Search results for: 'surface wind'

- Related search terms

- winding

- Winder c

- Winder ma

- Winder+ma

- winding ma'

-

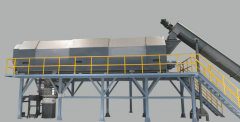

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More -

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTER

L-7136 MATTRESS DURABILITY COMPREHENSIVE TESTERABLE TO DO ROLLING TESTS ON MATTRESSES

DURABILITY TEST FOR THE BED SURFACE:

1. USES INDEPENDENT CONTROL SYSTEM. PLC CONTROL SEPARATELY. COOPERATE WITH COLOR TOUCH SCREEN. IT IS

CONVENIENT AND VISUAL TO OPERATE. THE TESTING PROCESS AND THE RUNNING STATUS BE CLEAR TO US, TEST TIMES CAN

BE SET FREELY.

2. SPECIAL LIFT DEVICE IS CONVENIENT TO LIFT UP THE HEAVY ROLLER AND EASY TO MOVE IT TO THE TEST AREA OF THE

MATTRESS. THEN PUT DOWN THE ROLLER AND MAKE ITS OWN WEIGHT FULLY LOAD TO THE SURFACE OF THE MATTRESS.

3.ROLLER CAN MOVE UP AND DOWN IN THE TESTING PROCESS, TO ADAPT TO CONCAVE AND CONVEX SURFACE OF THE

MATTRESS.

4. WHEN DOING DURABILITY TEST OF EDGE, ROLLER CAN BE MOVED TO THE “PARKING” AREA BEHIND THE INSTRUMENT.

5. DURABILITY TEST FOR THE EDGE IS DRIVEN BY SERVO MOTOR; IT IS QUIET, STEADY AND RELIABLE TO OPERATE.

6. INCORPORATES ADVANCED PHOTOELECTRIC SENSE TECHNOLOGY. THE BEGINNING POSITION OF THE CENTER LINE OF THE

CUSHION SURFACE RETURN TO THE HOME POSITION AUTOMATICALLY.

DURABILITY TEST FOR BED EDGE :

ADOPT INDEPENDENT CONTROL SYSTEM, USING DEDICATED HIGH-PRECISION AND HIGH INTELLIGENT ARAM CONTROLLER

AND SPECIAL TEST SOFTWARE. IT CAN RUN UNDER WINDOWS SYSTEM ON PC, IT IS OPERATED ALL BY SOFTWARE, THE

INTERFACE OF SOFTWARE IS EASY TO OPERATE.

SPECIAL TEST SOFTWARE ON PC, WINDOWS OPERATING PAGE, A HIGH DEGREE OF COMPATIBILITY.

TEST PROGRAM HAS ALREADY BEEN SET ON THE SOFTWARE ON PC ACCORDING TO THE TEST REQUIREMENT. A KEY TO TEST.

IT IS CONVENIENT FOR OPERATOR TO LEARN AND SAVE THE TRAINING TIME.

THE CURVE WINDOW OF TEST SOFTWARE DISPLAY THE VALUES OF FORCE AND SHIFT IN REAL TIME, COORDINATE MODEL.

LOADING CUSHION ON THE EDGE AND LOADING CUSHION WHICH IS USED FOR MEASURING USE GENERIC CONNECTION

HEAD THAT CAN BE IN INTERCHANGED. SHARING A SET OF DRIVING DEVICE, SAVE SPACE AND COST.

ADJUSTABLE RACK. THE PRESSURE PLATE CAN BE ADJUSTED THE POSITION ALONG THE DIRECTION OF X AND Y. IT CAN

MEASURE EACH POINT OF THE MATTRESS. IT IS DIFFERENT FROM THE TRADITION WAY TO SEPARATE. THE TEST CAN BE

FINISHED WITHOUT MOVING THE SAMPLE.

SAVE A LOT OF TESTING TIME, GREATLY REDUCES THE WORKING INTENSITY, OPERATORS CAN ACHIEVE SINGLE OPERATION,

SAVE THE COMPANY COST.

FORCE SENSOR AVOIDS DAMAGE TO THE CORE COMPONENTS BECAUSE IT CAN MAKE PROTECTION WHEN IT IS OVERLOAD.ROLLING TEST SPEED: 16±2CYCLES PER MINUTE (OR SPECIFIED BY CUSTOMER)

Learn More

CYLINDER ROLLER: 1400N, THE MIDDLE DIAMETER: 300mm, BOTH ENDS DIAMETER: 250mm, LENGTH: 1000

HEXAGON STYLE WOODEN ROLLER: SIZE AS STANDARD REQUIREMENT

COUNTER: 0~999999 CAN BE SET.

THE CONTROL WAY OF ROLLING: TOUCH SCREEN + PLC CONTROL

LOADING CUSHION ON THE EDGE: BUTTOCKS SHAPE, 380mm X 495mm

LOADING PARTS ON THE EDGE: THE MIDPOINT ON THE LONG EDGE OF THE MATTRESS.200 mm FROM EDGE.

LOADING FORCE ON THE EDGE: 1000N

LOADING TIME ON THE EDGE: 3S

POSITION OF MEASUREMENT: MATTRESS CENTER, LEFT AND RIGHT ARE BOTH 250mm, THE MIDPOINT ON THE LONG EDGE

OF THE MATTRESS 200 mm INWARD.

LOADING PLATE OF MEASUREMENT: DIAMETER 355mm, RADIUS OF CURVATURE OF THE END R800mm

CAPACITY OF FORCE SENSOR: 2KN

LOADING SPEED OF MEASUREMENT: 90±5mm/MIN

STROKE: 500mm

DRIVE MOTOR: SERVO MOTOR -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More -

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More

TT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MWTT-7680 SIEMENS SST 400 CONDENSING STEAM TURBINE, YEAR 2011, 50/60Hz, 30 MW SIEMENS SST 400 YEAR 2011 TYPE: SST 400 CONDENSING STEAM TURBINE WITH FOUR BLEEDS AND ONE EXTRACTION TURBOSE OUTPUT: (AT GENERATOR TERMINALS) NORMAL 30 MW MAXIMAL 31.88 MW MINIMAL 4.5 MW QUANTITY: 4 Learn More -

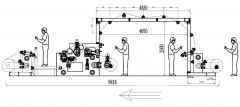

TT-8282 BEAM WINDER OF BEAM DYEING MACHINE, WIDTH 3660mm, WITH PAD FOULARDTT-8282 BEAM WINDER OF BEAM DYEING MACHINE, WIDTH 3660mm, WITH PAD FOULARD 1. WINDER OF BEAM DYEING MACHINE IS SUITABLE FOR RAW MATERIALS OF FABRIC SPOOLS OR A-SHAPED FRAMES. 2. IT UNDERGOES WIDENING FOR DE-CREASING WRINKLES, LASER ALIGNMENT, WATER TANK IMMERSION, WATER REMOVAL BY ROLLING, TENSION CONTROL, AND THE WINDING IS DONE ON THE AXIAL WINDING DRUM OR THE DEDICATED EQUIPMENT OF THE A-SHAPED FRAME. 3. MAIN PARAMETERS: 4. MATERIAL: STAINLESS STEEL 304 5. WIDTH OF FABRIC: 3660mm QUANTITY: 1 SET Learn More

TT-8282 BEAM WINDER OF BEAM DYEING MACHINE, WIDTH 3660mm, WITH PAD FOULARDTT-8282 BEAM WINDER OF BEAM DYEING MACHINE, WIDTH 3660mm, WITH PAD FOULARD 1. WINDER OF BEAM DYEING MACHINE IS SUITABLE FOR RAW MATERIALS OF FABRIC SPOOLS OR A-SHAPED FRAMES. 2. IT UNDERGOES WIDENING FOR DE-CREASING WRINKLES, LASER ALIGNMENT, WATER TANK IMMERSION, WATER REMOVAL BY ROLLING, TENSION CONTROL, AND THE WINDING IS DONE ON THE AXIAL WINDING DRUM OR THE DEDICATED EQUIPMENT OF THE A-SHAPED FRAME. 3. MAIN PARAMETERS: 4. MATERIAL: STAINLESS STEEL 304 5. WIDTH OF FABRIC: 3660mm QUANTITY: 1 SET Learn More -

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004 QUANTITY: 1 Learn More

T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004T-9531 DMT BOPP LINE, WIDTH 6800mm, YEAR 2004 QUANTITY: 1 Learn More -

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More

M-5244 TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mmREFERENCE NUMBER: M-5244 (1313JTBVXX12) L TOYOTA JAT610 AIR JET LOOMS YEAR 1998 WIDTH 1900mm-2800mm TOYOTA JAT610 AIR JET LOOMS, YEAR 1998 (60 LOOMS) X WIDTH 1900mm (12 LOOMS) X WIDTH 2800mm RUNNING CONDITION YEAR 1999 1 INVERTER FOR 36 LOOMS (2 INVERTERS FOR ALL 72 LOOMS) QUANTITY AVAILABLE: 27 LOOMS Learn More