Search results for: 'AUTOMATIC P''

- Related search terms

- automatic V'

- Automatic d

- Automatic 4

- Automatic+4

- AUTOMATIC''

-

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mm

A-1876 END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmREFERENCE NUMBER: A-1876

END OF LINE UNIT T4.0 FOR NEEDLEPUNCHED PRODUCTS – 4000mmPRODUCT TO BE PROCESSED: NEEDLEPUNCHED NONWOVENS

PRODUCT WIDTH: 4.000 MMWORKING SPEED: 1 – 20 M/MIN

QUANTITY: 1

Learn More -

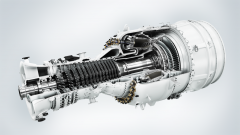

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More

TT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 HzTT-2153 SIEMENS SGT-800 GAS TURBINE, 54 MW, 11 KV, 50 Hz AND 1500 RPM, FUEL NATURAL GAS, FREQUENCY 50/60 Hz GROSS EFFICIENCY 38.86.0% HEAT RATE9, 256 KJ/KWH UNUSED CONDITION: EXCELLENT (NEW SURPLUS) TURBINES STORED TO SIEMENS RECOMMENDATION. NOTE: THIS IS A PACKAGE DEAL AND REQUIRES BUYER TO PURCHASE ALL 3 UNITS. POI AND POF REQUIRED UPFRONT. QUANTITY: 3 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More -

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More -

M-5282 COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGSREFERENCE NUMBER: M-5282 (1313121ANW12RX) L COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS NEW IN STOCK COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS FULLY AUTOMATIC MACHINE FOR PACKAGING ROUND PADS MADE OF COTTON OR SYNTHETIC FIBERS FOR COSMETIC USE IN DRAWSTRING BAGS AND BAGS WITH ZIPPER/ZIP-LOCK MADE OF PLASTIC MATERIAL. THE MACHINE REACHES THE MAXIMUM PERFORMANCE OF ABOUT 30 BAGS PER MINUTE. QUANTITY AVAILABLE: 1 Learn More

M-5282 COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGSREFERENCE NUMBER: M-5282 (1313121ANW12RX) L COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS NEW IN STOCK COSMETIC ROUND PADS PACKAGING MACHINE INTO BAGS FULLY AUTOMATIC MACHINE FOR PACKAGING ROUND PADS MADE OF COTTON OR SYNTHETIC FIBERS FOR COSMETIC USE IN DRAWSTRING BAGS AND BAGS WITH ZIPPER/ZIP-LOCK MADE OF PLASTIC MATERIAL. THE MACHINE REACHES THE MAXIMUM PERFORMANCE OF ABOUT 30 BAGS PER MINUTE. QUANTITY AVAILABLE: 1 Learn More -

YY-3477 FULLY AUTOMATIC ETO STERILIZER MACHINE, H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR) MILD STEEL BODYYY-3477 FULLY AUTOMATIC ETO STERILIZER MACHINE, H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR) MILD STEEL BODY SIZE: H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR). CONSTRUCTION OF MATERIAL: CONTACT PART MILD STEEL NON-CONTACT PART MILD STEEL. Learn More

YY-3477 FULLY AUTOMATIC ETO STERILIZER MACHINE, H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR) MILD STEEL BODYYY-3477 FULLY AUTOMATIC ETO STERILIZER MACHINE, H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR) MILD STEEL BODY SIZE: H 2200 X W 2800 X L 8000 mm (INNER SIZE) (DOUBLE DOOR). CONSTRUCTION OF MATERIAL: CONTACT PART MILD STEEL NON-CONTACT PART MILD STEEL. Learn More -

YY-3394 TOILET PAPER REWINDER, RAW PAPER WIDTH ≤ 1850mmYY-3394 TOILET PAPER REWINDER, RAW PAPER WIDTH ≤ 1850mm A DEVICE OPERATES FOR 8 HOURS PER SHIFT, WITH A PRODUCTION CAPACITY OF 2 TO 2.5 TONS Learn More

YY-3394 TOILET PAPER REWINDER, RAW PAPER WIDTH ≤ 1850mmYY-3394 TOILET PAPER REWINDER, RAW PAPER WIDTH ≤ 1850mm A DEVICE OPERATES FOR 8 HOURS PER SHIFT, WITH A PRODUCTION CAPACITY OF 2 TO 2.5 TONS Learn More -

TT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50HzTT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50Hz COMPLETE RECYCLING EREMA INTAREMA 1714 TVEPLUS YEAR 2017 AND WAS STARTED UP FOR THE FIRST TIME IN 2018 TYPE SELLING BRAND EREMA MODEL INTAREMA 1714 SINCE YEAR 2017 QUANTITY: 1 Learn More

TT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50HzTT-5555 EREMA INTAREMA 1714 TVEPLUS COMPLETE RECYCLING PLANT, YEAR 2017, 50Hz COMPLETE RECYCLING EREMA INTAREMA 1714 TVEPLUS YEAR 2017 AND WAS STARTED UP FOR THE FIRST TIME IN 2018 TYPE SELLING BRAND EREMA MODEL INTAREMA 1714 SINCE YEAR 2017 QUANTITY: 1 Learn More -

L-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILL

L-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILLL-1177 TRUTZSCHLER/RIETER COMPLETE SPINNING MILL

BLOW ROOM TRÜTZSCHLER

1 MONOTAMBOUR B4/1, YEAR 1989

1 MULTIMIXER MCM 6 /1200 YEAR 1997 + 1 CVT-4 / 1200 YEAR 1997

1 JOSSI THE VISION SHIELD FIBER DETECTOR EA-33-S YEAR 2002

1 DUSTEX DX 385 YEAR 1997

1 JOSSI THE SHIELD HIGH PERFORMANCE FIRE DETECTOR

TYPE D-11-250, YEAR 2005

3 TRÜTZSCHLER FAN

1 UNIMIX RIETER + ERM CLEANER RIETER

QUANTITY: 1BLOW ROOM RIETER

2 ERM B 5/5 YEAR 1989

1 ERM B 5/5 YEAR 1987

1 ERM B 5/5 YEAR 1988

2 JOSSI FIRE DETECTOR D-11-250 YEAR 2005

1 JOSSI FIBRE DETECTOR EA-33-S, YEAR 2002

3 BALE PRESS RIETER B3/4S, YEAR 1990-1991

QUANTITY: 1

CARDS TRÜTZSCHLER DK-803, YEAR 1996/ 1997 (3) COILER KH 950-1200,

AUTOMATIC REVOLVER, FEEDING FBK-533

QUANTITY: 3

CARDS TRÜTZSCHLER DK-903, YEAR 2002/2003 (1) COILER KH 600-1200, (2) COILER KH 450-1200

AUTOMATIC REVOLVER, FEEDING DKF

QUANTITY: 3

DRAWING FRAME TRÜTZSCHLER HSR-1000X2 , YEAR 2003, 1 DELIVERY 18” (450X1000), CREEL 8 CANS,

SLIVER MONITOR, AUTOLEVELLER

QUANTITY: 2

2 ROVING FRAME SIMPLEX ZINZER 670, YEAR 2003, DRAFT PK 1500, 120 SPINDLES,

CAPACITY BOBBIN 16”X6”, DRIVER CREEL, COLLECTIVE ASPIRATION,

INDIVIDUAL BLOWER ELECTRO-JET

2 AUTOMATIC TRANSPORT INSTALLATION FOR BOBBINS ELECTRO-JET

FOR 8 RING SPINNING FRAME OF 1.200 SPINDLES, YEAR 2003

QUANTITY: 1

5 RING SPINNING FRAME ZINZER RM 351, YEAR 2002 (4), YEAR 2003 (1), 1200 SPINDLES,

GAUGE 70 MM

DRAFT PK 2500, RING 42 MM, TUBE 220 MM, COWEMAT, COLLECTIVE ASPIRATION, INDIVIDUAL BLOWER

ELECTRO-JET WITH AUTOMATIC UNLOADING, TOTAL LENGTH 47 M

4 WINDER SCHLAFHORST 338 RM, 2 X YEAR 2002, COLOUR GREEN, 2 X YEAR 2003, COLOUR WHITE, 60 POSITIONS

MAGAZINE FEEDING 6 TUBES, 2 ROBOTS, WAXING, AUTOMATIC CONE CHANGE, TK-840,

CLEARER LOEPFE, DELIVERY 4.20 X 6”, INDIVIDUAL BLOWER

QUANTITY: 1

1 AUTOCORO SCHLAFHORST SE-11 ACO-288, YEAR 2001, 216 ROTORS, INFORMATOR,

DELIVERY CYLINDRICAL SLUBIER PINTER, ROTOR Ø 28-36-40 MM , ROLLERS B-174, CLEARERS COROLAB,

WAXING, 2 ROBOTS CONE CHANGE ROBOTS PIECERS

QUANTITY: 1

1 AUTOCORO SCHLAFHORST SE-9, 216 ROTORS, 2 ROBOTS, WAXING, COROLAB

INFORMATOR, YEAR 1998

QUANTITY: 1

1 INSTALLATION LTG, YEAR 2003, 5 PARTS, WASTE COLLECTING, AIR SYSTEM

1 INSTALLATION LTG, YEAR 2003, 3 PARTS, WASTE COLLECTING, AIR SYSTEM

1 INSTALLATION LTG, YEAR 2003, 5 PARTS, WASTE COLLECTING, CARDING FILTRATION

- POWER 380V/50HZ

- CONDITION COMPLETED

QUANTITY: 1

RIETER SPINNING COMBING PLANT

BLOW ROOM RIETER

UNIFLOC RIETER, A1/2, YEAR 2000

UNIMIX RIETER , B7/3, YEAR 2000

UNILEX B60, YEAR 2000

JOSSI , D-21-370-01, YEAR 2000

QUANTITY: 1

CARDS RIETER

10 X CARD RIETER C51, YEAR 2000, WITH IGS

WITH LUWA WASTE SYSTEM

QUANTITY: 10

1 X CARD RIETER C60 WITH MODUL IGS

YEAR :

QUANTITY: 1

DRAWING FRAMES RIETER

2 X DRAWING FRAME RIETER, SB-D10, YEAR 2000

QUANTITY: 2

1 X DRAW FRAME RIETER, RSB-D30C, YEAR 2000

QUANTITY: 1

2 X DRAWING FRAME RIETER, D-30QUANTITY: 2

1 X DRAWING FRAME RIETER, D-35QUANTITY: 1

COMBERS RIETER

1 X UNILAP RIETER E33, YEAR 2000

WITH TRANSPORT SYSTEM SCHONENBERGER , ARS-N2, 2000

5 X COMBING MACHINE RIETER , E72, YEAR 2000

1 X COMBING MACHINE RIETER, E75, YEAR 2006

1 X SERVOLAP RIETER , E25, YEAR 2000

WITH WASTE COLLECT SYSTEM AND PRESS

QUANTITY: 1

FLYERS RIETER

3 X ROVING FRAME RIETER, F33/120POS, YEAR 2000

AUTOMATIC BOBINES TRANSPORT , SCHONENBERGER , YEAR 2000

QUANTITY: 1

RING SPINNING MACHINES RIETER

6 X SPINNING FRAME RIETER G33

6 RIETER RINGFRAMES, TYPE G33, BUILT 1999, EACH WITH 1200 SPINDLES, RING DIAMETER 38 MM, TYPE SFB-TITAN, GAUGE 70 MM, LIFT 187 MM, SPINDLE TYPE HPS 25, AUTOMATIC DRAFTING SYSTEM, WITH AUTODOFFER AND MAGITEX OVERHEAD CLEANER, LINKED WITH MURATA CONER, TYPE 7V-II, BUILT 1999, EACH WITH 32 WINDING HEADS, AUTOMATIC FEEDING, AUTOMATIC PACKAGE CONVEYOR, YARN CLEARERS USTER QUANTUM WITH FIBER DETECTOR, MK-C-15F23, WITH WAXING, INFORMATOR MMC/3, CONICITY 4 DEG. 20 , VOLTAGE : 380V, 50HZ

QUANTITY: 61 X MURATA MINICONER

Learn More

LUWA AIRCONDITION, YEAR 2005

LUWA FILTER FOR CADING, YEAR 2005

LUWA FILTER FOR COMBING, YEAR 2005

LUWA FILTER FOR SPINNING AND WINDING, YEAR 2005

QUANTITY: 1 -

P-4325 WET WIPES PRODUCTION LINE

P-4325 WET WIPES PRODUCTION LINEREFERENCE NUMBER: P-4325

WET WIPES PRODUCTION LINE

Model L40

Machine Characteristic

Control system: Multi-Axis Motion Controller

Drive element: servo motor

Operate interface: 10" LCD touch screen

Cutting: synchronous flail knife

Packing style: end seal & reciprocating type(connecting 2 packing machine need explain)

Unwinding structure: 40 sets, 40 electronic eyes detect online(16 sets big rolls material)

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven, film, label detect respectively

Frequency division pulling: 2 sets dry wipes pulling , 2 sets wet wipes pulling

Auto splicing: film automatic splicing, label automatic switching

Frequency division detection: nonwoven ,film, label detect respectively

Metal detect: online metal detector

Inferior eliminate: aluminizing paste connector rejected online

Flow control: 2.5-4 times, flow meter control, no liquid recovery

Moisture type: 40 fluid pipes spray independently

SUS Agitate tank: 2 sets, 1000L stainless steel agitate tank

Liquid level control: electronic detection, auto control

Specifications

Raw material: spunlaced nonwoven, therbond etc. nonwovens

Raw material specification: max W220mm, φ1400mm, max W1050mm, φ1000mm

Axis QTY settings:40 rolls raw materials (auto splicing type 32 rolls)

Diameter of ventilating shaft: 3"

Suitable packing material :BOPP PET/PE PET/AL/PE etc. heat-seal material

Packing Film specification: max W420mm, φ350mm

Axis QTY settings: 2 sets film, automatic splicing without stopping machine

Diameter of ventilating shaft: 3"

Suitable label: transparent label & opaque label

Label size: max W100mm φ400mm

Axis QTY settings: 2 sets label, automatic switching without stopping(can be set as safety label)

Diameter of ventilating shaft: 3"

Folding type: single extraction & interfold type

Wet wipes size:L120-220mm W90-110mm

Open size: L120-220mm W150-220mm

Package size: L150-350mm W80-120mm H10-80mm

Design speed: 60bags/min &250cutting/min

Production speed: 50 bags/min &200 cutting/min

Machine space: L31000mm W2500mm H2100mm. L32600mm W3600mm H2100mm(auto splicing machine)

Power: AC 380V 50/60Hz 22KW(auto splicing machine:25KW)

Compressed air: 0.6-0.8Mpa 400L/min

Machine net weight :22000kg(auto splicing machine 25000Kg)

Option equipment: Coding machine Big roll material automatic splicingQUANTITY: 1

Learn More