Search results for: 'pre needle m'

-

M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004

M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004

OFFER 001

NONWOVEN NEEDLE FELT LINE – RENEWED 3 YEARS AGO

WORKING WIDTH: 4300mmOFFER 002

HERGETH BALE OPENER

YEAR: 1986

WORKING WIDTH: 1000mmOFFER 003

OILING UNIT

TANK CAPACITY: 250 LITRESOFFER 004

AUGUST PROTT FAN FOR FIBER TRANSPORT

POWER: 7.5 KWOFFER 005

TERMO GORING KERR METAL DETECTOR AND METAL SEPARATOR

YEAR: 2004OFFER 006

TEMAFA MIXING BINOFFER 007

FOR FAN FOR FIBER TRANSPORTATIONOFFER 008

FOR CHUTE FEED WITH MOVEABLE CONDENSOR

WORKING WIDTH: 2500mmOFFER 009

WEB DENSITY MEASURING AND AUTOMATIC ALIGNINGOFFER 010

FOR CARDING MACHINE

WORKING WIDTH: 2500mmOFFER 011

ASSELIN CROSSLAPPER

YEAR: 1984

INPUT WIDTH: 2500mmOFFER 012

FEHRER FIRST NEEDLE LOOM

YEAR: 1973

WORKING WIDTH: 4800mmOFFER 013

UNWINDING FOR PRELIMINARY WEBOFFER 014

CONVEYOR SYSTEM FOR WEB TRANSPORTATION TO SECOND NEEDLE LOOMOFFER 015

FEHRER SECOND NEEDLE LOOM

YEAR: 1970

WORKING WIDTH: 4400mmOFFER 016

FEHRER THIRD NEEDLE LOOM

YEAR: 1973

WORKING WIDTH: 4800mmOFFER 017

BENEDETTI & CALAMAI TRIMMING AND WINDING UNIT

YEAR: 1995

TABLE WIDTH: 5500mmOFFER 018

LAROCHE EDGE TRIM OPENERQUANTITY: 1 LINE

Learn More -

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More -

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More -

TT-3818 DILO DI-LOOM OD-II HSC 12.5 NEEDLE LOOM, WIDTH 1250mm, YEAR 2004TT-3818 DILO DI-LOOM OD-II HSC 12.5 NEEDLE LOOM, WIDTH 1250mm, YEAR 2004 BRAND: DILO NEEDLE LOOMS MODEL: DI-LOOM OD-II HSC 12.5 CONDITION: USED YEAR: 2004 ELECTRICITY: 480/3/60 QUANTITY: 1 Learn More

TT-3818 DILO DI-LOOM OD-II HSC 12.5 NEEDLE LOOM, WIDTH 1250mm, YEAR 2004TT-3818 DILO DI-LOOM OD-II HSC 12.5 NEEDLE LOOM, WIDTH 1250mm, YEAR 2004 BRAND: DILO NEEDLE LOOMS MODEL: DI-LOOM OD-II HSC 12.5 CONDITION: USED YEAR: 2004 ELECTRICITY: 480/3/60 QUANTITY: 1 Learn More -

J-1113 USED KARL MAYER LACE AND TRICOT MACHINES YEARS 1978-2001 WIDTH 43 SU TO 210”REFERENCE NUMBER: J-1113 (1111JKLBVXX10) USED KARL MAYER LACE AND TRICOT MACHINES YEARS 1978-2001 WIDTH 43 SU TO 210” QUANTITY AVAILABLE: 45 Learn More

J-1113 USED KARL MAYER LACE AND TRICOT MACHINES YEARS 1978-2001 WIDTH 43 SU TO 210”REFERENCE NUMBER: J-1113 (1111JKLBVXX10) USED KARL MAYER LACE AND TRICOT MACHINES YEARS 1978-2001 WIDTH 43 SU TO 210” QUANTITY AVAILABLE: 45 Learn More -

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More

YY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOURYY-2073 COMPUTERIZED CHAIN STITCH NON-SHUTTLE MULTI-NEEDLE QUILTING MACHINE, QUILTING WIDTH 2450mm -PRODUCTION SPEED 60 TO 300 METERS PER HOUR DETAILS: TECHNICAL PARAMETERS DIMENSIONS (L X W X H): 5400 X 1650 X 2360mm GROSS WEIGHT: 5800 KG MAIN SHAFT SPEED: 500 TO 1300 RPM PRODUCTION SPEED: 60 TO 300 METERS PER HOUR STITCH LENGTH: 3 TO 8mm NEEDLE TYPE: 24/180, 23/160, 22/140, 21/130 SPACE BETWEEN NEEDLE ROWS: (50.8, 76.2, 127) 5″, (76.2, 76.2, 152.4) 6″ SPACE BETWEEN NEEDLES: 12.7 / 25.4mm MAXIMUM HORIZONTAL MOVEMENT: 304.8mm QUILTING WIDTH: 2450mm QUILTING THICKNESS: ≤80mm VOLTAGE: 220 VOLTS OR 380 VOLTS, 50/60Hz, 3-PHASE POWER: 11 KW QUANTITY: 1 Learn More -

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

2 BAR , 150m DISTANCE BETWEEN BARS

WIDTH UP TO 2700mm = 106 INCHESMAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER

YEAR: 2014

96 SEPARATELY CONTROLLABLE NEEDLES

FULLY AUTOMATIC NEEDLE PLAN CHANGE

TOP AND BOTTOM THREAD CUTTER AT EACH SEWING POSITION

MATERIAL WIDTH UP TO 2700mm

TWO NEEDLE BARS

150mm SPACING

HANDWHEEL ADJUSTMENT OF HEIGHT OF PRESSER PLATE

ELECTRONIC THREAD BREAK DETECTOR FOR TOP AND BOTTOM THREADS

MATERIAL UNWIND DEVICE

RACKS FOR TOP AND BOTTOM THREAD

ONE CATWALK EACH ON FRONT AND REAR OPERATING SITE

TROUGH INFEED FOR UPPER MATERIAL WITH MOTOR-DRIVEN ROLLER SYSTEM

AUTOMATIC MARKING AND DETECTING UNIT FOR PATTERN CONFORM LATERAL CUT

ELECTRONICS AND MOTORS 400V, 3 PHASES

CONCRETE BASES AND VIBRATION DAMPERS

Learn More -

TT-8422 FEHRER NL9 NEEDLE PUNCH MACHINE, WORKING WIDTH 4400mm, YEAR 1984TT-8422 FEHRER NL9 NEEDLE PUNCH MACHINE, WORKING WIDTH 4400mm, YEAR 1984 1. FEHRER NL9 NEEDLE PUNCH MACHINE 2. THE FEHRER NL9 NEEDLE MACHINE IS AN INDUSTRIAL SEWING MACHINE THAT USES A SPECIAL NEEDLE WITH A HOOK OR LOOP INSTEAD OF A TRADITIONAL NEEDLE, THREADING THE THREAD THROUGH THE MATERIAL AND CREATING A SEAM. 3. INDUSTRIAL NEEDLE MACHINES ARE USED IN THE TEXTILE AND CLOTHING INDUSTRY TO SEW FABRIC, LEATHER, FUR AND OTHER MATERIALS. QUANTITY: 1 Learn More

TT-8422 FEHRER NL9 NEEDLE PUNCH MACHINE, WORKING WIDTH 4400mm, YEAR 1984TT-8422 FEHRER NL9 NEEDLE PUNCH MACHINE, WORKING WIDTH 4400mm, YEAR 1984 1. FEHRER NL9 NEEDLE PUNCH MACHINE 2. THE FEHRER NL9 NEEDLE MACHINE IS AN INDUSTRIAL SEWING MACHINE THAT USES A SPECIAL NEEDLE WITH A HOOK OR LOOP INSTEAD OF A TRADITIONAL NEEDLE, THREADING THE THREAD THROUGH THE MATERIAL AND CREATING A SEAM. 3. INDUSTRIAL NEEDLE MACHINES ARE USED IN THE TEXTILE AND CLOTHING INDUSTRY TO SEW FABRIC, LEATHER, FUR AND OTHER MATERIALS. QUANTITY: 1 Learn More -

TT-5274 DILO HYPERPUNCH NEEDLE LOOM, TYPE DI-LOOM OD-II 12.5, WORKING WIDTH 1250mm, YEAR 2004TT-5274 DILO HYPERPUNCH NEEDLE LOOM, TYPE DI-LOOM OD-II 12.5, WORKING WIDTH 1250mm, YEAR 2004 BRAND: DILO NEEDLE LOOMS SPECIFICATIONS CONDITION: USED QUANTITY: 1 Learn More

TT-5274 DILO HYPERPUNCH NEEDLE LOOM, TYPE DI-LOOM OD-II 12.5, WORKING WIDTH 1250mm, YEAR 2004TT-5274 DILO HYPERPUNCH NEEDLE LOOM, TYPE DI-LOOM OD-II 12.5, WORKING WIDTH 1250mm, YEAR 2004 BRAND: DILO NEEDLE LOOMS SPECIFICATIONS CONDITION: USED QUANTITY: 1 Learn More -

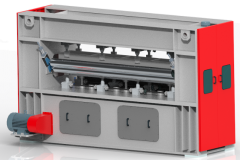

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More