Search results for: 'Operating sy'

- Related search terms

- Operating

- Operating s

- Operating system

- Operating sy'A=0

- operating sima 0

-

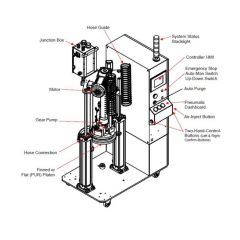

YY-2358 DM5 HOT MELT PAIL UNLOADERYY-2358 DM5 HOT MELT PAIL UNLOADER THE DM5 IS A STATIONARY PAIL MELTER (UNLOADER) THAT COMBINES A HEATED PLATEN, PUMP AND ALL CONTROLS NEEDED TO MELT AND DISPENSE HOT MELT ADHESIVES, SEALANTS, PURS OR COATINGS FROM A STANDARD 5-GALLON STEEL PAIL. THE CONTROLLER PROVIDES ACCURATE, PROPORTIONATE TEMPERATURE CONTROL FOR THE PLATEN, HOSES AND APPLICATORS. A “STANDBY” TEMPERATURE MAY BE PROGRAMMED SO THAT THE TEMPERATURE ZONES CAN BE INDEPENDENTLY MAINTAINED AT A LOWER TEMPERATURE WHEN THE UNIT IS NOT IN ACTIVE USE, ENABLING RAPID RETURN TO NORMAL OPERATION. A VARIETY OF GEAR PUMPS ARE AVAILABLE. THE MELTER CAN BE UTILIZED AS A BULK-TRANSFER UNIT OR AS A STAND-ALONE UNIT. IT CAN SUPPLY ONE OR TWO HAND-HELD APPLICATORS OR OTHER APPLICATORS. QUANTITY: 1 Learn More

YY-2358 DM5 HOT MELT PAIL UNLOADERYY-2358 DM5 HOT MELT PAIL UNLOADER THE DM5 IS A STATIONARY PAIL MELTER (UNLOADER) THAT COMBINES A HEATED PLATEN, PUMP AND ALL CONTROLS NEEDED TO MELT AND DISPENSE HOT MELT ADHESIVES, SEALANTS, PURS OR COATINGS FROM A STANDARD 5-GALLON STEEL PAIL. THE CONTROLLER PROVIDES ACCURATE, PROPORTIONATE TEMPERATURE CONTROL FOR THE PLATEN, HOSES AND APPLICATORS. A “STANDBY” TEMPERATURE MAY BE PROGRAMMED SO THAT THE TEMPERATURE ZONES CAN BE INDEPENDENTLY MAINTAINED AT A LOWER TEMPERATURE WHEN THE UNIT IS NOT IN ACTIVE USE, ENABLING RAPID RETURN TO NORMAL OPERATION. A VARIETY OF GEAR PUMPS ARE AVAILABLE. THE MELTER CAN BE UTILIZED AS A BULK-TRANSFER UNIT OR AS A STAND-ALONE UNIT. IT CAN SUPPLY ONE OR TWO HAND-HELD APPLICATORS OR OTHER APPLICATORS. QUANTITY: 1 Learn More -

YY-2328 N5 HIGH PERFORMANCE HOT MELT TANK, HOPPER CAPACITY 5 KGYY-2328 N5 HIGH PERFORMANCE HOT MELT TANK, HOPPER CAPACITY 5 KG DETAILS: HIGH QUALITY "MELT ON DEMAND" BASIC HOT MELT TANKS USED TO MELT AND PUMP A RANGE OF HOT MELT ADHESIVES AT PRECISE TEMPERATURES, FLOW RATES AND PRESSURES THROUGH FLEXIBLE HOT MELT HOSES TO HOT MELT HANDGUNS OR AUTOMATIC HOT MELT GUNS. OPTIONS: MOTOR ENABLE SWITCH TO TURN ON PUMP FROM DYNACHAMP HANDGUN. QUANTITY: 1 Learn More

YY-2328 N5 HIGH PERFORMANCE HOT MELT TANK, HOPPER CAPACITY 5 KGYY-2328 N5 HIGH PERFORMANCE HOT MELT TANK, HOPPER CAPACITY 5 KG DETAILS: HIGH QUALITY "MELT ON DEMAND" BASIC HOT MELT TANKS USED TO MELT AND PUMP A RANGE OF HOT MELT ADHESIVES AT PRECISE TEMPERATURES, FLOW RATES AND PRESSURES THROUGH FLEXIBLE HOT MELT HOSES TO HOT MELT HANDGUNS OR AUTOMATIC HOT MELT GUNS. OPTIONS: MOTOR ENABLE SWITCH TO TURN ON PUMP FROM DYNACHAMP HANDGUN. QUANTITY: 1 Learn More -

YY-2325 ECONOMELT 30 HOT MELT TANK, TANK CAPACITY 33 LBSYY-2325 ECONOMELT 30 HOT MELT TANK, TANK CAPACITY 33 LBS SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 33 LB CAPACITY, PRECISION GEAR PUMP, VARIABLE SPEED ALL ELECTRIC DRIVE, ABILITY TO OPERATE WITH TWO HOSES AND HANDGUNS OR AUTOMATIC GUNS. QUANTITY: 1 Learn More

YY-2325 ECONOMELT 30 HOT MELT TANK, TANK CAPACITY 33 LBSYY-2325 ECONOMELT 30 HOT MELT TANK, TANK CAPACITY 33 LBS SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 33 LB CAPACITY, PRECISION GEAR PUMP, VARIABLE SPEED ALL ELECTRIC DRIVE, ABILITY TO OPERATE WITH TWO HOSES AND HANDGUNS OR AUTOMATIC GUNS. QUANTITY: 1 Learn More -

TT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mmTT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mm RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210 APPLICATION: LAMINATING OF NONWOVEN FABRICS MATERIAL: PE MAXIMUM ROLL WIDTH: 2200mm QUANTITY: 1 Learn More

TT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mmTT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mm RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210 APPLICATION: LAMINATING OF NONWOVEN FABRICS MATERIAL: PE MAXIMUM ROLL WIDTH: 2200mm QUANTITY: 1 Learn More -

J-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTINGJ-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTING WORKING AREA: LENGTH 2500 x WIDTH 1600mm MAIN CUTTING CONFIGURATION: 1) AUTO FEEDING TABLE 2) BELT DRIVE SYSTEM 3) 8 INDEPENDENT SUCTION ZONES (UNDERNEATH THE MACHINE TABLE THERE ARE 8 TUBES CONNECTING TO THE VACUUM PUMP. THERE IS ONE SOLENOID VALVE WHICH CONTROLS THE OPENING AND CLOSING) 4) 7.5 KW VACUUM PUMP 5) ONE KNIFE HOLDER 6) OSCILLATING KNIFE QUANTITY: 1 Learn More

J-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTINGJ-4684 DIGITAL KNIFE CUTTING MACHINE, WORKING AREA 2500mm x 1600mm, FOR SINGLE PLY FILM CUTTING WORKING AREA: LENGTH 2500 x WIDTH 1600mm MAIN CUTTING CONFIGURATION: 1) AUTO FEEDING TABLE 2) BELT DRIVE SYSTEM 3) 8 INDEPENDENT SUCTION ZONES (UNDERNEATH THE MACHINE TABLE THERE ARE 8 TUBES CONNECTING TO THE VACUUM PUMP. THERE IS ONE SOLENOID VALVE WHICH CONTROLS THE OPENING AND CLOSING) 4) 7.5 KW VACUUM PUMP 5) ONE KNIFE HOLDER 6) OSCILLATING KNIFE QUANTITY: 1 Learn More -

TT-1723 DIGITAL CUTTING SYSTEM, SIZE 2500 LONG X 1600mm WIDE FOR SINGLE PLY FABRIC OR MULTI-PLY FABRIC UP TO 50mm HIGH STACKTT-1723 DIGITAL CUTTING SYSTEM, SIZE 2500 LONG X 1600mm WIDE FOR SINGLE PLY FABRIC OR MULTI-PLY FABRIC UP TO 50mm HIGH STACK TECHNICAL PARAMETERS SHIPPING PACKAGE SIZE: 4150 X 2320 X 1700mm OPERATING PROPERTIES: COMPUTER SYNCHRONOUS COMMUNICATION FOR QUICK DATA TRANSMISSION, MULTI-PAGE FILES AT ONCE CUTTING MATERIALS: CORRUGATED BOARD, PLASTIC CORRUGATED BOARD, GREY BOARD, PVC FOAM BOARD, PVC SHEET, ACRYLIC STICKER, FILM, AND OTHER SIMILAR PRODUCTS STANDARD TOOLS: OSCILLATING TOOL, UNIVERSAL TOOL, CCD CAMERA, CONVEYOR TABLE OPTIONAL: FOAM CUT, V CUT, DRIVING ROTARY TOOL, MILLING TOOL, KISS CUT CUTTING THICKNESS: UP TO 50mm (ACCORDING TO DIFFERENT MATERIALS) MAXIMUM SPEED: 300 TO 1400mm/SECOND (ACCORDING TO DIFFERENT MATERIALS) MATERIAL IS ADHERED TO THE TABLE DURING CUTTING BY VACUUM SUCTION REPEATABLE PRECISION: ≤0.01mm SOFTWARE RESOLUTION: 0.025 INTERFACE: ETHERNET PORT BUFFER MEMORY: 2G, FAST TRANSMISSION FOR MULTI-PAGE LARGE FILE COMMAND MODE: HP-GL/GP-GL COMPATIBLE FORMAT CONTROL PANEL: 7 INCH COLOR TOUCH SCREEN VOLTAGE/POWER: AC 380V ± 10%, 50Hz (OR 220 VOLTS, 60 Hz) FUSE: 6A/30A WORKING ENVIRONMENT MUST BE WITHIN: -10℃ ~ 45℃ Learn More

TT-1723 DIGITAL CUTTING SYSTEM, SIZE 2500 LONG X 1600mm WIDE FOR SINGLE PLY FABRIC OR MULTI-PLY FABRIC UP TO 50mm HIGH STACKTT-1723 DIGITAL CUTTING SYSTEM, SIZE 2500 LONG X 1600mm WIDE FOR SINGLE PLY FABRIC OR MULTI-PLY FABRIC UP TO 50mm HIGH STACK TECHNICAL PARAMETERS SHIPPING PACKAGE SIZE: 4150 X 2320 X 1700mm OPERATING PROPERTIES: COMPUTER SYNCHRONOUS COMMUNICATION FOR QUICK DATA TRANSMISSION, MULTI-PAGE FILES AT ONCE CUTTING MATERIALS: CORRUGATED BOARD, PLASTIC CORRUGATED BOARD, GREY BOARD, PVC FOAM BOARD, PVC SHEET, ACRYLIC STICKER, FILM, AND OTHER SIMILAR PRODUCTS STANDARD TOOLS: OSCILLATING TOOL, UNIVERSAL TOOL, CCD CAMERA, CONVEYOR TABLE OPTIONAL: FOAM CUT, V CUT, DRIVING ROTARY TOOL, MILLING TOOL, KISS CUT CUTTING THICKNESS: UP TO 50mm (ACCORDING TO DIFFERENT MATERIALS) MAXIMUM SPEED: 300 TO 1400mm/SECOND (ACCORDING TO DIFFERENT MATERIALS) MATERIAL IS ADHERED TO THE TABLE DURING CUTTING BY VACUUM SUCTION REPEATABLE PRECISION: ≤0.01mm SOFTWARE RESOLUTION: 0.025 INTERFACE: ETHERNET PORT BUFFER MEMORY: 2G, FAST TRANSMISSION FOR MULTI-PAGE LARGE FILE COMMAND MODE: HP-GL/GP-GL COMPATIBLE FORMAT CONTROL PANEL: 7 INCH COLOR TOUCH SCREEN VOLTAGE/POWER: AC 380V ± 10%, 50Hz (OR 220 VOLTS, 60 Hz) FUSE: 6A/30A WORKING ENVIRONMENT MUST BE WITHIN: -10℃ ~ 45℃ Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

TT-1025 SCHIAVI PADANI SIRIO 6 COLOR FLEXO PRESS, 1300mm WIDE, YEAR 1995TT-1025 SCHIAVI PADANI SIRIO 6 COLOR FLEXO PRESS, 1300mm WIDE, YEAR 1995 PADANI SIRIO / SELLER LOOKING FOR OFFERS YEAR 1995 1300mm WIDE (51.1 INCHES WIDE) WITH 10mm CP GEAR PITCH 4 DECKS WITH DOCTOR BLADES 2 DECKS WITH FOUNTAIN ROLL TURRET UNWIND AND REWIND AUTO SPLICE 32” DIAMETER ROLLS ELECTRIC DRYING 3” AND 6” CORES ROSSINI SLEEVE SYSTEM SLEEVE INVENTORY: 6@460mm, 4@500, 6@510, 9@550, 3@560, 4@590, 6@620, 6@650, 12@700, 9@760 THE DIMENSIONS ARE: HEIGHT: 20 FEET WIDTH: 14 FEET + 6 FEET FOR OPERATING PANEL LENGTH: 45 FEET BRAND: SCHIAVI 6 COLOR CI FLEXO PRESS 1300mm WIDE MODEL: PADANI SIRIO YEAR: 1995 QUANTITY: 1 Learn More

TT-1025 SCHIAVI PADANI SIRIO 6 COLOR FLEXO PRESS, 1300mm WIDE, YEAR 1995TT-1025 SCHIAVI PADANI SIRIO 6 COLOR FLEXO PRESS, 1300mm WIDE, YEAR 1995 PADANI SIRIO / SELLER LOOKING FOR OFFERS YEAR 1995 1300mm WIDE (51.1 INCHES WIDE) WITH 10mm CP GEAR PITCH 4 DECKS WITH DOCTOR BLADES 2 DECKS WITH FOUNTAIN ROLL TURRET UNWIND AND REWIND AUTO SPLICE 32” DIAMETER ROLLS ELECTRIC DRYING 3” AND 6” CORES ROSSINI SLEEVE SYSTEM SLEEVE INVENTORY: 6@460mm, 4@500, 6@510, 9@550, 3@560, 4@590, 6@620, 6@650, 12@700, 9@760 THE DIMENSIONS ARE: HEIGHT: 20 FEET WIDTH: 14 FEET + 6 FEET FOR OPERATING PANEL LENGTH: 45 FEET BRAND: SCHIAVI 6 COLOR CI FLEXO PRESS 1300mm WIDE MODEL: PADANI SIRIO YEAR: 1995 QUANTITY: 1 Learn More -

T-9656 SCHIAVI PADANI SIRIO FLEXO PRESS, 6 COLORS, YEAR 1995T-9656 SCHIAVI PADANI SIRIO FLEXO PRESS, 6 COLORS, YEAR 1995 THE DIMENSIONS ARE: HEIGHT: 20 FEET WIDTH: 14 FEET + 6 FEET FOR OPERATING PANEL LENGTH: 45 FEET Learn More

T-9656 SCHIAVI PADANI SIRIO FLEXO PRESS, 6 COLORS, YEAR 1995T-9656 SCHIAVI PADANI SIRIO FLEXO PRESS, 6 COLORS, YEAR 1995 THE DIMENSIONS ARE: HEIGHT: 20 FEET WIDTH: 14 FEET + 6 FEET FOR OPERATING PANEL LENGTH: 45 FEET Learn More -

T-8542 3 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 35 TO 200 PACKS PER MINUTET-8542 3 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 35 TO 200 PACKS PER MINUTE 3 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 35 TO 200 PACKS PER MINUTE MACHINE SIZE (L X W X H): 2500mm X 1000mm X 1500mm QUANTITY: 1 Learn More

T-8542 3 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 35 TO 200 PACKS PER MINUTET-8542 3 SIDE SEALING WET WIPES MACHINE, STABLE SPEED 35 TO 200 PACKS PER MINUTE 3 SIDE SEALING WET WIPES MACHINE DRIVE MODE: AUTOMATIC STABLE SPEED: 35 TO 200 PACKS PER MINUTE MACHINE SIZE (L X W X H): 2500mm X 1000mm X 1500mm QUANTITY: 1 Learn More