Search results for: 'process equipment'

- Related search terms

- process'[0]

- Process+of+cl

- process+equi

- process+equipment

- equipment in

-

P-8696 ULTRASONIC SEWING MACHINELearn More

P-8696 ULTRASONIC SEWING MACHINELearn MoreREFERENCE NUMBER: P-8696

ULTRASONIC SEWING MACHINE

CAN BE USED WITH EITHER 20 KHz, 30 KHz OR 40 KHz EQUIPMENT

LED DISPLAY FOR EASY PROCESS MONITORING

19” (483mm) THROAT

INDEPENDENT CONTROLS FOR SLITTING AND ROTARY ANVIL WELDING

DUAL SEALING CAPABILITIES WITH INDEPENDENT ADJUSTMENTS

EDGE GUIDING, REWINDING, AND FEED ROLLS CAN BE USED

CAN BE OPERATOR CONTROLLED AS A BENCHTOP UNIT OR INTEGRATED INTO AN EXISTING LINE

QUANTITY: 1

-

T-6575 NON-INVASIVE VENTILATOR

T-6575 NON-INVASIVE VENTILATORNON-INVASIVE VENTILATOR

Learn More

CERTIFICATE: CE

MEDICAL VENTILATOR

TECHNICAL PARAMETERS OF DOUBLE LEVEL VENTILATOR

VENTILATOR TYPE: ELECTRIC CONTROL

SCOPE OF APPLICATION: TREATMENT AND TITRATION OF SLEEP APNEA HYPOPNEA SYNDROME, SEVERE SNORING, AND RESPIRATORY INSUFFICIENCY.

DISPLAY INTERFACE: 3.5-INCH LED SCREEN, CHINESE OPERATING SYSTEM

*VENTILATION MODE: CPAP, S, S/T, T

PRESSURE RANGE:

PRESSURE RANGE: 4-30CMH2O (±0.5CMH2O)

PRESSURE ACCURACY: + 0.5CMH2O

PARAMETER SETTING:

DELAYED BOOST: 0-60MIN, SET THE DIVISION INTERVAL 5MIN

INITIAL PRESSURE: 4CMH2O TREATMENT PRESSURE / RESPIRATORY PRESSURE SETTING

THERAPEUTIC PRESSURE: 4-20CMH2O (IN CPAP MODE)

TARGET TIDAL VOLUME: 150ML - 1500ML, ON/ OFF

MAXIMUM SUCTION PRESSURE: 4-30CMH2O, (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

MINIMUM SUCTION PRESSURE: 4-30CMH2O (NOT HIGHER THAN THE SUCTION PRESSURE), (CAN BE SET WHEN THE TARGET TIDAL VOLUME FUNCTION IS ON)

INSPIRATORY PHASE PRESSURE: 4-30CMH2O

EXPIRATORY PRESSURE: 4-30CMH2O

EXPIRATORY DECOMPRESSION: PATIENT, OFF, 1-3, THREE ADJUSTABLE

MANUAL VOLTAGE REGULATION: 0-2 GEAR, 0-2CMH2O (ONLY AVAILABLE IN CPAP MODE)

INSPIRATORY SENSITIVITY: 1-8 STALLS

EXPIRATORY SENSITIVITY: 1-8 STALLS

RESPIRATORY FREQUENCY: 3-40 TIMES / MIN

INSPIRATORY TIME: 0.3-3.0S

BACKUP RATE: ON / OFF, DEFAULT 10

PRESSURE RISE TIME: 1-4 STALLS

HUMIDIFIER: 1-5 ADJUSTABLE IN 5 GEARS

*TITRATION FUNCTION: SUPPORT MANUAL AND AUTOMATIC PRESSURE TITRATION, BUILT-IN REMOTE WIRELESS COMMUNICATION MODULE, COMPLETE THE RANDOM SWITCHING OF SINGLE AND DOUBLE LEVEL MODES IN THE TITRATION PROCESS, AND CONTROL MORE THAN 11 VENTILATOR PARAMETERS AT THE SAME TIME.

AUXILIARY FUNCTION: AUTOMATIC AIR LEAKAGE COMPENSATION, AUTOMATIC STARTUP, AUTOMATIC SHUTDOWN, DELAYED SHUTDOWN, SCREEN BACKLIGHT ADJUSTMENT

MONITORING PARAMETERS: PRESSURE, TIDAL VOLUME, RESPIRATORY RATE, MINUTE VENTILATION VOLUME, AIR LEAKAGE VOLUME, INSPIRATORY TIME, BLOOD OXYGEN SATURATION

WAVY CURVE: PRESSURE TIME WAVEFORM, FLOW RATE TIME WAVEFORM

ALARM PROMPT: PIPELINE AND MASK FALLING OFF, AIR LEAKAGE PROMPT, POWER INTERRUPTION, TREATMENT MACHINE FAILURE, HUMIDIFIER FAILURE, LOW VOLTAGE, HIGH RESPIRATORY RATE, LOW RESPIRATORY RATE, LOW MINUTE VENTILATION VOLUME, LOW BLOOD OXYGEN, REPLACEMENT OF FILTER COTTON, FULL SD CARD, RE INSERTION OF SD CARD

*DATA MANAGEMENT:

NETWORK DATA: BMC + RESPIRATORY HEALTH MANAGEMENT CLOUD PLATFORM

SD CARD DATA: RESART NPAP DATA ANALYSIS SOFTWARE

PARTS:

SD CARD: STANDARD

SD CARD SLOT: STANDARD

PIPING: 9 22MM, 1.8M LONG

FACE SHIELD: F2 NOSE MASK AS STANDARD

NOISE: LESS THAN 30DB

ENVIRONMENT CONDITION:

TEMPERATURE:

(WHEN USED) 5 -35 C

(DURING TRANSPORTATION AND STORAGE) -20 C -55 C

ATMOSPHERIC PRESSURE:

(WHEN USED) 760-1060HPA

(DURING TRANSPORTATION AND STORAGE) 760-1060HPA

WORKING HOURS: MORE THAN 8 HOURS

POWER SUPPLY REQUIREMENTS:

AC VOLTAGE: 100-240V

FREQUENCY: 50HZ/60HZ

INPUT POWER: LESS THAN 2A

WATERPROOF LEVEL: IP22 - DRIP PROOF EQUIPMENT

INSTRUMENT SIZE: 290mm X 180mm X 134mm

WEIGHT: 1.5KG (EXCLUDING HUMIDIFIER) 2.5KG (INCLUDING HUMIDIFIER)

ITEM 001

QUANTITY: 10 SETS-999 SETS

ITEM 002

QUANTITY: 1,000 SETS-9,999SETS

ITEM 003

QUANTITY: ≥10,000 SETS -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

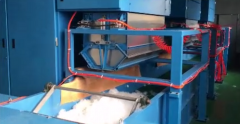

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mm

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mmREFERENCE NUMBER: L-4682

Learn More

WIDTH: 1200mm

CAPACITY: 200-600KG/H

QUANTITY: 1 -

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOUR

P-4421 LAUNDRY SOAP PRODUCTION LINECAPACITY 1000 to 1500 KILOGRAMS PER HOURREFERENCE NUMBER: P-4421

VOLUME: 10m3SIZE:φ2800 x 3000, 20 m3POWER: 5.5 KILOWATTS PER SETLearn More -

R-7080 840N 40KG INDUSTRIAL COFFEE ROASTER

R-7080 840N 40KG INDUSTRIAL COFFEE ROASTERR-7080 840N 40KG INDUSTRIAL COFFEE ROASTER

CAPACITY: 40KG

SIZE: 3000X2600X3000 (mm)

TYPE: HALF HOT-AIR

POWER: 220V/40A

FOR INDUSTRIAL PURPOSE.

EXCLUSIVE PRODUCTION LARGE BATCH VOLUME. CREATE STABLE QUALITY FOR YOUR BEANS.

840N BUILT-IN WITH CYCLONE, STOVE WINDOW, 16 LEVELS OF AIRFLOW, DIGITAL BEAN AND AIR-FLOW TEMP, MOREOVER, ADJUSTABLE DRUM SPEED WITH STEPPER MOTOR. POWERFUL COOLING SYSTEM, IT ALLOWS YOU TO ROAST THE NEXT BATCH DURING COOLING PROCESS.

OPTIONAL ANCILLARY EQUIPMENT: GREEN BEANS LOADER、ROASTED BEANS DESTONERQUANTITY: 1

Learn More -

R-7079 820N 20KG INDUSTRIAL COFFEE ROASTER

R-7079 820N 20KG INDUSTRIAL COFFEE ROASTERR-7079 820N 20KG INDUSTRIAL COFFEE ROASTER

CAPACITY: 20KG

SIZE: 2700X1400X2600 (mm)

TYPE: HALF HOT-AIR

POWER: 5000W

FOR INDUSTRIAL PURPOSE.

STURDY PRODUCTION OF LARGE BATCH VOLUME. CREATE STABLE QUALITY FOR YOUR BEANS.

820N BUILT-IN WITH CYCLONE, STOVE WINDOW, 16 LEVELS OF AIRFLOW, DIGITAL BEAN AND AIR-FLOW TEMP, MOREOVER, ADJUSTABLE DRUM SPEED WITH STEPPER MOTOR. POWERFUL COOLING SYSTEM, IT ALLOWS YOU TO ROAST THE NEXT BATCH DURING COOLING PROCESS.

OPTIONAL ANCILLARY EQUIPMENT: GREEN BEANS LOADER, ROASTED BEANS DESTONERQUANTITY: 1

Learn More -

R-7078 810N 12KG INDUSTRIAL COFFEE ROASTER

R-7078 810N 12KG INDUSTRIAL COFFEE ROASTERR-7078 810N 12KG INDUSTRIAL COFFEE ROASTER

CAPACITY: 12KG

SIZE: 2600X1000X2300 (mm)

WEIGHT: 650KG

PACKING SIZE: 2160X1650X2100 (mm)

PACKING WEIGHT: 750KG

TYPE: HALF HOT-AIR

POWER: 1800W

FOR INDUSTRIAL PURPOSE.

RELIABLE PRODUCTION LARGE VOLUME. CREATE STABLE QUALITY FOR YOUR BEANS. 810N BUILT IN WITH FOOTSTOOL, CYCLONE, STOVE WINDOW, 16 LEVELS OF AIRFLOW, DIGITAL BEAN AND AIR-FLOW TEMP, MOREOVER, ADJUSTABLE DRUM SPEED WITH STEPPER MOTOR. POWERFUL COOLING SYSTEM, IT ALLOWS YOU TO ROAST THE NEXT BATCH DURING COOLING PROCESS.

OPTIONAL ANCILLARY EQUIPMENT: GREEN BEANS LOADER, ROASTED BEANS DESTONERQUANTITY: 1

Learn More -

P-5072 STA IMPIANTI ROASTER 15 KILOS

P-5072 STA IMPIANTI ROASTER 15 KILOSP-5072 STA IMPIANTI ROASTER 15 KILOS

ROASTING MACHINES LINE PARTICULARLY SUITABLE FOR ARTISANAL SPECIALIZED ACTIVITIES IN MEDIUM BATCHES OF HIGH-QUALITY ROASTED COFFEE, SUCH AS ARTISAN MARKET OR COFFEE SHOPS. TECHNOLOGICALLY ADVANCED, CONFIRMS THEMELVES AS IDEAL TOOL FOR ROASTING COMPANIES SPECIALIZED IN SELECTED COFFEES OF HIGHER QUALITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS OR DIESEL-FUEL BURNER AT MULTIPLE LEVELS OF FLAME AND MANUAL OR AUTOMATIC CONTROL SYSTEM.

TECHNICAL DATA:

ROASTER CAPACITY: 15 KG. | MAX. 19 KG./ CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 60 KG. ÷ 90

INSTALLED ELECTRIC POWER: 1,8 KW | 380 VOLT THREEPHASE + NEUTRAL 50 HZ

THERMAL POWER: 24,000 KCAL/H/ 29 KW.

(NATURAL GAS OR LPG)MAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL.

COOLING TANK IN STAINLESS STEEL WITH DOOR FOR CLEANING OPERATIONS

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD TO CHECK AND CONTROL THE MACHINE ACCORDING CE RULES, COMPLETE OF PLC + TOUCH SCREEN FOR MACHINE MANAGEMENT AND TEMPERATURES SIGHT.

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE AND DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS)

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH 3 ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD FOR MACHINE MANAGEMENT ACCORDING CE RULES INTEGRATED.

COMPLETE OF PLC + TOUCH SCREEN FOR MACHINE MANAGEMENT AND TEMPERATURES VISUALIZATION.

POSSIBLE RECORDING OF ROASTING PARAMETERS.

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

P-5047 STA IMPIANTI ROASTER 10 KILOS

P-5047 STA IMPIANTI ROASTER 10 KILOSP-5047 STA IMPIANTI ROASTER 10 KILOS

STA

MODEL: IMPIANTI

ROASTER

10 KILOS

ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISANAL LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER ( AVAILABLE ALSO BY ELECTRIC RESISTANCES ) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.TECHNICAL DATA:

ROASTER CAPACITY: 10 KG. / MAX. 13 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 40 KG. ÷ 60

INSTALLED ELECTRIC POWER: 1,5 KW, SINGLEPHASE: 220 VOLT, 50 HZ | SPECIAL TRIPLEPHASE: 220 VOLT, 60 HZ

THERMAL POWER (NATURAL GAS OR LPG): 16000 KCAL/HMAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT

POSSIBLE RECORDING OF ROASTING PARAMETERS

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS).

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD ACCORDING CE RULES INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC-FAN FOR COOLING TANK.QUANTITY: 1

Learn More