YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE

QUANTITY: 1

In stock

SKU

YY-1521

REFERENCE NUMBER: YY-1521

COMPUTERIZED SINGLE HEAD QUILTING MACHINE

DETAILS:

1. 1:1 FRAME FIXED STRUCTURE, MOST COMPACT MACHINE DESIGN.

FIXED QUILTING FRAME, SEWING HEAD MOVE IN X DIRECTION AND SADDLETREE MOVE IN Y DIRECTION, IT IS THE MOST COMPACT QUILTING MACHINE STRUCTURE.

MAXIMUM QUILTING AREA WITH MINIMUM REQUESTED INSTALLATION AREA, SOLVED THE PROBLEM ON TRADITIONAL MACHINE WITH OCCUPIED 2 TO 4 TIMES OF MOVING FRAME MODEL, SAVE WORKING SPACE.

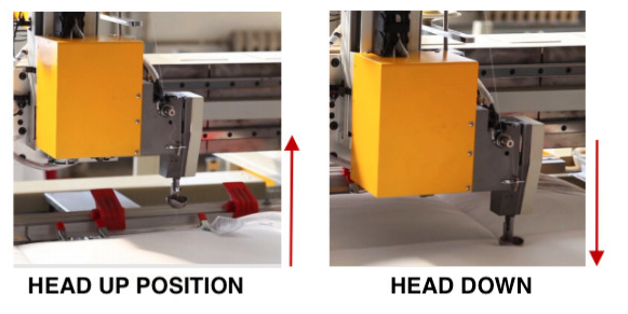

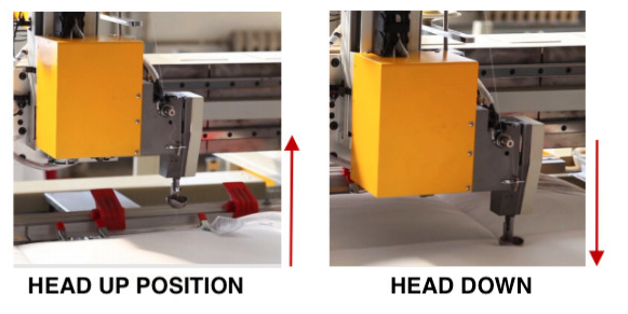

2. HEAD LIFT-UP 15CM.

- SEWING HEAD LIFT UP AUTOMATICALLY UP TO 15CM AFTER FINISHING QUILTING.

- EASY TO CHANGE THE FRAME AT ANY STOP POINT, EASIER MOVE HEAD FOR JUMP PATTERN, AND THICKER MATERIAL PATTERN.

- ABLE TO WORK 2 SMALL QUILT JUMP FROM ONE TO ANOTHER FROM THE ALUMINUM BORDER FRAME.

3. MACHINE SPEED: 3000RPM

- HIGH SPEED MACHINE WORKING UP TO 3000RPM.

- MASS PRODUCTION WORKING SPEED 2600 TO 2800RPM.

- STABLE AND PRECISE QUILTING AT HIGH SPEED.

VIDEOS AVAILABLE

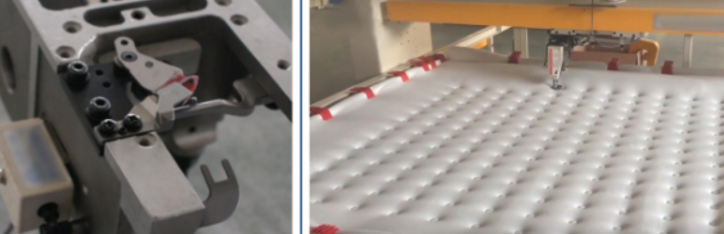

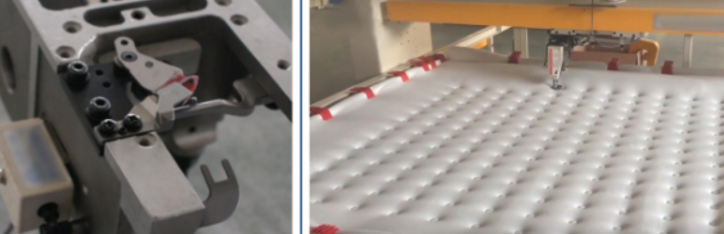

4. AUTOMATIC THREAD CUTTER

- STABLE AND RELIABLE MOVABLE KNIFE CUTTING SYSTEM.

- CUT UPPER THREAD AND BOBBIN THREAD AUTOMATICALLY FOR JUMP PATTERN.

3. MACHINE SPEED: 3000RPM

- HIGH SPEED MACHINE WORKING UP TO 3000RPM.

- MASS PRODUCTION WORKING SPEED 2600 TO 2800RPM.

- STABLE AND PRECISE QUILTING AT HIGH SPEED.

VIDEOS AVAILABLE

4. AUTOMATIC THREAD CUTTER

- STABLE AND RELIABLE MOVABLE KNIFE CUTTING SYSTEM.

- CUT UPPER THREAD AND BOBBIN THREAD AUTOMATICALLY FOR JUMP PATTERN.

5. WALKING PRESSER FOOT

- WALKING PRESSER FOOT TECHNOLOGY, PRESS MATERIAL TIGHTLY BEFORE NEEDLE POINT PIERCING INTO FABRIC.

- ENSURE THE BEST STITCH QUALITY AND PATTERN PRECISION.

- SUITABLE FOR HEAVY MATERIAL QUILTING.

5. WALKING PRESSER FOOT

- WALKING PRESSER FOOT TECHNOLOGY, PRESS MATERIAL TIGHTLY BEFORE NEEDLE POINT PIERCING INTO FABRIC.

- ENSURE THE BEST STITCH QUALITY AND PATTERN PRECISION.

- SUITABLE FOR HEAVY MATERIAL QUILTING.

6. LINEAR GUIDEWAY

- OUR LINEAR GUIDEWAY FOR MACHINE HEAD, HOOK CASE, AND BRIDGE LINEAR MOTION SMOOTHLY AT HIGH SPEED.

- ACHIEVE HIGH PRECISION AND GREATLY ENHANCED NEEDLE AND HOOK MOVING ACCURACY. ENSURE STABLE AND QUIET AND LONG-LIFE WORK AT HIGH-SPEED RUNNING CONDITION.

- HIGH RIGIDITY GUIDEWAY BLOCKS OFFER EQUAL LOAD AND SELF-ALIGN TO ABSORB INSTALLATION ERROR, OFFER HIGH QUALITY STITCH PATTERN IN ANY SHAPE, ANGLES, SIZE AND STITCH IN ANY DIRECTION.

6. LINEAR GUIDEWAY

- OUR LINEAR GUIDEWAY FOR MACHINE HEAD, HOOK CASE, AND BRIDGE LINEAR MOTION SMOOTHLY AT HIGH SPEED.

- ACHIEVE HIGH PRECISION AND GREATLY ENHANCED NEEDLE AND HOOK MOVING ACCURACY. ENSURE STABLE AND QUIET AND LONG-LIFE WORK AT HIGH-SPEED RUNNING CONDITION.

- HIGH RIGIDITY GUIDEWAY BLOCKS OFFER EQUAL LOAD AND SELF-ALIGN TO ABSORB INSTALLATION ERROR, OFFER HIGH QUALITY STITCH PATTERN IN ANY SHAPE, ANGLES, SIZE AND STITCH IN ANY DIRECTION.

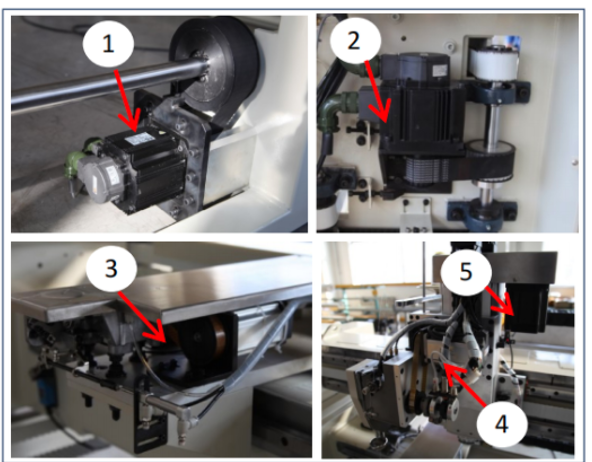

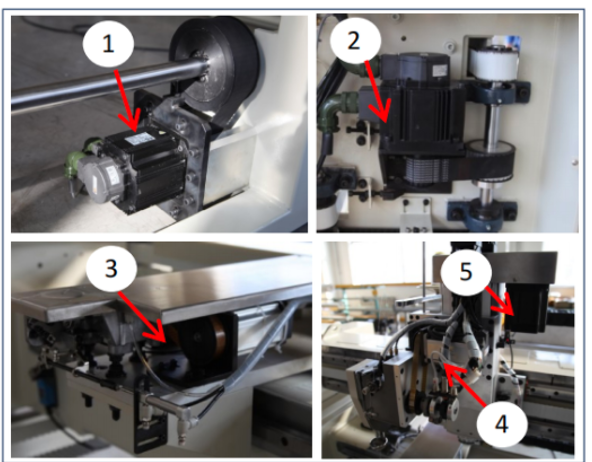

7. 5 PANASONIC SERVO MOTORS

- ALL MACHINE’S MOVEMENTS ARE DRIVEN BY 5 PIECES OF PANASONIC SERVO MOTORS, WHICH PROVIDE POWERFUL AND ACCURATE DRIVING FORCE.

- HEAD & HOOK CASE MOVING, BRIDGE MOVING BY SERVO MOTORS.

- NEEDLE SEWING AND HOOK ROTARY DRIVEN BY 2 SEPARATED SERVO MOTOR AND SYNCHRONIZING BY THE COMPUTER CONTROL SYSTEM, MAXIMUM THE WORKING AREA UP TO 3.2 METERS, WITH HIGH PRECISION AT ANY POINT OF THE QUILTING AREA.

- ELECTRONIC SYNCHRONIZE HEAD AND HOOK SET WORKING PRINCIPLE AVOID THE DISADVANTAGES OF MECHANIC WEARING, KEEP MACHINE STITCH PRECISE AFTER LONG WORKING TIME.

7. 5 PANASONIC SERVO MOTORS

- ALL MACHINE’S MOVEMENTS ARE DRIVEN BY 5 PIECES OF PANASONIC SERVO MOTORS, WHICH PROVIDE POWERFUL AND ACCURATE DRIVING FORCE.

- HEAD & HOOK CASE MOVING, BRIDGE MOVING BY SERVO MOTORS.

- NEEDLE SEWING AND HOOK ROTARY DRIVEN BY 2 SEPARATED SERVO MOTOR AND SYNCHRONIZING BY THE COMPUTER CONTROL SYSTEM, MAXIMUM THE WORKING AREA UP TO 3.2 METERS, WITH HIGH PRECISION AT ANY POINT OF THE QUILTING AREA.

- ELECTRONIC SYNCHRONIZE HEAD AND HOOK SET WORKING PRINCIPLE AVOID THE DISADVANTAGES OF MECHANIC WEARING, KEEP MACHINE STITCH PRECISE AFTER LONG WORKING TIME.

8. IGUS CABLE CARRIER

- GERMAN IGUS ENERGY CHAINS FOR HEAD AND HOOK CASE MOVE, BRIDGE MOVE AND HEAD UP/DOWN.

- IGUS SIGNAL CABLE FOR MAIN DATA TRANSFER.

- FLEXIBLE AND DURABLE PROTECT COMPUTER WIRES OFFER STABLE WORKING, PROLONG CABLE LIFE SPAN.

8. IGUS CABLE CARRIER

- GERMAN IGUS ENERGY CHAINS FOR HEAD AND HOOK CASE MOVE, BRIDGE MOVE AND HEAD UP/DOWN.

- IGUS SIGNAL CABLE FOR MAIN DATA TRANSFER.

- FLEXIBLE AND DURABLE PROTECT COMPUTER WIRES OFFER STABLE WORKING, PROLONG CABLE LIFE SPAN.

9. DRIVING BELT

- ITALY MADE FAMOUS BRAND BELT FOR HEAD, BRIDGE AND HOOK CASE MOVING.

- HIGH STRENGTH STEEL CORDS INSIDE THE BELT, TOP FLEXIBILITY AND LOW ELONGATION.

- FAMOUS BRAND JAPAN MADE BELT FOR MOTOR OR NEEDLE, HOOK DRIVING.

- QUALITY BELTS WITH HIGH LEVELS OF WEAR RESISTANCE, BETTER STRENGTH, PRECISION DRIVE, NOISELESS AND LONG WORKING LIFE.

9. DRIVING BELT

- ITALY MADE FAMOUS BRAND BELT FOR HEAD, BRIDGE AND HOOK CASE MOVING.

- HIGH STRENGTH STEEL CORDS INSIDE THE BELT, TOP FLEXIBILITY AND LOW ELONGATION.

- FAMOUS BRAND JAPAN MADE BELT FOR MOTOR OR NEEDLE, HOOK DRIVING.

- QUALITY BELTS WITH HIGH LEVELS OF WEAR RESISTANCE, BETTER STRENGTH, PRECISION DRIVE, NOISELESS AND LONG WORKING LIFE.

10. QUALITY BEARING

- QUALITY BEARING MADE IN JAPAN IS EQUIPPED FOR WHOLE MACHINE.

- ALL BEARING HOLDERS ARE JAPAN MADE.

- SUPER PRECISION, LONG-LIFE USE AND ANTI-WEARING. INCREASE THE MACHINE RELIABILITY AND DURABILITY.

10. QUALITY BEARING

- QUALITY BEARING MADE IN JAPAN IS EQUIPPED FOR WHOLE MACHINE.

- ALL BEARING HOLDERS ARE JAPAN MADE.

- SUPER PRECISION, LONG-LIFE USE AND ANTI-WEARING. INCREASE THE MACHINE RELIABILITY AND DURABILITY.

11. PNEUMATIC PARTS

- JAPAN BRAND FILTER, FLOW AND PRESSURE CONTROL, FITTING AND AIR TUBES.

- AIR VALVES AND TUBES.

- AUTOMATIC ALARMING FUNCTION IN CASE AIR PRESSER IS LOWER UNDER SAFETY LEVEL.

11. PNEUMATIC PARTS

- JAPAN BRAND FILTER, FLOW AND PRESSURE CONTROL, FITTING AND AIR TUBES.

- AIR VALVES AND TUBES.

- AUTOMATIC ALARMING FUNCTION IN CASE AIR PRESSER IS LOWER UNDER SAFETY LEVEL.

12. 100% ORIGINAL HOOKS

- IMPORTED HOOK SET ORIGINALLY MADE IN JAPAN.

- JUMBO SIZE HOOK AND BOBBIN CONTAIN MORE BOBBIN THREAD.

- ORIGINAL BOBBIN MADE IN JAPAN.

12. 100% ORIGINAL HOOKS

- IMPORTED HOOK SET ORIGINALLY MADE IN JAPAN.

- JUMBO SIZE HOOK AND BOBBIN CONTAIN MORE BOBBIN THREAD.

- ORIGINAL BOBBIN MADE IN JAPAN.

13. ATOMIZATION LUBRICATION

- OIL ATOMIZER LUBRICATION SYSTEM PROGRAMABLE LUBRICATE TIME THEN OILING AUTOMATICALLY, OR PRESS KEY FOR MANUAL LUBRICATE.

- AUTOMATIC OILING MOVING PARTS BY A MIST OF OIL, MAKE OIL COATING TO PARTS, WORKING MORE SMOOTHLY UNDER HIGH SPEED AND CONTINUOUSLY WORKING CONDITION.

- AVOID LIQUID OR GREASE OILING PROBLEM OF OIL DROP THEN POLLUTION TO FABRIC MATERIAL.

- WITH TRANSPARENT BOWL GUARD, ALLOWING 360O MONITORING OIL LEVEL.

13. ATOMIZATION LUBRICATION

- OIL ATOMIZER LUBRICATION SYSTEM PROGRAMABLE LUBRICATE TIME THEN OILING AUTOMATICALLY, OR PRESS KEY FOR MANUAL LUBRICATE.

- AUTOMATIC OILING MOVING PARTS BY A MIST OF OIL, MAKE OIL COATING TO PARTS, WORKING MORE SMOOTHLY UNDER HIGH SPEED AND CONTINUOUSLY WORKING CONDITION.

- AVOID LIQUID OR GREASE OILING PROBLEM OF OIL DROP THEN POLLUTION TO FABRIC MATERIAL.

- WITH TRANSPARENT BOWL GUARD, ALLOWING 360O MONITORING OIL LEVEL.

14. RELIABLE COMPONENTS

- ALL COMPONENTS ARE SUPPLIED BY FAMOUS INTERNATIONAL BRANDS, RELIABLE AND TOP-QUALITY STANDARD.

- OMRON BRAND APPROACHING SWITCHES, PROTECT WORKING SAFETY. DATASENSOR GERMANY SENSORS.

- SCHNEIDER BRAND ELECTRONIC PARTS & SWITCHES.

- DELTA PLC, TRANSFORMER AND INTERFACE.

14. RELIABLE COMPONENTS

- ALL COMPONENTS ARE SUPPLIED BY FAMOUS INTERNATIONAL BRANDS, RELIABLE AND TOP-QUALITY STANDARD.

- OMRON BRAND APPROACHING SWITCHES, PROTECT WORKING SAFETY. DATASENSOR GERMANY SENSORS.

- SCHNEIDER BRAND ELECTRONIC PARTS & SWITCHES.

- DELTA PLC, TRANSFORMER AND INTERFACE.

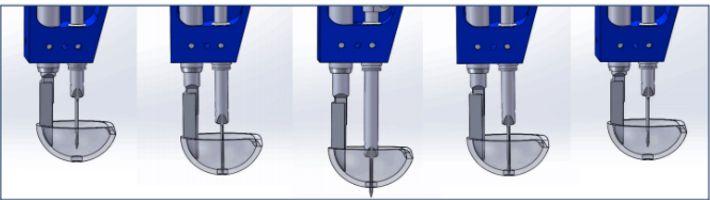

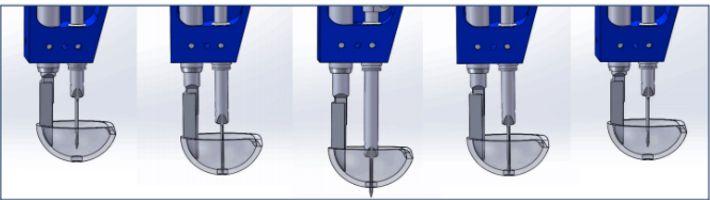

15. HOOK CLEARANCE DESIGN

- SAFETY CLEARANCE DESIGN BETWEEN HOOK POINT TO NEEDLE POINT THANKS TO ALL HIGH PRECISION AND QUALITY PARTS MOUNTED ON MACHINE.

- SILENCE WORKING AT HIGH SPEED, REDUCE HOOK AND NEEDLE WEARING AND EXTEND HOOK WORKING LIFE.

15. HOOK CLEARANCE DESIGN

- SAFETY CLEARANCE DESIGN BETWEEN HOOK POINT TO NEEDLE POINT THANKS TO ALL HIGH PRECISION AND QUALITY PARTS MOUNTED ON MACHINE.

- SILENCE WORKING AT HIGH SPEED, REDUCE HOOK AND NEEDLE WEARING AND EXTEND HOOK WORKING LIFE.

16. 10.4 INCHES COMPUTER

- 10.4 INCHES TOUCHING SCREEN COMPUTER, USER FRIENDLY.

- EASIER AND SIMPLIFY OPERATION, RELIABLE COMPUTER CONTROL SYSTEM.

COMPUTER FUNCTIONS:

1. AUTOMATIC THREAD TRIMMING FUNCTION.

2. THREAD BREAKAGE DETECTION, MACHINE WILL AUTOMATICALLY STOP ONCE THREAD GETS BROKEN.

3. REMEMBER STOP POSITION AND AUTOMATICALLY BACK TO THE STOPPING POINT TO CONTINUE SEWING.

4. EMERGENCY STOP BY ONE PUSH ON BUTTON.

5. ENHANCING SEWING BY BACK STITCHES WHEN START OR FINISH A PATTERN.

6. STITCH LENGTH DEFINABLE, ANGLE COMPENSATION, PATTERN ZOON IN/OUT.

7. SPEED AUTOMATIC ADJUSTABLE CONTROL, ABLE TO MAKE SHARP ANGEL OR CONTROL SEWING QUALITY AS DEMANDS.

8. AUTOMATIC NEEDLE & ROTARY HOOK POSITIONING ADJUSTMENT CONTROL BY COMPUTER TO ENSURE HIGH PRECISION STITCH QUALITY.

9. JUMP QUILTING FUNCTION FOR INDEPENDENT DESIGN.

10. STITCH STATISTIC TO COUNT MACHINE OUTPUT.

11. SET BOBBIN CHANGE TIME BY STITCH OR SHEET NUMBER, MACHINE STOP AUTOMATICALLY TO CHANGE BOBBIN BEFORE BOBBIN THREAD RUN OUT.

12. STORAGE CAPACITY IS 300.000 STITCHES UP TO 200 PATTERNS.

13. SUPPORT POPULAR QUILTING DESIGN FORMATS.

14. ENGLISH AND OTHER SPECIAL LANGUAGES ARE AVAILABLE UPON REQUEST.

15. POWER FAILURE PROTECTION.

16. USB OR WIFI (OPTIONAL) INPUT PATTERN, LARGE SIZE PATTERN CAN BE READ.

OPTIONAL CONFIGURATION:

1. SAFETY PROTECTION

- INFRARED FACILITY INCREASES SAFETY FACTOR (OPTION).

- WORKING AREA PROTECTION FROM TWO SIDE AND BACK SIDE OF MACHINE.

16. 10.4 INCHES COMPUTER

- 10.4 INCHES TOUCHING SCREEN COMPUTER, USER FRIENDLY.

- EASIER AND SIMPLIFY OPERATION, RELIABLE COMPUTER CONTROL SYSTEM.

COMPUTER FUNCTIONS:

1. AUTOMATIC THREAD TRIMMING FUNCTION.

2. THREAD BREAKAGE DETECTION, MACHINE WILL AUTOMATICALLY STOP ONCE THREAD GETS BROKEN.

3. REMEMBER STOP POSITION AND AUTOMATICALLY BACK TO THE STOPPING POINT TO CONTINUE SEWING.

4. EMERGENCY STOP BY ONE PUSH ON BUTTON.

5. ENHANCING SEWING BY BACK STITCHES WHEN START OR FINISH A PATTERN.

6. STITCH LENGTH DEFINABLE, ANGLE COMPENSATION, PATTERN ZOON IN/OUT.

7. SPEED AUTOMATIC ADJUSTABLE CONTROL, ABLE TO MAKE SHARP ANGEL OR CONTROL SEWING QUALITY AS DEMANDS.

8. AUTOMATIC NEEDLE & ROTARY HOOK POSITIONING ADJUSTMENT CONTROL BY COMPUTER TO ENSURE HIGH PRECISION STITCH QUALITY.

9. JUMP QUILTING FUNCTION FOR INDEPENDENT DESIGN.

10. STITCH STATISTIC TO COUNT MACHINE OUTPUT.

11. SET BOBBIN CHANGE TIME BY STITCH OR SHEET NUMBER, MACHINE STOP AUTOMATICALLY TO CHANGE BOBBIN BEFORE BOBBIN THREAD RUN OUT.

12. STORAGE CAPACITY IS 300.000 STITCHES UP TO 200 PATTERNS.

13. SUPPORT POPULAR QUILTING DESIGN FORMATS.

14. ENGLISH AND OTHER SPECIAL LANGUAGES ARE AVAILABLE UPON REQUEST.

15. POWER FAILURE PROTECTION.

16. USB OR WIFI (OPTIONAL) INPUT PATTERN, LARGE SIZE PATTERN CAN BE READ.

OPTIONAL CONFIGURATION:

1. SAFETY PROTECTION

- INFRARED FACILITY INCREASES SAFETY FACTOR (OPTION).

- WORKING AREA PROTECTION FROM TWO SIDE AND BACK SIDE OF MACHINE.

2. EASY FRAME CHANGER

- DOUBLE LAYERS FRAME CHANGER, FOR PREPARING MATERIAL AND CHANGE QUILT FRAMES EASILY.

- ADJUSTABLE AND EXTENDABLE ALUMINUM QUILTING FRAMES, THE SIZE OF FRAME CAN BE ADJUSTED FREELY ACCORDING THE PRODUCTION DEMAND.

2. EASY FRAME CHANGER

- DOUBLE LAYERS FRAME CHANGER, FOR PREPARING MATERIAL AND CHANGE QUILT FRAMES EASILY.

- ADJUSTABLE AND EXTENDABLE ALUMINUM QUILTING FRAMES, THE SIZE OF FRAME CAN BE ADJUSTED FREELY ACCORDING THE PRODUCTION DEMAND.

VIDEO AVAILABLE

3. AUTOMATIC FRAME CHANGER

- FRAME UP & DOWN DRIVE BY MOTORS AUTOMATICALLY.

- EASY TO FEED QUILT FRAMES TO THE QUILTING MACHINE WITH JUST A BREEZE PUSH.

- OPERATE BY ONE PERSON EASILY WHICH DECREASE THE WORKLOAD.

VIDEO AVAILABLE

3. AUTOMATIC FRAME CHANGER

- FRAME UP & DOWN DRIVE BY MOTORS AUTOMATICALLY.

- EASY TO FEED QUILT FRAMES TO THE QUILTING MACHINE WITH JUST A BREEZE PUSH.

- OPERATE BY ONE PERSON EASILY WHICH DECREASE THE WORKLOAD.

VIDEO AVAILABLE

4. WIFI/USB PATTERN TRANSFER

- [OPTIONAL] WIFI PATTERN TRANSFER DEVICES, ABLE TO TRANSFER PATTERNS DIRECTLY FROM OFFICE COMPUTER CONTROL SYSTEM TO QUILTING MACHINE.

- ALTERNATIVE PATTERN TRANSFER BY USB KEY.

VIDEO AVAILABLE

4. WIFI/USB PATTERN TRANSFER

- [OPTIONAL] WIFI PATTERN TRANSFER DEVICES, ABLE TO TRANSFER PATTERNS DIRECTLY FROM OFFICE COMPUTER CONTROL SYSTEM TO QUILTING MACHINE.

- ALTERNATIVE PATTERN TRANSFER BY USB KEY.

5. BELT SUPPORT SYSTEM

- BELT SUPPORT SYSTEM AVAILABLE BASED ON 1:1 DESIGN QUILTING MACHINE, OFFER SUPPORT ON THE BACK SIDE OF QUILT, FLATTEN THE MATERIAL DURING WHOLE WORKING PROCESS.

- ESPECIALLY GOOD FOR PRODUCTION OF DOWN FILLED DUVET, MATTRESS TOP, OR SEPARATED FIBER FILLED COMFORTERS, SUCH AS WOOL, BALL FIBERS, PREVENT FILLING MATERIAL SLIP OR ACCUMULATION DURING QUILTING.

- HIGH PATTERN ACCURACY FOR HEAVY MATERIAL BUT HIGH PATTERN QUALITY PRODUCTS SUCH AS SOFA, FURNITURE QUILTING.

VIDEO AVAILABLE

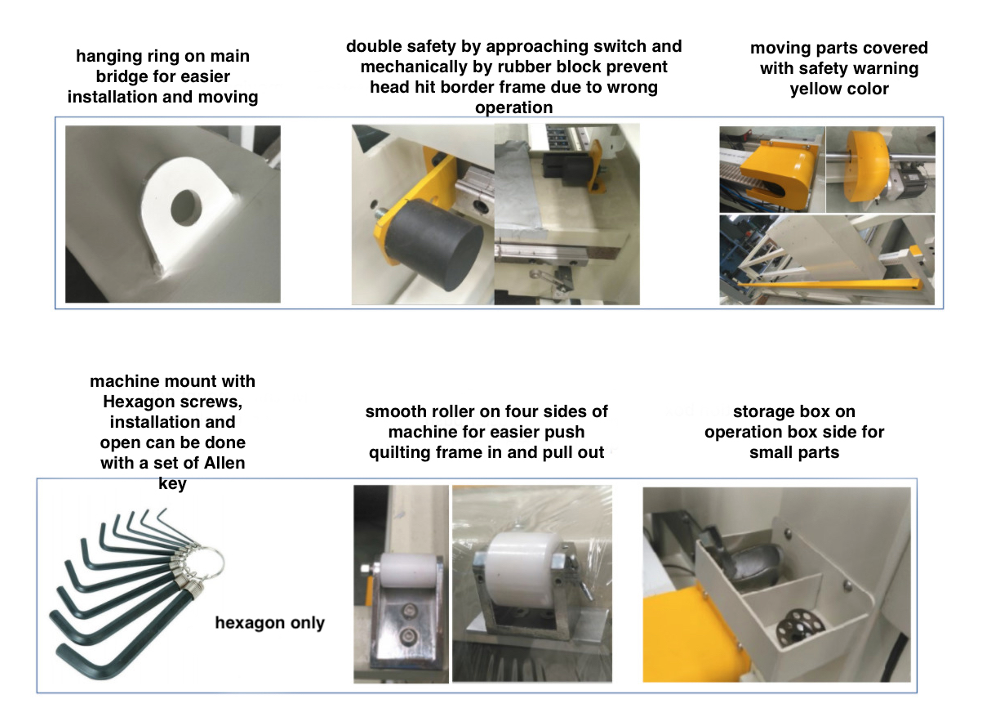

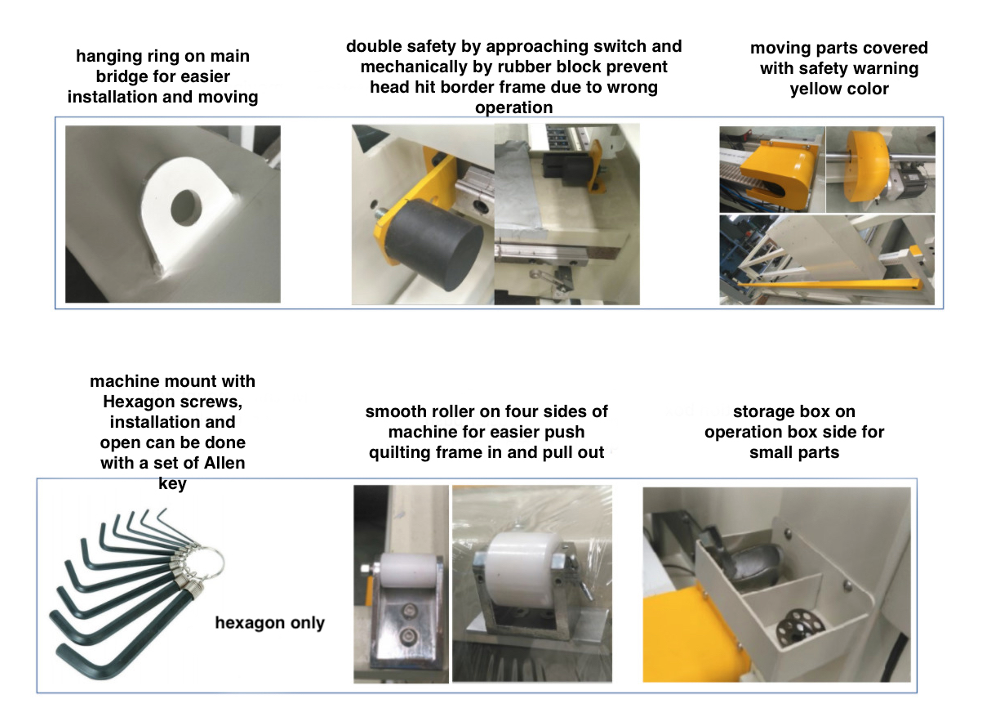

MORE MACHINE DETAILS, CARE OF USERS

5. BELT SUPPORT SYSTEM

- BELT SUPPORT SYSTEM AVAILABLE BASED ON 1:1 DESIGN QUILTING MACHINE, OFFER SUPPORT ON THE BACK SIDE OF QUILT, FLATTEN THE MATERIAL DURING WHOLE WORKING PROCESS.

- ESPECIALLY GOOD FOR PRODUCTION OF DOWN FILLED DUVET, MATTRESS TOP, OR SEPARATED FIBER FILLED COMFORTERS, SUCH AS WOOL, BALL FIBERS, PREVENT FILLING MATERIAL SLIP OR ACCUMULATION DURING QUILTING.

- HIGH PATTERN ACCURACY FOR HEAVY MATERIAL BUT HIGH PATTERN QUALITY PRODUCTS SUCH AS SOFA, FURNITURE QUILTING.

VIDEO AVAILABLE

MORE MACHINE DETAILS, CARE OF USERS

QUILTING DESIGN SOFTWARE

OUR PROFESSIONAL QUILTING DESIGN SYSTEM IS ESPECIALLY DEVELOPED FOR DESIGNING, PRODUCING AND SIMULATING OF COMPUTERIZED QUILTING PATTERNS.

- IT ENHANCES THE ESTABLISHING, SETTING, EDITING AND MANAGING ABILITY WHILE MAKING A QUILTING PATTERN, ALSO IT SAVES YOUR PRECIOUS TIME.

- ITS PROFESSIONAL DRAWING TOOLS ENABLES DESIGNING ALL KINDS OF COMPLICATED QUILTING PATTERNS.

- THE PRINTING AND SCANNING FUNCTIONS MAKE TO OBSERVE REALISTIC EFFECT AS EASY AS A BREEZE.

- A BUILD-IN DESIGN SOFTWARE IS INCLUDED IN COMPUTER CONTROL SYSTEM, CREATE OR EDIT SIMPLE PATTERNS FAST AND EASILY.

QUILTING PATTERNS:

- FREE PATTERN AVAILABLE, CONTACT WITH US TO GET FREE PATTERN BOOKS.

- MAKE ANY NEW DESIGN WITH OUR QUILTING CAD SYSTEM.

PATTERN AND SAMPLES:

THIS MACHINE IS WIDELY USED FOR PRODUCING ALL KINDS OF BEDDING PRODUCTS SUCH AS: BED QUILTS, COMFORTERS, BED COVER, BED MAT, SLEEPING BAGS, MATTRESS COVER, SOFA COVER ETC.

INSTALLATION DIAGRAM

SINGLE HEAD QUILTING MACHINE INSTALLATION FLOOR PLAN TOGETHER WITH AN EASY FRAME CHANGER. CONTACT US FOR DETAILS INSTRUCTION FILES.

QUANTITY: 1

QUILTING DESIGN SOFTWARE

OUR PROFESSIONAL QUILTING DESIGN SYSTEM IS ESPECIALLY DEVELOPED FOR DESIGNING, PRODUCING AND SIMULATING OF COMPUTERIZED QUILTING PATTERNS.

- IT ENHANCES THE ESTABLISHING, SETTING, EDITING AND MANAGING ABILITY WHILE MAKING A QUILTING PATTERN, ALSO IT SAVES YOUR PRECIOUS TIME.

- ITS PROFESSIONAL DRAWING TOOLS ENABLES DESIGNING ALL KINDS OF COMPLICATED QUILTING PATTERNS.

- THE PRINTING AND SCANNING FUNCTIONS MAKE TO OBSERVE REALISTIC EFFECT AS EASY AS A BREEZE.

- A BUILD-IN DESIGN SOFTWARE IS INCLUDED IN COMPUTER CONTROL SYSTEM, CREATE OR EDIT SIMPLE PATTERNS FAST AND EASILY.

QUILTING PATTERNS:

- FREE PATTERN AVAILABLE, CONTACT WITH US TO GET FREE PATTERN BOOKS.

- MAKE ANY NEW DESIGN WITH OUR QUILTING CAD SYSTEM.

PATTERN AND SAMPLES:

THIS MACHINE IS WIDELY USED FOR PRODUCING ALL KINDS OF BEDDING PRODUCTS SUCH AS: BED QUILTS, COMFORTERS, BED COVER, BED MAT, SLEEPING BAGS, MATTRESS COVER, SOFA COVER ETC.

INSTALLATION DIAGRAM

SINGLE HEAD QUILTING MACHINE INSTALLATION FLOOR PLAN TOGETHER WITH AN EASY FRAME CHANGER. CONTACT US FOR DETAILS INSTRUCTION FILES.

QUANTITY: 1

3. MACHINE SPEED: 3000RPM

- HIGH SPEED MACHINE WORKING UP TO 3000RPM.

- MASS PRODUCTION WORKING SPEED 2600 TO 2800RPM.

- STABLE AND PRECISE QUILTING AT HIGH SPEED.

VIDEOS AVAILABLE

4. AUTOMATIC THREAD CUTTER

- STABLE AND RELIABLE MOVABLE KNIFE CUTTING SYSTEM.

- CUT UPPER THREAD AND BOBBIN THREAD AUTOMATICALLY FOR JUMP PATTERN.

3. MACHINE SPEED: 3000RPM

- HIGH SPEED MACHINE WORKING UP TO 3000RPM.

- MASS PRODUCTION WORKING SPEED 2600 TO 2800RPM.

- STABLE AND PRECISE QUILTING AT HIGH SPEED.

VIDEOS AVAILABLE

4. AUTOMATIC THREAD CUTTER

- STABLE AND RELIABLE MOVABLE KNIFE CUTTING SYSTEM.

- CUT UPPER THREAD AND BOBBIN THREAD AUTOMATICALLY FOR JUMP PATTERN.

5. WALKING PRESSER FOOT

- WALKING PRESSER FOOT TECHNOLOGY, PRESS MATERIAL TIGHTLY BEFORE NEEDLE POINT PIERCING INTO FABRIC.

- ENSURE THE BEST STITCH QUALITY AND PATTERN PRECISION.

- SUITABLE FOR HEAVY MATERIAL QUILTING.

5. WALKING PRESSER FOOT

- WALKING PRESSER FOOT TECHNOLOGY, PRESS MATERIAL TIGHTLY BEFORE NEEDLE POINT PIERCING INTO FABRIC.

- ENSURE THE BEST STITCH QUALITY AND PATTERN PRECISION.

- SUITABLE FOR HEAVY MATERIAL QUILTING.

6. LINEAR GUIDEWAY

- OUR LINEAR GUIDEWAY FOR MACHINE HEAD, HOOK CASE, AND BRIDGE LINEAR MOTION SMOOTHLY AT HIGH SPEED.

- ACHIEVE HIGH PRECISION AND GREATLY ENHANCED NEEDLE AND HOOK MOVING ACCURACY. ENSURE STABLE AND QUIET AND LONG-LIFE WORK AT HIGH-SPEED RUNNING CONDITION.

- HIGH RIGIDITY GUIDEWAY BLOCKS OFFER EQUAL LOAD AND SELF-ALIGN TO ABSORB INSTALLATION ERROR, OFFER HIGH QUALITY STITCH PATTERN IN ANY SHAPE, ANGLES, SIZE AND STITCH IN ANY DIRECTION.

6. LINEAR GUIDEWAY

- OUR LINEAR GUIDEWAY FOR MACHINE HEAD, HOOK CASE, AND BRIDGE LINEAR MOTION SMOOTHLY AT HIGH SPEED.

- ACHIEVE HIGH PRECISION AND GREATLY ENHANCED NEEDLE AND HOOK MOVING ACCURACY. ENSURE STABLE AND QUIET AND LONG-LIFE WORK AT HIGH-SPEED RUNNING CONDITION.

- HIGH RIGIDITY GUIDEWAY BLOCKS OFFER EQUAL LOAD AND SELF-ALIGN TO ABSORB INSTALLATION ERROR, OFFER HIGH QUALITY STITCH PATTERN IN ANY SHAPE, ANGLES, SIZE AND STITCH IN ANY DIRECTION.

7. 5 PANASONIC SERVO MOTORS

- ALL MACHINE’S MOVEMENTS ARE DRIVEN BY 5 PIECES OF PANASONIC SERVO MOTORS, WHICH PROVIDE POWERFUL AND ACCURATE DRIVING FORCE.

- HEAD & HOOK CASE MOVING, BRIDGE MOVING BY SERVO MOTORS.

- NEEDLE SEWING AND HOOK ROTARY DRIVEN BY 2 SEPARATED SERVO MOTOR AND SYNCHRONIZING BY THE COMPUTER CONTROL SYSTEM, MAXIMUM THE WORKING AREA UP TO 3.2 METERS, WITH HIGH PRECISION AT ANY POINT OF THE QUILTING AREA.

- ELECTRONIC SYNCHRONIZE HEAD AND HOOK SET WORKING PRINCIPLE AVOID THE DISADVANTAGES OF MECHANIC WEARING, KEEP MACHINE STITCH PRECISE AFTER LONG WORKING TIME.

7. 5 PANASONIC SERVO MOTORS

- ALL MACHINE’S MOVEMENTS ARE DRIVEN BY 5 PIECES OF PANASONIC SERVO MOTORS, WHICH PROVIDE POWERFUL AND ACCURATE DRIVING FORCE.

- HEAD & HOOK CASE MOVING, BRIDGE MOVING BY SERVO MOTORS.

- NEEDLE SEWING AND HOOK ROTARY DRIVEN BY 2 SEPARATED SERVO MOTOR AND SYNCHRONIZING BY THE COMPUTER CONTROL SYSTEM, MAXIMUM THE WORKING AREA UP TO 3.2 METERS, WITH HIGH PRECISION AT ANY POINT OF THE QUILTING AREA.

- ELECTRONIC SYNCHRONIZE HEAD AND HOOK SET WORKING PRINCIPLE AVOID THE DISADVANTAGES OF MECHANIC WEARING, KEEP MACHINE STITCH PRECISE AFTER LONG WORKING TIME.

8. IGUS CABLE CARRIER

- GERMAN IGUS ENERGY CHAINS FOR HEAD AND HOOK CASE MOVE, BRIDGE MOVE AND HEAD UP/DOWN.

- IGUS SIGNAL CABLE FOR MAIN DATA TRANSFER.

- FLEXIBLE AND DURABLE PROTECT COMPUTER WIRES OFFER STABLE WORKING, PROLONG CABLE LIFE SPAN.

8. IGUS CABLE CARRIER

- GERMAN IGUS ENERGY CHAINS FOR HEAD AND HOOK CASE MOVE, BRIDGE MOVE AND HEAD UP/DOWN.

- IGUS SIGNAL CABLE FOR MAIN DATA TRANSFER.

- FLEXIBLE AND DURABLE PROTECT COMPUTER WIRES OFFER STABLE WORKING, PROLONG CABLE LIFE SPAN.

9. DRIVING BELT

- ITALY MADE FAMOUS BRAND BELT FOR HEAD, BRIDGE AND HOOK CASE MOVING.

- HIGH STRENGTH STEEL CORDS INSIDE THE BELT, TOP FLEXIBILITY AND LOW ELONGATION.

- FAMOUS BRAND JAPAN MADE BELT FOR MOTOR OR NEEDLE, HOOK DRIVING.

- QUALITY BELTS WITH HIGH LEVELS OF WEAR RESISTANCE, BETTER STRENGTH, PRECISION DRIVE, NOISELESS AND LONG WORKING LIFE.

9. DRIVING BELT

- ITALY MADE FAMOUS BRAND BELT FOR HEAD, BRIDGE AND HOOK CASE MOVING.

- HIGH STRENGTH STEEL CORDS INSIDE THE BELT, TOP FLEXIBILITY AND LOW ELONGATION.

- FAMOUS BRAND JAPAN MADE BELT FOR MOTOR OR NEEDLE, HOOK DRIVING.

- QUALITY BELTS WITH HIGH LEVELS OF WEAR RESISTANCE, BETTER STRENGTH, PRECISION DRIVE, NOISELESS AND LONG WORKING LIFE.

10. QUALITY BEARING

- QUALITY BEARING MADE IN JAPAN IS EQUIPPED FOR WHOLE MACHINE.

- ALL BEARING HOLDERS ARE JAPAN MADE.

- SUPER PRECISION, LONG-LIFE USE AND ANTI-WEARING. INCREASE THE MACHINE RELIABILITY AND DURABILITY.

10. QUALITY BEARING

- QUALITY BEARING MADE IN JAPAN IS EQUIPPED FOR WHOLE MACHINE.

- ALL BEARING HOLDERS ARE JAPAN MADE.

- SUPER PRECISION, LONG-LIFE USE AND ANTI-WEARING. INCREASE THE MACHINE RELIABILITY AND DURABILITY.

11. PNEUMATIC PARTS

- JAPAN BRAND FILTER, FLOW AND PRESSURE CONTROL, FITTING AND AIR TUBES.

- AIR VALVES AND TUBES.

- AUTOMATIC ALARMING FUNCTION IN CASE AIR PRESSER IS LOWER UNDER SAFETY LEVEL.

11. PNEUMATIC PARTS

- JAPAN BRAND FILTER, FLOW AND PRESSURE CONTROL, FITTING AND AIR TUBES.

- AIR VALVES AND TUBES.

- AUTOMATIC ALARMING FUNCTION IN CASE AIR PRESSER IS LOWER UNDER SAFETY LEVEL.

12. 100% ORIGINAL HOOKS

- IMPORTED HOOK SET ORIGINALLY MADE IN JAPAN.

- JUMBO SIZE HOOK AND BOBBIN CONTAIN MORE BOBBIN THREAD.

- ORIGINAL BOBBIN MADE IN JAPAN.

12. 100% ORIGINAL HOOKS

- IMPORTED HOOK SET ORIGINALLY MADE IN JAPAN.

- JUMBO SIZE HOOK AND BOBBIN CONTAIN MORE BOBBIN THREAD.

- ORIGINAL BOBBIN MADE IN JAPAN.

13. ATOMIZATION LUBRICATION

- OIL ATOMIZER LUBRICATION SYSTEM PROGRAMABLE LUBRICATE TIME THEN OILING AUTOMATICALLY, OR PRESS KEY FOR MANUAL LUBRICATE.

- AUTOMATIC OILING MOVING PARTS BY A MIST OF OIL, MAKE OIL COATING TO PARTS, WORKING MORE SMOOTHLY UNDER HIGH SPEED AND CONTINUOUSLY WORKING CONDITION.

- AVOID LIQUID OR GREASE OILING PROBLEM OF OIL DROP THEN POLLUTION TO FABRIC MATERIAL.

- WITH TRANSPARENT BOWL GUARD, ALLOWING 360O MONITORING OIL LEVEL.

13. ATOMIZATION LUBRICATION

- OIL ATOMIZER LUBRICATION SYSTEM PROGRAMABLE LUBRICATE TIME THEN OILING AUTOMATICALLY, OR PRESS KEY FOR MANUAL LUBRICATE.

- AUTOMATIC OILING MOVING PARTS BY A MIST OF OIL, MAKE OIL COATING TO PARTS, WORKING MORE SMOOTHLY UNDER HIGH SPEED AND CONTINUOUSLY WORKING CONDITION.

- AVOID LIQUID OR GREASE OILING PROBLEM OF OIL DROP THEN POLLUTION TO FABRIC MATERIAL.

- WITH TRANSPARENT BOWL GUARD, ALLOWING 360O MONITORING OIL LEVEL.

14. RELIABLE COMPONENTS

- ALL COMPONENTS ARE SUPPLIED BY FAMOUS INTERNATIONAL BRANDS, RELIABLE AND TOP-QUALITY STANDARD.

- OMRON BRAND APPROACHING SWITCHES, PROTECT WORKING SAFETY. DATASENSOR GERMANY SENSORS.

- SCHNEIDER BRAND ELECTRONIC PARTS & SWITCHES.

- DELTA PLC, TRANSFORMER AND INTERFACE.

14. RELIABLE COMPONENTS

- ALL COMPONENTS ARE SUPPLIED BY FAMOUS INTERNATIONAL BRANDS, RELIABLE AND TOP-QUALITY STANDARD.

- OMRON BRAND APPROACHING SWITCHES, PROTECT WORKING SAFETY. DATASENSOR GERMANY SENSORS.

- SCHNEIDER BRAND ELECTRONIC PARTS & SWITCHES.

- DELTA PLC, TRANSFORMER AND INTERFACE.

15. HOOK CLEARANCE DESIGN

- SAFETY CLEARANCE DESIGN BETWEEN HOOK POINT TO NEEDLE POINT THANKS TO ALL HIGH PRECISION AND QUALITY PARTS MOUNTED ON MACHINE.

- SILENCE WORKING AT HIGH SPEED, REDUCE HOOK AND NEEDLE WEARING AND EXTEND HOOK WORKING LIFE.

15. HOOK CLEARANCE DESIGN

- SAFETY CLEARANCE DESIGN BETWEEN HOOK POINT TO NEEDLE POINT THANKS TO ALL HIGH PRECISION AND QUALITY PARTS MOUNTED ON MACHINE.

- SILENCE WORKING AT HIGH SPEED, REDUCE HOOK AND NEEDLE WEARING AND EXTEND HOOK WORKING LIFE.

16. 10.4 INCHES COMPUTER

- 10.4 INCHES TOUCHING SCREEN COMPUTER, USER FRIENDLY.

- EASIER AND SIMPLIFY OPERATION, RELIABLE COMPUTER CONTROL SYSTEM.

COMPUTER FUNCTIONS:

1. AUTOMATIC THREAD TRIMMING FUNCTION.

2. THREAD BREAKAGE DETECTION, MACHINE WILL AUTOMATICALLY STOP ONCE THREAD GETS BROKEN.

3. REMEMBER STOP POSITION AND AUTOMATICALLY BACK TO THE STOPPING POINT TO CONTINUE SEWING.

4. EMERGENCY STOP BY ONE PUSH ON BUTTON.

5. ENHANCING SEWING BY BACK STITCHES WHEN START OR FINISH A PATTERN.

6. STITCH LENGTH DEFINABLE, ANGLE COMPENSATION, PATTERN ZOON IN/OUT.

7. SPEED AUTOMATIC ADJUSTABLE CONTROL, ABLE TO MAKE SHARP ANGEL OR CONTROL SEWING QUALITY AS DEMANDS.

8. AUTOMATIC NEEDLE & ROTARY HOOK POSITIONING ADJUSTMENT CONTROL BY COMPUTER TO ENSURE HIGH PRECISION STITCH QUALITY.

9. JUMP QUILTING FUNCTION FOR INDEPENDENT DESIGN.

10. STITCH STATISTIC TO COUNT MACHINE OUTPUT.

11. SET BOBBIN CHANGE TIME BY STITCH OR SHEET NUMBER, MACHINE STOP AUTOMATICALLY TO CHANGE BOBBIN BEFORE BOBBIN THREAD RUN OUT.

12. STORAGE CAPACITY IS 300.000 STITCHES UP TO 200 PATTERNS.

13. SUPPORT POPULAR QUILTING DESIGN FORMATS.

14. ENGLISH AND OTHER SPECIAL LANGUAGES ARE AVAILABLE UPON REQUEST.

15. POWER FAILURE PROTECTION.

16. USB OR WIFI (OPTIONAL) INPUT PATTERN, LARGE SIZE PATTERN CAN BE READ.

OPTIONAL CONFIGURATION:

1. SAFETY PROTECTION

- INFRARED FACILITY INCREASES SAFETY FACTOR (OPTION).

- WORKING AREA PROTECTION FROM TWO SIDE AND BACK SIDE OF MACHINE.

16. 10.4 INCHES COMPUTER

- 10.4 INCHES TOUCHING SCREEN COMPUTER, USER FRIENDLY.

- EASIER AND SIMPLIFY OPERATION, RELIABLE COMPUTER CONTROL SYSTEM.

COMPUTER FUNCTIONS:

1. AUTOMATIC THREAD TRIMMING FUNCTION.

2. THREAD BREAKAGE DETECTION, MACHINE WILL AUTOMATICALLY STOP ONCE THREAD GETS BROKEN.

3. REMEMBER STOP POSITION AND AUTOMATICALLY BACK TO THE STOPPING POINT TO CONTINUE SEWING.

4. EMERGENCY STOP BY ONE PUSH ON BUTTON.

5. ENHANCING SEWING BY BACK STITCHES WHEN START OR FINISH A PATTERN.

6. STITCH LENGTH DEFINABLE, ANGLE COMPENSATION, PATTERN ZOON IN/OUT.

7. SPEED AUTOMATIC ADJUSTABLE CONTROL, ABLE TO MAKE SHARP ANGEL OR CONTROL SEWING QUALITY AS DEMANDS.

8. AUTOMATIC NEEDLE & ROTARY HOOK POSITIONING ADJUSTMENT CONTROL BY COMPUTER TO ENSURE HIGH PRECISION STITCH QUALITY.

9. JUMP QUILTING FUNCTION FOR INDEPENDENT DESIGN.

10. STITCH STATISTIC TO COUNT MACHINE OUTPUT.

11. SET BOBBIN CHANGE TIME BY STITCH OR SHEET NUMBER, MACHINE STOP AUTOMATICALLY TO CHANGE BOBBIN BEFORE BOBBIN THREAD RUN OUT.

12. STORAGE CAPACITY IS 300.000 STITCHES UP TO 200 PATTERNS.

13. SUPPORT POPULAR QUILTING DESIGN FORMATS.

14. ENGLISH AND OTHER SPECIAL LANGUAGES ARE AVAILABLE UPON REQUEST.

15. POWER FAILURE PROTECTION.

16. USB OR WIFI (OPTIONAL) INPUT PATTERN, LARGE SIZE PATTERN CAN BE READ.

OPTIONAL CONFIGURATION:

1. SAFETY PROTECTION

- INFRARED FACILITY INCREASES SAFETY FACTOR (OPTION).

- WORKING AREA PROTECTION FROM TWO SIDE AND BACK SIDE OF MACHINE.

2. EASY FRAME CHANGER

- DOUBLE LAYERS FRAME CHANGER, FOR PREPARING MATERIAL AND CHANGE QUILT FRAMES EASILY.

- ADJUSTABLE AND EXTENDABLE ALUMINUM QUILTING FRAMES, THE SIZE OF FRAME CAN BE ADJUSTED FREELY ACCORDING THE PRODUCTION DEMAND.

2. EASY FRAME CHANGER

- DOUBLE LAYERS FRAME CHANGER, FOR PREPARING MATERIAL AND CHANGE QUILT FRAMES EASILY.

- ADJUSTABLE AND EXTENDABLE ALUMINUM QUILTING FRAMES, THE SIZE OF FRAME CAN BE ADJUSTED FREELY ACCORDING THE PRODUCTION DEMAND.

VIDEO AVAILABLE

3. AUTOMATIC FRAME CHANGER

- FRAME UP & DOWN DRIVE BY MOTORS AUTOMATICALLY.

- EASY TO FEED QUILT FRAMES TO THE QUILTING MACHINE WITH JUST A BREEZE PUSH.

- OPERATE BY ONE PERSON EASILY WHICH DECREASE THE WORKLOAD.

VIDEO AVAILABLE

3. AUTOMATIC FRAME CHANGER

- FRAME UP & DOWN DRIVE BY MOTORS AUTOMATICALLY.

- EASY TO FEED QUILT FRAMES TO THE QUILTING MACHINE WITH JUST A BREEZE PUSH.

- OPERATE BY ONE PERSON EASILY WHICH DECREASE THE WORKLOAD.

VIDEO AVAILABLE

4. WIFI/USB PATTERN TRANSFER

- [OPTIONAL] WIFI PATTERN TRANSFER DEVICES, ABLE TO TRANSFER PATTERNS DIRECTLY FROM OFFICE COMPUTER CONTROL SYSTEM TO QUILTING MACHINE.

- ALTERNATIVE PATTERN TRANSFER BY USB KEY.

VIDEO AVAILABLE

4. WIFI/USB PATTERN TRANSFER

- [OPTIONAL] WIFI PATTERN TRANSFER DEVICES, ABLE TO TRANSFER PATTERNS DIRECTLY FROM OFFICE COMPUTER CONTROL SYSTEM TO QUILTING MACHINE.

- ALTERNATIVE PATTERN TRANSFER BY USB KEY.

5. BELT SUPPORT SYSTEM

- BELT SUPPORT SYSTEM AVAILABLE BASED ON 1:1 DESIGN QUILTING MACHINE, OFFER SUPPORT ON THE BACK SIDE OF QUILT, FLATTEN THE MATERIAL DURING WHOLE WORKING PROCESS.

- ESPECIALLY GOOD FOR PRODUCTION OF DOWN FILLED DUVET, MATTRESS TOP, OR SEPARATED FIBER FILLED COMFORTERS, SUCH AS WOOL, BALL FIBERS, PREVENT FILLING MATERIAL SLIP OR ACCUMULATION DURING QUILTING.

- HIGH PATTERN ACCURACY FOR HEAVY MATERIAL BUT HIGH PATTERN QUALITY PRODUCTS SUCH AS SOFA, FURNITURE QUILTING.

VIDEO AVAILABLE

MORE MACHINE DETAILS, CARE OF USERS

5. BELT SUPPORT SYSTEM

- BELT SUPPORT SYSTEM AVAILABLE BASED ON 1:1 DESIGN QUILTING MACHINE, OFFER SUPPORT ON THE BACK SIDE OF QUILT, FLATTEN THE MATERIAL DURING WHOLE WORKING PROCESS.

- ESPECIALLY GOOD FOR PRODUCTION OF DOWN FILLED DUVET, MATTRESS TOP, OR SEPARATED FIBER FILLED COMFORTERS, SUCH AS WOOL, BALL FIBERS, PREVENT FILLING MATERIAL SLIP OR ACCUMULATION DURING QUILTING.

- HIGH PATTERN ACCURACY FOR HEAVY MATERIAL BUT HIGH PATTERN QUALITY PRODUCTS SUCH AS SOFA, FURNITURE QUILTING.

VIDEO AVAILABLE

MORE MACHINE DETAILS, CARE OF USERS

QUILTING DESIGN SOFTWARE

OUR PROFESSIONAL QUILTING DESIGN SYSTEM IS ESPECIALLY DEVELOPED FOR DESIGNING, PRODUCING AND SIMULATING OF COMPUTERIZED QUILTING PATTERNS.

- IT ENHANCES THE ESTABLISHING, SETTING, EDITING AND MANAGING ABILITY WHILE MAKING A QUILTING PATTERN, ALSO IT SAVES YOUR PRECIOUS TIME.

- ITS PROFESSIONAL DRAWING TOOLS ENABLES DESIGNING ALL KINDS OF COMPLICATED QUILTING PATTERNS.

- THE PRINTING AND SCANNING FUNCTIONS MAKE TO OBSERVE REALISTIC EFFECT AS EASY AS A BREEZE.

- A BUILD-IN DESIGN SOFTWARE IS INCLUDED IN COMPUTER CONTROL SYSTEM, CREATE OR EDIT SIMPLE PATTERNS FAST AND EASILY.

QUILTING PATTERNS:

- FREE PATTERN AVAILABLE, CONTACT WITH US TO GET FREE PATTERN BOOKS.

- MAKE ANY NEW DESIGN WITH OUR QUILTING CAD SYSTEM.

PATTERN AND SAMPLES:

THIS MACHINE IS WIDELY USED FOR PRODUCING ALL KINDS OF BEDDING PRODUCTS SUCH AS: BED QUILTS, COMFORTERS, BED COVER, BED MAT, SLEEPING BAGS, MATTRESS COVER, SOFA COVER ETC.

INSTALLATION DIAGRAM

SINGLE HEAD QUILTING MACHINE INSTALLATION FLOOR PLAN TOGETHER WITH AN EASY FRAME CHANGER. CONTACT US FOR DETAILS INSTRUCTION FILES.

QUANTITY: 1

QUILTING DESIGN SOFTWARE

OUR PROFESSIONAL QUILTING DESIGN SYSTEM IS ESPECIALLY DEVELOPED FOR DESIGNING, PRODUCING AND SIMULATING OF COMPUTERIZED QUILTING PATTERNS.

- IT ENHANCES THE ESTABLISHING, SETTING, EDITING AND MANAGING ABILITY WHILE MAKING A QUILTING PATTERN, ALSO IT SAVES YOUR PRECIOUS TIME.

- ITS PROFESSIONAL DRAWING TOOLS ENABLES DESIGNING ALL KINDS OF COMPLICATED QUILTING PATTERNS.

- THE PRINTING AND SCANNING FUNCTIONS MAKE TO OBSERVE REALISTIC EFFECT AS EASY AS A BREEZE.

- A BUILD-IN DESIGN SOFTWARE IS INCLUDED IN COMPUTER CONTROL SYSTEM, CREATE OR EDIT SIMPLE PATTERNS FAST AND EASILY.

QUILTING PATTERNS:

- FREE PATTERN AVAILABLE, CONTACT WITH US TO GET FREE PATTERN BOOKS.

- MAKE ANY NEW DESIGN WITH OUR QUILTING CAD SYSTEM.

PATTERN AND SAMPLES:

THIS MACHINE IS WIDELY USED FOR PRODUCING ALL KINDS OF BEDDING PRODUCTS SUCH AS: BED QUILTS, COMFORTERS, BED COVER, BED MAT, SLEEPING BAGS, MATTRESS COVER, SOFA COVER ETC.

INSTALLATION DIAGRAM

SINGLE HEAD QUILTING MACHINE INSTALLATION FLOOR PLAN TOGETHER WITH AN EASY FRAME CHANGER. CONTACT US FOR DETAILS INSTRUCTION FILES.

QUANTITY: 1

Write Your Own Review