Search results for: 'line p'

- Related search terms

- line

- Line b

- Line bleach

- Line bleach co

- line up with

-

P-2200 MULTILAYER PAPER SACK TUBE MAKING + BOTTOM MACHINE WITH 4 COLORS IN-LINE FLEXO PINTERREFERENCE NUMBER: P-2200 MULTILAYER PAPER SACK TUBE MAKING + BOTTOM MACHINE WITH 4 COLORS IN-LINE FLEXO PINTER MULTILAYER PAPER SACK TUBE MAKING MACHINE MODEL: ZT1080 SPEED: (11- to 120) NORMAL PRODUCTION RATE/MIN MAXIMUM SPEED OF 150/MINUTES (AND THE QUALITY OF PAPER, PAPER AND THE RISE OF THE SKILLED OPERATORS) TUBE CUR-OFF LENGTH: 540 to 1080mm TUBE WIDTH: 300 to 620mm THE BIGGEST RISE PAPER: 5 LAYERS (LAYER 4-LAYER PE PAPER +1) AIR COMPRESSOR PARAMETERS: ABOUT 1100L/MIN TOTAL POWER: 15 KILOWATTS UNIT WEIGHT: 34.4T OVERALL APPEARANCE DIMENSIONS: 34(L) x 2.4(W) x 2.7(H)m MULTI LAYER PAPER SACK BOTTOM MAKING MACHINE MODEL: HD 620/180 SPEED: 110 NORMAL PRODUCTION RATE/MIN THE MAXIMUM SPEED OF 125/MINUTES (AND THE QUALITY OF PAPER, PAPER AND THE RISE OF THE SKILLED OPERATORS) PAPER CENTER DISTANCE: 350 to 830mm WIDTH OF BAG: 350 to 620mm PASTE BOTTOM WIDTH: 80mm to 180mm TOTAL POWER: 22 KILOWATTA UNIT WEIGHT: 24.5T OVERALL APPEARANCE DIMENSIONS: 28(L) x 2.5(W) x 2(H)m MACHINES ARE WORKING NOW QUANTITY AVAILABLE: 2 Learn More

P-2200 MULTILAYER PAPER SACK TUBE MAKING + BOTTOM MACHINE WITH 4 COLORS IN-LINE FLEXO PINTERREFERENCE NUMBER: P-2200 MULTILAYER PAPER SACK TUBE MAKING + BOTTOM MACHINE WITH 4 COLORS IN-LINE FLEXO PINTER MULTILAYER PAPER SACK TUBE MAKING MACHINE MODEL: ZT1080 SPEED: (11- to 120) NORMAL PRODUCTION RATE/MIN MAXIMUM SPEED OF 150/MINUTES (AND THE QUALITY OF PAPER, PAPER AND THE RISE OF THE SKILLED OPERATORS) TUBE CUR-OFF LENGTH: 540 to 1080mm TUBE WIDTH: 300 to 620mm THE BIGGEST RISE PAPER: 5 LAYERS (LAYER 4-LAYER PE PAPER +1) AIR COMPRESSOR PARAMETERS: ABOUT 1100L/MIN TOTAL POWER: 15 KILOWATTS UNIT WEIGHT: 34.4T OVERALL APPEARANCE DIMENSIONS: 34(L) x 2.4(W) x 2.7(H)m MULTI LAYER PAPER SACK BOTTOM MAKING MACHINE MODEL: HD 620/180 SPEED: 110 NORMAL PRODUCTION RATE/MIN THE MAXIMUM SPEED OF 125/MINUTES (AND THE QUALITY OF PAPER, PAPER AND THE RISE OF THE SKILLED OPERATORS) PAPER CENTER DISTANCE: 350 to 830mm WIDTH OF BAG: 350 to 620mm PASTE BOTTOM WIDTH: 80mm to 180mm TOTAL POWER: 22 KILOWATTA UNIT WEIGHT: 24.5T OVERALL APPEARANCE DIMENSIONS: 28(L) x 2.5(W) x 2(H)m MACHINES ARE WORKING NOW QUANTITY AVAILABLE: 2 Learn More -

L-4023 SAUSAGE PRODUCTION LINE

L-4023 SAUSAGE PRODUCTION LINEL-4023 SAUSAGE PRODUCTION LINE

FROZEN MEAT GRINDER

NOT FROZEN BONELESS MEAT CHUNKS CAN ALSO BE PROCESSED

DIMENSIONS: 850 X 500 X 860mm

POWER: 5.5 KW

VOLTAGE: 380 VOLTS

OUTPUT : 500 KGS PER HOUR

WEIGHT : 182 KGSSLICING MACHINE

MADE OF STAINLESS STEEL

SPACE BETWEEN THE KNIFE AND THE CHOPPING POT IS LESS THAN 2mm

OUTPUT: 30 KGS PER POT

VOLUME OF POT: 40 LITERS

POWER: 5.1 KW

VOLTAGE: 380 VOLTS (OR AS PER CLIENT’S REQUEST)

3 X CHOPPING KNIVES

CUTTING SPEED: 1500 TO 3600 RPM

ROTATING SPEED OF CHOPPING POT: 7 RPM

EXTERNAL DIMENSIONS: 1110 X 865 X 1200mmVACUUM ROLLING MACHINE

FOR STIRRING THE MEAT IN A VACUUM

CONSISTS OF A BARREL, FRAME, VACUUM PUMP, REDUCER, AND ELECTRICAL SYSTEM

CAN SPEED UP THE EXTRACTION AND DISSOLUTION OF PROTEINHYDRAULIC SAUSAGE FILLING MACHINE

VOLUME: 50 LITERS

POWER: 2.2 KW

FILLING DIAMETER: 10 TO 50mm

OUTPUT: 600 TO 700 KGS PER HOUR

DIMENSIONS: 1050 X 850 X 1400mmSEMI-AUTOMATIC SAUSAGE BINDING MACHINE

FRAME MADE OF STAINLESS STEEL

FOR HOT DOGS, SHEEP CASING, PLASTIC CASING, TAIWAN HOT DOGS, FRIED SAUSAGE, ETC.

POWER: 0.55 KW

CAPACITY: 80 TIMES PER MINUTE

CASING DIAMETER: 10 TO 35mm

EXTERNAL DIMENSIONS: 1100 X 750 X 900mmSMOKE OVEN

Learn More

FOR COOKING, DRYING, BAKING, SMOKING, ETC.

OUTPUT: 100 KGS

POWER: 12 KW

HIGH PRESSURE STEAM: 0.3 TO 0.6 mpa

LOW PRESSURE STEAM: 0.1 TO 0.2 mpa -

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE

J-2788 SEMI-AUTOMATIC DISPOSABLE FLAT MASK PRODUCTION LINE3 LAYER MASKS CONSTRUCTED OF NONWOVEN AND MELTBLOWN FABRIC

MASK DIMENSIONS: 175 x 95mm (ADULT) & 145 x 90mm (CHILD)---COMPOSED OF TWO MACHINES, AS BELOW

1) AUTOMATIC MASK LAYER MAKING AND CUTTING MACHINE

CAPACITY: 200 TO 300 PIECES PER MINUTE

INCLUDES

• MATERIAL FEEDING FRAME

• MACHINE FRAME

• ALUMINUM NOSE STRIP INSERTION

• ULTRASONIC WELDING

• CONVEYOR

DIMENSIONS: 4600 x 500 x 2100mm

WEIGHT: 300 KGS

POWER: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER)

2) MANUAL EAR BAND WELDING MACHINE

CAPACITY: 30 TO 40 PIECES PER MINUTE

INCLUDES

• WORKBENCH

• LIGHT

• AIR CYLINDER

• ULTRASONIC GENERATOR

• CONTROL SYSTEM

DIMENSIONS: 800 x 500 x 1000mm

WEIGHT: 43 KGS

POWER: 380 VOLTS, 50 Hz (OR AS PER CUSTOMER)WARRANTY: 1 YEAR FOR MAJOR COMPONENTS, LIFELONG SERVICE FOR THE USER

QUANTITY: 1 COMPLETE SEMI-AUTOMATIC LINE

Learn More -

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More

AA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINEAA-1159 FOUR NOZZLES PILLOW FILLING PRODUCTION LINE FOUR NOZZLES PILLOW FILLING MACHINE: IT IS SUITABLE FOR OPENING AND PROCESSING FIBER RAW MATERIAL, FILLING PILLOW CORE AND CUSHION. CHARACTERISTICS: LESS INVESTMENT, HIGH EFFICIENCY, SIMPLE OPERATION, WITH FREQUENCY CONVERSION DEVICE. RAW MATERIAL REQUIREMENTS: FIBERS ABOVE 0.78D, CAN BE OPENED AT ONE TIME. Learn More -

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More

MELT BLOWN CLOTH PRODUCTION LINE 600mmREFERENCE NUMBER: A-2488 MELT BLOWN CLOTH PRODUCTION LINE 600mm SPECIFICATIONS: PLASTIC AUTOMATIC CHARGER • FEEDING CAPACITY: 200 KG / H • AIR PUMP POWER: 0.75 KW HOPPER PLASTIC DRYER • HOPPER CUBIC CAPACITY: 100 L • FEEDING CAPACITY: 50 KG • HEATING POWER: 3.7 KW • BLOWER POWER: 0.12 KW SJ55/30 SINGLE SCREW EXTRUDER • SCREW, BARREL: SCREW AND BARREL MATERIAL 38CRMOALA, NITRIDE • SCREW DIAMETER: 55 mm • SCREW L/D: 30:1 • MAIN MOTOR POWER: 15 KW SIEMENS STANDARD • MOTOR MAIN MOTOR SPEED ADJUSTMENT: 15 KW ABB INVERTER • BARREL HEATING: CASTING - HEATER WITH AIR COOLING • HEATING POWER: 2.8 KW X 4 ZONES • GEAR BOX: ZLYJ SERIES RIGID GEAR BOX • EXTRUSION CAPACITY: 15 TO 40 KG/H HYDRAULIC SCREEN CHANGER • MOTOR POWER: 1.1 KW • STRUCTURE: DOUBLE POSITION, PLATE TYPE • HEATERS: STAINLESS STEEL HEATING BAR METERING PUMP • MOTOR POWER: 2.2KW • CAPACITY: 30CC • SPEED CONTROL: • HEATERS: STAINLESS STEEL HEATING BAR T-DIE • STRUCTURE: T-DIE • MATERIAL OF MOULD: HIGH QUALITY ALLOYED STEEL, SURFACE CHROME PLATED • FLOW CHANNEL CHROME PLATED, POLISHED • SPECIFICATION OF PRODUCT: WIDTH 600 mm • AIR INCOME HOLES: 12 PCS, HIGH PRECISION TEMPERATURE CONTROL FORMING MACHINE • MOTOR POWER: 1.5 KW • SPEED CONTROL: INVERTER • SUCTION FAN: 5.5 KW ELECTROSTATIC ELECTRET DEVICE • INCLUDES ELECTROSTATIC GENERATOR, VOLTAGE REGULATOR, ELECTRET FRAME • APPLICATION: GENERATE ELECTROSTATIC CHARGE, INCREASES THE FILTERING EFFICIENCY • MOTOR POWER: 2.2 KW • BLADES: 4 PCS • HAULING SPEED CONTROL: ADOPTABB INVERTER COLIER • COILING SHAFT: 2 PCS • COMPACTION: BY PNEUMATIC CONTROL • COILING METHOD: BY SELF FRICTION SCREW AIR COMPRESSOR • MOTOR POWER: 37 KW • STRUCTURE: SCREW TYPE, LOW NOISY • PLC CONTROL AIR FILTER • CAPACITY: 7 M3/min • PRESSURE: 1.0 MPA • FILTRATION EFFICIENCY: 3 MICRON / 5 PPM AIR DRYER • CAPACITY: 6 NM3/min • PRESSURE: 1 MPA • POWER: 2 HP AIR TANK • VOLUME: 1000 L • PRESSURE: 1.05 MPA HOT AIR SYSTEM • HEATING POWER: 60 KW • HEATING TYPE: ELECTRIC HEATING • WITH HEAT INSULATION LAYER Learn More -

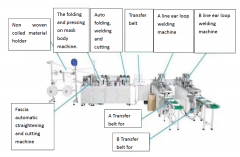

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAY

J-2733 COMPLETE AUTOMATIC PRODUCTION LINE FOR FACE MASKS – 140,000 PIECES PER 24-HOUR DAYPRODUCES FLAT MASKS AUTOMATICALLY: COILS STOCK, FOLDS AND PRESSES, MOLDS MASK, CUTS, LOADS AND WELDS EAR LOOPS, FINISHED PRODUCTS EXIT THE MACHINE

Learn More

MASKS ARE COMFORTABLE, NO PRESSURE, EASY TO WEAR AND PROVIDE GOOD FILTRATION

LINE FEATURES

ULTRASONIC WELDING MACHINE

HIGH SPEED PRODUCTION: 120,000 TO 140,000 PIECES PER 24-HOUR DAY

-APPROXIMATELY 90 TO 110 PIECES PER MINUTE

MODULAR AND PERSONNEL-FRIENDLY DESIGN WITH EASY MAINTENANCE

AUTOMATIC STOP AND ALARM FEATURE FOR MATERIAL BREAKAGE AND OTHER EXCEPTIONS, WITH ON-SCREEN HELP FOR CORRECTING THE BREAKAGE/EXCEPTIONS

DIMENSIONS: 6500mm LENGTH x 2500mm WIDTH x 1950mm HEIGHT

WEIGHT: </= 5000 KG

POWER: 220 VOLTS +/- 5% , 50 Hz, GROUND PROTECTION (OR AS PER CUSTOMER)

TOTAL KW: APPROXIMATELY 8.8 KW

AIR: 0.4 TO 0.6 MP (CLEAN AIR AFTER DEWATER, OIL-LESS, FILTRATION AND PRESSURE)

MAIN ACCESSORY: AIRTAC AIR CYLINDER

QUANTITY: 1 COMPLETE LINE (2 SETS CURRENTLY AVAILABLE MARCH 17TH) -

R-7836 BERLINER KRAPFEN DONUT LINE, YEAR 2008, 5,000 PIECES PER HOUR

R-7836 BERLINER KRAPFEN DONUT LINE, YEAR 2008, 5,000 PIECES PER HOURBERLINER (KRAPFEN PRODUCTION) 5,000 PIECES PER HOUR YEAR 2008

DONUT PRODUCTION 5,000 PIECES PER HOUR

INCLUDING AUTOMATIC INFEED CONVEYOR

INCLUDING EXTRACTED HOOD WITH SUCTION SYSTEM

INCLUDING AUTOMATIC FILLING OF THE JAM

INCLUDING AUTOMATIC DEPOSITOR

INCLUDING OUTFEED CONVEYOR FOR FRIED PRODUCT

INCLUDING PROOVING CLOTHES FOR THE BERLINER KRAPFEN

ELECTRIC HEATED 50 KW

Learn More -

M-3471 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: M-3471 (880OKRSHH7) L NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm TECHNICAL DATA: RAW MATERIALS: NYLON, POLYESTER, POLYPROPYLENE, GLASS FIBER, ETC. FINENESS OF FIBER: 2.5 TO 10DENIER LENGTH OF FIBER: 38 TO 76mm MIXING RATIO BETWEEN TWO FIBERS: 20 TO 100% SPEED: 6m/min (PER 2.5-6D× 38-51mm) MAX. 5000 KG/DAY (PER 22 HOURS/DAY) RANGE OF GRAM WEIGHT: 100 TO 250g/m2 CARDING MACHINE FEATURES ARE ACCORDING GRAM WEIGHT: 250G/M², 300G/M² PROCESS FLOW CHART: BALE OPENER---PER-OPENER—FINE OPENER--FEEDER---CARDING MACHINE-- CROSSLAPPER--TRANSIT APRON---HIGH-SPEED PRE-NEEDLE LOOM---(2) HIGH-SPEED MAIN NEEDLE LOOM--CALENDER---CUTTER AND REWINDER QUANTITY AVAILABLE: 1 Learn More

M-3471 NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mmREFERENCE NUMBER: M-3471 (880OKRSHH7) L NEEDLE PUNCHED NONWOVEN PRODUCTION LINE 4500mm TECHNICAL DATA: RAW MATERIALS: NYLON, POLYESTER, POLYPROPYLENE, GLASS FIBER, ETC. FINENESS OF FIBER: 2.5 TO 10DENIER LENGTH OF FIBER: 38 TO 76mm MIXING RATIO BETWEEN TWO FIBERS: 20 TO 100% SPEED: 6m/min (PER 2.5-6D× 38-51mm) MAX. 5000 KG/DAY (PER 22 HOURS/DAY) RANGE OF GRAM WEIGHT: 100 TO 250g/m2 CARDING MACHINE FEATURES ARE ACCORDING GRAM WEIGHT: 250G/M², 300G/M² PROCESS FLOW CHART: BALE OPENER---PER-OPENER—FINE OPENER--FEEDER---CARDING MACHINE-- CROSSLAPPER--TRANSIT APRON---HIGH-SPEED PRE-NEEDLE LOOM---(2) HIGH-SPEED MAIN NEEDLE LOOM--CALENDER---CUTTER AND REWINDER QUANTITY AVAILABLE: 1 Learn More -

E-6016 TRUTZSCHLER PREPARATION LINE FOR COTTON FIBERSINVENTORY NUMBER: E-6016 TRUTZSCHLER PREPARATION LINE FOR COTTON FIBERS YEAR 2003 FOR SALE AS A COMPLETE PLANT ONLY TRUTZSCHLER COTTON PROCESSING MACHINE, C/O, MODEL SC 1552002 QUANTITY AVAILABLE: 1 Learn More

E-6016 TRUTZSCHLER PREPARATION LINE FOR COTTON FIBERSINVENTORY NUMBER: E-6016 TRUTZSCHLER PREPARATION LINE FOR COTTON FIBERS YEAR 2003 FOR SALE AS A COMPLETE PLANT ONLY TRUTZSCHLER COTTON PROCESSING MACHINE, C/O, MODEL SC 1552002 QUANTITY AVAILABLE: 1 Learn More -

TT-8221 TETRA PAK ASEPTIC FILLING LINE, YEAR 2004 TO 2006, 82700 HOURSTT-8221 TETRA PAK ASEPTIC FILLING LINE, YEAR 2004 TO 2006, 82700 HOURS FILLING MACHINE: 1. BRAND: TETRA PAK 2. TYPE: A3 FLEX 3. YEAR OF MANUFACTURE: 2004 4. FORMAT: 1000 ML SLIM 5. CAP: DIMC LIGHT CAP 24 6. DEV. STAGE: 100V 7. HOURS OF OPTION: 82700 H Learn More

TT-8221 TETRA PAK ASEPTIC FILLING LINE, YEAR 2004 TO 2006, 82700 HOURSTT-8221 TETRA PAK ASEPTIC FILLING LINE, YEAR 2004 TO 2006, 82700 HOURS FILLING MACHINE: 1. BRAND: TETRA PAK 2. TYPE: A3 FLEX 3. YEAR OF MANUFACTURE: 2004 4. FORMAT: 1000 ML SLIM 5. CAP: DIMC LIGHT CAP 24 6. DEV. STAGE: 100V 7. HOURS OF OPTION: 82700 H Learn More