Search results for: 'roller p'

- Related search terms

- roller

- roller convey

- roller press

- roller ri

- roller+p'

-

M-5221 NONWOVEN LINE WIDTH 2500mm

M-5221 NONWOVEN LINE WIDTH 2500mmREFERENCE NUMBER: M-5221 (1313565TNY12RX) L

NONWOVEN LINE WIDTH 2500mmCARD FEEDING

CARDINGQUANTITY AVAILABLE: 1

Learn More -

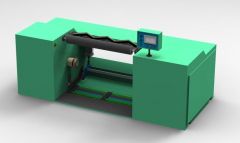

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More

TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012TT-1726 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY, 264 WINDERS, YEAR 2012 POLYPROPYLENE TAPE LINE EXTRUDER 15 TONS DAILY CAPACITY CONDITION: USED MODEL: POLYPROPYLENE TAPE LINE EXTRUDER CAPACITY: 15 TONS DAILY CAPACITY YEAR: 2012 QUANTITY: 1 Learn More -

TT-4388 MENZEL OPEN WIDTH BLEACHING RANGE, WIDTH 3200mm, YEAR 2015 TO 2016TT-4388 MENZEL OPEN WIDTH BLEACHING RANGE, WIDTH 3200mm, YEAR 2015 TO 2016 OPEN WIDTH BLEACHING RANGE 3400mm UPPER ROLLER WIDTH SUITABLE FOR FABRIC WIDTH OF UPTO 3200mm OR 2 X 1600mm YEAR OF MAKE 2015 TO 2016 BRAND MENZEL/GERMANY QUANTITY: 1 Learn More

TT-4388 MENZEL OPEN WIDTH BLEACHING RANGE, WIDTH 3200mm, YEAR 2015 TO 2016TT-4388 MENZEL OPEN WIDTH BLEACHING RANGE, WIDTH 3200mm, YEAR 2015 TO 2016 OPEN WIDTH BLEACHING RANGE 3400mm UPPER ROLLER WIDTH SUITABLE FOR FABRIC WIDTH OF UPTO 3200mm OR 2 X 1600mm YEAR OF MAKE 2015 TO 2016 BRAND MENZEL/GERMANY QUANTITY: 1 Learn More -

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More

TT-1389 LAB RING SPINNING FRAMETT-1389 LAB RING SPINNING FRAME KEY SPECIFICATION: CONTROL MODE: TOUCH SCREEN & PLC NUMBER OF SPINDLES: 6 APPLICABLE FIBER LENGTH: 22 TO 50mm DRAFT RANGE: 10 TO 50 DRAFT CONTROL: AUTOMATIC ROLLER DIAMETER: FRONT ROLLER: Φ25mm, MIDDLE ROLLER: Φ25mm BACK ROLLER: Φ25mm CENTER DISTANCE OF ROLLERS: FRONT AND MIDDLE: 43mm FRONT AND BACK: 143mm PRESSURE MODE: SPRING CRADLE TWIST SETTABLE RANGE: 200 TO 2,000 TWIST/M RING DIAMETER: RING NOT NEEDED IF THERE IS NO NEED FOR TWISTING FUNCTION. THIS MACHINE WILL USE A SHAFT TO MOVE THE YARN UP AND DOWN TO WIND ON THE PIRN TOTAL KW: 1.5 KW VOLTAGE: 220 VOLTS, 3-PHASE, 60 Hz WEIGHT: 650 KG DIMENSIONS: 1750 x 760 x 1950mm SPINDLE SPEED: 3800 RPM QUANTITY: 1 SET Learn More -

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More

A-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mmA-2524 MELTBLOWN FABRIC PRODUCTION MACHINE 1600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 1600mm PRODUCTION SPEED: 24 TO 30 M/min EXTRUDER DIAMETER IN mm: 90mm EXTRUDER MOTOR IN KW: 45 KW PRODUCT WEIGHT RANGE: 8000 TO 1000 KGS MELTBLOWN FABRIC THICKNESS: 25 TO 30 GSM MAX OUTPUT: 1500 TO 1800 KG / 24 HOURS DIMENSION: 20000 X 8000 X 9000 mm WEIGHT: 8000 TO 1000 KGS POWER (TOTAL KW): 575 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 + 1 X 20 PRODUCTION TIME: 45 DAYS Learn More -

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More

M-0428 CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAYREFERENCE NUMBER: M-0428-SHORT VERSION CATTLE SLAUGHTERING AND PROCESSING EQUIPMENT FOR 200 CATTLES PER DAY 200 CATTLES PER DAY QUANTITY AVAILABLE: 1 Learn More -

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More -

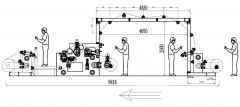

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

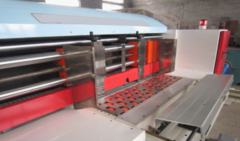

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More

YY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARDYY-2245 AUTOMATIC ROTARY DIE CUTTER, MAXIMUM DIE CUTTING SIZE 2100 X 1200mm-FOR CORRUGATED CARDBOARD MAIN FUNCTION AND USAGE: FULLY COMPUTERISED ROTARY DIE CUTTING MACHINE WITH ADVANCED LEADING EDGE CARDBOARD FEEDING SYSTEM, (4 LINES WHEELS DESIGN), CARDBOARD FEEDING WITH HIGH PRECISION, FAST SPEED, CARDBOARD FEED WHEEL LIFE IS LONG, FEEDS CARDBOARD TO ACHIEVE 10000 PIECES/HOUR DESIGN SPEED IS 160 PIECES/MINUTE WORKING SPEED IS 120 PIECES/MINUTE DIE-CUTTING PRECISION OF ± 1mm. DOUBLE FREQUENCY CHANGER CONTROL, MAIN MOTOR AND DRAUGHT FAN. QUANTITY: 1 Learn More