Search results for: 'two for'

- Related search terms

- fork

- TWO FOR ONE

- two for o

- form fill

- For in

-

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More

FULLY AUTOMATIC MASK MACHINEREFERENCE NUMBER: P-8845 FULLY AUTOMATIC MASK MACHINE THIS EQUIPMENT IS A FULL-AUTOMATIC ONE-TIME PLANE MASK FORMING MACHINE, WHICH IS USED FOR THE FORMING OF ONE-TIME RECTANGULAR EAR HANGING THREE DRAWER MASKS. ONE MAIN MACHINE IS EQUIPPED WITH TWO EAR BELT SPOT WELDING MACHINES (ONE FOR TWO). THE DRIVING MOTOR IS SERVO MOTOR, SO IT HAS THE ADVANTAGES OF HIGH RELIABILITY, EASY OPERATION, ACCURATE TRANSMISSION, STABLE CONTROL, ADJUSTABLE SPEED, LOW COST AND CONVENIENT MAINTENANCE, ESPECIALLY SUITABLE FOR THE PRODUCTION OF HIGH-QUALITY MASKS. SPECIFICATIONS TEMPERATURE: 10 TO 350, HUMIDITY 5 TO 35%, NO FLAMMABILITY AND NONCORROSIVE GAS VOLTAGE: 220V POWER FREQUENCY: 50Hz PER 60Hz TOTAL POWER OF EQUIPMENT: 8.5KW ULTRASONIC FREQUENCY: 5 TO 20KHz MAX FEEDING WITH OVERALL DIMENSION OF EQUIPMENT: 6100 x 3300 x 1800 MACHINE WEIGHT: 2 TONS PRODUCTION EFFICIENCY: 80 TO 120 TABLETS PER MIN (EACH WORKING STATION 60 PCS PER MIN, AS WE HAVE TWO WORKING STATION). OPERATOR: 1 PERSON QUANTITY: 1 Learn More -

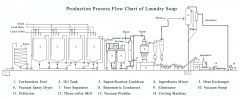

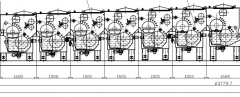

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More

X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MOREREFERENCE NUMBER: X-0008 ELECTRONICALLY CONTROLLED SEMI-AUTOMATIC FILLING FOR PILLOW, CUSHIONS, QUILTS, BABY MATTRESSES AND MORE THIS MACHINE IS A STAND-ALONE AND VERY VERSATILE PILLOW STUFFING AND BAGGING MACHINE. ITS SIMPLE OPERATION ALLOWS TO USE THE SAME EQUIPMENT TO ACCOMPLISH THE TWO PROCESSES: STUFFING A BATT OR A FOAM CORE IN A COVER (OR AN INSERT IN THE FINAL DEC COVER / A PILLOW IN THE FINAL ZIPPERED COVER) AND/OR PUT A FINISHED PILLOW IN A BAG (INDIVIDUAL PE BAG, TWIN-PACK BAG, ZIPPERED VINYL BAG, ETC). THE MACHINE CAN BE LOADED MANUALLY OR WITH A CONVEYOR ON THE REAR PART, WHILE AN OPERATOR IS NEEDED IN THE FRONT: HE PUTS THE COVER/BAG ONTO THE STUFFING BELTS, ACTIVATES THE TENSIONING FORKS WITH THE PEDAL AND HOLDING THE COVER/BAG FACILITATES THE PILLOW STUFFING. POWER SUPPLY IS 400 VOLTS, WILL NEED A TRANSFORMER TO OPERATE ON 480 VOLTS, INQUIRE IF NEEDED Learn More -

TT-7926 PEDERSEN 601M-16 HYDRAULIC PRESS, 1000 X 1600mm, 100 TONTT-7926 PEDERSEN 601M-16 HYDRAULIC PRESS, 1000 X 1600mm, 100 TON 1. HYDRAULIC PRESSES 2. BRAND: PEDERSEN 3. MODEL: 601M-16S 4. CONDITION: REBUILT 5. REFURBISHED QUANTITY: 1 Learn More

TT-7926 PEDERSEN 601M-16 HYDRAULIC PRESS, 1000 X 1600mm, 100 TONTT-7926 PEDERSEN 601M-16 HYDRAULIC PRESS, 1000 X 1600mm, 100 TON 1. HYDRAULIC PRESSES 2. BRAND: PEDERSEN 3. MODEL: 601M-16S 4. CONDITION: REBUILT 5. REFURBISHED QUANTITY: 1 Learn More -

TT-7922 FH4163-100M HYDRAULIC PRESS, BED SIZE 41.3” D X 63” W WITH SINGLE AUTOMATED SLIDE TABLE AND PAD SHIFTER ON THE HEAD, 100 TONTT-7922 FH4163-100M HYDRAULIC PRESS, BED SIZE 41.3” D X 63” W WITH SINGLE AUTOMATED SLIDE TABLE AND PAD SHIFTER ON THE HEAD, 100 TON 1. BRAND: APMC 2. MODEL: FH4163-100M 3. FULL HEAD PRESS QUANTITY: 1 Learn More

TT-7922 FH4163-100M HYDRAULIC PRESS, BED SIZE 41.3” D X 63” W WITH SINGLE AUTOMATED SLIDE TABLE AND PAD SHIFTER ON THE HEAD, 100 TONTT-7922 FH4163-100M HYDRAULIC PRESS, BED SIZE 41.3” D X 63” W WITH SINGLE AUTOMATED SLIDE TABLE AND PAD SHIFTER ON THE HEAD, 100 TON 1. BRAND: APMC 2. MODEL: FH4163-100M 3. FULL HEAD PRESS QUANTITY: 1 Learn More -

T-9596 BUTTON PULL TEST MACHINET-9596 BUTTON PULL TEST MACHINE FEATURE: 1. SNAP BUTTON PULL TEST MACHINE IS A SIMPLE BUT EFFECTIVE DESIGN MAINLY CONSISTING OF A HIGH PRECISION GAUGE, A STURDY REQUIRED BY STANDARDS & REGULATIONS IS BE FIXED HORIZONTALLY (CONSTANT FORCE IS APPLIED TO SECURE THE SAMPLE) SO THAT SNAP OR OTHER ACCESSORIES ATTACHED IN FABRIC CAN BE CLAMPED INTO. 2. MOREOVER, A STANDARD WEIGHT IS ALSO OFFERED SO THAT IT CAN BE REGULARLY CHECKED IF IT MEETS THE SAFETY REQUIREMENTS. 3. THE CAPABILITY OF THE BUTTON PULL TEST MACHINE CAN BE ENHANCED WITH CLAMPS & ACCESSORIES FOR TESTING OF OTHER SNAPS, JEAN BUTTONS, FOUR HOLE BUTTONS & GARMENTS ACCESSORIES SUCH AS ZIPPERS, BOWS, APPLIQUÉ, TOGGLES, HOOKS/BARS, AND D-RINGS, AMONGST OTHERS. SPECIFICATION: DIMENSIONS: 260 X 310 X 820mm NET WEIGHT: 32KG ACCESSORIES: STANDARD ACCESSORIES 1PC - IMADA FORCE GAUGE FB-30K 1PC - UPPER UNIVERSAL GRIP 1PC - UPPER STUD GRIP 1PC - LOWER FABRIC CLAMP & LEVEL ARM LOCKING 1PC - LOWER GRASP BUTTON ACCESSORY KIT 1PC - CALIBRATION WEIGHT 15LB 1PC - THREE PRONGED GRIP 1PC - UPPER LONG NOSE VISE GRIP Learn More

T-9596 BUTTON PULL TEST MACHINET-9596 BUTTON PULL TEST MACHINE FEATURE: 1. SNAP BUTTON PULL TEST MACHINE IS A SIMPLE BUT EFFECTIVE DESIGN MAINLY CONSISTING OF A HIGH PRECISION GAUGE, A STURDY REQUIRED BY STANDARDS & REGULATIONS IS BE FIXED HORIZONTALLY (CONSTANT FORCE IS APPLIED TO SECURE THE SAMPLE) SO THAT SNAP OR OTHER ACCESSORIES ATTACHED IN FABRIC CAN BE CLAMPED INTO. 2. MOREOVER, A STANDARD WEIGHT IS ALSO OFFERED SO THAT IT CAN BE REGULARLY CHECKED IF IT MEETS THE SAFETY REQUIREMENTS. 3. THE CAPABILITY OF THE BUTTON PULL TEST MACHINE CAN BE ENHANCED WITH CLAMPS & ACCESSORIES FOR TESTING OF OTHER SNAPS, JEAN BUTTONS, FOUR HOLE BUTTONS & GARMENTS ACCESSORIES SUCH AS ZIPPERS, BOWS, APPLIQUÉ, TOGGLES, HOOKS/BARS, AND D-RINGS, AMONGST OTHERS. SPECIFICATION: DIMENSIONS: 260 X 310 X 820mm NET WEIGHT: 32KG ACCESSORIES: STANDARD ACCESSORIES 1PC - IMADA FORCE GAUGE FB-30K 1PC - UPPER UNIVERSAL GRIP 1PC - UPPER STUD GRIP 1PC - LOWER FABRIC CLAMP & LEVEL ARM LOCKING 1PC - LOWER GRASP BUTTON ACCESSORY KIT 1PC - CALIBRATION WEIGHT 15LB 1PC - THREE PRONGED GRIP 1PC - UPPER LONG NOSE VISE GRIP Learn More -

M-7984 TS PLZEN (SKODA) CKW60/80 FORGING PRESS YEAR 2010

M-7984 TS PLZEN (SKODA) CKW60/80 FORGING PRESS YEAR 2010REFERENCE NUMBER: M-7984

TS PLZEN (SKODA) CKW60/80 FORGING PRESS YEAR 2010

FORGING PRESS

MAKE: TS PLZEN (FORMERLY KNOWN AS SKODA)

YEAR: 2010

MODEL: CKW60/80

PULL DOWN TYPE

OIL HYDRAULIC

QUANTITY: 1

Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More -

TT-8186 ATLAS COPCO BOTTLING LINE IN PET FOR STILL WATER UP TO 30000 BPHTT-8186 ATLAS COPCO BOTTLING LINE IN PET FOR STILL WATER UP TO 30000 BPH 1. BRAND: ATLAS COPCO 2. SPEED: 30000 BPH 3. PRODUCTS: WATER (STILL) 4. CONTAINERS: PET 5. FORMATS: 0.33 L, 0.50 L, 0.75 L, 1.0 L, 1.5 L 6. AFETY FEATURES: YES 7. MANUALS: YES 8. FILL TYPE: GRAVITY/LIGHT DEPRESSION 9. NECK TYPE: 29,25 Learn More

TT-8186 ATLAS COPCO BOTTLING LINE IN PET FOR STILL WATER UP TO 30000 BPHTT-8186 ATLAS COPCO BOTTLING LINE IN PET FOR STILL WATER UP TO 30000 BPH 1. BRAND: ATLAS COPCO 2. SPEED: 30000 BPH 3. PRODUCTS: WATER (STILL) 4. CONTAINERS: PET 5. FORMATS: 0.33 L, 0.50 L, 0.75 L, 1.0 L, 1.5 L 6. AFETY FEATURES: YES 7. MANUALS: YES 8. FILL TYPE: GRAVITY/LIGHT DEPRESSION 9. NECK TYPE: 29,25 Learn More