Search results for: 'machine+can'

- Related search terms

- machine+can+0

-

C-4354 FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

C-4354 FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGEREFERENCE NUMBER: C-4354

FULL-AUTO HIGH SPEED WET TISSUE FOLDING MACHINE Y-2700(A) AND FULL-AUTO WET TISSUE PACKING MACHINE Y-360, CAPACITY 40 TO 120 PCS/PACKAGE

DETAILS:

Y-2700A+360 FULL AUTOMATIC WET TISSUE FOLDING AND PACKING MACHINE

MAKING 40PCS TO 120PCS/PACK WET WIPES

IS A MACHINE THAT CAN SLITTING THE BIG JUMBO RAW MATERIAL, FOLDING, WETTING, CUTTING IN LENGTH

STACKING THEN TRANSFER TO PACKING MACHINE FOR PACKING FROM RAW MATERIAL TO FINISH PRODUCT ALL THE STEPS ARE FINISHED ON MACHINE

THE PROCESS IS QUICK AND CLEAN

THE FOLDING MACHINE AND PACKING MACHINE CAN BE COMBINE TOGETHER TO BE A FULL AUTOMATIC LINE OR CAN BE SEPARATED WHEN NEEDED THAT CAN MAX USE THE MACHINES AND MAKE MORE OUTPUT

QUANTITY: 1

Learn More -

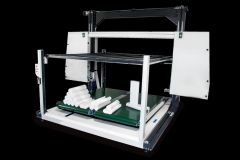

K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mmREFERENCE NUMBER: K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mm MODEL F26 LOADING CONVEYOR 2100 X 2100mm UNLOADING CONVEYOR 2100 X 2100mm MAX. DRILLING WIDTH 2100mm MAXIJMUM LENGTH 2100mm MAX. DRILLING HEIGHT 180mm HOLE DIAMETER 6-30mm QUANTITY AVAILABLE: 1 Learn More

K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mmREFERENCE NUMBER: K-2246 FOAM DRILLING MACHINE-FOR FOAM MATTRESS 2200 X 2200 X 1800mm MODEL F26 LOADING CONVEYOR 2100 X 2100mm UNLOADING CONVEYOR 2100 X 2100mm MAX. DRILLING WIDTH 2100mm MAXIJMUM LENGTH 2100mm MAX. DRILLING HEIGHT 180mm HOLE DIAMETER 6-30mm QUANTITY AVAILABLE: 1 Learn More -

YY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mmYY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mm DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS WEIGHT (KG): 350 VIDEO OUTGOING-INSPECTION: PROVIDED MACHINERY TEST REPORT: PROVIDED WARRANTY OF CORE COMPONENTS: 1 YEAR CORE COMPONENTS: BEARING MACHINE TYPE: CASHMERE SAMPLE MAKING MACHINE PRODUCT: CHENILLE MATERIAL CAPABILITIES: SHEEP WOOL CARDING MACHINE CERTIFICATION: CE NAME: SAMPLE MAKING MACHINE FEATURE: SMALL CARDING MACHINE CYLINDER WIDTH: 300 mm DIMENSION: 1299 X 850 X 950 (mm) CYLINDER SPEED: 85 RPM DOFFER SPEED: 10 TO 12 RPM LICKER-IN SPEED: 28 RPM QUANTITY: 1 Learn More

YY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mmYY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mm DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS WEIGHT (KG): 350 VIDEO OUTGOING-INSPECTION: PROVIDED MACHINERY TEST REPORT: PROVIDED WARRANTY OF CORE COMPONENTS: 1 YEAR CORE COMPONENTS: BEARING MACHINE TYPE: CASHMERE SAMPLE MAKING MACHINE PRODUCT: CHENILLE MATERIAL CAPABILITIES: SHEEP WOOL CARDING MACHINE CERTIFICATION: CE NAME: SAMPLE MAKING MACHINE FEATURE: SMALL CARDING MACHINE CYLINDER WIDTH: 300 mm DIMENSION: 1299 X 850 X 950 (mm) CYLINDER SPEED: 85 RPM DOFFER SPEED: 10 TO 12 RPM LICKER-IN SPEED: 28 RPM QUANTITY: 1 Learn More -

TT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mmTT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mm ITEM 001 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER IN 1980 STARTED PRODUCTION TEST POSSIBLE – IMMEDIATELY FREE FOR SALE ITEM 002 STAMPING AND EMBOSSING MACHINE HEIDEMANN ITEM 003 WAX-LAMINATOR KROENERT-PACK 850 THE MACHINE CAN BE DISMANTLED AS FROM NOW. Learn More

TT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mmTT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mm ITEM 001 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER IN 1980 STARTED PRODUCTION TEST POSSIBLE – IMMEDIATELY FREE FOR SALE ITEM 002 STAMPING AND EMBOSSING MACHINE HEIDEMANN ITEM 003 WAX-LAMINATOR KROENERT-PACK 850 THE MACHINE CAN BE DISMANTLED AS FROM NOW. Learn More -

TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022 MACHINE TYPE: CONTOUR CUTTING MACHINE CNC, FOR FOAM BRAND: INFOTEC MODEL: INFOTEC 2424 C FOAM YEAR OF CONSTRUCTION: 2022 CONDITION: NEW THE CONTOUR CUTTING MACHINE CUTS A VARIETY OF SHAPES FROM FLEXIBLE POLYURETHANE FOAM BLOCKS. USED IN THE MANY INDUSTRIES, ESPECIALLY IN THE PRODUCTION OF UPHOLSTERED FURNITURE AND MATTRESSES. FOR CUTTING FOAM BLOCKS WITH A MAXIMUM SIZE OF: 2400 X 2400 X 1300mm. THE MACHINE IS EQUIPPED WITH A ROTARY TABLE, WHICH MAKES IT POSSIBLE TO CUT OUT ANY COMPLEX SPATIAL SHAPES. IT CAN ALSO SLICE BLOCKS OF FOAM AS A VERTICAL OR AS HORIZONTAL MACHINE DOES. Learn More

TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022TT-2004 INFOTEC 2424 C FOAM CONTOUR CUTTING MACHINE CNC, YEAR 2022 MACHINE TYPE: CONTOUR CUTTING MACHINE CNC, FOR FOAM BRAND: INFOTEC MODEL: INFOTEC 2424 C FOAM YEAR OF CONSTRUCTION: 2022 CONDITION: NEW THE CONTOUR CUTTING MACHINE CUTS A VARIETY OF SHAPES FROM FLEXIBLE POLYURETHANE FOAM BLOCKS. USED IN THE MANY INDUSTRIES, ESPECIALLY IN THE PRODUCTION OF UPHOLSTERED FURNITURE AND MATTRESSES. FOR CUTTING FOAM BLOCKS WITH A MAXIMUM SIZE OF: 2400 X 2400 X 1300mm. THE MACHINE IS EQUIPPED WITH A ROTARY TABLE, WHICH MAKES IT POSSIBLE TO CUT OUT ANY COMPLEX SPATIAL SHAPES. IT CAN ALSO SLICE BLOCKS OF FOAM AS A VERTICAL OR AS HORIZONTAL MACHINE DOES. Learn More -

TT-6031 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON, YEAR 2023TT-6031 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON, YEAR 2023 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON YEAR: 2023 QUANTITY: 1 LINE Learn More

TT-6031 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON, YEAR 2023TT-6031 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON, YEAR 2023 COMPLETE RIETER OPEN END SPINNING PLANT FOR REGENERATED COTTON YEAR: 2023 QUANTITY: 1 LINE Learn More -

TT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KNTT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KN 50KN TENSILE STRENGTH TEST KEY SPECIFICATIONS: CAPACITY KGF 5000, 10000, 15000 KN 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 800 CROSSHEAD TRAVEL (mm): 1480 TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200 MAXIMUM FORCE AT FULL SPEED (KGF): 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION (mm): 0.001 DRIVING METHOD: AC SERVO MOTOR POWER: SPECIFICATIONS 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CAPACITY: 5000KGF, 10000KGF, 15000KGF 50KN, 100KN, 150KN CONSUMPTION: 3KVA DIMENSIONS: FRAME (mm) 1540 X 600 X 2130 CONTROL BOX (mm): COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG): FRAME 800, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY QUANTITY: 1 Learn More

TT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KNTT-1041UNIVERSAL TENSILE STRENGTH TESTER, 50KN 50KN TENSILE STRENGTH TEST KEY SPECIFICATIONS: CAPACITY KGF 5000, 10000, 15000 KN 50, 100, 150 UNIT: LOAD N, KN, G, KG, TON, LB DISPLACEMENT: mm, CM, INCH LOAD RESOLUTION: 1/20,000 LOAD ACCURACY: ±1% (±0.5% OPTIONAL) LOAD AMPLIFICATION: X 1, X 2, X 5, X 10 AUTO RANGE TESTING WIDTH (mm): 800 CROSSHEAD TRAVEL (mm): 1480 TESTING STROKE: CROSSHEAD TRAVEL MINUS UPPER/LOWER GRIPS AND GRIPPING LENGTH TEST SPEED RANGE (mm/MIN): 0.5~500 OR 0.2~200 MAXIMUM FORCE AT FULL SPEED (KGF): 2000 MAXIMUM SPEED AT FULL LOAD (mm/MIN): 100 SPEED ACCURACY: ±0.5% SERVO CONTROL DISPLACEMENT RESOLUTION (mm): 0.001 DRIVING METHOD: AC SERVO MOTOR POWER: SPECIFICATIONS 3Ø, 220VAC, 50/60Hz (380/415V OPTIONAL) CAPACITY: 5000KGF, 10000KGF, 15000KGF 50KN, 100KN, 150KN CONSUMPTION: 3KVA DIMENSIONS: FRAME (mm) 1540 X 600 X 2130 CONTROL BOX (mm): COMPUTER TYPE 1200 X 600 X 740 MICRO-COMPUTER TYPE 660 X 600 X 740 WEIGHT (KG): FRAME 800, CONTROL BOX 100 STANDARD ACCESSORIES: TENSILE GRIPS X 1 SET, NECESSARY TOOLS X 1 SET, OPERATIONAL MANUAL X 1 COPY, CERTIFICATE OF CALIBRATION X 1 COPY QUANTITY: 1 Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More -

M-5221 NONWOVEN LINE WIDTH 2500mm

M-5221 NONWOVEN LINE WIDTH 2500mmREFERENCE NUMBER: M-5221 (1313565TNY12RX) L

NONWOVEN LINE WIDTH 2500mmCARD FEEDING

CARDINGQUANTITY AVAILABLE: 1

Learn More -

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More