Search results for: 'cut f'

- Related search terms

- Cutti

- cutti'

- Cutting+m

- cutti''

- CUTTING S'

-

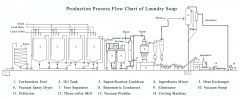

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

G-2715 HORIZONTAL HARD PU CUTTING MACHINE (SKYVER)REFERENCE NUMBER: G-2715 HORIZONTAL HARD PU CUTTING MACHINE (SKYVER) QUANTITY AVAILABLE: 1 Learn More

G-2715 HORIZONTAL HARD PU CUTTING MACHINE (SKYVER)REFERENCE NUMBER: G-2715 HORIZONTAL HARD PU CUTTING MACHINE (SKYVER) QUANTITY AVAILABLE: 1 Learn More -

G-2228 HEAVY DUTY NEW FOAM SHREDDER

G-2228 HEAVY DUTY NEW FOAM SHREDDERMODEL: FS-30

TOTAL POWER: 36KW

MACHINE WEIGHT: 2000KG

SCREEN SIZES INCLUDED (8mm, 18mm, 30mm): 3 PCS

GRINDER MOTOR: 30 kw (40Hp)

SUCTION FAN MOTOR: 5.5 kw

HOPPER SIZE OPENING AT THE TOP 890mm (35") x 915mm (36")

CUTTING CHAMBER WIDTH: 890mm (35")

MACHINE DIMENSIONS: 3400 L x 2150 W x 1900mm H (133" x 84" x 75")

CUTTING METHOD: 3 HEAD ROTATING UNIT WITH ONE BLADE ON EACH HEAD CUTTING

AGAINST 4 STATIONARY (FIXED) BLADES ; BLADE THICKNESS 18mm (.7 INCH)

CHAMBER SIZE 11 INCH X 34 INCH (280mm X 864mm)

CHAMBER COOLING PUMP WITH RECIRCULATION TANK

STANDARD SCREEN SIZES : 30mm , 18mm , 8mmMANY DIFFERENT SIZES OF SCREENS AVAILABLE (SPARES CAN BE ORDERED)

Learn More -

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More

V-0025 COTTON PAD, BALL, SWAB MACHINESREFERENCE NUMBER: V-0025 COTTON PAD, BALL, SWAB MACHINES M-5138 SQUARE COTTON PAD PRODUCTION MACHINE M-5139 COTTON GAUZE PAD PRODUCTION MACHINE M-5140 MACHINE TO PRODUCE VARIOUS TYPES OF COTTON PADS M-5141 COTTON PAD PRODUCTION MACHINE M-5142 MAKEUP REMOVING COTTON PAD PRODUCTION MACHINE M-5143 ROUND COTTON PAD MAKING MACHINE M-5144 SQUARE ABSORBENT COTTON PAD PRODUCTION MACHINE M-5145 ROUND ABSORBENT COTTON PAD PRODUCTION MACHINE M-5146 ROUND COTTON PADS MAKING MACHINE M-5147 COTTON PAD MAKING MACHINE M-5148 COTTON PAD MAKING MACHINE M-5168 COTTON PADS MAKING MACHINE M-5169 COTTON Q-TIP MAKING MACHINE (100PCS/BAG) M-5170 COTTON BALL MAKING MACHINE (NEW) M-5171 COSMETIC COTTON PAD (GLOVE SHAPE) MAKING MACHINE M-5172 COSMETIC COTTON PAD MAKING MACHINE (ROUND PAD) M-5101 MEDICAL COTTON BALL MAKING MACHINE 20KG/HOUR QUANTITY AVAILABLE: 17 Learn More -

J-0030 ROSENTHAL SHEETER YEAR 2008 WIDTH 1830mmREFERENCE NUMBER: J-0030 (1313KDVBMNXX12) ROSENTHAL SHEETER YEAR 2008 WIDTH 1830mm ROSENTHAL SHEETER, DUAL UNWINDS, TWO CUTTING HEADS WAS-6-DUJEAAAAC7 WITH SERVO DRIVE AND VACUUM POSITIONING CONVEYOR YEAR: 2008 WIDTH 1830mm QUANTITY AVAILABLE: 1 Learn More

J-0030 ROSENTHAL SHEETER YEAR 2008 WIDTH 1830mmREFERENCE NUMBER: J-0030 (1313KDVBMNXX12) ROSENTHAL SHEETER YEAR 2008 WIDTH 1830mm ROSENTHAL SHEETER, DUAL UNWINDS, TWO CUTTING HEADS WAS-6-DUJEAAAAC7 WITH SERVO DRIVE AND VACUUM POSITIONING CONVEYOR YEAR: 2008 WIDTH 1830mm QUANTITY AVAILABLE: 1 Learn More -

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More

M-5147 COTTON PAD MAKING MACHINEREFERENCE NUMBER: M-5147 (1212NDTYXX11) L COTTON PAD MAKING MACHINE PUT ON MAKE-UP THE COTTON AND KAPOK PRODUCTION PROCESS: THE EQUIPMENT IS DIVIDES CUTS THE GOOD DEGREASING TO LAP, THE ADHESIVE-BONDED CLOTH OR THE GAUZE, LAYING ASIDE RAW MATERIAL AFTER THE COMPACTION, THE HEATING EMBOSSES, ROLLS CUTS PROCESS ONE TIME TO COMPLETE. MAIN FEATURE THE HIGH SPEED PUNCH PRESS REVOLVING BLANKING PRINCIPLE OF WORK, THE TECHNOLOGY IS MATURE, THE WORK IS STABLE, THE SERVICE WORK LOAD ARE FEW, OUTPUT MODE: THE PIPELINE ARRANGEMENT OUTPUT, THE CODE FALLS NEATLY, THE BAGGING IS CONVENIENT, A PERSON THEN OPERATES THE COMPLETE MACHINE, BIG REDUCED ARTIFICIAL AMOUNT OF USE; THE GOOD MAN-MACHINE OPERATION CONTACT SURFACE, MAY UNFOLD THE REAL TIME OPERATION INFORMATION, IS ADVANTAGEOUS FOR THE PRODUCTION MONITORING; THE MOLD REPLACEMENT IS CONVENIENT, THE CONSTRUCTION COST IS LOWER THAN GREATLY ROLLS CUTS THE CARVING FLOWER CUTTER BAR, MOREOVER AFTER THE MOLD WEARS, EASY TO REPAIR, DOES NOT NEED TO DISCARD THE REPLACEMENT, SAVES THE MAINTENANCE COST. PUT ON MAKE-UP THE COTTON AND KAPOK MAJOR TECHNIQUE PARAMETER: PRODUCTION SPEED: 20--30M/MIN PRODUCTION SPECIFICATION: MAY ACCORDING TO THE REQUEST ADJUSTMENT TOTAL POWER: 5KW MACHINE DIMENSION: 3.5M*1.7M*2.5M MODEL: A QUANTITY: 1 Learn More -

ROSENTHAL KNIFE SHEETER YEAR 2008ROSENTHAL 72” WIDE, DUAL UNWINDS, TWO CUTTING HEAD YEAR: 2008 72” WIDE (1.83M) ROSENTHAL SHEETER WAS-6-DUJEAAAAC7 WITH SERVO DRIVE AND VACUUM POSITIONING CONVEYOR. UP CUT WITH A MAXIMUM CUT WIDTH OF 1800mm SHEET LENGTH TOLERANCE OF +/- 1/64" SIEMANS PLC SERIES 7 WITH ETHERNET CAPABILITY, MP 277 TOUCH SCREEN AND PROFIBUS, WIRED FOR 480V-60 CYCLE. THE ROSENTHAL HAS TWO SEPARATE SHEETING HEADS, ONE OR BOTH CAN BE USED. SHEAR CUT CAN BE ADDED. ANTI STATIC BARS THOUGH OUT THE WEB PATH. DUAL DRIVEN UNWIND STANDS FOR SHEETING TWO ROLLS OR ONE ROLL AT A TIME WITH CLOSED LOOP FEEDBACK FOR FINE UNWIND TENSION CONTROL. ONE LINER REWINDER WITH 3" AIR EXPANDING UNWIND SHAFT. MAXIMUM WEIGHT OF THE UNWIND IS 2200 LBS. COMES WITH 3" UNWIND SHAFTS AND 6" CHUCKS. MAXIMUM UNWIND DIAMETER ON EACH UNWIND IS 35". THE SHEETER WAS USED TO SHEET MATERIAL FOR THE MANUFACTURE OF SOLAR PANELS. FOOTPRINT 102" X 204". Learn More

ROSENTHAL KNIFE SHEETER YEAR 2008ROSENTHAL 72” WIDE, DUAL UNWINDS, TWO CUTTING HEAD YEAR: 2008 72” WIDE (1.83M) ROSENTHAL SHEETER WAS-6-DUJEAAAAC7 WITH SERVO DRIVE AND VACUUM POSITIONING CONVEYOR. UP CUT WITH A MAXIMUM CUT WIDTH OF 1800mm SHEET LENGTH TOLERANCE OF +/- 1/64" SIEMANS PLC SERIES 7 WITH ETHERNET CAPABILITY, MP 277 TOUCH SCREEN AND PROFIBUS, WIRED FOR 480V-60 CYCLE. THE ROSENTHAL HAS TWO SEPARATE SHEETING HEADS, ONE OR BOTH CAN BE USED. SHEAR CUT CAN BE ADDED. ANTI STATIC BARS THOUGH OUT THE WEB PATH. DUAL DRIVEN UNWIND STANDS FOR SHEETING TWO ROLLS OR ONE ROLL AT A TIME WITH CLOSED LOOP FEEDBACK FOR FINE UNWIND TENSION CONTROL. ONE LINER REWINDER WITH 3" AIR EXPANDING UNWIND SHAFT. MAXIMUM WEIGHT OF THE UNWIND IS 2200 LBS. COMES WITH 3" UNWIND SHAFTS AND 6" CHUCKS. MAXIMUM UNWIND DIAMETER ON EACH UNWIND IS 35". THE SHEETER WAS USED TO SHEET MATERIAL FOR THE MANUFACTURE OF SOLAR PANELS. FOOTPRINT 102" X 204". Learn More -

T-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIALT-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIAL PROPERTIES: SINCE ALL FIBERS POINT IN ONE DIRECTION, THE SCRIM CAN BE IDEALLY DRAPED GOOD SOAKABILITY WITH LITTLE RESIN CONSUMPTION CAN BE DRAPED VERY WELL AROUND CURVES AND EDGES EASY TO CUT ELECTRICALLY CONDUCTIVE, INFUSIBLE HIGH STRENGTH AND RIGIDITY DUE TO GRAPHITE-LIKE FIBER STRUCTURE BIOCOMPATIBLE TRANSPARENT TO X-RAYS LOW SPECIFIC WEIGHT IDEAL FOR SURFACE USE (LITTLE FIBER IMPRINTS) IDEAL FOR PROCESSING WITH EPOXY RESIN! TEXTILE SEMI-FINISHED PRODUCTS MADE OF PRE-SPREAD AND PLANE-PARALLEL LAID FIBERS FORM THE GROUP OF UNIDIRECTIONAL FABRICS. THE FIBERS ARE USUALLY LAID AT 0°, MORE RARELY AT 90°. BY LAYING THE UD FABRICS ALONG THE LINES OF FORCE ACTING IN THE COMPONENT, THE LIGHTWEIGHT POTENTIAL OF THE CARBON FIBER IS OPTIMALLY EXPLOITED. UD FABRICS CONSIST OF ONE OR MORE SUPERIMPOSED FIBER LAYERS FIXED WITH AN EPOXY-COMPATIBLE BINDER THREAD. THE SPECIAL SPREADING TECHNIQUE PRODUCES FABRICS WITH HIGH FIBER PARALLELISM, WITHOUT KNOTS AND FIBER TWIST. SPREAD FIBERS ABSORB THE RESIN BETTER, RESULTING IN HIGHEST LAMINATE STRENGTHS. QUANTITY: 3 LINES Learn More

T-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIALT-9752 KARL MAYER CARBON MACHINES BIAXIAL AND MULTIAXIAL PROPERTIES: SINCE ALL FIBERS POINT IN ONE DIRECTION, THE SCRIM CAN BE IDEALLY DRAPED GOOD SOAKABILITY WITH LITTLE RESIN CONSUMPTION CAN BE DRAPED VERY WELL AROUND CURVES AND EDGES EASY TO CUT ELECTRICALLY CONDUCTIVE, INFUSIBLE HIGH STRENGTH AND RIGIDITY DUE TO GRAPHITE-LIKE FIBER STRUCTURE BIOCOMPATIBLE TRANSPARENT TO X-RAYS LOW SPECIFIC WEIGHT IDEAL FOR SURFACE USE (LITTLE FIBER IMPRINTS) IDEAL FOR PROCESSING WITH EPOXY RESIN! TEXTILE SEMI-FINISHED PRODUCTS MADE OF PRE-SPREAD AND PLANE-PARALLEL LAID FIBERS FORM THE GROUP OF UNIDIRECTIONAL FABRICS. THE FIBERS ARE USUALLY LAID AT 0°, MORE RARELY AT 90°. BY LAYING THE UD FABRICS ALONG THE LINES OF FORCE ACTING IN THE COMPONENT, THE LIGHTWEIGHT POTENTIAL OF THE CARBON FIBER IS OPTIMALLY EXPLOITED. UD FABRICS CONSIST OF ONE OR MORE SUPERIMPOSED FIBER LAYERS FIXED WITH AN EPOXY-COMPATIBLE BINDER THREAD. THE SPECIAL SPREADING TECHNIQUE PRODUCES FABRICS WITH HIGH FIBER PARALLELISM, WITHOUT KNOTS AND FIBER TWIST. SPREAD FIBERS ABSORB THE RESIN BETTER, RESULTING IN HIGHEST LAMINATE STRENGTHS. QUANTITY: 3 LINES Learn More -

YY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINEYY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINE FOR THE FOLLOWING TYPES OF FABRICS: WOVEN FABRICS, TENT FABRIC, SHOE FABRIC, UMBRELLA FABRIC, FOAM, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE FABRIC, REINFORCED BELTING MATERIAL, CONDUCTIVE CLOTH, AND OTHER MATERIALS OF VARIOUS WIDTHS. CAN DO BIAS FABRIC. QUANTITY: 1 Learn More

YY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINEYY-2899 BALONEY FABRIC ROLL SLITTER, 3000mm X 400mm DIAMETER (118 INCHES BY 15.7 INCHES) – NEW MACHINE FOR THE FOLLOWING TYPES OF FABRICS: WOVEN FABRICS, TENT FABRIC, SHOE FABRIC, UMBRELLA FABRIC, FOAM, LEATHER, REFLECTIVE MATERIAL, PLASTIC, PAPER, DOUBLE SIDED TAPE, ACETATE FABRIC, REINFORCED BELTING MATERIAL, CONDUCTIVE CLOTH, AND OTHER MATERIALS OF VARIOUS WIDTHS. CAN DO BIAS FABRIC. QUANTITY: 1 Learn More -

TT-1199 TUFTCO AND CMC TUFTING MACHINES, YEAR 1989 TO 2001TT-1199 TUFTCO AND CMC TUFTING MACHINES, YEAR 1989 TO 2001 ITEM 001 4000mm, 1/10TH GAUGE TUFTCO SERVO SCROLL DRIVE SYSTEM TUFTING MACHINE YEAR 2000 QUANTITY: 1 ITEM 002 4000mm, 1/8TH GAUGE CMC CUT PILE TUFTING MACHINE YEAR 1989 QUANTITY: 3 ITEM 003 4000mm, 1/10TH GAUGE, TUFTCO, SERVO SCROLL, LOOP TUFTING MACHINE YEAR 2003 QUANTITY: 4 ITEM 004 4000mm, 1/10TH GAUGE, TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1998 QUANTITY: 6 ITEM 005 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP TUFTING MACHINE WITH 6 ROLLS, SPLIT ROLLER RAINBOW ON FRONT SIDE, SPLIT ROLL LOOP YEAR 1998 QUANTITY: 8 ITEM 006 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE WITH ELG DRIVE SYSTEM YEAR 2001 QUANTITY: 10 ITEM 007 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1997 QUANTITY: 8 ITEM 008 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1996 QUANTITY: 12 ITEM 009 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1996 QUANTITY: 13 ITEM 010 4000mm, 5/64TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1999 QUANTITY: 3 AVAILABLE IMMEDIATELY Learn More

TT-1199 TUFTCO AND CMC TUFTING MACHINES, YEAR 1989 TO 2001TT-1199 TUFTCO AND CMC TUFTING MACHINES, YEAR 1989 TO 2001 ITEM 001 4000mm, 1/10TH GAUGE TUFTCO SERVO SCROLL DRIVE SYSTEM TUFTING MACHINE YEAR 2000 QUANTITY: 1 ITEM 002 4000mm, 1/8TH GAUGE CMC CUT PILE TUFTING MACHINE YEAR 1989 QUANTITY: 3 ITEM 003 4000mm, 1/10TH GAUGE, TUFTCO, SERVO SCROLL, LOOP TUFTING MACHINE YEAR 2003 QUANTITY: 4 ITEM 004 4000mm, 1/10TH GAUGE, TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1998 QUANTITY: 6 ITEM 005 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP TUFTING MACHINE WITH 6 ROLLS, SPLIT ROLLER RAINBOW ON FRONT SIDE, SPLIT ROLL LOOP YEAR 1998 QUANTITY: 8 ITEM 006 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE WITH ELG DRIVE SYSTEM YEAR 2001 QUANTITY: 10 ITEM 007 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1997 QUANTITY: 8 ITEM 008 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1996 QUANTITY: 12 ITEM 009 4000mm, 1/10TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1996 QUANTITY: 13 ITEM 010 4000mm, 5/64TH GAUGE TUFTCO ENHANCED LOOP GRAPHICS TUFTING MACHINE YEAR 1999 QUANTITY: 3 AVAILABLE IMMEDIATELY Learn More