Search results for: 'Production'

- Related search terms

- Production+capa

- production+line

- Production+capacity'

- Production capa'

- Production+capa'

-

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More

TT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINETT-8624 TETRA PAK TBA/19 200 B BEVERAGE PRODUCTION MACHINE 1. MACHINE TYPE: BEVERAGE PRODUCTION MACHINE 2. BRAND: TETRA PAK 3. MODEL: TBA/19 200 B 4. CONDITION: EXCELLENT (USED) Learn More -

TT-4169 F.O.R. ITALY HIGH PRODUCTION CARD, TYPE GIGANT, WORKING WIDTH 2500mm, YEAR 1976TT-4169 F.O.R. ITALY HIGH PRODUCTION CARD, TYPE GIGANT, WORKING WIDTH 2500mm, YEAR 1976 F.O.R. ITALY HIGH PRODUCTION CARD TYPE GIGANT YEAR 1976 WORKING WIDTH 2500mm QUANTITY: 1 Learn More

TT-4169 F.O.R. ITALY HIGH PRODUCTION CARD, TYPE GIGANT, WORKING WIDTH 2500mm, YEAR 1976TT-4169 F.O.R. ITALY HIGH PRODUCTION CARD, TYPE GIGANT, WORKING WIDTH 2500mm, YEAR 1976 F.O.R. ITALY HIGH PRODUCTION CARD TYPE GIGANT YEAR 1976 WORKING WIDTH 2500mm QUANTITY: 1 Learn More -

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More

TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024TT-5081 PRODUCTION LINE FOR NEEDLE-PUNCHED NONWOVEN FABRICS, 50 Hz, YEAR 1992 TO 2024 THE FOLLOWING WEIGHTS OF NONWOVEN FABRIC CAN BE MADE ON THE PRODUCTION LINE: 200 TO 1000 G/M² LINE EFFICIENCY: 300 KG/H FINAL WORKING WIDTH OF THE NONWOVEN FABRIC: 2500mm POWER SUPPLY: 400 V, 50 Hz, INSTALLED POWER: 62 KW THE LINE IS EQUIPPED WITH MODERN CONTROL IN CONTROL CABINETS NECESSARY AREA FOR THE ROPE: LENGTH: 17000mm, WIDTH: 10000mm, Learn More -

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More

V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”)V-2068 WRINKLE TYPE BANDAGE ROLLS PRODUCTION LINE INCLUDING PREFOLDING, BANDAGE DRYING, FOLDING, AND ROLLING MACHINERY (PRODUCT IS LIKE KENDALL “KERLIX”) THIS LINE INCLUDES PREFOLDING MACHINE, BANDAGE DRYING MACHINE, FOLDING MACHINE, AND WINDING MACHINE. FINAL PRODUCT IS 6 PLY USES 4 OUTPUT LINES, OUTPUT IS APPROXIMATELY 48 PIECES PER MINUTE FINAL WIDTH OF FABRIC: USUALLY CUSTOMERS USE 780mm WIDTH, MACHINE CAN BE MADE ACCORDING TO DIFFERENT REQUESTS MACHINE TOTAL LENGTH: 19 METERS (62.3 FEET) TOTAL QUANTITY: 1 COMPLETE PRODUCTION LINE Learn More -

T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011 THE PLANT IS FOR THE TRANSFORMATION OF THE TOW ON TOPS FOR ACRYLIC DOES NOT PRODUCE YARNS EQUIPMENT IS STILL RUNNING THE PLANT PRODUCE 15600 KGS HOURLY PRODUCTION PER MONTH IS 468 TONS Learn More

T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011T-9927 COMPLETE PLANT FOR ACRYLIC FIBER PRODUCTION, YEAR 1982 TO 2011 THE PLANT IS FOR THE TRANSFORMATION OF THE TOW ON TOPS FOR ACRYLIC DOES NOT PRODUCE YARNS EQUIPMENT IS STILL RUNNING THE PLANT PRODUCE 15600 KGS HOURLY PRODUCTION PER MONTH IS 468 TONS Learn More -

YY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINEYY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINE GENERAL DESCRIPTION: WIDTH OF PRODUCT: 3.2M; WEIGHT RANGE: 15 TO 170G/M2; PRODUCTION CAPACITY: 556KG/H (BASED ON PRODUCT WITH BASIS WEIGHT OF 50G/M2 OR ABOVE, AND WITH WIDTH OF 3.2M AND FABRIC DELIVERING SPEED OF 58M/MIN). THE DESIGNED ANNUAL CAPACITY IS 4000 TONS PET SPUNBONDED NONWOVEN FABRICS (OUTPUT CALCULATION IS BASED ON THE PRODUCT WITH BASIS WEIGHT OF 50G/M2 AND WITH WIDTH OF 3.2M AND 8000 WORKING HOURS ANNUALLY AND AT FABRIC CONVEYING SPEED OF 58M/MIN, AND THE EFFICIENCY OF 95%). PROCESS SPEED: 10M/MIN TO 150M/MIN; FIBER FINENESS: 1.0 TO 3.0 DPF; MACHINERY DIMENSIONS (L×W×H): 25M×18M×10.5M (FOR REFERENCE ONLY AND DEPENDS ON THE ACTUAL DESIGN). TOTAL INSTALLED POWER: 1492KW (ACTUAL POWER CONSUMPTION: APPROXIMATELY 746KW). Learn More

YY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINEYY-1845 PET SINGLE BEAM SPUNBONDED NONWOVENS PRODUCTION LINE GENERAL DESCRIPTION: WIDTH OF PRODUCT: 3.2M; WEIGHT RANGE: 15 TO 170G/M2; PRODUCTION CAPACITY: 556KG/H (BASED ON PRODUCT WITH BASIS WEIGHT OF 50G/M2 OR ABOVE, AND WITH WIDTH OF 3.2M AND FABRIC DELIVERING SPEED OF 58M/MIN). THE DESIGNED ANNUAL CAPACITY IS 4000 TONS PET SPUNBONDED NONWOVEN FABRICS (OUTPUT CALCULATION IS BASED ON THE PRODUCT WITH BASIS WEIGHT OF 50G/M2 AND WITH WIDTH OF 3.2M AND 8000 WORKING HOURS ANNUALLY AND AT FABRIC CONVEYING SPEED OF 58M/MIN, AND THE EFFICIENCY OF 95%). PROCESS SPEED: 10M/MIN TO 150M/MIN; FIBER FINENESS: 1.0 TO 3.0 DPF; MACHINERY DIMENSIONS (L×W×H): 25M×18M×10.5M (FOR REFERENCE ONLY AND DEPENDS ON THE ACTUAL DESIGN). TOTAL INSTALLED POWER: 1492KW (ACTUAL POWER CONSUMPTION: APPROXIMATELY 746KW). Learn More -

AA-1182 MELTBLOWN NONWOVEN PRODUCTION LINE, 600mm (WORKING WIDTH)AA-1182 MELTBLOWN NONWOVEN PRODUCTION LINE, 600mm (WORKING WIDTH) PRODUCTIVITY: 500KG/DAY (20KG/H) TOTAL POWER OF THE PRODUCTION LINE: 200KW ACTUAL ELECTRICITY CONSUMPTION: 110 TO 140KWH MECHANICAL LINEAR SPEED: 4 TO 20m/MIN FINISHED WIDTH: 600mm PRODUCT WEIGHT: 3 TO 45G/m2 Learn More

AA-1182 MELTBLOWN NONWOVEN PRODUCTION LINE, 600mm (WORKING WIDTH)AA-1182 MELTBLOWN NONWOVEN PRODUCTION LINE, 600mm (WORKING WIDTH) PRODUCTIVITY: 500KG/DAY (20KG/H) TOTAL POWER OF THE PRODUCTION LINE: 200KW ACTUAL ELECTRICITY CONSUMPTION: 110 TO 140KWH MECHANICAL LINEAR SPEED: 4 TO 20m/MIN FINISHED WIDTH: 600mm PRODUCT WEIGHT: 3 TO 45G/m2 Learn More -

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

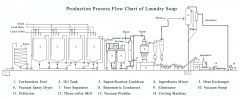

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More