Search results for: 'Blade'

- Related search terms

- Blade w

- Blade wi

- Blade pp-

- Blade pp-11)9

- Blade pp-11

-

TT-1259 UNITED CONVERTING S60-2 INDUSTRIAL ROLL LINE, WIDTH 106”, YEAR 2006TT-1259 UNITED CONVERTING S60-2 INDUSTRIAL ROLL LINE, WIDTH 106”, YEAR 2006 AVAILABILITY: IMMEDIATE INSPECTION: IN PRODUCTION QUANTITY: 1 Learn More

TT-1259 UNITED CONVERTING S60-2 INDUSTRIAL ROLL LINE, WIDTH 106”, YEAR 2006TT-1259 UNITED CONVERTING S60-2 INDUSTRIAL ROLL LINE, WIDTH 106”, YEAR 2006 AVAILABILITY: IMMEDIATE INSPECTION: IN PRODUCTION QUANTITY: 1 Learn More -

TT-1273 GIESSE MODEL AC97/EM CHENILLE MACHINE WITH 80 SPINDLES, YEAR 1997TT-1273 GIESSE MODEL AC97/EM CHENILLE MACHINE WITH 80 SPINDLES, YEAR 1997 DELIVERY: IMMEDIATE CONDITION: USED IN EXCELLENT CONDITION QUANTITY: 1 Learn More

TT-1273 GIESSE MODEL AC97/EM CHENILLE MACHINE WITH 80 SPINDLES, YEAR 1997TT-1273 GIESSE MODEL AC97/EM CHENILLE MACHINE WITH 80 SPINDLES, YEAR 1997 DELIVERY: IMMEDIATE CONDITION: USED IN EXCELLENT CONDITION QUANTITY: 1 Learn More -

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More

J-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEWJ-2628 COMPLETE BIAS BINDING SYSTEM (SEWING, SLITTING & WINDING SYSTEM) – NEW SEWING MACHINE FOLDS FABRIC, STITCHES EDGE OF FABRIC FOR TWILL EFFECT WORKS TOGETHER WITH WINDING MACHINE AND STRIP CUTTING MACHINE WINDING MACHINE OPENS PREVIOUSLY FORMED TUBE MATERIAL, SPIRALLY, IN THE BIAS, AND REWINDS A SINGLE PLY ROLL, AT BOTTOM OF MACHINE THERE IS A KNIFE TO CUT SEWING FABRIC SEPARATELY, PREPARED FOR THE SLITTER SLITTER MACHINE HAS MANUAL, SEMI-AUTOMATIC AND FULLY AUTOMATIC MODES. WILL SLIT ANY TYPE OF MATERIAL ON THE ROLL (OPEN KNITS, WOVEN FABRIC, LEATHER, POLYESTER, SOME PAPER PRODUCTS, NONWOVEN, ETC) QUANTITY: 1 SLITTER, 1 WINDER Learn More -

YY-2080 USED W&H ASTRAFLEX 50" 10 COLOR PRESS, YEAR 2003YY-2080 USED W&H ASTRAFLEX 50" 10 COLOR PRESS, YEAR 2003 MANUFACTURER: W&H MODEL: ASTRAFLEX 53" YEAR: 2003 CONDITION: USED 2003 W&H ASTRAFLEX 53" 10 COLOR CI PRESS WITH 40" DIAMETER TURRET UNWIND AND REWIND, GAS DRYING, DOCTOR BLADES, AUTO DECK POSITIONING. MANY CYLINDERS AND SPARE ANILOX ROLLS. IN GREAT CONDITION, AVAILABLE NOW, CAN BE SEEN RUNNING. 1200'/MIN REPEAT RANGE: 13"- 27" FOOT PRINT DIMENSIONS: 75' LONG X 21' HIGH X 34' WIDE (PRESS BUILT IN 2002, INSTALLED IN 2003) QUANTITY: 1 Learn More

YY-2080 USED W&H ASTRAFLEX 50" 10 COLOR PRESS, YEAR 2003YY-2080 USED W&H ASTRAFLEX 50" 10 COLOR PRESS, YEAR 2003 MANUFACTURER: W&H MODEL: ASTRAFLEX 53" YEAR: 2003 CONDITION: USED 2003 W&H ASTRAFLEX 53" 10 COLOR CI PRESS WITH 40" DIAMETER TURRET UNWIND AND REWIND, GAS DRYING, DOCTOR BLADES, AUTO DECK POSITIONING. MANY CYLINDERS AND SPARE ANILOX ROLLS. IN GREAT CONDITION, AVAILABLE NOW, CAN BE SEEN RUNNING. 1200'/MIN REPEAT RANGE: 13"- 27" FOOT PRINT DIMENSIONS: 75' LONG X 21' HIGH X 34' WIDE (PRESS BUILT IN 2002, INSTALLED IN 2003) QUANTITY: 1 Learn More -

TT-1196 NONWOVEN MACHINES FOR NEEDLEFELTS PRODUCTON, YEAR 1995 TO 2015TT-1196 NONWOVEN MACHINES FOR NEEDLEFELTS PRODUCTON, YEAR 1995 TO 2015 MACHINES FOR THE PRODUCTION OF NEEDLEPUNCHED FELTS 1. BLENDING THT YEAR 2015 2. OPENING: THT YEAR 2015 3. CARDING: F.O.R. YEAR 1995 UPDATED ON 2015 4. CROSSLAPPING: GUASCH YEAR 2000 UPDATED ON 2015 5. NEEDLEPUNCHING: CHANGSHU SNM YEAR 2015 6. SLITTING. CROSSCUTTING & WINDING: THT YEAR 2015 Learn More

TT-1196 NONWOVEN MACHINES FOR NEEDLEFELTS PRODUCTON, YEAR 1995 TO 2015TT-1196 NONWOVEN MACHINES FOR NEEDLEFELTS PRODUCTON, YEAR 1995 TO 2015 MACHINES FOR THE PRODUCTION OF NEEDLEPUNCHED FELTS 1. BLENDING THT YEAR 2015 2. OPENING: THT YEAR 2015 3. CARDING: F.O.R. YEAR 1995 UPDATED ON 2015 4. CROSSLAPPING: GUASCH YEAR 2000 UPDATED ON 2015 5. NEEDLEPUNCHING: CHANGSHU SNM YEAR 2015 6. SLITTING. CROSSCUTTING & WINDING: THT YEAR 2015 Learn More -

J-4509 EDGE SWEETS HORIZONTAL FOAM SAW, MODEL 5088 – 50” MAXIMUM BUN HEIGHTJ-4509 EDGE SWEETS HORIZONTAL FOAM SAW, MODEL 5088 – 50” MAXIMUM BUN HEIGHT MAKE: EDGE SWEETS MODEL: 5088 OFFERED REBUILT AND IN GUARANTEED RUNNING CONDITION QUANTITY: 1 Learn More

J-4509 EDGE SWEETS HORIZONTAL FOAM SAW, MODEL 5088 – 50” MAXIMUM BUN HEIGHTJ-4509 EDGE SWEETS HORIZONTAL FOAM SAW, MODEL 5088 – 50” MAXIMUM BUN HEIGHT MAKE: EDGE SWEETS MODEL: 5088 OFFERED REBUILT AND IN GUARANTEED RUNNING CONDITION QUANTITY: 1 Learn More -

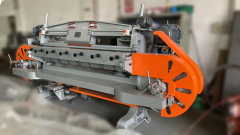

J-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mmJ-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mm WEIGHT: ABOUT 3.5 TONS REQUIRES 1 20 FOOT CONTAINER QUANTITY: 1 Learn More

J-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mmJ-4504 RUBBER EVA SPLITTING MACHINE (SKIVING MACHINE), WORKING WIDTH 1780mm WEIGHT: ABOUT 3.5 TONS REQUIRES 1 20 FOOT CONTAINER QUANTITY: 1 Learn More -

J-4496 EASTMAN RAPTOR 75X- 78X7-5J-4496 EASTMAN RAPTOR 75X- 78X7-5 MACHINE IS PRACTICALLY NEW, ONLY RAN ABOUT 200 HOURS IN PERFECT RUNNING CONDITION AVAILABLE IMMEDIATELY MADE IN THE USA STANDARD EQUIPMENT RECIPROCATING STRAIGHT KNIFE WITH QUICK-REMOVAL CLAMP, 10 SPARE BLADES 2 AUTOMATED SHARPENING DISCS, 1 EXTRA SET OF DISCS INCLUDED (CHOICE OF: 60,80,100, OR 150 GRIT) Learn More

J-4496 EASTMAN RAPTOR 75X- 78X7-5J-4496 EASTMAN RAPTOR 75X- 78X7-5 MACHINE IS PRACTICALLY NEW, ONLY RAN ABOUT 200 HOURS IN PERFECT RUNNING CONDITION AVAILABLE IMMEDIATELY MADE IN THE USA STANDARD EQUIPMENT RECIPROCATING STRAIGHT KNIFE WITH QUICK-REMOVAL CLAMP, 10 SPARE BLADES 2 AUTOMATED SHARPENING DISCS, 1 EXTRA SET OF DISCS INCLUDED (CHOICE OF: 60,80,100, OR 150 GRIT) Learn More -

YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004 HIGH PRODUCTION DIRECT FEEDING SYSTEM MADE BY MASIAS ON 2004 SUITABLE FOR THE PRODUCTION OF QUILTS (DUVETS & MATTRESSES) AND/OR WADDING. ALSO, SOME NEEDLEPUNCHED SPECIAL PRODUCTS FOR FURNITURE/MATTRESSES/TRANSPORT PROTECTION. Learn More

YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004YY-2112 MASIAS SAD 3000 DIRECT FEEDING LINE SYSTEM FOR QUILTS, WADDINGS & SPECIAL NEEDLEPUNCHED PRODUCTS, YEAR 2004 HIGH PRODUCTION DIRECT FEEDING SYSTEM MADE BY MASIAS ON 2004 SUITABLE FOR THE PRODUCTION OF QUILTS (DUVETS & MATTRESSES) AND/OR WADDING. ALSO, SOME NEEDLEPUNCHED SPECIAL PRODUCTS FOR FURNITURE/MATTRESSES/TRANSPORT PROTECTION. Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More