Search results for: 'convey'

- Related search terms

- Conveyor

- conveyor- F

- conveyor- F-F

- conveyor-+F-K

- conveyor-+F-

-

G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINEREFERENCE NUMBER: G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINE QUANTITY AVAILABLE: 1 Learn More

G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINEREFERENCE NUMBER: G-8018 BEDLINE FULL AUTOMATIC MATTRESS FINISHING LINE QUANTITY AVAILABLE: 1 Learn More -

K-4730 MATTRESS VACUUM COMPRESSING LINEREFERENCE NUMBER: K-4730 MATTRESS VACUUM COMPRESSING LINE THIS MACHINE IS PREPARED WITH AUTOMATIC CYCLES TO REMOVE WORKERS AND REDUCE PRODUCTION TIME FROM EDGING UP TO PACKAGING OR ROLLING VACUUM. COULD BE DONE HIGH SPEED VERSIONS FOR 4 MATTRESSES PER MINUTE. QUANTITY AVAILABLE: 1 Learn More

K-4730 MATTRESS VACUUM COMPRESSING LINEREFERENCE NUMBER: K-4730 MATTRESS VACUUM COMPRESSING LINE THIS MACHINE IS PREPARED WITH AUTOMATIC CYCLES TO REMOVE WORKERS AND REDUCE PRODUCTION TIME FROM EDGING UP TO PACKAGING OR ROLLING VACUUM. COULD BE DONE HIGH SPEED VERSIONS FOR 4 MATTRESSES PER MINUTE. QUANTITY AVAILABLE: 1 Learn More -

X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS THIS MACHINE IS SPECIFIC FOR THE SEWING OF ANY KIND OF SYNTHETIC FIBRES AND FOAM, RESIN OR SIMILAR IN ANY THICKNESS AND WEIGHT USED TO COVER THE WOODEN FRAME QUANTITY AVAILABLE: 1 Learn More

X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONSREFERENCE NUMBER: X-0007 SPECIAL SEWING MACHINE FOR CLOSING PILLOWS AND CUSHIONS THIS MACHINE IS SPECIFIC FOR THE SEWING OF ANY KIND OF SYNTHETIC FIBRES AND FOAM, RESIN OR SIMILAR IN ANY THICKNESS AND WEIGHT USED TO COVER THE WOODEN FRAME QUANTITY AVAILABLE: 1 Learn More -

M-4618 CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTHREFERENCE NUMBER: M-4618 (111152JYP10RX) D CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTH YEAR: 1986, COMPLETELY OVERHAULED IN THE YEAR 2011 ROLLERS WIDTH: 2000MM WORKING WIDTH: 1800MM QUANTITY AVAILABLE: 1 Learn More

M-4618 CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTHREFERENCE NUMBER: M-4618 (111152JYP10RX) D CIBITEX SANFORIZING - COMPACTING AND SHRINKING LINE FOR WOVEN FABRIC IN OPEN WIDTH YEAR: 1986, COMPLETELY OVERHAULED IN THE YEAR 2011 ROLLERS WIDTH: 2000MM WORKING WIDTH: 1800MM QUANTITY AVAILABLE: 1 Learn More -

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More

M-2042 WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGSREFERENCE NUMBER: M-2042 (770IDFGXX6) WISCONSIN OVEN GAS FIRED BATCH OVEN FOR TEMPERING MATTRESS INNERSPRINGS GAS FIRED BATCH OVEN MANUFACTURER: WISCONSIN OVEN STILL ASSEMBLED TODAY OVEN WILL BE USED FOR TEMPERING STEEL SPRING ASSEMBLIES WITH A LOADING OF APPROXIMATELY 50 ASSEMBLIES WEIGHING APPROXIMATELY 40 POUNDS, IN THE OVEN AT A TIME THE SIZE IS BASED ON APPROXIMATELY 4 TO 5 CYCLES PER HOUR PROVIDING THE LOADING AND UNLOADING IS ACCOMPLISHED PROMPTLY THE HEATING RATE IS BASED ON A HEATING CYCLE OF APPROXIMATELY 12 MINUTES PER CYCLE THE OVEN WILL INCLUDE, BUT NOT BE LIMITED TO, THE DEISNG FEATURES OUTLINED IN OUR SPECIFICATIONS LISTED BELOW FURTHER MODIFICATIONS AND DESIGN CHANGES MAY BE INCORPORATED AT THE FINAL ENGINEERING STAGES TO PRODUCE THE BEST EQUIPMENT POSSIBLE QUANTITY AVAILABLE: 1 Learn More -

P-1131 LECTRA LASER CUTTING MACHINE MODEL FOCUS 10 C WIDTH 2500mmREFERENCE NUMBER: P-1131 LECTRA LASER CUTTING MACHINE MODEL FOCUS 10 C WIDTH 2500mm LECTRA LASER CUTTING MACHINE MODEL: FOCUS 10 C ROFIN SINAR DC015 TO 1500 WATT CUTTING SURFACE 1500mm x WIDTH 2500mm HONEY COMB LATH CONVEYOR WIDTH 2500mm MAX CUTTING SPEED 150m per min. MIN CONVEYOR SPEED 10m per min. QUANTITY: 1 Learn More

P-1131 LECTRA LASER CUTTING MACHINE MODEL FOCUS 10 C WIDTH 2500mmREFERENCE NUMBER: P-1131 LECTRA LASER CUTTING MACHINE MODEL FOCUS 10 C WIDTH 2500mm LECTRA LASER CUTTING MACHINE MODEL: FOCUS 10 C ROFIN SINAR DC015 TO 1500 WATT CUTTING SURFACE 1500mm x WIDTH 2500mm HONEY COMB LATH CONVEYOR WIDTH 2500mm MAX CUTTING SPEED 150m per min. MIN CONVEYOR SPEED 10m per min. QUANTITY: 1 Learn More -

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More -

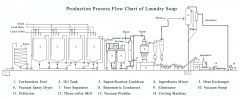

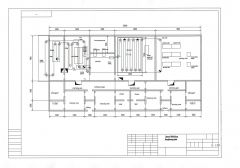

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More

K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HRREFERENCE NUMBER: K-3712 SOAP PRODUCTION LINE-CAPACITY 1000 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1 Learn More -

K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOURREFERENCE NUMBER: K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More

K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOURREFERENCE NUMBER: K-3378 CHICKEN SLAUGHTERING LINE – 500 BIRDS PER HOUR QUANTITY AVAILABLE: 1 Learn More