Search results for: 'Auto+8'

-

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More

YY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOURYY-1347 PSA OXYGEN GENERATION SYSTEM SCHEME, CAPACITY 50 m3 PER HOUR PURITY: ≥ 93%, FLOW RATE: 50M3 PER H, (PRESSURE: 200 BAR AUTOMATIC FILLING SYSTEM) Learn More -

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

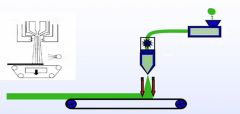

Z-1616 AUTO MATTRESS COMPRESS AND ROLLZ-1616 AUTO MATTRESS COMPRESS AND ROLL THE COMPLETE PACKAGE LINE CONTAINS THE EQUIPMENT AUTO MATRESS COMPRESSING MACHINE AUTO MATRESS FOLDING AND ROTATING MACHINE MATRESS ROLL PACKING MACHINE MACHINE SIZE: L13100xW4200xH3300mm WEIGHT: 14000KG QUANTITY: 1 Learn More

Z-1616 AUTO MATTRESS COMPRESS AND ROLLZ-1616 AUTO MATTRESS COMPRESS AND ROLL THE COMPLETE PACKAGE LINE CONTAINS THE EQUIPMENT AUTO MATRESS COMPRESSING MACHINE AUTO MATRESS FOLDING AND ROTATING MACHINE MATRESS ROLL PACKING MACHINE MACHINE SIZE: L13100xW4200xH3300mm WEIGHT: 14000KG QUANTITY: 1 Learn More -

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More -

J-2779 SEMI-AUTOMATIC FACE MASK EAR STRAP WELDING MACHINE, 20 PIECES PER MINUTE -This machine fastens the ear straps to masks only. For mask production, See J-2778

J-2779 SEMI-AUTOMATIC FACE MASK EAR STRAP WELDING MACHINE, 20 PIECES PER MINUTE -This machine fastens the ear straps to masks only. For mask production, See J-2778SEMI-AUTOMATIC BLANK FACE MASK EAR STRAP WELDING MACHINE

ULTRASONICALLY WELDS EAR STRAPS TO FACE MASK BLANKS

MASK DIMENSIONS: 175 x 95mm

CAPACITY: 15 TO 20 PIECES PER MINUTE

POWER: 2 KW

DIMENSIONS: 1200mm L x 750mm W x 1700mm H

WEIGHT: 350 KGWITH AUTOMATIC FEEDING AUTOMATIC CUTTING OF EAR STRAP MATIERAL

MANUAL LOADING & UNLOADING

FLEXIBLE CONFIGURATION, EASY TO OPERATE

VERY EFFICIENT, WITH LOW FAILURE RATEPACKAGE BY WOODEN BOX: 800 X 1250 X 1600mm

Learn More

TOTAL WEIGHT IS EXPECTED TO BE AROUND 100KGS -

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

J-1563 COFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENTCOFFEE, SYRUP, LABELERS, CARTONERS AND SIMILAR EQUIPMENT

Learn More -

P-5078 JOPER CAST IRON SHOP BATCH ROASTER 25 KILOS

P-5078 JOPER CAST IRON SHOP BATCH ROASTER 25 KILOSP-5078 JOPER CAST IRON SHOP BATCH ROASTER 25 KILOS

THE NEW JOPER CAST IRON ROASTER - THE TIMELESS TRADITION OF THE FAMOUS UG22 - IMPROVED AND PRESERVED. WITH GREAT CONTROL OPTIONS AS WELL. PATTERNED AFTER AND IMPROVED UPON THE FAMOUS UG22.

ATTRIBUTES SIMILAR TO PROBAT. CAST IRON CONSTRUCTION. ROASTING PROCESS USES HOT AIR SYSTEM AND HAS

CYCLONE SEPARATE FROM ROASTER. CYLINDER IS NOT DRILLED AND HAS SPECIAL BLADES WHICH PROVIDES EXCELLENT MOVEMENT OF THE BEANS. COMPLETE ELECTRIC CONTROL BOARD WHICH STARTS THE ROASTING CYCLE AND BUILT IN SOUND AND LIGHT ALARMS.

TWO MODELS: GAS AND PROFILE (AUTOMATIC)

JOPER CAST IRON SHOP BATCH 25 KILO ROASTERTHE NEW JOPER CAST IRON ROASTER - THE TIMELESS TRADITION OF THE FAMOUS UG22 - IMPROVED AND PRESERVED. WITH GREAT CONTROL OPTIONS AS WELL. PATTERNED AFTER AND IMPROVED UPON THE FAMOUS UG22.

ATTRIBUTES SIMILAR TO PROBAT. CAST IRON CONSTRUCTION. ROASTING PROCESS USES HOT AIR SYSTEM AND HAS

CYCLONE SEPARATE FROM ROASTER. CYLINDER IS NOT DRILLED AND HAS SPECIAL BLADES WHICH PROVIDES EXCELLENT MOVEMENT OF THE BEANS. COMPLETE ELECTRIC CONTROL BOARD WHICH STARTS THE ROASTING CYCLE AND BUILT IN SOUND AND LIGHT ALARMS.

TWO MODELS: GAS AND PROFILE (AUTOMATIC)PRICES

MODEL BSR25 - 25 KILO GAS OR PROPANE $46,560

MODEL BPR25 - 25 KILO ROAST PROFILE SYSTEM $54,690

OPTIONAL ACCESSORIES:

JOPER DESTONER (INCLUDES FAN) $8,500

JOPER GREEN BEAN LOADER $7,030

CUSTOM COLOR AVAILABLE. SEE RAL COLOR CHART BELOW.NOTE: CRATING AND FREIGHT COSTS ARE NOT INCLUDED. ORIGIN IS EUROPE.

DUE TO THE HUGE INCREASE IN ORDERS WE NOW HAVE TO CONTEND WITH LEAD TIMES FOR 5 TO 7 MONTHS AND MAYBE A LITTLE LONGER IN SOME CASES . . . FRUSTRATING, BUT REAL.

PROFILE ROAST CONTROL OPTION

THE JOPER 25 KILO ROASTER OPTION WITH THE TOUCH SCREEN PROFILE CONTROL COMES WITH A BRIGUS COFFEE ROAST CONTROL & LOG SYSTEM. THIS WAS SPECIALLY CREATED TO WORK WITH THE BPR ROASTERS FROM JOPER. TOGETHER, THEY ARE THE TRUE MASTER OF COFFEE ROAST. BRIGUS (BRE 'GOS) IS A NEW CONCEPT OF COFFEE ROASTING CONTROL SYSTEM.

WITH IT, ATTENTION AND EXPERTISE WILL BE CONCENTRATED ON WHAT MATTERS:

DEFINE NEW PROFILES BASED ON STORED ONES

ROAST BASED ON A PRE-DEFINED PROFILE

MANUAL OR AUTOMATIC PROCESS CONTROL

ROASTING VS. DESIRED PROFILE EVOLUTION DURING PROCESS

REGISTER OCCURRENCES, EVENTS AND NOTES

RECORD ALL PROCESS

ANALYZE AND COMPARE ROAST BATCHESTECHNICAL SPECIFICATIONS FOR BSR-25 & BPR-25:

BATCH CAPACITY: 25 KG. / 55 POUNDS

CONTROL DESIGN: MANUAL

CAPACITY PER HOUR: 100 KG. / 220 POUNDS

ROASTING TIME: 15-18 MIN.

EXHAUST AIR TREATMENT: OPTIONAL

COOLING TIME: 3 MIN.

TYPE OF COOLING: AIR AMBIENT

SAFETY DEVICE: YES

OPERATION TYPE BURNER: MODULATING

FUEL TYPE (GAS OVEN): PROPANE OR NATURAL GAS

POWER REQUIREMENTS: 20 AMP

VOLTAGE: 380/50/3 OR 230/60/3 V/HZ/PH

Ø EXHAUST CHIMNEY (ROASTER CYCLONE): 150 MM / 5.9 INCHES

Ø EXHAUST CHIMNEY (COOLER): 150 MM / 5.9 INCHES

ROASTER WEIGHT WITH COOLER AND CYCLONE: 850 KG. / 1874 POUNDS

BURNER POWER: 52 KW / 177431 BTU

ROASTER FAN MOTOR: 1,5 HP

COOLER FAN MOTOR: 2 HP

DRUM GEARBOX: 1 HP

COOLER GEARBOX: 0,75 HP

ROASTER FAN (NORMAL WORK CONDITIONS RUNNING AT 60HZ. DAMPER 70 %): 587 M3/H/345 CFM (587 X .589= X 345 CFM)

COOLER FAN (RUNNING AT 60HZ): 1465 M3/H/862 CFM

BUILT TO UL295 STANDARDS.QUANTITY: 1

Learn More -

P-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWING

P-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWINGP-5039 COMPLETE PLANT WITH DYEING – FINISHING – WEAVING - SEWING

PLAIN DYEING AND FINISHING EQUIPMENT:

7 DYEING MACHINES

9 AUTOMATIC DOSING SYSTEM

10 DYEING MACHINE – JIGGER

11 DYEING MACHINE – JIGGER

15 INSPECTION MACHINE

16 MACHINES FOR BONDING PIECES (GOODS)

18 WINDING MACHINE

19 INSPECTION MACHINE

20 MEASURING WINDING MACHINE

21 HEAT EXCHANGER

DOUBLING MACHINEYARN DYEING AND DRYING:

1 DYEING APPARATUS

2 DYEING APPARATUS

3 DYEING APPARATUS

4 PRESSURE DRYING APPARATUS – TANDEM

5 DYEING APPARATUS

6 DYEING APPARATUS

7 THE LOADING AND UNLOADING DEVICE

8 BRIDGE CRANE

9 PROCESS WATER REGENERATION + TANKSEWING:

8 SEWING MACHINE FOR WASHING GLOVES

9 CONTROL TABLES

10 PACKING MACHINESDOUBLING, TWISTING, WARPING AND WEAVING:

3 WINDING MACHINE

4 MOBILE REGALS FOR YARN STORAGEWARPING AND WEAVING:

1 WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

2 WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

3 WARPING MACHINE

4 SIZING MACHINE

5 SIZING MACHINE

13 COMPRESSOR FOR COMPRESSED AIR

14 KNOTTING MACHINES

15 ELEVATOR FOR BEAMS

16 ELEVATOR FOR BEAMS

17 PUNCH MACHINE

18 ELEVATOR FOR BEAMS

19 MOBILE REGALS FOR BEAM STORAGEWEAVING SAURER 1;2;3;4:

STAUBLI JACQUARD – WITH 560 HOOKS X 4 – 10 PIECES

STAUBLI JACQUARD – WITH 768 HOOKS X 4 – 4 PIECES

STAUBLI JACQUARD – WITH 1120 HOOKS X 2 - 2 PIECES

STAUBLI JACQUARD – WITH 912 HOOKS X 2 – 1 PIECEWEAVING SILK:

WEAVING MACHINE – LOOMS SM 93

CONTROL TABLEREADY MADE DEPARTMENT FOR TERRY BATHROBES:

CUTTING TABLE – BULLMERWERK – 1 PIECE

SEWING MACHINE – JUKI – 2 PIECES

SEWING MACHINE – JUKI – 1 PIECE

SEWING MACHINE – JUKI – 1 PIECE

SEWING MACHINE –LEVIS – 1 PIECE

SEWING MACHINE – PFAFF – 2 PIECES

SEWING MACHINE – JUKI – 2 PIECE

SEWING MACHINE – MAUSER SPECIAL – 1 PIECE

SEWING MACHINE – PFAFF – 2 PIECES

SEWING MACHINE – 1 PIECE

SEWING MACHINE – NECCHI – 4 PIECES

SEWING MACHINE – PFAFF – 1 PIECE

SEWING MACHINE – JUKI – 1 PIECELABOR MACHINES:

APPARATUS FOR MEASURING ZTWIST, TURN/ROLL – TORSIOMETER

APPARATUS FOR MEASURING THE FRICTION COEFFICIENT

LIGHTING CHAMBER

AA WINDING APPARATUS FOR THE DYEING TUBE THE SAMPLING DEVICE

WINDING APPARATUS FOR COLOR STANDARDS

YARN DYEING APPARATUS PRETEMA MULTICOLOR

DYNAMOMETER FOR SPINNING

SPEKTROFOTOMETER DATACOLOR INTERNATIONAL – LABOR MACHINE

APPARATUS FOR THE VISUAL APPEARANCE OF THE YARN – LABOR MACHINEADDITIONAL DESCRIPTION

PLAIN DYEING AND FINISHING EQUIPMENT:

7. DYEING MACHINE

SCHIRM

MODEL: SURFER

YEAR: 1994

CAPACITY : 380 – 400 KG

TECHNICAL INFORMATION:

WOVEN TERRY DYEING, WASHING AND BLEACHING AIR - FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

SEDOMAT PC 3100

QUANTITY: 1 (NO 94)9. AUTOMATIC DOSING SYSTEM

LAWER

YEAR: 2002

CHEMICAL DISPENSING SYSTEM

20 PVC TANKS (CAPACITY 200 L TO 1200 L)

2 EXTERNAL TANKS CAPACITY 1500 L

TRANSFER PUMP

QUANTITY: 110. DYEING MACHINE - JIGGER

MCS

MODEL: S - 300 MCS

YEAR: 1993

TECHNICAL INFORMATION:

WORKING WIDTH : 3000MM

WOVEN FABRIC DYEING, WASHING AND BLEACHING AIR -FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

MICROPROCESOR CT400

DIMENSIONS LENGTH 65000 MM X WIDTH 43000 MM X HEIGHT 25000 MM

INSTALLED ELECTRIC POWER: 3 X 63 A

QUANTITY: 1(NO 54)11. DYEING MACHINE - JIGGER

MCS

MODEL: S - 300 MCS

YEAR: 1993

TECHNICAL INFORMATION:

WORKING WIDTH : 1600MM

WOVEN FABRIC DYEING, WASHING AND BLEACHING AIR - FLOW

WORKING TEMPERATURE: UP TO 98˚ C (NOT HT)

MICROPROCESOR CT400

THE HYDRAULIC SYSTEM HAS FAILED/NOT WORKING

DIMENSIONS LENGTH 5,300 CM X WIDTH 4,300 CM X HEIGHT 2,500 CM

QUANTITY: 1(NO 53)15. INSPECTION MACHINE

MONFORTS

TECHNICAL INFORMATION:

MACHINE FOR INSPECTING THE GOOD

QUANTITY: 116. MACHINE FOR BONDING PIECES (GOODS)

GEBRUDER DOHLE

MODEL: 799/03

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR BONDING GOODS

QUANTITY: 218. WINDING MACHINE

MARK: AEG

TECHNICAL INFORMATION:

WINDING GOODS

QUANTITY: 119. INSPECTION MACHINE

MONFORTS

MODEL: MBH

YEAR: 1977

TECHNICAL INFORMATION:

MACHINE FOR INSPECTING THE GOOD

QUANTITY: 120. MEASURING WINDING MACHINE

MENZEL

MODEL: MWE2

YEAR: 1986

TECHNICAL INFORMATION:

WINDING DIFFERENT LENGTHS OF GOOD

QUANTITY: 121. HEAT EXCHANGER

PT-S

YEAR: 2002

TECHNICAL INFORMATION:

RECUPERATION

QUANTITY: 123. DOUBLING MACHINE

MODEL: MLH

YEAR: 1975

TECHNICAL INFORMATION:

DOUBLING AND COMPOUNDING GOODS

QUANTITY: 1YARN DYEING AND DRYING:

1. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 1250

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN : MAX 336 KG, MIN. 134 KG

5 INCHES BOBBIN : MAX 235 KG, MIN. 98 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

QUANTITY: 2 PCS (NO 12, NO 14)2. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 850

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY;

6 INCHES BOBBIN : MAX 144 KG, MIN. 58 KG

5 INCHES BOBBIN : MAX 100 KG, MIN. 42 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

THICKNESS OF PLATE = 30 CM

PART OF A MACHINE IN THE BASEMENT, HEIGHT = 2.00 CM

DIMENSIONS: LENGTH 3100MM X WIDTH 2000MM X HEIGHT 1800MM X HEIGHT 2900MM

INSTALLED ELECTRIC

POWER: 45 KW

CUPBOARD FOR ELECTRONICS:

LENGTH 2500MM X WIDTH 600MM

INSTALLATION OF THE SOIL = 60CM DEEPER

(APPLY TO ALL INSTALLATION)

QUANTITY: 1(NO 18)3. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS TYPE 600

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN: MAX 84 KG, MIN. 34 KG

5 INCHES BOBBIN: MAX 59 KG, MIN. 26 KG

WORKING TEMPERATURE: UP TO 140˚ C

PRESSURE : UP TO 4.5 BAR

BARCO SEDO SEDOMAT 3500

DIMENSIONS: LENGTH 2500MM X WIDTH 2000MM X HEIGHT 1800MM X HEIGHT 2900MM

INSTALLED ELECTRIC POWER: 17 KW

CUPBOARD FOR ELECTRONICS:

LENGTH 2500MM X WIDTH 600MM

QUANTITY: 1(NO 16)4. PRESSURE DRYING APPARATUS – TANDEM

JASPER

YEAR: 1998

TECHNICAL INFORMATION:

DIMENSION: LENGTH 290CM WIDTH 3300MM X HEIGHT 1800MM X HEIGHT 2900MM

CUPBOARD FOR ELECTRONICS

LENGTH 250CM X WIDTH 60CM

QUANTITY: 2 TANDEM WORKING AS ONE UNIT5. DYEING APPARATUS

JASPER

MODEL: DYEING APPARATUS

TYPE: 1250

YEAR: 1998

TECHNICAL INFORMATION:

DYEING APPARATUS WITH VARIABLE VOLUME OF BATH

CAPACITY:

6 INCHES BOBBIN : MAX 336 KG, MIN. 134 KG

5 INCHES BOBBIN: MAX 235 KG, MIN. 98 KG

WORKING TEMPERATURE: UP TO 98˚ C

PRESSURE: UP TO 4.5 BAR

MANUAL PROCESSOR

DIMENSIONS: LENGTH 2800MM X WIDTH 3100MM X HEIGHT 2500MM X HEIGHT 2900MM

(WITH A DOSING DEVICE IN THE FORM OF "V")

INSTALLED ELECTRIC

POWER: 45 KW

CUPBOARD FOR ELECTRONICS: LENGTH 2500MM X WIDTH 60MM

QUANTITY: 1 (NO 13)6. DYEING APPARATUS

THEN

MODEL: HL 40/7,8

YEAR: 1986

WIDTH: 1800MM

5 INCHES BOBBIN: MAX 12 PIECES

WORKING TEMPERATUR: UP TO 140˚ C

HEIGHT: 2160MM

PRESSURE: UP TO 4,5 BAR

INSTALLED ELECTRIC POWER – 3X16 A

TECHNICALINFORMATION: DYEING APPARATUS

DIMENSIONS: LENGTH 1600MM

QUANTITY: 17. THE LOADING AND UNLOADING DEVICE

JASPER

YEAR: 1998

TECHNICAL INFORMATION; LOADING DEVICE FOR BOBBINS

THICKNESS OF PLATE = 300MM (APPLY TO ALL INSTALLATIONS)

PART OF A MACHINE IN THE BASEMENT, HEIGHT = 2000MM (APPLY TO ALL INSTALLATION)

DIMENSIONS : Ø 1700MM : HEIGHT1600MM

INSTALLED ELECTRIC POWER : 10KW

QUANTITY: 18. BRIDGE CRANE

TECHNICAL INFORMATION:

THE CARGO TRANSFER

QUANTITY : 29. PROCESS WATER REGENERATION + TANK

JASPER

TECHNICAL INFORMATION:

STORAGE OF WATER FOR THE PRODUCTION PROCESS

QUANTITY : 1SEWING:

8. SEWING MACHINE FOR WASHING GLOVES

TEXPA ARBTER

MODEL: WASCHLA 10

YEAR: 1994

TECHNICAL INFORMATION:

SEWING WASHING GLOVES, FITTING LABELS AND CORD.

QUANTITY: 19. CONTROL TABLES

TECHNICAL INFORMATION:

GOOD INSPECTION AND WEIGHING

QUANTITY: 310. PACKING MACHINE

BECK

TECHNICAL INFORMATION:

PACKING TOWELS INTO FOIL

QUANTITY: 13. WINDING MACHINE

SCHLAFHORST

MODEL: BKN

YEAR: 1975

TECHNICAL INFORMATION:

96 PIECES SPINDLES (2 X 48 SPINDLES)

QUANTITY: 24. MOBILE REGALS FOR YARN STORAGE

INCLUDED SELLING YARN

QUANTITY: 3WARPING AND WEAVING:

1. WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

HACOBA

MODEL: USK T1000/SM

YEAR: 1990

TECHNICAL INFORMATION:

ELEKTRONIC COMPUTER, AUTOMATIC SETTING OF CONE,

DEVICE FOR CROSSING THE FLOOR DIVISION THREADS

PRELIMINARY SETTING : OF LENGTH IN METERS (YARN LEGTH RECORDER), NUMBER OF REVOLUTIONS, …

CONE CREEL/CREELS 2 X 32 CROSS-WOUND COME (MAX. DIAMETER CROSS-WOUND IS 225 MM)

WETTING TROUTH FOR COLD STARCHING BY APPLICATOR ROLLER

MAXIMUM WARPING WIDTH : 240 CM/ WARPING WIDTH (MARKED) 240 CM

QUANTITY: 12. WARPING MACHINE FOR WARPING BY SECTION AND WARPING REEL

SUCKER MÜLLER HACOBA

MODEL: USK -S/SM

YEAR: 1998

TECHNICAL INFORMATION:

MAXIMUM WARPING WIDTH : 2000MM

QUANTITY: 13. WARPING MACHINE

BENNINGER

MODEL: 97126 FB

YEAR: 1978

TECHNICAL INFORMATION:

MAX. NUMBER OF CONES 704

QUANTITY: 14. SIZING MACHINE

BENNINGER ZELL

MODEL: BZ-7M

YEAR: 1975

TECHNICAL INFORMATION:

MAXIMUM WORKING WIDTH 2400MM

TOTAL BEAM 8 PCS

DRUM DRYER TEFLONIZED

MAHLO MOISTURE CONTROL

SIZING KITCHEN

QUANTITY: 15. SIZING MACHINE

BENNINGER ZELL

MODEL: XK Z6F

YEAR: 1986

TECHNICAL INFORMATION:

MAX. WORKING WIDTH 240 CM

TOTAL BEAM 12 PCS

DRUM DRYER TEFLONIZED

MAHLO MOISTURE CONTROL

QUANTITY: 113. COMPRESSOR FOR COMPRESSED AIR

KAESER

MODEL: CS 76, ABT 72

YEAR: 2003

NO. OF MASHINES: 314. KNOTTING MACHINE

KNOTEX

MODEL: AS/2 8013 EA03

YEAR: 2002

TECHNICAL INFORMATION:

WITH TWO TROLLEY SIZE 2500MM

QUANTITY: 515. ELEVATOR FOR BEAMS

GENKINGER

MODEL: EE-KHHR

YEAR: 1998

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 116. ELEVATOR FOR BEAMS

HUBTEX

MODEL: KHHW

YEAR: 1988

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 117. PUNCH MACHINE

GROSSE

MODEL: LSE 600

YEAR: 1998

TECHNICAL INFORMATION:

PUNCHING CARDS

QUANTITY: 118. ELEVATOR FOR BEAMS

TECHNICAL INFORMATION:

LIFTING UP THE WEAVING BEAMS

QUANTITY: 119. MOBILE REGALS FOR BEAM STORAGE

TECHNICAL INFORMATION:

UP - DOWN MOVING REGALS

QUANTITY: 13WEAVING SAURER 1;2;3;4:

1. STÄUBLI JACQUARD

WITH 560 HOOKS X 4

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 102. STÄUBLI JACQUARD

WITH 768 HOOKS X 4

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 43. STÄUBLI JACQUARD

WITH 1120 HOOKS X 2

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 24. STÄUBLI JACQUARD

WITH 912 HOOKS X 2

COMPATIBLE LOOMS

WITH SAURER DIETRICH, MODEL S400, WIDTH 2250MM

2-3 PRE-WINDERS PER LOOM

NUMBER OF MASHINES: 1WEAVING SILK:

1. WEAVING MACHINE

SOMET

MODEL: MASTER SM93

YEAR OF CONSTRUCTION: 1990

TECHNICAL INFORMATION:

WITH STÄUBLI JACQUARD, JC4 CONTROLLER

5-6 PRE-WINDERS PER LOOM

NUMBER OF MACHINES: 22. CONTROL TABLE

TECHNICAL INFORMATION:

GOOD INSPECTION

NUMBER OF MACHINES: 1

READY MADE DEPARTMENT FOR TERRY BATHROBES:

1. CUTTING TABLE

BULLMERWERK

MODEL: KOMET II

TECHNICAL INFORMATION:

CUTTING GOODS BY CUTTING PATTERNS FOR TERRY

BATHROBES

QUANTITY: 12. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY

PRODUCTS

QUANTITY: 23. SEWING MACHINE

JUKI

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 15. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY

PRODUCTS

TRIPLE STICH OVERLOK

QUANTITY: 16. SEWING MACHINE

LEWIS

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

BLIND STICH

QUANTITY: 17. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 28. SEWING MACHINE

JUKI

TECHNICAL

INFORMATION:

SEWING TERRY PRODUCTS

OVERLOK

QUANTITY: 29. SEWING MACHINE

MAUSER SPECIAL

TECHNICAL INFORMATION:

SEWING NAPKINS

OVERLOK

QUANTITY: 110. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 211. SEWING MACHINE

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR BONDING GOODS

QUANTITY: 112. SEWING MACHINE

NECCHI

TECHNICAL INFORMATION:

SEWING MACHINE USED FOR

BONDING GOODS

QUANTITY: 413. SEWING MACHINE

PFAFF

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 114. SEWING MACHINE

JUKI

TECHNICAL INFORMATION:

SEWING TERRY PRODUCTS

QUANTITY: 1LABOR MACHINES:

1. APPARATUS FOR MEASURING ZTWIST, TURN/ROLL - TORSIOMETER

MARK: CALDERARA BOSI

YEAR: 1989

QUANTITY: 12. APPARATURS FOR MEASURING THE FRICTION COEFFICIENT -

ZWEIGLE

MODEL: µ-METER G 530

TYPE: 530

YEAR: 1972

TECHNICAL INFORMATION:

NOT WORKING

QUANTITY: 13. LIGHTING CHAMBER

MARK: DATACOLIR INTERNATIONAL

YEAR: 2004

TECHNICAL INFORMATION:

FROM 4 TYPES OF LIGHT ONLY WORKS 1

QUANTITY: 14.AA WINDING APPARATURS FOR THE DYEING TUBE THE SAMPLING DEVICE

ZWEIGLE (REUTLIGEN)

QUANTITY: 15. WINDING APPARATURS FOR COLOR STANDARDS

IZDELANO V SVILANITU

YEAR: 2001

QUANTITY: 16. YARN DYEING APPARATURS PRETEMA MULTICOLOR

PRETEMA

MODEL: TYPE MC-320

YEAR: 1982

TECHNICAL INFORMATION:

V 22 W 1800

DIMENSIONS: LENGTH 119 CM X WIDTH 61 CM X HEIGHT 126 CM

INSTALLED ELECTRIC POWER: 1800 W

QUANTITY: 17. DYNAMOMETER FOR SPINNING

KARL SCHRÖDER

YEAR: 1977

QUANTITY: 18. SPEKTROFOTOMETER DATACOLOR INTERNATIONAL

DATACOLOR INTERNATIONAL

MODEL: SPECTRAFLASH SF600 PLUS CT

YEAR: 1999

TECHNICAL INFORMATION:

RATINGS: 100-240 V ̴47-63 HZ, 100 VA

NOT WORKING (DO NOT KNOW THE TYPE OF TROUBLE)

QUANTITY: 19. APPARATURS FOR THE VISUAL APPEARANCE OF THE YARN

ZWEIGLE KG REITLINGEN

QUANTITY: 1QUANTITY: 1 COMPLETE PLANT

Learn More -

C-4835 RICE CAKE MACHINES

C-4835 RICE CAKE MACHINESC-4835 RICE CAKE MACHINES

OFFER 001

MODEL: 8501 (EASY CLEANING)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 1 PC EVERY 10 SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 85 OR 90mm * T: 3 TO 10mm (3 TO 15mm OPTION)

CAPACITY: 360 PCS/HOUR

QUANTITY: 1OFFER 002

MODEL: 10001

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 1PC EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 100mm * T: 3 TO 12mm (3 TO 15mm OPTION)

CAPACITY: 360 PCS/HOUR

QUANTITY: 1OFFER 003

MODEL: 6502

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 2PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 65mm * T: 3 TO 12mm (3 TO 15mm OPTION)

CAPACITY: 720 PCS/HOUR

QUANTITY: 1OFFER 004

MODEL: 4506

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 6PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 45mm * T: 3 TO 12mm

CAPACITY: 2,160 PCS/HOUR

QUANTITY: 1

OFFER 005

MODEL: 2515

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 15PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 25mm * T: 3 TO 12mm

CAPACITY: 5,400PCS/HOUR

QUANTITY: 1OFFER 006

MODEL: 8585(S1)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 1PC EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 85 OR 90 OR 100mm (SQUARE) * T: 3 TO 12mm

CAPACITY: 360 PCS/HOUR

QUANTITY: 1OFFER 007

MODEL: 50115(S1)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 1PC EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 50*115mm (RECTANGLE) * T: 3 TO 12mm

CAPACITY: 360 PCS/HOUR

QUANTITY: 1OFFER 008

MODEL: 6060(S2)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 2PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 60*60mm (SQUARE) * T: 3 TO 12mm

CAPACITY: 720 PCS/HOUR

QUANTITY: 1OFFER 009

MODEL: 4570(S3)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 3PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 45*70mm (RECTANGLE) * T: 3 TO 12mm

CAPACITY: 1,080 PCS/HOUR

QUANTITY: 1OFFER 010

MODEL: 2575(S5)

SIZE: 575(L) mm X 470(W) mm X 1,420(H) mm

WEIGHT: 165 KGS

ELECTRIC: 220V / 50 OR 60HZ (1 PHASE 3.5 KW MAX)

ELECTRIC CONSUMPTION: 2KW

WORKING CAPACITY: 5PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 25*75mm (RECTANGLE) * T: 3 TO 12mm

CAPACITY: 1,800 PCS/HOUR

QUANTITY: 1OFFER 011

MODEL: 4509 (PLC CONTROL)

SIZE: 1,150(L) mm X 460(W) mm X 1,400(H) mm

WEIGHT: 420 KGS

ELECTRIC: 220 TO 380V / 50 OR 60HZ (3 PHASE 6 KW MAX)

HEATER TEMPERATURE: MAX: 400 ℃: MIN: -10 ℃

WORKING CAPACITY: 9PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 45mm* T: 10mm

CAPACITY: 3,240 TO 4,500 PCS/HOUR

QUANTITY: 1OFFER 012

MODEL: 50115 (S3) (PLC CONTROL)

SIZE: 1,150(L) mm X 460(W) mm X 1,400(H) mm

WEIGHT: 420 KGS

ELECTRIC: 220 TO 380V / 50 OR 60HZ (3 PHASE 6 KW MAX)

HEATER TEMPERATURE: MAX: 400 ℃: MIN: -10 ℃

WORKING CAPACITY: 3 PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 50*115mm (RECTANGLE) * T: 10mm

CAPACITY: 1,080 PCS/HOUR

QUANTITY: 1OFFER 013

Learn More

MODEL: 6060(S6) (PLC CONTROL)

SIZE: 1,150(L) mm X 460(W) mm X 1,400(H) mm

WEIGHT: 420 KGS

ELECTRIC: 220 TO 380V / 50 OR 60HZ (3 PHASE 6 KW MAX)

HEATER TEMPERATURE: MAX: 400 ℃: MIN: -10 ℃

WORKING CAPACITY: 6PCS EVERY 10SEC

MATERIAL: 100% OF VARIOUS GRAINS

SIZE OF SNACK: D: 60*60mm (SQUARE) * T: 10mm

CAPACITY: 2,160 PCS/HOUR

QUANTITY: 1

-

F-1428 FEATHER FILLING MACHINE MODEL SR-2

F-1428 FEATHER FILLING MACHINE MODEL SR-2REFERENCE NUMBER: F-1428

FEATHER FILLING MACHINE MODEL SR-2

PRODUCT FEATURES

• FULLY ENCLOSED DESIGN TO KEEP SURROUNDINGS CLEAN AND TO SAVE MATERIAL

• AUTOMATIC WEIGHING WITH ACCURATE LOAD CELL TO ENSURE PRODUCTION QUALITY

• FILLING TIME IS 2 TO 5 SECONDS

• NICE DESIGN SUITABLE FOR ALL KINDS OF FABRIC

• CE CERTIFICATE

• ITEM NO.: SR-2

• DIMENSION: APPROX. 11000 x 2500 x 3000MM

• VOLTAGE: 200/380415V 50/60HZ 3PHASE

• POWER: 13KW

• FILLING RANGE: 2 TO 100 G, DEPENDING ON THE MATERIAL

• ACCURACY: ±1G

• AIR PRESSURE: 0.5-0.8MPA

• THERE ARE 4 WEIGHING SYSTEMS AND ONE WORKING TABLE FOR DOWN FEATHER

• IT IS MAINLY USED TO MAKE DOWN FEATHER QUILT

• IT INCLUDES TWO AUTOMATIC FILLING TABLES, THE WORKING TABLE INCLUDES PNEUMATIC CLAMPING DEVICE FOR TWO FILLING PIPES, COMPOUND SHOE CLAMPING DEVICE, RING CLAMPING DEVICE AIR SUCTION, COMPRESSED AIR RING INJECTOR

• THE FEATHER DOWN FILLING USES VACUUM METHOD STYLE FUNCTION THAT HELPS TO KEEP THE MATERIAL SOFT, ELASTIC AND HAND FEELING AND AVOIDS THE FEATHER BEING DAMAGED DURING THE FILLING PROCEDURE

• WEIGHING ACCURACY CAN BE CONTROLLED WITHIN 1 GRAM WHICH CAN BE ADJUSTED BY SINGLE SET OR SINGLE PIECE ACCORDING TO DIFFERENT REQUIREMENT OF DIFFERENT PRODUCTS.

THIS HELPS QUALITY CONTROLLING AND AVOIDS MATERIAL WASTE ALSO

• SIMPLE OPERATION THAT SAVES LABOR COST AND THE WHOLE SET CAN BE HANDLED BY ONE OPERATOR.

• WORKING SURROUNDINGS ARE KEPT CLEAN BECAUSE ALL FILLING MATERIALS ARE KEPT INSIDE OF THE HOPPER

• ADVANCED TECHNOLOGY LEVEL; THE WHOLE SET IS CONTROLLED BY PLC SYSTEM WITH AN ENGLISH OPERATION MENU WHEREIN 100 RECIPES CAN BE SET UP, EACH RECIPE CAN BE SET UP WITH ABOUT 80 SETS OF WEIGHT VALUE WHICH IS SUITABLE FOR VERY COMPLICATED PRODUCT DESIGN WITHIN ONE PIECE

• HIGH WORKING CAPACITY; THE AVERAGE MATERIAL MEASURING TIME IS 4 TO 6 SECONDS. THE FILLING TIME CAN BE ADJUSTED AS DESIRED SO THAT TWO FILLERS CAN BE HANDLED BY ONLY ONE OPERATOR.

• WITH OUR PROFESSIONAL R&D GROUP WE CAN DESIGN THE INDIVIDUAL FILLINGS ACCORDING TO YOUR REQUIREMENTS

EQUIPMENT INCLUDED:

• MATERIAL HOPPER: DIA.1700 x 2500 1PCS

• WEIGHING SYSTEM: 800 x 1000 x 1200MM 2PCS

• PLC CONTROL SYSTEM & CONTROL PANEL: 1 SETS

• MATERIAL CHANGING HOPPER: 1200 x 1200 x 2500MM 1PCS

• AIR HOPPER: 1200 x 1200 x 2500MM 1PCS

• MATERIAL FEEDER: 1200 x 1200 x 1200MM 1PCS

• BLOWER: 4PCS

• PIPE: 1SET

• AUTOMATIC WORKING TABLE: 2SETS

• ENGLISH EDITION ARTICLE AND VIDEO FOR OPERATION DESCRIPTION

Learn More