Search results for: 'sealing+machine'

-

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

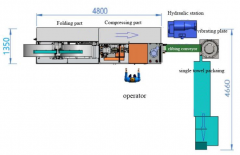

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More -

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More -

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More

AA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTEAA-1152 AUTOMATIC CARTONING MACHINE, 30 TO 40 BOXES PER MINUTE 1. CARTONING FORM: HORIZONTAL CARTONING 2. CARTONING SPEED: 30 TO 40 BOXES PER MINUTE 3. PROCESS REQUIREMENTS: AUTOMATIC BOX OPENING, CARTONING, GLUE SPRAYING, BOX SEALING 4. INCOMING DIRECTION: FROM LEFT TO RIGHT 5. VOLTAGE: 220 VOLTS, 50 Hz (OR AS PER CUSTOMER) 6. THE INDENTATION OF THE CARTON IS GENERALLY 0.4mm DEEP, AND THE CARTON NEEDS TO HAVE A PRE-FOLDING EFFECT. IF THE BOX IS OPENED MANUALLY, IT CANNOT BE FORMED, AND THE MACHINE CANNOT OPEN THE BOX. QUANTITY: 1 Learn More -

P-4338 TOILET TISSUE PAPER PACKING MACHINE

P-4338 TOILET TISSUE PAPER PACKING MACHINEREFERENCE NUMBER: P-4338

TOILET TISSUE PAPER PACKING MACHINE

Model: TL-R

Machine Characteristic

Control system: PLC

Drive element: servo motor

Operate interface: LCD touch screen

Packing style: back sealing by interfold sealing type, end sealing by flat type

Detection online: roll tissue deliver detect

Auto feeding: servo motor synchronous feeding

Specifications

Suitable production: paper in roll adaptable

Production size: L90-230mm,φ80-130mm

Suitable packing material: OPP CPP PE etc. heat-seal material

Packing Film specification: max W450mm,φ350mm

Diameter of ventilating shaft :3"

Production speed: 80 bags/min design 100 bags/min

Machine space: L7250mm W1900mm H1650mm

Power: AC380V 50/60Hz 15KW

Compressed air:0.6-0.8Mpa 0.5m³ /min

Machine net weight: 1500kg

Option equipment: Coding machine, Roll paper storage machine, Roll paper flail knifeQUANTITY: 1

Learn More -

J-4128 AUTOMATIC VACUUM PACKING MACHINE, 6 TO 8 PIECES PER MINUTEJ-4128 AUTOMATIC VACUUM PACKING MACHINE, 6 TO 8 PIECES PER MINUTE AUTOMATIC VACUUM PACKING MACHINE CAPACITY: 6 TO 8 PIECES PER MINUTE WORKING AREA: 800 x 800mm SEALING LENGTH: 800mm POWER: 1.5 KW QUANTITY: 1 Learn More

J-4128 AUTOMATIC VACUUM PACKING MACHINE, 6 TO 8 PIECES PER MINUTEJ-4128 AUTOMATIC VACUUM PACKING MACHINE, 6 TO 8 PIECES PER MINUTE AUTOMATIC VACUUM PACKING MACHINE CAPACITY: 6 TO 8 PIECES PER MINUTE WORKING AREA: 800 x 800mm SEALING LENGTH: 800mm POWER: 1.5 KW QUANTITY: 1 Learn More -

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More

Z-1613 AUTOMATIC CARTON PACKAGING MACHINEZ-1613 AUTOMATIC CARTON PACKAGING MACHINE CARTONING FORM: HORIZONTAL CARTONING CARTONING SPEED: 30 TO 40 BOXES PER MINUTE (DEPENDING ON CARTON DIMENSIONS) PROCESS REQUIREMENTS: -AUTOMATIC BOX OPENING, CARTONING -GLUE SPRAYING -BOX SEALING VOLTAGE: 220 VOLTS, 60Hz PLC MICRO COMPUTER FULL AUTOMATIC CONTROL MAN-MACHINE INTERFACE OPERATION SYSTEM (HMI), AUTOMATICALLY DISPLAYS THE PACKING SPEED, QUANTITY, FAULT REASON AND OTHER PERFORMANCE PARAMETERS. THE INDENTATION OF THE CARTON IS GENERALLY: 0.4mm DEEP QUANTITY: 1 Learn More -

V-1213 MATTRESS FILM PACKING MACHINE-MANUAL

V-1213 MATTRESS FILM PACKING MACHINE-MANUALREFERENCE NUMBER: V-1213

MATTRESS FILM PACKING MACHINE-MANUAL

MODEL: 26C

VOLTAGE: 220V/50Hz

DIMENSIONS (W X L X H): 2900mm x 760mm x 2700mm

QUANTITY: 1

Learn More -

TT-7500 TETRA PAK FILLING MACHINE A3 FLEX 600V 1000 EDGE 7000 BPH, YEAR 2006TT-7500 TETRA PAK FILLING MACHINE A3 FLEX 600V 1000 EDGE 7000 BPH, YEAR 2006 1. BRAND: TETRA PAK® 2. MODEL: A3 FLEX 600V 3. YEAR: 2006 4. SPEED: 7000 BPH QUANTITY: 1 Learn More

TT-7500 TETRA PAK FILLING MACHINE A3 FLEX 600V 1000 EDGE 7000 BPH, YEAR 2006TT-7500 TETRA PAK FILLING MACHINE A3 FLEX 600V 1000 EDGE 7000 BPH, YEAR 2006 1. BRAND: TETRA PAK® 2. MODEL: A3 FLEX 600V 3. YEAR: 2006 4. SPEED: 7000 BPH QUANTITY: 1 Learn More