Search results for: 'mattress s'

- Related search terms

- mattress

- Mattress q

- Mattress r

- Mattress f

- Mattress t

-

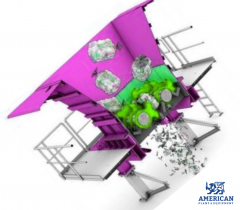

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More

YY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCINGYY-2853 INNERSPRING SHREDDING MACHINE FOR MATTRESS CORE SHREDDING AND VOLUME REDUCING WORKING PRINCIPLE OF THE FOUR SHAFT SHREDDER: THE FOUR SHAFT SHREDDER IS A SLOW RUNNING, HIGH TORQUE TWIN SHAFT CRUSHER. THE MATERIAL ENTERS THE INSIDE OF THE BOX THROUGH THE FEED SYSTEM AND HAS TWO ROTOR SHAFTS CARRIED ON THE BOX TO COLLECT IT, WHICH ALTERNATELY ROTATE INWARDS OR OUTWARDS. EACH SHAFT IS EQUIPPED WITH A ROW OF SPECIAL GEOMETRICAL SHREDDING BLADES. THE MATERIAL IS SHREDDED INTO SMALL PIECES BY THE COMBINED EFFECT OF SHEARING, SQUEEZING AND TEARING OF THE SHREDDING BLADES AND IS REMOVED FROM THE LOWER PART OF THE BOX. Learn More -

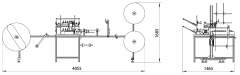

YY-2706 MATTRESS FAUX TAPE EDGE SEWING MACHINE, NONWOVEN SIZE 100 TO 200mmYY-2706 MATTRESS FAUX TAPE EDGE SEWING MACHINE, NONWOVEN SIZE 100 TO 200mm TECHNICAL FEATURES: - JAPAN'S HIGH SPEED CHAIN STITCH SEWING HEAD; - COVER WITH A FIXTURE ON THE EDGE OF THE WRAP; - AUTO STOP FOR MATERIAL DEPLETION; - AUTOMATIC ROLL DEVICE; - SEWING HEAD WITH AUTOMATIC LUBRICATION; - SYNCHRONOUS FEEDING DEVICE. QUANTITY: 1 Learn More

YY-2706 MATTRESS FAUX TAPE EDGE SEWING MACHINE, NONWOVEN SIZE 100 TO 200mmYY-2706 MATTRESS FAUX TAPE EDGE SEWING MACHINE, NONWOVEN SIZE 100 TO 200mm TECHNICAL FEATURES: - JAPAN'S HIGH SPEED CHAIN STITCH SEWING HEAD; - COVER WITH A FIXTURE ON THE EDGE OF THE WRAP; - AUTO STOP FOR MATERIAL DEPLETION; - AUTOMATIC ROLL DEVICE; - SEWING HEAD WITH AUTOMATIC LUBRICATION; - SYNCHRONOUS FEEDING DEVICE. QUANTITY: 1 Learn More -

M-4725 SPUHL F65/SW SPRING COILERS FOR MATTRESS SPRINGS YEAR 1984REFERENCE NUMBER: M-4725 (111119SDF10RX) L SPUHL F65/SW SPRING COILERS FOR MATTRESS SPRINGS YEAR 1984 SPRING COILER FOR MATTRESS SPRINGS MAKE: SPUHL TYPE: F65/SW CONSTRUCTION YEAR: 1984 WIRE DIAMETER: 1.8-3.0mm SPRING DIAMETER: 110mm OUTPUT – PIECES/MIN: 50 QUANTITY AVAILABLE: 1 Learn More

M-4725 SPUHL F65/SW SPRING COILERS FOR MATTRESS SPRINGS YEAR 1984REFERENCE NUMBER: M-4725 (111119SDF10RX) L SPUHL F65/SW SPRING COILERS FOR MATTRESS SPRINGS YEAR 1984 SPRING COILER FOR MATTRESS SPRINGS MAKE: SPUHL TYPE: F65/SW CONSTRUCTION YEAR: 1984 WIRE DIAMETER: 1.8-3.0mm SPRING DIAMETER: 110mm OUTPUT – PIECES/MIN: 50 QUANTITY AVAILABLE: 1 Learn More -

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

M-3006 AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)REFERENCE NUMBER: M-3006

AUTOMATIC MATTRESS WRAPPER SINGLE/QUEEN/KING (88” WIDE)

AUTOMATIC MATTRESS WRAPPER

SINGLE/QUEEN/KING

WITH 14 ROLLERS AT THE ENTRANCE CONVEYOR

WIDTH OF ROLLERS: 86”

WITH (2) SEALERS: LENGTH 100”

MAX. DISTANCE BETWEEN THE SEALERS: 80 ¾”

MAX. HEIGHT OF SEALERS FROM TABLE: APPROX. 9”

THIS WRAPPER HAS A FIXED HEIGHT OF 17”

IT INCLUDES (1) METAL TABLE AT THE END OF THE ENTRANCE

WIDTH OF TABLE: 72”

DEPTH OF TABLE: 51”

WRAPPER EXIT WIDTH: 83”

MAX. DISTANCE BETWEEN RIGHT AND LEFT SIDE OF THE BAGGER: 89 ½”

MAX. WORKING HEIGHT: 17” (430mm)

THE INSIDE DISTANCE BETWEEN THE RIGHT SEALER AND LEFT SEALER: 76 ½”

Learn More -

V-2186 (same as V-1212-F) SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE-VIDEO AVAILABLE (IN STOCK)V-2186 (same as V-1212-F) SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE-VIDEO AVAILABLE (IN STOCK) IN STOCK, BRAND NEW, SKIDDED, AND READY FOR IMMEDIATE LOADING AND SHIPMENT QUANTITY: 1 Learn More

V-2186 (same as V-1212-F) SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE-VIDEO AVAILABLE (IN STOCK)V-2186 (same as V-1212-F) SEMI-AUTOMATIC MATTRESS COMPRESSION MACHINE, PRESS PLATE TYPE-VIDEO AVAILABLE (IN STOCK) IN STOCK, BRAND NEW, SKIDDED, AND READY FOR IMMEDIATE LOADING AND SHIPMENT QUANTITY: 1 Learn More -

J-4882 JAMES CASH TAPE EDGE MACHINE, 12” MATTRESS HEIGHT, EXTENSIONS FOR KING SIZEJ-4882 JAMES CASH TAPE EDGE MACHINE, 12” MATTRESS HEIGHT, EXTENSIONS FOR KING SIZE QUANTITY: 1 Learn More

J-4882 JAMES CASH TAPE EDGE MACHINE, 12” MATTRESS HEIGHT, EXTENSIONS FOR KING SIZEJ-4882 JAMES CASH TAPE EDGE MACHINE, 12” MATTRESS HEIGHT, EXTENSIONS FOR KING SIZE QUANTITY: 1 Learn More -

TT-2046 (090) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 (BRAND NEW MACHINE –NEVER USED) FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSESTT-2046 (090) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 (BRAND NEW MACHINE –NEVER USED) FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 Learn More

TT-2046 (090) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 (BRAND NEW MACHINE –NEVER USED) FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSESTT-2046 (090) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 (BRAND NEW MACHINE –NEVER USED) FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 Learn More -

YY-2125 FULLY AUTOMATIC CNC WIRE BENDING MACHINE FOR MATTRESS SPRING UNIT, PRODUCTION CAPACITY 1400 FRAMES PER 8 HOURSYY-2125 FULLY AUTOMATIC CNC WIRE BENDING MACHINE FOR MATTRESS SPRING UNIT, PRODUCTION CAPACITY 1400 FRAMES PER 8 HOURS TECHNICAL PARAMETERS: WIRE DIAMETER: Φ3.9 – 4.1mm Φ4.2 – 4.4mm Φ4.5 – 4.7mm Φ4.8 – 5.0mm INNER DIAMETER OF WIRE ROLL: MINIMUM 1600mm OUTER DIAMETER OF WIRE ROLL: MAXIMUM 2400mm ACCEPTABLE WEIGHT OF WIRE ROLL: MAXIMUM 2500KG POWER SUPPLY: 3AC 380V 50/60 Hz OR 220V 50/60Hz INPUT CURRENT: 20A CABLE SECTION: 5 X 4MM2 AIR CONSUMPTION: 0.6M’/MIN AIR PRESSURE: 0.6 TO 0.7MPA WORKING TEMPERATURE: +5C- +45 °C POWER: 8KW PRODUCTION CAPACITY: 1400 FRAMES / 8 HOURS WEIGHT: 4000KG STANDARD: L: 1800-2200mm, W: 900-2000mm QUANTITY: 1 Learn More

YY-2125 FULLY AUTOMATIC CNC WIRE BENDING MACHINE FOR MATTRESS SPRING UNIT, PRODUCTION CAPACITY 1400 FRAMES PER 8 HOURSYY-2125 FULLY AUTOMATIC CNC WIRE BENDING MACHINE FOR MATTRESS SPRING UNIT, PRODUCTION CAPACITY 1400 FRAMES PER 8 HOURS TECHNICAL PARAMETERS: WIRE DIAMETER: Φ3.9 – 4.1mm Φ4.2 – 4.4mm Φ4.5 – 4.7mm Φ4.8 – 5.0mm INNER DIAMETER OF WIRE ROLL: MINIMUM 1600mm OUTER DIAMETER OF WIRE ROLL: MAXIMUM 2400mm ACCEPTABLE WEIGHT OF WIRE ROLL: MAXIMUM 2500KG POWER SUPPLY: 3AC 380V 50/60 Hz OR 220V 50/60Hz INPUT CURRENT: 20A CABLE SECTION: 5 X 4MM2 AIR CONSUMPTION: 0.6M’/MIN AIR PRESSURE: 0.6 TO 0.7MPA WORKING TEMPERATURE: +5C- +45 °C POWER: 8KW PRODUCTION CAPACITY: 1400 FRAMES / 8 HOURS WEIGHT: 4000KG STANDARD: L: 1800-2200mm, W: 900-2000mm QUANTITY: 1 Learn More -

M-3561 LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC

M-3561 LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETCREFERENCE NUMBER: M-3561

LINE FOR THERMO BONDED WADDING YEAR 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC

LINE FOR THERMO BONDED WADDING -YOC 1987 - FOR MATTRESS AND BUILDING SECTOR, ETC.

( ESPECIALLY IN POLYESTER + NATURAL FIBERS MIXED).

THE LINE HAS A PRODUCTION OF 350/400 KGS PER HOUR WITH A WORKING WIDTH FROM 150 CMS INTIL 240.

COMPOSITION :

. BONINO LOADER WORKING WIDTH mm. 2800

. BONINO CARDING MACHINE WORKING WIDTH mm. 2800 SINGLE DOFFER

. TECHNOPLANTS CROSS LAPPER WORKING WIDTH ENTRY/EXIT mm. 3000

. SICAM OVEN - 2 FIELDS. WORKING WIDTH 2400 mm. + COOLING SECTION

. TECNICA TESSSILE CUTTING MACHINE WITH HORIZONTAL AND VERTICAL CUT WORKING WIDTH mm. 3000

. MECAP PACKAGING MACHINE FOR ROLLS

QUANTITY: 1

Learn More -

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More