Search results for: 'cott'

- Related search terms

- Cotton ring Spinning

- Cotton ring frames

- Cotton

- Cotton+ring+Spinning

- Cotton+Spinning

-

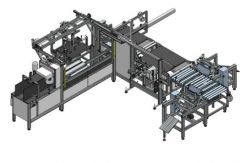

K-9335 PILLOW CASE MACHINE MOD. C14REFERENCE NUMBER: K-9335 PILLOW CASE MACHINE MOD. C14 ADAPTED TO WORK COTTON, POLY COTTON AND NO WOVEN FABRICS QUANTITY AVAILABLE: 1 Learn More

K-9335 PILLOW CASE MACHINE MOD. C14REFERENCE NUMBER: K-9335 PILLOW CASE MACHINE MOD. C14 ADAPTED TO WORK COTTON, POLY COTTON AND NO WOVEN FABRICS QUANTITY AVAILABLE: 1 Learn More -

K-1314 PILLOW CASE MACHINE MOD. C14REFERENCE NUMBER: K-9335 PILLOW CASE MACHINE MOD. C14 ADAPTED TO WORK COTTON, POLY COTTON AND NO WOVEN FABRICS QUANTITY AVAILABLE: 1 Learn More

K-1314 PILLOW CASE MACHINE MOD. C14REFERENCE NUMBER: K-9335 PILLOW CASE MACHINE MOD. C14 ADAPTED TO WORK COTTON, POLY COTTON AND NO WOVEN FABRICS QUANTITY AVAILABLE: 1 Learn More -

G-7566 TRUTZSCHLER WASTE RECOVERY PLANT YEAR 2004REFERENCE NUMBER: G-7566 TRUTZSCHLER WASTE RECOVERY PLANT YEAR 2004 TRUTZSCHLER & LTG SUBJECT TO PRIOR SALE: ALL MACHINES MADE IN YEAR 2004. EXCELLENT CONDITION. PLANT IS DESIGNED FOR PROCESSING OF COTTON WASTE FROM MILLS OR COTTON GINNING MOTES, CLEANING CAPACITY UP TO 80%, WITH A SUCTION CAPACITY OF 1500 KG / HOUR. QUANTITY AVAILABLE: 1 Learn More

G-7566 TRUTZSCHLER WASTE RECOVERY PLANT YEAR 2004REFERENCE NUMBER: G-7566 TRUTZSCHLER WASTE RECOVERY PLANT YEAR 2004 TRUTZSCHLER & LTG SUBJECT TO PRIOR SALE: ALL MACHINES MADE IN YEAR 2004. EXCELLENT CONDITION. PLANT IS DESIGNED FOR PROCESSING OF COTTON WASTE FROM MILLS OR COTTON GINNING MOTES, CLEANING CAPACITY UP TO 80%, WITH A SUCTION CAPACITY OF 1500 KG / HOUR. QUANTITY AVAILABLE: 1 Learn More -

M-5003 FIBER OPENING MACHINESREFERENCE NUMBER: M-5003 (1212FJWLHH11) L FIBER OPENING MACHINES DIFFERENT KINDS OF FIBER OPENING MACHINES – CAPACITY 220KG/H, 250KG/H, 300KG/H, 400 KG/H, 550KG/H. THE FIBER OPENING MACHINE IS ALSO CALLED AN OPENER – MAINLY SUITABLE FOR OPENING COTTON, POLYESTER STAPLE FIBER, WOOL, POLYESTER WADDING, AND SCRAP MATERIALS WITHIN 64mm. ALL THE WORK ROLLERS GO THROUGH DYNAMIC BALANCE PROCESSING, NO VIBRATION AND LOW NOISE IN THE OPERATION. TO USE THE FORCE GENERATED BY LONG FINE-TOOTH AND MULTI-TOOTH ROLLER’S REVERSE OPERATION STRENGTHENS THE LOOSENING ACTION, MAKING FIBER COTTON OR STAPLE FILAMENT OPEN TO BEST EFFECT. THE POWER DISTRIBUTION, IN ACCORDANCE WITH INTERNATIONAL ELECTRIC TECHNICAL STANDARD, COMPLIES WITH SAFETY STANDARDS OF AUSTRALIA, EU, AND NORTH AMERICA (MODEL 001) FIBER OPENING MACHINE CAPACITY: 250KG/H DIMENSION: 1350mm x 1220mm x 950mm WEIGHT: 550KG (MODEL 002) FIBER OPENING MACHINE CAPACITY: 280KG/H DIMENSION: 1800mm x 1220mm x 1050mm WEIGHT: 750KG (MODEL 003) FIBER OPENING MACHINE CAPACITY: 300KG/H DIMENSION: 3350mm x 1500mm x 1350mm WEIGHT: 1480KG (MODEL 004) FIBER OPENING MACHINE CAPACITY: 400KG/H DIMENSION: 2000mm x 1350mm x 1150mm WEIGHT: 1100KG (MODEL 005) FIBER OPENING MACHINE CAPACITY: 550KG/H DIMENSION: 2350mm x 1500mm x 1350mm WEIGHT: 1400KG QUANTITY AVAILABLE: 1 Learn More

M-5003 FIBER OPENING MACHINESREFERENCE NUMBER: M-5003 (1212FJWLHH11) L FIBER OPENING MACHINES DIFFERENT KINDS OF FIBER OPENING MACHINES – CAPACITY 220KG/H, 250KG/H, 300KG/H, 400 KG/H, 550KG/H. THE FIBER OPENING MACHINE IS ALSO CALLED AN OPENER – MAINLY SUITABLE FOR OPENING COTTON, POLYESTER STAPLE FIBER, WOOL, POLYESTER WADDING, AND SCRAP MATERIALS WITHIN 64mm. ALL THE WORK ROLLERS GO THROUGH DYNAMIC BALANCE PROCESSING, NO VIBRATION AND LOW NOISE IN THE OPERATION. TO USE THE FORCE GENERATED BY LONG FINE-TOOTH AND MULTI-TOOTH ROLLER’S REVERSE OPERATION STRENGTHENS THE LOOSENING ACTION, MAKING FIBER COTTON OR STAPLE FILAMENT OPEN TO BEST EFFECT. THE POWER DISTRIBUTION, IN ACCORDANCE WITH INTERNATIONAL ELECTRIC TECHNICAL STANDARD, COMPLIES WITH SAFETY STANDARDS OF AUSTRALIA, EU, AND NORTH AMERICA (MODEL 001) FIBER OPENING MACHINE CAPACITY: 250KG/H DIMENSION: 1350mm x 1220mm x 950mm WEIGHT: 550KG (MODEL 002) FIBER OPENING MACHINE CAPACITY: 280KG/H DIMENSION: 1800mm x 1220mm x 1050mm WEIGHT: 750KG (MODEL 003) FIBER OPENING MACHINE CAPACITY: 300KG/H DIMENSION: 3350mm x 1500mm x 1350mm WEIGHT: 1480KG (MODEL 004) FIBER OPENING MACHINE CAPACITY: 400KG/H DIMENSION: 2000mm x 1350mm x 1150mm WEIGHT: 1100KG (MODEL 005) FIBER OPENING MACHINE CAPACITY: 550KG/H DIMENSION: 2350mm x 1500mm x 1350mm WEIGHT: 1400KG QUANTITY AVAILABLE: 1 Learn More -

M-5005 BALL FIBER MACHINEREFERENCE NUMBER: M-5005 (1212WAJWHH11) L BALL FIBER MACHINE 300KG/H, 600KG/H CAN STILL CHANGE THE CAPACITY OF THIS MACHINE ACCORDING TO REQUIREMENTS OPERATION OF THE PRODUCTION LINE IS VERY SIMPLE: PUT THE FIBER OR THE COTTON ON THE OPENING MACHINE, THEN VIA THE OPENING MACHINE, CAN MAKE THE COTTON AND FIBER LOOSER (MORE OPEN) THAN BEFORE. THE BLOWER IS CONNECTED BETWEEN THE OPENING MACHINE AND THE BALL FIBER MACHINE IN ORDER TO SEND THE FIBER INTO THE BALL FIBER MACHINE. THE BALL FIBER MACHINE MAKES THE FIBER INTO FIBER BALL. ADVANTAGE OF THIS MACHINE: THIS MACHINE CAN SAVE ON THE COST OF LABOR. TWO BALL FIBER MACHINES CAN BE HANDLED BY ONE OPERATOR THAT CAN OPERATE THE OPENING MACHINE AND BALL FIBER MACHINE. THE POWER, 36.85KW/H. SMALL WORKING AREA, JUST NEED 5500mm x 3500mm x 2300mm (MODEL 002) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 160 TO 250KG/H (IF INCLUDING OPENING MACHINE, THE PRODUCTIVITY CAN BE UP TO 300KG/H) POWER: 17.75KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 1450KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (PACKAGING OPENING MACHINE AND DISTRIBUTION BOX) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) TWO WOODEN CASES SHIPPING DIMENSION: 4500mm x 3500mm x 1500mm AN OPENING MACHINE, A BALL FIBER MACHINE, AND A BLOWER (MODEL 003) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 300 TO 400KG/H (PRODUCTIVITY CAN BE UP TO 600KG/H) POWER: 36.85KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 2300KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (OPENING MACHINE AND DISTRIBUTION MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) THREE WOODEN CASES SHIPPING DIMENSION: 5500mm x 3500mm x 2300mm AN OPENING MACHINE, TWO BALL FIBER MACHINES, AND TWO BLOWERS QUANTITY AVAILABLE: 1 Learn More

M-5005 BALL FIBER MACHINEREFERENCE NUMBER: M-5005 (1212WAJWHH11) L BALL FIBER MACHINE 300KG/H, 600KG/H CAN STILL CHANGE THE CAPACITY OF THIS MACHINE ACCORDING TO REQUIREMENTS OPERATION OF THE PRODUCTION LINE IS VERY SIMPLE: PUT THE FIBER OR THE COTTON ON THE OPENING MACHINE, THEN VIA THE OPENING MACHINE, CAN MAKE THE COTTON AND FIBER LOOSER (MORE OPEN) THAN BEFORE. THE BLOWER IS CONNECTED BETWEEN THE OPENING MACHINE AND THE BALL FIBER MACHINE IN ORDER TO SEND THE FIBER INTO THE BALL FIBER MACHINE. THE BALL FIBER MACHINE MAKES THE FIBER INTO FIBER BALL. ADVANTAGE OF THIS MACHINE: THIS MACHINE CAN SAVE ON THE COST OF LABOR. TWO BALL FIBER MACHINES CAN BE HANDLED BY ONE OPERATOR THAT CAN OPERATE THE OPENING MACHINE AND BALL FIBER MACHINE. THE POWER, 36.85KW/H. SMALL WORKING AREA, JUST NEED 5500mm x 3500mm x 2300mm (MODEL 002) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 160 TO 250KG/H (IF INCLUDING OPENING MACHINE, THE PRODUCTIVITY CAN BE UP TO 300KG/H) POWER: 17.75KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 1450KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (PACKAGING OPENING MACHINE AND DISTRIBUTION BOX) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) TWO WOODEN CASES SHIPPING DIMENSION: 4500mm x 3500mm x 1500mm AN OPENING MACHINE, A BALL FIBER MACHINE, AND A BLOWER (MODEL 003) BALL FIBER MACHINE USING RANGE: PILLOW, JACKET, QUILT PRODUCTIVITY: 300 TO 400KG/H (PRODUCTIVITY CAN BE UP TO 600KG/H) POWER: 36.85KW VOLTAGE: AS PER CUSTOMER REQUIREMENT WEIGHT: 2300KG DIMENSION OF BOX: 2500mm x 900mm x 1300mm (OPENING MACHINE AND DISTRIBUTION MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) 2400mm x 1150mm x 1300mm (BALL FIBER MACHINE) THREE WOODEN CASES SHIPPING DIMENSION: 5500mm x 3500mm x 2300mm AN OPENING MACHINE, TWO BALL FIBER MACHINES, AND TWO BLOWERS QUANTITY AVAILABLE: 1 Learn More -

J-0027 SCHLAFHORST SE 12 ACO 360 YEAR 2009REFERENCE NUMBER: J-0027 (1212ACNYTXX11) SCHLAFHORST SE 12 ACO 360 YEAR 2009 QUANTITY AVAILABLE: 2 Learn More

J-0027 SCHLAFHORST SE 12 ACO 360 YEAR 2009REFERENCE NUMBER: J-0027 (1212ACNYTXX11) SCHLAFHORST SE 12 ACO 360 YEAR 2009 QUANTITY AVAILABLE: 2 Learn More -

SCHLAFHORST SE12 OPEN END YEAR 2006 – 300 ROTORSYEAR: 2006 NUMBER OF ROTORS PER M/C: 360 ROTOR DIAMETER: 31MM CHEESE LENGTH: 170MM OPENING ROLLER: B174 EYC: COROLAB XQ ROBOTS PER M/C: 2 RPM SPEED: 100,000 COTTON / SYNTHETIC: COTTON MANUAL OR AUTO DOFFING: AUTO Learn More

SCHLAFHORST SE12 OPEN END YEAR 2006 – 300 ROTORSYEAR: 2006 NUMBER OF ROTORS PER M/C: 360 ROTOR DIAMETER: 31MM CHEESE LENGTH: 170MM OPENING ROLLER: B174 EYC: COROLAB XQ ROBOTS PER M/C: 2 RPM SPEED: 100,000 COTTON / SYNTHETIC: COTTON MANUAL OR AUTO DOFFING: AUTO Learn More -

M-4701 RAMISCH RK 360-H CALENDER YEAR 1971 WIDTH 2200mm (RENEWED IN 2008)REFERENCE NUMBER: M-4701 (1111DPTVXX10) L RAMISCH RK 360-H CALENDER YEAR 1971 WIDTH 2200mm (RENEWED IN 2008) RAMISCH CALENDER TYPE RK 360 – H (FOR CALENDERING AND COTTON LUSTERING) WORKING WIDTH 2200mm 3 ROLLERS TOTAL WIDTH 2400mm (STEEL/COTTON/STEEL) YEAR 1971 BUT TOTALLY RENEWED IN YEAR 2008 MAXIMUM PRESSURE 160 BARS ON BOTH LATERAL HYDRAULIC CYLINDERS (LEFT AND RIGHT) INVERTER HITACHI SJ 300 TEMPERATURE CONTROL APAR AR650, AR682 METER COUNTER SIMEX SLK-94 METAL DETECTOR CEIA SEAM DETECTION CACCIA ELECTRNICA WITH DOUBLE CONTROLLER STEAM PRESSURE 4 BARS STEAM CONSUMPTION CA 400 KG/H MOTOR POWER: 30 KW QUANTITY AVAILABLE: 1 Learn More

M-4701 RAMISCH RK 360-H CALENDER YEAR 1971 WIDTH 2200mm (RENEWED IN 2008)REFERENCE NUMBER: M-4701 (1111DPTVXX10) L RAMISCH RK 360-H CALENDER YEAR 1971 WIDTH 2200mm (RENEWED IN 2008) RAMISCH CALENDER TYPE RK 360 – H (FOR CALENDERING AND COTTON LUSTERING) WORKING WIDTH 2200mm 3 ROLLERS TOTAL WIDTH 2400mm (STEEL/COTTON/STEEL) YEAR 1971 BUT TOTALLY RENEWED IN YEAR 2008 MAXIMUM PRESSURE 160 BARS ON BOTH LATERAL HYDRAULIC CYLINDERS (LEFT AND RIGHT) INVERTER HITACHI SJ 300 TEMPERATURE CONTROL APAR AR650, AR682 METER COUNTER SIMEX SLK-94 METAL DETECTOR CEIA SEAM DETECTION CACCIA ELECTRNICA WITH DOUBLE CONTROLLER STEAM PRESSURE 4 BARS STEAM CONSUMPTION CA 400 KG/H MOTOR POWER: 30 KW QUANTITY AVAILABLE: 1 Learn More -

SCHLAFHORST SE-12 AUTOCORO YEAR 2006 – 360 ROTORS – 2 ROBOTS – 33mm ROTORREFERENCE NUMBER: M-4076 (9902888BB8U) L SCHLAFHORST SE-12 AUTOCORO YEAR 2006 – 360 ROTORS – 2 ROBOTS – 33mm ROTOR AUTOCORO SE-12 SCHLAFHORST YEAR 2006 360 ROTORS PER MACHINE 33mm ROTOR DIAMETER CHEESE LENGTH: 170mm ADAPTER DIAMETER: 44 X 60 OPENING ROLLER: B174 EYC: COROLAB 8 (XQ) 2 ROBOTS PER MACHINE RPM SPEED: 102,000 COTTON/SYNTHETIC: COTTON MANUAL OR AUTO PRESSING: AUTO QUANTITY AVAILABLE: 2 Learn More

SCHLAFHORST SE-12 AUTOCORO YEAR 2006 – 360 ROTORS – 2 ROBOTS – 33mm ROTORREFERENCE NUMBER: M-4076 (9902888BB8U) L SCHLAFHORST SE-12 AUTOCORO YEAR 2006 – 360 ROTORS – 2 ROBOTS – 33mm ROTOR AUTOCORO SE-12 SCHLAFHORST YEAR 2006 360 ROTORS PER MACHINE 33mm ROTOR DIAMETER CHEESE LENGTH: 170mm ADAPTER DIAMETER: 44 X 60 OPENING ROLLER: B174 EYC: COROLAB 8 (XQ) 2 ROBOTS PER MACHINE RPM SPEED: 102,000 COTTON/SYNTHETIC: COTTON MANUAL OR AUTO PRESSING: AUTO QUANTITY AVAILABLE: 2 Learn More -

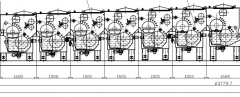

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More