Search results for: 'conveyors'

-

V-1325 FEHRER NEEDLE LOOM MODEL NL21/S, WIDTH 3000mm, YEAR 1986 – 5000 NEEDLES/METER

V-1325 FEHRER NEEDLE LOOM MODEL NL21/S, WIDTH 3000mm, YEAR 1986 – 5000 NEEDLES/METERV-1325 FEHRER NEEDLE LOOM MODEL NL21/S, WIDTH 3000mm, YEAR 1986 – 5000 NEEDLES/METER

NEEDLE LOOM

MAKE: FEHRER

MODEL: NL21/S

WIDTH: 3000mm

YEAR: 1986

NEEDLE PATTERN 2 X 5000 PATTERN K1 (300mm FRONT TO BACK)

TOTAL 6 SECTION BOARDS 1000mm WIDE EACH

STROKE 35mm

1800 RPM

OUTLET ROLLER 200mm DIAMETERQUANTITY: 1

Learn More -

P-3444 TORTILLA MIXING, FRYING & COOKING LINE

P-3444 TORTILLA MIXING, FRYING & COOKING LINETORTILLA MIXING, FRYING & COOKING LINE

MAJOR ITEMS INCLUDE:

PEERLESS DOUGH MIXER WITH TILT BOWL, ALL STAINLESS STEEL

DOUGH SHEETER WITH ROTARY CUTTER

HEAT & CONTROL MODEL BPF-2005X FRYER

CASA HERRERA MODEL 10 GAS-FIRED BELT OVEN

ALSO INCLUDES:

THERMO SYSTEM SPIRAL FREEZER WITH FES COMPRESSOR, 36 INCHES WIDE BELT, 750 LINEAR FEET

2 HINDS BOCK PISTON FILLERS / DEPOSITORS

2 GROEN 100 GALLON COOKING KETTLES

2 TAMALE STEAMERS

MISCELLANEOUS:

BELT CONVEYORS

STAINLESS STEEL TANKS

FORKLIFTS

COMPRESSORS AND MORE

QUANTITY: 1

Learn More -

V-1278 TAYLOR STILES 536 X 4 BLADE MACHINE, WIDTH 36”

V-1278 TAYLOR STILES 536 X 4 BLADE MACHINE, WIDTH 36”V-1278 TAYLOR STILES 536 X 4 BLADE MACHINE, WIDTH 36”

MAKE: TAYLOR STILES

536 X 4 BLADE MACHINE

THEY HAVE 12’ INFEED CONVEYORS

36” WIDE BLADESQUANTITY: 2

Learn More -

V-1277 TAYLOR STILES ENVIROTECH 536 ROTARY CUTTER

V-1277 TAYLOR STILES ENVIROTECH 536 ROTARY CUTTERREFERENCE NUMBER: V-1277

TAYLOR STILES ENVIROTECH 536 ROTARY CUTTER(2) 36" BLADES, ~16' INFEED AND 8' DISCHARGE CONVEYORS

QUANTITY: 1

Learn More -

M-6061 THERMOBONDING LINE, WIDTH 2600mm TO 4000mm, YEAR 1984 TO 1999

M-6061 THERMOBONDING LINE, WIDTH 2600mm TO 4000mm, YEAR 1984 TO 1999M-6061 THERMOBONDING LINE, WIDTH 2600mm TO 4000mm, YEAR 1984 TO 1999

OFFER 001

THERMOBONDING LINE

YEAR: 1984 TO 1999

WORKING WIDTH: 2600mm

CAPACITY: 800 KG PER HOUROFFER 002

BALE OPENER

YEAR: 1996OFFER 003

DELL’ORCO & VILLANI MIXING BOX

YEAR: 1996

WIDTH: 4000mm

HEIGHT: 3500mm

LENGTH: 8000mmOFFER 004

BEMATIC CARDING MACHINE

YEAR: 1984

WORKING WIDTH: 3000mmOFFER 005

AUTOMATEX CROSSLAPPER

YEAR: 1999OFFER 006

SICAM OVEN

YEAR: 1996

WORKING WIDTH: 2600mmOFFER 007

AUTOMATEX CUTTING

YEAR: 1989QUANTITY: 1 LINE

Learn More -

X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015)REFERENCE NUMBER: X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015) 1) –Opening and Blending line 2) - CROSSLAPER 3)- Thermobonding Oven 4) – Including main control panel. 3 YEAR EXTENDED WARRANTY OUR COMPANY OFFERS INSTALLATION AND COMMISSIONING OF THIS LINE FOR OUR MACHINES 2 TECHNICAL IN THE PLACE TO BE APPOINTED BY THE CUSTOMER. Learn More

X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015)REFERENCE NUMBER: X-1016 NONWOVEN LINE FOR PRODUCING POLYESTER BATTING WIDTH 3600 mm (NEW 2015) 1) –Opening and Blending line 2) - CROSSLAPER 3)- Thermobonding Oven 4) – Including main control panel. 3 YEAR EXTENDED WARRANTY OUR COMPANY OFFERS INSTALLATION AND COMMISSIONING OF THIS LINE FOR OUR MACHINES 2 TECHNICAL IN THE PLACE TO BE APPOINTED BY THE CUSTOMER. Learn More -

C-1856 GRASSI COMPACT LAMINATING MACHINE, YEAR 1998REFERENCE NUMBER: C-1856 GRASSI COMPACT LAMINATING MACHINE, YEAR 1998 DETAILS: LAMINATING MACHINE N 957 YEAR: 1998 SIZE 100X140 LAMINATING FATS COMPACT MODEL CONVEYORS IN EXCELLENT CONDITION IN PRODUCTION IN TOP WORKING CONDITION DAMAGE FREE QUANTITY AVAILABLE: 1 Learn More

C-1856 GRASSI COMPACT LAMINATING MACHINE, YEAR 1998REFERENCE NUMBER: C-1856 GRASSI COMPACT LAMINATING MACHINE, YEAR 1998 DETAILS: LAMINATING MACHINE N 957 YEAR: 1998 SIZE 100X140 LAMINATING FATS COMPACT MODEL CONVEYORS IN EXCELLENT CONDITION IN PRODUCTION IN TOP WORKING CONDITION DAMAGE FREE QUANTITY AVAILABLE: 1 Learn More -

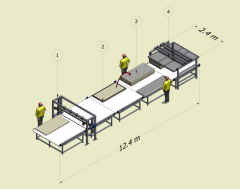

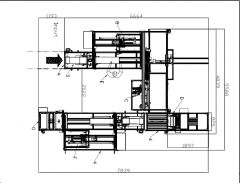

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More

M-1456 COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATEDREFERENCE NUMBER: M-1456 (660211BTC5R) COMPLETE PILLOW SEWING/FILLING/PACKING LINE-FULLY AUTOMATED QUANTITY AVAILABLE: 1 Learn More -

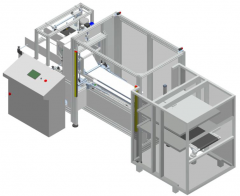

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More

K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOXREFERENCE NUMBER: K-1289 AUTOMATIC LINE FOR PACKAGING PILLOWS - BY ROBOT INSERTING ADVERTISING SHEET , AUTOMATIC PLACING INTO PLASTIC BAG, FLATTENING OF PLASTIC BAG AND PUSHING INTO A BOX FOR THE PACKAGING WITH ROBOTIC MACHINES FOR ALL THE MOVEMENTS: CHECKING, FILLING, PRESSING AND WELDING, SCRAPPING THE MATERIAL IN EXCESS, MOTORIZED OUTPUT INTO CARTON BOXES OF PILLOWS OR CUSHIONS. SPECIFIC FOR AUTOMATIC FILLING OF PILLOWS AND CUSHIONS INTO PLASTIC BAGS WITH PRESSING AND WELDING SYSTEM, SCRAPPING THE MATERIAL IN EXCESS AND THE EJECT OF THE BAGGED PILLOWS INTO BOXES, WITHOUT OPERATORS QUANTITY AVAILABLE: 1 Learn More