Search results for: 'Manage'

- Related search terms

- Manage su

- Manage subs

- Management

-

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

R-3246 STA RE-5 CONVECTION ROASTER - 5 KILOSR-3246 STA RE-5 CONVECTION ROASTER - 5 KILOS

THIS IS A REALLY GREAT ROASTER - ESPECIALLY FRIENDLY TO BLENDS AS IT CREATES A VERY EVEN ROAST WITH NO TIPPING OR SCORCHING. THIS IS A BRAND THAT IS MORE KNOWN IN ITALY - BUT THE STA ROASTING GROUP HAS A HISTORY OF PRINCIPALS WITH LOTS OF ROASTING MACHINERY BACKGROUND. THUS THEIR CHANGES ARE MORE TECHNICALLY ADVANCED AND NOT SO MUCH FOR COSMETICS.

FEATURES:

SINGLE PHASE

FOUR MOTORS

AUTOMATIC GAS BURNER TWO FANS (COOLING AND CHAFF COLLECTION)

CHAFF COLLECTION CHAMBER

CAPACITY IS 20 KG PER HOUR.

LOCATED IN CROATIATECHNICAL DATA:

CHARGE HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM IS PERFORATED FOR MAXIMUM AIR CONTROL

HEATING IS HOT CONVECTION AIR GENERATOR OF NEW GENERATION

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL - COOLING TRAY IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TRAY

ELECTRIC CONTROL BOARD TO CHECK AND CONTROL THE MACHINE ACCORDING CE RULES, INTEGRATED COMPLETE OF THERMO-REGULATOR DEVICE FOR BURNER MANAGEMENT AND DISPLAY FOR TEMPERATURES SIGHT

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TRAY

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TRAY

CYCLONE FOR CHAFF COLLECTING

SEMIAUTOMATIC MANAGEMENT OF THE ROASTING CYCLE.

FUEL: NATURAL GAS OR PROPANE

HEATING CONVECTION SYSTEM:

PATENTED SYSTEM BY STA IMPIANTI. THIS SYSTEM ALLOWS SHORTER AND HOMOGENEOUS ROASTING TIME:

BY CONVECTION OF HOT AIR FLOWING THROUGH THE COFFEE IN THE DRUM.

BY CONDUCTION (LIMITED AMOUNT ONLY) DUE TO THE HEATED AIR HITTING THE PERFORATED ROASTING DRUM.

BY RADIANCE FROM THE GRATE LOCATED BETWEEN THE FLAME AND THE ROASTING DRUM (INFRARED RAYS).SPECS:

ROASTER CAPACITY: 5 STANDARD 7 MAX TO KILOS PER CYCLE

INDICATIVE ROASTING CYCLE: 9 ÷ 20 MINUTES

INSTALLED POWER: 0,9 KW

THERMAL POWER: 10 KW

WEIGHT: 170 KG

DIMENSIONS: 850mm (34") L X 1150mm (45") W X 1530mm H (60")QUANTITY: 1

Learn More -

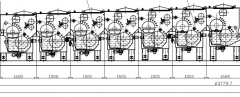

A-2101 MURATA VORTEX MSV861 AIR JET SPINNING FRAMES, YEAR 2006-2007, 80 SPINDLES

A-2101 MURATA VORTEX MSV861 AIR JET SPINNING FRAMES, YEAR 2006-2007, 80 SPINDLESA-2101 MURATA VORTEX MSV861 AIR JET SPINNING FRAMES, YEAR 2006-2007, 80 SPINDLES

YEAR: 2006

MODEL: MSV861

80 SPINDLES PER FRAME

6 INCH TUBE TAKE UP

3 MURATEC SPLICERS PER FRAME

1 MARATEC AUTOMATIC DOFFERS WITH FRONT YARN CONVEYORS

MURATEC “VOS II” YARN MANAGEMENT SYSTEM

WAXING DEVICES

SPINDLES INSTALLED: 1/3 (SPARE DIAMETER 1.1 & 1.2)

NEEDLE HOLDER: 2PZ8.8L8

NOZZLE: 4 HOLES ECO (Z)1

4 LINE SILVER CREELS FOR 20 INCH DIAMETER CANS

1 MACHINE SET UP FOR COTTONYEAR: 2007

MODEL: MVS861

80 SPINDLES

6 INCH TUBE TAKE UP

3 MURATEC SPLICERS

1 MURATEX AUTOMATIC DOFFERS WITH FRONT YARN CONVEYORS

MURATEC “VOS II” YARN MANAGEMENT SYSTEM

WAXING DEVICES

SPINDLES INSTALLED: 1/3 (SPARE DIAMETER 1.1 & 1.2)

NEEDLE HOLDER: 2PZ8.8L8

NOZZLE: 4 HOLES ECO (Z)1

4 LINE SILVER CREELS FOR 20 INCH DIAMETER CANSQUANTITY: 2

Learn More -

P-5047 STA IMPIANTI ROASTER 10 KILOS

P-5047 STA IMPIANTI ROASTER 10 KILOSP-5047 STA IMPIANTI ROASTER 10 KILOS

STA

MODEL: IMPIANTI

ROASTER

10 KILOS

ROASTING MACHINES LINE, PARTICULARLY SUITABLE FOR LITTLE PRODUCTION ACTIVITIES OF HIGH QUALITY ROASTED COFFEE, SUCH AS SHOPS, PASTRIES OR ARTISANAL LABORATORIES. SMALL SIZE, TECHNOLOGICALLY ADVANCED, CONFIRM THEM ELVES AS IDEAL TOOL FOR THE PRODUCTION OF SELECTED COFFEES IN LITTLE QUANTITY. MADE WITH THE SAME REQUIREMENTS FOR RELIABILITY AND SECURITY FEATURES OF THE BIGGER AND MORE SOPHISTICATED INDUSTRIAL ROASTING MACHINES, ARE AVAILABLE WITH HEATING GENERATOR TYPE GAS BURNER ( AVAILABLE ALSO BY ELECTRIC RESISTANCES ) AND AUTOMATIC CONTROL SYSTEM WITH SEMIAUTOMATIC MANAGEMENT.TECHNICAL DATA:

ROASTER CAPACITY: 10 KG. / MAX. 13 KG. CYCLE

ROASTING CYCLE: 9 MINUTES ÷ 20

RAW COFFEE PROCESSING PER HOUR: 40 KG. ÷ 60

INSTALLED ELECTRIC POWER: 1,5 KW, SINGLEPHASE: 220 VOLT, 50 HZ | SPECIAL TRIPLEPHASE: 220 VOLT, 60 HZ

THERMAL POWER (NATURAL GAS OR LPG): 16000 KCAL/HMAIN COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL

ROASTING DRUM

HEATING GENERATOR OF NEW GENERATION, PATENTED AND COMPLETE OF BURNER

RAMP VALVES FOR GAS SAFETY AND ELECTRIC DEVICE TO CHECK FLAMES RATIFIED AND COMPLETE OF ALARM SIGNAL

COOLING TANK IN STAINLESS STEEL

SAFETY PREVENTION SYSTEM ON THE COOLING TANK

SUPPORTING FRAME FOR THE OVER INDICATED COMPONENTS

ELECTRIC CONTROL BOARD ACCORDING CE RULES, INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN DEVICE FOR ROASTING MACHINE CONTROL AND MANAGEMENT

POSSIBLE RECORDING OF ROASTING PARAMETERS

INDEPENDENT FANS FOR THE ROASTING DRUM AND THE COOLING TANK

INDEPENDENT MOTORS FOR THE ROASTING DRUM AND THE COOLING TANK

CYCLONE FOR CHAFFS COLLECTINGDETAILS OF COMPONENTS:

HOPPER OF CHARGE IN STAINLESS STEEL WITH MANUAL IN-LET OF COFFEE WITH DOOR UNLOADING SYSTEM

ROASTING DRUM: MADE BY A FIXED ELEMENT WITH DOUBLE WALLS INSULATED FOR THERMAL PROTECTION AND SUPPORT OF THE ROTATING CYLINDER MOVING THE PRODUCT. SUCH CYLINDER, COMPLETELY MADE IN COMPOUND STEEL TO OVERCOME THE THERMAL CHANGES, IS DEVELOPED WITH A PERFORATED PLATE FOR THE CONTAINMENT AND SPECIAL BLENDERS ON THE RIGHT AND LEFT SIDE PLACED ON DIFFERENT LEVELS TO GET A PERFECT BLENDING OF COFFEE. AT THE END OF THE ROASTING CYCLE, A WIDE DOOR WITH MANUAL OPENING/CLOSING SYSTEM ALLOWS THE PRODUCT UNLOADING.

HEATING GAS GENERATOR OF NEW CONCEPT, PATENTED, COMPLETE OF BURNER, RAMP VALVES FOR GAS SAFETY AND ELECTRONIC EQUIPMENTS FOR FLAME CONTROL RATIFIED AND COMPLETE OF SIGNALLING ALARM (N°2 FLAME LEVELS).

COOLING TANK IN STAINLESS STEEL: WIDE SURFACE PERFORATED WITH TWO ARMS AND CROSSED FLOWS. UNLOADING MOUTH WITH HAND DRIVE.

SUPPORTING FRAME: MONO-BLOCK, PLATE PRESS-BENDED, STEEL MADE, SUPPORTING THE ELEMENTS PREVIOUSLY DESCRIBED.

SAFETY PROTECTION FOR COOLING TANK

ELECTRIC CONTROL BOARD ACCORDING CE RULES INTEGRATED, COMPLETE OF PLC + TOUCH SCREEN FOR ROASTING MACHINE CONTROL AND MANAGEMENT.

POSSIBLE RECORDING OF ROASTING PARAMETERS

CYCLONE FOR CHAFFS COLLECTING

INDEPENDENT MOTORIZATION FOR ROASTING DRUM AND COOLING TANK

INDEPENDENT ELECTRIC-FAN FOR ROASTING DRUM AND ELECTRIC-FAN FOR COOLING TANK.QUANTITY: 1

Learn More -

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

TT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 HzTT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 Hz 1. STX MAN DIESEL/HFO 18V32/40 GENSETS 2. GROSS ELECTRICAL OUTPUT APPROX. 9.0 MW 3. BRAND MAN DIESEL & TURBO, TYPE 18V32/40 - 4 STROKE, UNUSED EACH UNIT CONSISTS OF MOTOR, GENERATOR, RACK / BASE-FRAME QUANTITY: 20 UNITS Learn More

TT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 HzTT-8633 STX MAN DIESEL/HFO 18V32/40 GENSETS, 9.0 MW, 50/60 Hz 1. STX MAN DIESEL/HFO 18V32/40 GENSETS 2. GROSS ELECTRICAL OUTPUT APPROX. 9.0 MW 3. BRAND MAN DIESEL & TURBO, TYPE 18V32/40 - 4 STROKE, UNUSED EACH UNIT CONSISTS OF MOTOR, GENERATOR, RACK / BASE-FRAME QUANTITY: 20 UNITS Learn More -

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More -

TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025 1. MASTER BAG 300X – SQUARE BOTTOM PAPER BAG MACHINE 2. YEAR: 2025 Learn More

TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025TT-8230 MASTER BAG 300X SQUARE BOTTOM PAPER BAG MACHINE, YEAR 2025 1. MASTER BAG 300X – SQUARE BOTTOM PAPER BAG MACHINE 2. YEAR: 2025 Learn More -

TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016 1. BRAND: TETRA PAK® 2. MODEL: A3FLEX 3. YEAR: 2016 4. SPEED: 7500 BPH 5. PRODUCTS: DAIRY, JUICE 6. CONTAINERS: BRIK Learn More

TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016TT-8178 TETRA PAK FILLING MACHINE A3 FLEX 7500 BPH, YEAR 2016 1. BRAND: TETRA PAK® 2. MODEL: A3FLEX 3. YEAR: 2016 4. SPEED: 7500 BPH 5. PRODUCTS: DAIRY, JUICE 6. CONTAINERS: BRIK Learn More -

TT-7918 MAN HFO 18V32-40 GENERATING SETS - NEW, 50 Hz, 11 KVTT-7918 MAN HFO 18V32-40 GENERATING SETS - NEW, 50 Hz, 11 KV 1. MAN HFO 18V32-40 GENERATING SETS 2. NEW 3. MODEL 18V32-40 4. GROSS ELECTRICAL OUTPUT APPROX. 9,0 MW 5. DOUBLE FUEL 6. MAN DIESEL ENGINES 18V32/40, NEVER INSTALLED, MANUFACTURED AT MAN-GERMANY. 7. THE GROSS ELECTRICAL OUTPUT OF THIS PLANT IS APPROXIMATELY 9 MW EACH SPECIFIED AT THE GENERATOR TERMINALS. 8. THE OFFERED ENGINES ARE DESIGNED FOR FIRING BY GAS OR HFO/DIESEL. IN THIS OFFER THE AUXILIARY IS LISTED TOR 1 UNIT, SO THE DESCRIPTIONS REFER TO 1 UNIT ONLY. ALL ENGINES ARE EQUIPPED WITH BRAND NEW ABB GENERATORS BASED ON THE LIMITED INFORMATION AVAILABLE THE PRICE IS OF BUDGETARY NATURE. 9. PRICE IS BASED ON SEVERAL ASSUMPTIONS THAT NEED TO BE CONFIRMED/UPDATED BEFORE A FIRM CONTRACT OFFER CAN BE MADE. QUANTITY: 12 Learn More

TT-7918 MAN HFO 18V32-40 GENERATING SETS - NEW, 50 Hz, 11 KVTT-7918 MAN HFO 18V32-40 GENERATING SETS - NEW, 50 Hz, 11 KV 1. MAN HFO 18V32-40 GENERATING SETS 2. NEW 3. MODEL 18V32-40 4. GROSS ELECTRICAL OUTPUT APPROX. 9,0 MW 5. DOUBLE FUEL 6. MAN DIESEL ENGINES 18V32/40, NEVER INSTALLED, MANUFACTURED AT MAN-GERMANY. 7. THE GROSS ELECTRICAL OUTPUT OF THIS PLANT IS APPROXIMATELY 9 MW EACH SPECIFIED AT THE GENERATOR TERMINALS. 8. THE OFFERED ENGINES ARE DESIGNED FOR FIRING BY GAS OR HFO/DIESEL. IN THIS OFFER THE AUXILIARY IS LISTED TOR 1 UNIT, SO THE DESCRIPTIONS REFER TO 1 UNIT ONLY. ALL ENGINES ARE EQUIPPED WITH BRAND NEW ABB GENERATORS BASED ON THE LIMITED INFORMATION AVAILABLE THE PRICE IS OF BUDGETARY NATURE. 9. PRICE IS BASED ON SEVERAL ASSUMPTIONS THAT NEED TO BE CONFIRMED/UPDATED BEFORE A FIRM CONTRACT OFFER CAN BE MADE. QUANTITY: 12 Learn More