Search results for: 'poly-fil'

- Related search terms

- poly-fil pillow stuffing

- poly-fil pillow stuffing machine

-

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More -

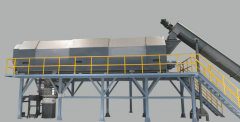

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More

E-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBERE-4401-4 NOZZLE NEW PILLOW FILLING MACHINE (4 NOZZLE): FOR 3 DENIER x 51mm SILICONIZED VIRGIN FIBER FOR POLYESTER STAPLE FIBER OPENING AND FILLING INTO UPHOLSTERY CUSHIONS OR PILLOWS. CAPACITY 250 KGS PER HOUR X 400 HOURS PER MONTH = 100,000 KGS PER MONTH AT 100% EFFICIENCY HOPPER FEED (REF G-3768) WITH 4.5 KW MOTOR FIBER OPENER TRANSFER FAN MIXING MACHINE (SILO WITH FOUR EXITS) FILLING STATION (FAN) , FOUR FILLING FANS WITH NOZZLE CLAMPS AND WITH TABLES SPARE PARTS SUGGESTED Learn More -

V-2065 (LIST) ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATEDV-2065 (LIST)ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATED MAXIMUM MATTRESS HEIGHT: 21 INCHES MAXIMUM MATTRESS WIDTH: 85 INCHES MACHINE IS CURRENTLY FULLY ASSEMBLED AND OPERATIONAL. REFERENCE NUMBER: TT-2043 ATLANTA ATTACHMENT COMPANY ROLL PACKER, YEAR 2017 QUANTITY: 1 REFERENCE NUMBER: TT-2044 ATLANTA ATTACHMENT COMPANY MATTRESS FOLDER, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2045 ATLANTA ATTACHMENT COMPANY MATTRESS VACCUM/SEAL, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2046 (090) (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY (BRAND NEW) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 REFERENCE NUMBER: TT-2047 (091) ATLANTA ATTACHMENT COMPANY FLIP TABLE, DIMENSION 80” X 96”, YEAR 2017 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 REFERENCE NUMBER: TT-2048 (092) ATLANTA ATTACHMENT COMPANY AIR TABLE, DIMENSION 84” X 80”, YEAR 2018 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 TOTAL QUANTITY: 1 ATLANTA ATTACHMENT ROLLPACKER Learn More

V-2065 (LIST) ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATEDV-2065 (LIST)ATLANTA ATTACHMENT ROLLPACKER (ONE MACHINE) – SOLD TOGETHER – CANNOT BE SEPARATED MAXIMUM MATTRESS HEIGHT: 21 INCHES MAXIMUM MATTRESS WIDTH: 85 INCHES MACHINE IS CURRENTLY FULLY ASSEMBLED AND OPERATIONAL. REFERENCE NUMBER: TT-2043 ATLANTA ATTACHMENT COMPANY ROLL PACKER, YEAR 2017 QUANTITY: 1 REFERENCE NUMBER: TT-2044 ATLANTA ATTACHMENT COMPANY MATTRESS FOLDER, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2045 ATLANTA ATTACHMENT COMPANY MATTRESS VACCUM/SEAL, YEAR 2017 USED QUANTITY: 1 REFERENCE NUMBER: TT-2046 (090) (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY (BRAND NEW) ATLANTA ATTACHMENT COMPANY MATTRESS FILLER MODEL 11458-CONV – NEW, YEAR 2017 FOR FILLING ZIPPERED MATTRESSES FROM THE SIDE, 90 INCHES WIDE, 24 INCHES THICK HEAVY DUTY FOR SPRING AND FOAM MATTRESSES NEW QUANTITY: 1 REFERENCE NUMBER: TT-2047 (091) ATLANTA ATTACHMENT COMPANY FLIP TABLE, DIMENSION 80” X 96”, YEAR 2017 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 REFERENCE NUMBER: TT-2048 (092) ATLANTA ATTACHMENT COMPANY AIR TABLE, DIMENSION 84” X 80”, YEAR 2018 (OPTIONAL, NOT INCLUDED IN THE PRICE) – THIS IS AVAILABLE SEPARATELY USED QUANTITY: 1 TOTAL QUANTITY: 1 ATLANTA ATTACHMENT ROLLPACKER Learn More -

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More

TT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANSTT-4057 PILLOW/BOLSTER PILLOW/CUSHION FILLING, 14KW, WITH TWO FILLING FANS PILLOW/BOLSTER PILLOW/CUSHION FILLING POWER SUPPLY: 3-PHASE 4-WIRE 380V POWER: 14KW QUANTITY: 1 Learn More -

M-1483 FIBER FEEDER SYSTEMREFERENCE NUMBER: M-1483 (66032FTG5UF) FIBER FEEDER SYSTEM SUITABLE RAW MATERIALS: CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER≤100mm; HOLLOW SILICONIZED POLYESTER FIBER≤100mm; MICROFIBER 0.7D-3D, LENGTH 32mm-64mm; FIRE PROOF FIBER THIS PRODUCTION LINE IS MAINLY USED FOR PILLOW FILLING, CUSHION AND CHAIRPAD FILLING. IT CAN BE OPERATED BY TWO OPERATORS, ADJUSTED BY FOOT SWITCHES, AND CONTROLLED BY SIEMENS PLC. QUANTITY AVAILABLE: 1 Learn More

M-1483 FIBER FEEDER SYSTEMREFERENCE NUMBER: M-1483 (66032FTG5UF) FIBER FEEDER SYSTEM SUITABLE RAW MATERIALS: CONJUGATE HOLLOW SILICONIZED POLYESTER FIBER≤100mm; HOLLOW SILICONIZED POLYESTER FIBER≤100mm; MICROFIBER 0.7D-3D, LENGTH 32mm-64mm; FIRE PROOF FIBER THIS PRODUCTION LINE IS MAINLY USED FOR PILLOW FILLING, CUSHION AND CHAIRPAD FILLING. IT CAN BE OPERATED BY TWO OPERATORS, ADJUSTED BY FOOT SWITCHES, AND CONTROLLED BY SIEMENS PLC. QUANTITY AVAILABLE: 1 Learn More -

TT-3593 SML CAST FILM EXTRUSION LINE, 3 LAYERS, WIDTH 2000mm, YEAR 1997TT-3593 SML CAST FILM EXTRUSION LINE, 3 LAYERS, WIDTH 2000mm, YEAR 1997 BRAND: SML EXTRUDERS CONDITION: USED YEAR: 1997 QUANTITY: 1 Learn More

TT-3593 SML CAST FILM EXTRUSION LINE, 3 LAYERS, WIDTH 2000mm, YEAR 1997TT-3593 SML CAST FILM EXTRUSION LINE, 3 LAYERS, WIDTH 2000mm, YEAR 1997 BRAND: SML EXTRUDERS CONDITION: USED YEAR: 1997 QUANTITY: 1 Learn More -

TT-1683 SML CAST FILM EXTRUDER, 3 LAYERS, WIDTH 2800mm, YEAR 2003TT-1683 SML CAST FILM EXTRUDER, 3 LAYERS, WIDTH 2800mm, YEAR 2003 QUANTITY: 1 Learn More

TT-1683 SML CAST FILM EXTRUDER, 3 LAYERS, WIDTH 2800mm, YEAR 2003TT-1683 SML CAST FILM EXTRUDER, 3 LAYERS, WIDTH 2800mm, YEAR 2003 QUANTITY: 1 Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More