Search results for: 'machine ci'

- Related search terms

- Machine c

- Machine+c

- machine f'

- machine''''

- machine'''''

-

TT-2172 TETRA PAK, TYPE TETRA REX TR7 FILLING MACHINE / LINE FOR GABLE TOP PACKS 250-1000MLTT-2172 TETRA PAK, TYPE TETRA REX TR7 FILLING MACHINE / LINE FOR GABLE TOP PACKS 250-1000ML DOCUMENTS: 1: CIRCUIT DIAGRAM 2: ELECTRICAL DOCUMENTATION 3: ELECTRICAL COMPONENTS DOCUMENTATION 4: MECHANICAL SPARE PARTS DRAWINGS AND NUMBERS THE EQUIPMENT IS COMPLETELY DISASSEMBLED AND READY FOR LOADING. QUANTITY: 1 Learn More

TT-2172 TETRA PAK, TYPE TETRA REX TR7 FILLING MACHINE / LINE FOR GABLE TOP PACKS 250-1000MLTT-2172 TETRA PAK, TYPE TETRA REX TR7 FILLING MACHINE / LINE FOR GABLE TOP PACKS 250-1000ML DOCUMENTS: 1: CIRCUIT DIAGRAM 2: ELECTRICAL DOCUMENTATION 3: ELECTRICAL COMPONENTS DOCUMENTATION 4: MECHANICAL SPARE PARTS DRAWINGS AND NUMBERS THE EQUIPMENT IS COMPLETELY DISASSEMBLED AND READY FOR LOADING. QUANTITY: 1 Learn More -

TT-2112 KARL MAYER FILSIZE-S-F-1800 SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 2018TT-2112 KARL MAYER FILSIZE-S-F-1800 SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 2018 BRAND: KARL MAYER TYPE: FILSIZE-S-F-1800 YEAR: 2018 WORKING WIDTH: 1800mm COMMAND BY KAMCOS KARL MAYER SYSTEM QUANTITY: 1 Learn More

TT-2112 KARL MAYER FILSIZE-S-F-1800 SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 2018TT-2112 KARL MAYER FILSIZE-S-F-1800 SIZING MACHINE, WORKING WIDTH 1800mm, YEAR 2018 BRAND: KARL MAYER TYPE: FILSIZE-S-F-1800 YEAR: 2018 WORKING WIDTH: 1800mm COMMAND BY KAMCOS KARL MAYER SYSTEM QUANTITY: 1 Learn More -

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More -

TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002 COMPLETE FLOCKING LINE WORKING WIDTH 3200mm QUANTITY: 1 Learn More

TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002TT-1903 COMPLETE FLOCKING LINE, WORKING WIDTH 3200mm, YEAR 2002 COMPLETE FLOCKING LINE WORKING WIDTH 3200mm QUANTITY: 1 Learn More -

T-9762 KARL MAYER GOM 24 SAMPLING WARPER, WORKING WIDTH 2250mm, YEAR 2010 INSTALLED 2011T-9762 KARL MAYER GOM 24 SAMPLING WARPER, WORKING WIDTH 2250mm, YEAR 2010 INSTALLED 2011 VOLTAGE: 380 VOLTS, 50 Hz CONDITION CLOSE TO NEW QUANTITY: 1 Learn More

T-9762 KARL MAYER GOM 24 SAMPLING WARPER, WORKING WIDTH 2250mm, YEAR 2010 INSTALLED 2011T-9762 KARL MAYER GOM 24 SAMPLING WARPER, WORKING WIDTH 2250mm, YEAR 2010 INSTALLED 2011 VOLTAGE: 380 VOLTS, 50 Hz CONDITION CLOSE TO NEW QUANTITY: 1 Learn More -

TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007 DISMANTLED, READY FOR SHIPPING REQUIRES 20 TO 22 40 FOOT HIGH CUBE CONTAINERS TO SHIP Learn More

TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007TT-1585 ACRYLIC SPINNING PLANT, YEAR 2001 TO 2007 DISMANTLED, READY FOR SHIPPING REQUIRES 20 TO 22 40 FOOT HIGH CUBE CONTAINERS TO SHIP Learn More -

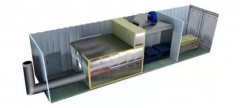

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More -

YY-2186 THERMAL SHOCK TEST CHAMBER, TEST METHOD 2 ZONE TYPE OR 3 ZONE TYPEYY-2186 THERMAL SHOCK TEST CHAMBER, TEST METHOD 2 ZONE TYPE OR 3 ZONE TYPE DETAILS: THE THERMAL SHOCK TEST CHAMBER IS WELL ESTABLISHED TESTING MACHINE OF ELECTRONIC COMPONENTS, METAL, CHEMICAL MATERIALS, AUTOMATION COMPONENTS, COMMUNICATION MODULE, NATIONAL DEFENSE INDUSTRY, AEROSPACE INDUSTRY, PCB SUBSTRATE, ELECTRONIC CHIP INTEGRATED CIRCUITS, SEMICONDUCTOR CERAMIC AND HIGH POLYMER MATERIALS. MEET THE FOLLOWING STANDARDS: GB/T2423.1-1989, GB/T2423.2-1989, GB/R2423.22-1989, GJB150.5-86, GJB360.7-87, GJB367.2-87 405, SJ/T10187-91Y73, SJ/T10186-91Y73, IEC68-2-14, GB/T2424.13-2002, GB/T 2423.22-2002, QC/T17-92, EIA 364-32. QUANTITY: 1 Learn More

YY-2186 THERMAL SHOCK TEST CHAMBER, TEST METHOD 2 ZONE TYPE OR 3 ZONE TYPEYY-2186 THERMAL SHOCK TEST CHAMBER, TEST METHOD 2 ZONE TYPE OR 3 ZONE TYPE DETAILS: THE THERMAL SHOCK TEST CHAMBER IS WELL ESTABLISHED TESTING MACHINE OF ELECTRONIC COMPONENTS, METAL, CHEMICAL MATERIALS, AUTOMATION COMPONENTS, COMMUNICATION MODULE, NATIONAL DEFENSE INDUSTRY, AEROSPACE INDUSTRY, PCB SUBSTRATE, ELECTRONIC CHIP INTEGRATED CIRCUITS, SEMICONDUCTOR CERAMIC AND HIGH POLYMER MATERIALS. MEET THE FOLLOWING STANDARDS: GB/T2423.1-1989, GB/T2423.2-1989, GB/R2423.22-1989, GJB150.5-86, GJB360.7-87, GJB367.2-87 405, SJ/T10187-91Y73, SJ/T10186-91Y73, IEC68-2-14, GB/T2424.13-2002, GB/T 2423.22-2002, QC/T17-92, EIA 364-32. QUANTITY: 1 Learn More -

TT-1213 SCHIAVI ROTOGRAVURE PRESSES, YEAR 1997 EXTENDED 2017TT-1213 SCHIAVI ROTOGRAVURE PRESSES, YEAR 1997 EXTENDED 2017 SCHIAVI ROTOGRAVURE PRESSES MODEL: ROTO-CADET-S - 8 COLORS YEAR 1997 EXTENDED 2017 Learn More

TT-1213 SCHIAVI ROTOGRAVURE PRESSES, YEAR 1997 EXTENDED 2017TT-1213 SCHIAVI ROTOGRAVURE PRESSES, YEAR 1997 EXTENDED 2017 SCHIAVI ROTOGRAVURE PRESSES MODEL: ROTO-CADET-S - 8 COLORS YEAR 1997 EXTENDED 2017 Learn More -

YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004 YEAR: 2004 WIDTH: 1800mm QUANTITY: 1 Learn More

YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004YY-2101 MASTER INDIGO DYEING LINE, WIDTH 1800mm, YEAR 2004 YEAR: 2004 WIDTH: 1800mm QUANTITY: 1 Learn More