Search results for: 'Machine+we'

- Related search terms

- Machine+weight

-

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

M-2057 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: M-2057 (77011229TGUX) NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More

F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mmREFERENCE NUMBER: F-1225 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 3300mm Learn More -

YY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mmYY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mm DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS WEIGHT (KG): 350 VIDEO OUTGOING-INSPECTION: PROVIDED MACHINERY TEST REPORT: PROVIDED WARRANTY OF CORE COMPONENTS: 1 YEAR CORE COMPONENTS: BEARING MACHINE TYPE: CASHMERE SAMPLE MAKING MACHINE PRODUCT: CHENILLE MATERIAL CAPABILITIES: SHEEP WOOL CARDING MACHINE CERTIFICATION: CE NAME: SAMPLE MAKING MACHINE FEATURE: SMALL CARDING MACHINE CYLINDER WIDTH: 300 mm DIMENSION: 1299 X 850 X 950 (mm) CYLINDER SPEED: 85 RPM DOFFER SPEED: 10 TO 12 RPM LICKER-IN SPEED: 28 RPM QUANTITY: 1 Learn More

YY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mmYY-2043 NEW EASY OPERATION SHEEP WOOL CASHMERE SAMPLE MAKING MACHINE/SMALL CARDING MACHINE, CYLINDER WIDTH 300 mm DETAILS: CONDITION: NEW APPLICABLE INDUSTRIES: MANUFACTURING PLANT, FARMS WEIGHT (KG): 350 VIDEO OUTGOING-INSPECTION: PROVIDED MACHINERY TEST REPORT: PROVIDED WARRANTY OF CORE COMPONENTS: 1 YEAR CORE COMPONENTS: BEARING MACHINE TYPE: CASHMERE SAMPLE MAKING MACHINE PRODUCT: CHENILLE MATERIAL CAPABILITIES: SHEEP WOOL CARDING MACHINE CERTIFICATION: CE NAME: SAMPLE MAKING MACHINE FEATURE: SMALL CARDING MACHINE CYLINDER WIDTH: 300 mm DIMENSION: 1299 X 850 X 950 (mm) CYLINDER SPEED: 85 RPM DOFFER SPEED: 10 TO 12 RPM LICKER-IN SPEED: 28 RPM QUANTITY: 1 Learn More -

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More -

T-9596 BUTTON PULL TEST MACHINET-9596 BUTTON PULL TEST MACHINE FEATURE: 1. SNAP BUTTON PULL TEST MACHINE IS A SIMPLE BUT EFFECTIVE DESIGN MAINLY CONSISTING OF A HIGH PRECISION GAUGE, A STURDY REQUIRED BY STANDARDS & REGULATIONS IS BE FIXED HORIZONTALLY (CONSTANT FORCE IS APPLIED TO SECURE THE SAMPLE) SO THAT SNAP OR OTHER ACCESSORIES ATTACHED IN FABRIC CAN BE CLAMPED INTO. 2. MOREOVER, A STANDARD WEIGHT IS ALSO OFFERED SO THAT IT CAN BE REGULARLY CHECKED IF IT MEETS THE SAFETY REQUIREMENTS. 3. THE CAPABILITY OF THE BUTTON PULL TEST MACHINE CAN BE ENHANCED WITH CLAMPS & ACCESSORIES FOR TESTING OF OTHER SNAPS, JEAN BUTTONS, FOUR HOLE BUTTONS & GARMENTS ACCESSORIES SUCH AS ZIPPERS, BOWS, APPLIQUÉ, TOGGLES, HOOKS/BARS, AND D-RINGS, AMONGST OTHERS. SPECIFICATION: DIMENSIONS: 260 X 310 X 820mm NET WEIGHT: 32KG ACCESSORIES: STANDARD ACCESSORIES 1PC - IMADA FORCE GAUGE FB-30K 1PC - UPPER UNIVERSAL GRIP 1PC - UPPER STUD GRIP 1PC - LOWER FABRIC CLAMP & LEVEL ARM LOCKING 1PC - LOWER GRASP BUTTON ACCESSORY KIT 1PC - CALIBRATION WEIGHT 15LB 1PC - THREE PRONGED GRIP 1PC - UPPER LONG NOSE VISE GRIP Learn More

T-9596 BUTTON PULL TEST MACHINET-9596 BUTTON PULL TEST MACHINE FEATURE: 1. SNAP BUTTON PULL TEST MACHINE IS A SIMPLE BUT EFFECTIVE DESIGN MAINLY CONSISTING OF A HIGH PRECISION GAUGE, A STURDY REQUIRED BY STANDARDS & REGULATIONS IS BE FIXED HORIZONTALLY (CONSTANT FORCE IS APPLIED TO SECURE THE SAMPLE) SO THAT SNAP OR OTHER ACCESSORIES ATTACHED IN FABRIC CAN BE CLAMPED INTO. 2. MOREOVER, A STANDARD WEIGHT IS ALSO OFFERED SO THAT IT CAN BE REGULARLY CHECKED IF IT MEETS THE SAFETY REQUIREMENTS. 3. THE CAPABILITY OF THE BUTTON PULL TEST MACHINE CAN BE ENHANCED WITH CLAMPS & ACCESSORIES FOR TESTING OF OTHER SNAPS, JEAN BUTTONS, FOUR HOLE BUTTONS & GARMENTS ACCESSORIES SUCH AS ZIPPERS, BOWS, APPLIQUÉ, TOGGLES, HOOKS/BARS, AND D-RINGS, AMONGST OTHERS. SPECIFICATION: DIMENSIONS: 260 X 310 X 820mm NET WEIGHT: 32KG ACCESSORIES: STANDARD ACCESSORIES 1PC - IMADA FORCE GAUGE FB-30K 1PC - UPPER UNIVERSAL GRIP 1PC - UPPER STUD GRIP 1PC - LOWER FABRIC CLAMP & LEVEL ARM LOCKING 1PC - LOWER GRASP BUTTON ACCESSORY KIT 1PC - CALIBRATION WEIGHT 15LB 1PC - THREE PRONGED GRIP 1PC - UPPER LONG NOSE VISE GRIP Learn More -

YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS)YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS) 1. MACHINE STRUCTURE: THE MAIN BODY OF THE MACHINE IS MADE OF A STEEL PLATE STRUCTURE, AND THE REWINDING HAS A UP & DOWN AXIS REWINDING. THE CYLINDER LET OFF AUTOMATICALLY SETS FOR CUTTING, AND HAS FUNCTIONS SUCH AS METER COUNTING, RE-SETTING THE METER TO ZERO, AND AUTOMATIC SPEED INCREASE. 2. PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM, DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS, CLOTH, VINYLS AND SIMILAR MATERIALS. 3. CUTTING TYPE: ROTATING BLADE FOR AUTOMATIC CUTTING. 4. REWINDING ACCURACY ERROR: 0.1%. 5. MAXIMUM UNWINDING DIAMETER: Φ 915mm, WEIGHT 1000KGS. 6. MAXIMUM UNWINDING WIDTH: 2200mm. 7. MAXIMUM REWINDING DIAMETER: Φ420mm, WEIGHT 100KGS. 8. MAXIMUM MECHANICAL SPEED: 200 METERS/MINUTE. 9. COMPLETE MACHINE POWER: 20KW. 10. EQUIPMENT OVERALL SIZE: 2600×2900×1600mm. QUANTITY: 1 Learn More

YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS)YY-2869 SEMI-AUTOMATIC REWINDING MACHINE, WORKING WIDTH 2200mm – FLIPPING (ALTERNATING WINDING ROLLS) 1. MACHINE STRUCTURE: THE MAIN BODY OF THE MACHINE IS MADE OF A STEEL PLATE STRUCTURE, AND THE REWINDING HAS A UP & DOWN AXIS REWINDING. THE CYLINDER LET OFF AUTOMATICALLY SETS FOR CUTTING, AND HAS FUNCTIONS SUCH AS METER COUNTING, RE-SETTING THE METER TO ZERO, AND AUTOMATIC SPEED INCREASE. 2. PRODUCT USAGE: THIS MACHINE IS MAINLY USED FOR RE-WINDING AND TRIMMING OF VARIOUS PAPERS, PAPER-PLASTIC COMPOSITES, FILM, DECORATIVE MATERIALS AS WELL AS PACKAGING MATERIALS, CLOTH, VINYLS AND SIMILAR MATERIALS. 3. CUTTING TYPE: ROTATING BLADE FOR AUTOMATIC CUTTING. 4. REWINDING ACCURACY ERROR: 0.1%. 5. MAXIMUM UNWINDING DIAMETER: Φ 915mm, WEIGHT 1000KGS. 6. MAXIMUM UNWINDING WIDTH: 2200mm. 7. MAXIMUM REWINDING DIAMETER: Φ420mm, WEIGHT 100KGS. 8. MAXIMUM MECHANICAL SPEED: 200 METERS/MINUTE. 9. COMPLETE MACHINE POWER: 20KW. 10. EQUIPMENT OVERALL SIZE: 2600×2900×1600mm. QUANTITY: 1 Learn More -

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More

V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW -480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS)V-1961 AUTOMATIC PET PAD MAKING MACHINE – 400 PADS PER MINUTE – 350KW-480,000 PADS IN 20 HOURS (PER 3-SHIFT DAY, AFTER REMOVING EFFICIENCIES = 500,000 PADS PER 24 HOURS) FULLY AUTOMATIC PET PAD MAKING MACHINE THE MACHINE OPERATORS JOB IS ONLY TO ADD THE RAW MATERIALS AND VERIFY THAT THE MACHINE IS RUNNING PROPERLY. ABSORBENT CORE CRUSH, MIX AND MAKE THE CORE. TOP SHEET, ABSORBENT CORE, BACK SHEET (PE FILM), LAMINATED. FINAL PRODUCTS ARE FOLDED HORIZONTALLY CUTS PAD INTO FINAL SIZE CREATES VERTICAL FOLD MAIN TECHNICAL PARAMETERS: DESIGN SPEED: 300 METERS PER MINUTE (60mm x 90mm) WORKING SPEED: 250 METERS PER MINUTE (60mm x 90mm) QUALIFIED RATE: >98% EFFICIENCY: >85% INSTALLED POWER: 300 KW (MAIN MACHINE) ELECTRICITY: 480 VOLTS, 60 Hz AIR PRESSURE: 0.6 MPA, 2.6 m3 PER MINUTE TOTAL WEIGHT: 65 TONS PRODUCT SIZE: 400mm x 600mm, 600mm x 600mm, 900mm x 600mm, 560mm x 560mm, 4 SIZES, ACCORDING TO ORDER QUANTITY: 1 Learn More -

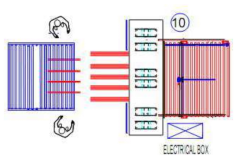

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More

YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES)YY-2745 ELECTRONIC AUTOMATIC FILLING MACHINE FOR COVER & AUTOMATIC INSERTION OF FOAM LAYERS INTO COVERS, MACHINE N. 10, MACHINE NAME BRAND GRASSI (ITALY), WORKING WIDTH 2200mm (86 INCHES) SPECIFICATION OF THE MACHINE: MAXIMUM WORKING AREA: FROM 700mm TO 2200mm; MAXIMUM HEIGHT: FROM 05CM TO 40CM; KING OF MATERIALS: ANY KIND OF FOAM LAYERS; PRODUCTION: 2 CYCLES/MINUTE; DIMENSIONS: 3500 X 3500 X H2200 mm (WITH ALL OPTIONAL); WEIGHT: 3.250 KG; POWER: 8 KW; POWER SUPPLY: 480V – AC – 60 Hz – 3PHASES; AIR PRESSURE: 6/8 BAR. QUANTITY: 1 Learn More -

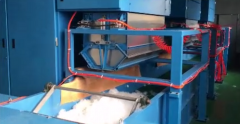

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mm

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mmREFERENCE NUMBER: L-4682

Learn More

WIDTH: 1200mm

CAPACITY: 200-600KG/H

QUANTITY: 1