn More -

K-3238 COMPLETE RING SPINNING PLANT 24,500 SPINDLES YEAR 1990 TO 1998REFERENCE NUMBER: K-3238 COMPLETE RING SPINNING PLANT 24,500 SPINDLES YEAR 1990 TO 1998 QUANTITY AVAILABLE: 1 Learn More

K-3238 COMPLETE RING SPINNING PLANT 24,500 SPINDLES YEAR 1990 TO 1998REFERENCE NUMBER: K-3238 COMPLETE RING SPINNING PLANT 24,500 SPINDLES YEAR 1990 TO 1998 QUANTITY AVAILABLE: 1 Learn More -

K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOURREFERENCE NUMBER: K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More

K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOURREFERENCE NUMBER: K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More