Search results for: 'foam+r'

-

L-3389 CATERPILLAR 950H WHEEL LOADER YEAR 2008

L-3389 CATERPILLAR 950H WHEEL LOADER YEAR 2008L-3389 CATERPILLAR 950H WHEEL LOADER YEAR 2008

YEAR: 2008

MODEL: 950H

EROPS CAB WITH AIR & HEAT

3.25 YARD GP BUCKET WITH STRAIGHT EDGE

FORKS AND BOOM

QUICK COUPLER

TIRES ARE POOR

17,958 TOTAL FRAME HOURSQUANTITY: 1

Learn More -

A-1405 RELIANCE GRIBETZ QUILTER TACK AND JUMP, CHAINSTITCH- 90 INCH

A-1405 RELIANCE GRIBETZ QUILTER TACK AND JUMP, CHAINSTITCH- 90 INCHA-1405 RELIANCE GRIBETZ QUILTER TACK AND JUMP, CHAINSTITCH- 90 INCH

3 BAR

NEW IN JULY 2001

RUNNING NOW

COMPLETE WITH THREAD RACK AND FOAM AND FABRIC FEED

NO PANEL CUTTER INCLUDEDQUANTITY: 1

Learn More -

M-6067 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WIDTH 2400mm, YEAR 2004 TO 2008

M-6067 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WIDTH 2400mm, YEAR 2004 TO 2008M-6067 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WIDTH 2400mm, YEAR 2004 TO 2008

OFFER 001

MACKIE, LAROCHE, STUMMER AIRLAY LINE

YEAR: 2004 TO 2008

WORKING WIDTH: 2400mmOFFER 002

MACKIE HOPERS FOR FIBER FEEDINGOFFER 003

TOWER FEED

WORKING WIDTH: 1000mmOFFER 004

BLENDING BIN FOAM PANEL

DIMENSIONS: 8000mm x 4000mm x 3500mm HEIGHTOFFER 005

LAROCHE FINE OPENER

YEAR: 2004OFFER 006

STUMMER VERTICAL OPENER

YEAR: 2008

WORKING WIDTH: 1200mmOFFER 007

STUMMER AIR BLENDER

YEAR: 2008OFFER 008

LAROCHE AIRLAY HEAD

YEAR: 2004

WORKING WIDTH: 2400mmOFFER 009

THERMOBONDING OVENOFFER 010

BURNEROFFER 011

COOLING SECTION WITH TOP AND BOTTOMOFFER 012

SLITTING SYSTEMOFFER 013

CROSS CUT HIGH SPEED BLADE CUTTING SYSTEMOFFER 014

BATT PACKER (FOR PACKING BATTS INTO BAGS)OFFER 015

RECLAIM OPENERQUANTITY: 1 LINE

Learn More -

M-6037 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WORKING WIDTH 1000mm TO 2400mm, YEAR 2004 TO 2008

M-6037 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WORKING WIDTH 1000mm TO 2400mm, YEAR 2004 TO 2008M-6037 MACKIE/LAROCHE/STUMMER AIRLAY LINE, WORKING WIDTH 1000mm TO 2400mm, YEAR 2004 TO 2008

OFFER 001

AIRLAY LINE

MANUFACTURER: MACKIE, LAROCHE, STUMMER

YEAR: 2004 TO 2008

WORKING WIDTH: 2400mmCONSISTS OF:

OFFER 002

MACKIE HOPPERS FOR FIBER FEEDINGOFFER 003

TOWER FEEDOFFER 004

BLENDING BIN FOAM PANELOFFER 005

LAROCHE FINE OPENEROFFER 006

STUMMER VERTICAL OPENEROFFER 007

STUMMER AIR BLENDEROFFER 008

LAROCHE AIRLAY HEADOFFER 009

THERMOBONDING OVENOFFER 010

SLITTING SYSTEM WITH 5 BLADESOFFER 011

CROSS CUT HIGH SPEED BLADE CUTTING SYSTEMOFFER 012

BATT PACKER (FOR PACKING BATTS INTO BAGS)OFFER 013

RECLAIM OPENERQUANTITY: 1 LINE

Learn More -

V-1209 AUTOMATIC MATTRESS COMPRESSION MACHINE FOR INNERSPRING OR FOAM MATTRESS

V-1209 AUTOMATIC MATTRESS COMPRESSION MACHINE FOR INNERSPRING OR FOAM MATTRESSAUTOMATIC MATTRESS COMPRESSION MACHINE FOR INNERSPRING OR FOAM MATTRESS

MODEL: G-11M

Learn More

SIZE OF PRESSURE PLATE: 2100 X 2200mm

WORKING PRESSURE: 30 TONS

DISTANCE OF OPENNING GEAR: 500M

NUMBER OF OIL CYLINDER: 4PCS

NUMBER OF AIR CYLINDER: 10PCS

POWER OF OIL PRESSURE: 5.5KW

HEATING POWER: 3KW

PUMPING POWER: 3KW

EXTERMAL DIMENSION: 2200 X 2100mm

NET WEIGHT: 4000KG

VIDEO AVAILABLE -

M-0017 AUTOMATIC VACUUM FOAMING BATCH MACHINEREFERENCE NUMBER: M-0017 AUTOMATIC VACUUM FOAMING BATCH MACHINE AUTOMATIC VACUUM FOAMING BATCH MACHINE, USES BATCHING TECHNOLOGY, FOAMING IN VACUUM CONDITION. IT IS COMPOSED OF STORAGE TANKS, BATCHING, MIXING, VACUUM, MOULD, AND COMPUTERIZED CONTROLLING SYSTEMS. USES NUMERICAL CONTROL DURING THE WHOLE PRODUCTION. IT IS USED FOR MAKING ALL KINDS OF FOAM. ADVANTAGE: *USING THE SAME PPH OF WATER, FOAMING DENSITY WILL BE LOWER: ≤30% * REDUCES THE CHEMICAL CONSUMPTION, AND SAVES ON THE FOAMING COST: ≤20% * SUCTION AND FILTRATE THE FOAMING AIR. * MONITOR THE WHOLE FOAMING BY WIRED TELEVISION. * WITH NUMERICAL CONTROL WITH ACCURATE AND CONVENIENT MEASURING DURING THE WHOLE PRODUCTION. EASY AND STABLE TO OPERATE THE MACHINE. OUTPUT 1 BLOCK / 12MIN CHEMICALS 8 GROUPS MIXER 220 KGS MOULD SIZE 2200(L)X 1800(W)X 1300 (H) mm 2200(L)X 1500(W)X 1300 (H) mm LIFTING PLATFORM SPEED ≤3M/MIN ( AUTOMATIC REGULATION ) MAX SUCTION 0.05MPA POWER 42KW QUANTITY AVAILABLE: 1 Learn More

M-0017 AUTOMATIC VACUUM FOAMING BATCH MACHINEREFERENCE NUMBER: M-0017 AUTOMATIC VACUUM FOAMING BATCH MACHINE AUTOMATIC VACUUM FOAMING BATCH MACHINE, USES BATCHING TECHNOLOGY, FOAMING IN VACUUM CONDITION. IT IS COMPOSED OF STORAGE TANKS, BATCHING, MIXING, VACUUM, MOULD, AND COMPUTERIZED CONTROLLING SYSTEMS. USES NUMERICAL CONTROL DURING THE WHOLE PRODUCTION. IT IS USED FOR MAKING ALL KINDS OF FOAM. ADVANTAGE: *USING THE SAME PPH OF WATER, FOAMING DENSITY WILL BE LOWER: ≤30% * REDUCES THE CHEMICAL CONSUMPTION, AND SAVES ON THE FOAMING COST: ≤20% * SUCTION AND FILTRATE THE FOAMING AIR. * MONITOR THE WHOLE FOAMING BY WIRED TELEVISION. * WITH NUMERICAL CONTROL WITH ACCURATE AND CONVENIENT MEASURING DURING THE WHOLE PRODUCTION. EASY AND STABLE TO OPERATE THE MACHINE. OUTPUT 1 BLOCK / 12MIN CHEMICALS 8 GROUPS MIXER 220 KGS MOULD SIZE 2200(L)X 1800(W)X 1300 (H) mm 2200(L)X 1500(W)X 1300 (H) mm LIFTING PLATFORM SPEED ≤3M/MIN ( AUTOMATIC REGULATION ) MAX SUCTION 0.05MPA POWER 42KW QUANTITY AVAILABLE: 1 Learn More -

V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAMREFERENCE NUMBER: V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAM MODEL SRM-P-1200 1067mm WIDE (42 INCHES) 2032mm LONG (80 INCHES) 560mm TALL (22 INCHES) THE MATERIAL IS 225 KGS PER CUBIC METER DENSITY (14 LBS/CUBIC FOOT) QUANTITY AVAILABLE: 1 Learn More

V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAMREFERENCE NUMBER: V-1065 AUTOMATIC CUTTING MACHINE (NEW) HEAVY DUTY HORIZONTAL CUTTING MACHINE FOR 14 LB (225 KG/CUBIC METER) FOAM MODEL SRM-P-1200 1067mm WIDE (42 INCHES) 2032mm LONG (80 INCHES) 560mm TALL (22 INCHES) THE MATERIAL IS 225 KGS PER CUBIC METER DENSITY (14 LBS/CUBIC FOOT) QUANTITY AVAILABLE: 1 Learn More -

V-1035 YQ-2150A FOAM PEELING CUTTING MACHINE – 2150mmREFERENCE NUMBER: V-1035 YQ-2150A FOAM PEELING CUTTING MACHINE – 2150mm 1.CUTTING SIZE: DIA 2000 X 2150mm. 2.CUTTING THICKNESS: 3~25mm. 3.BLADE LENGTH: 9350mm. 4.TURNING SPEED: 5M~30M/MIN. 5.TOTAL POWER: 6.59KW. 6.MACHINE WEIGHT: 1800KG. 7.MACHINE EXTERNAL SIZE: L 4560mm X W 1650mm X H 1950mm. 8.SPARE PARTS: 3PCS OF BLADES, 4PCS OF GRINDING WHEELS, 1 SET OF MAINTAIN TOOLS. 9.GUARANTEE: CE CERTIFICATE, MAINTAIN FOR ONE YEAR. OPTION: SERVO SYSTEM & BALL SCREW QUANTITY AVAILABLE: 1 SET Learn More

V-1035 YQ-2150A FOAM PEELING CUTTING MACHINE – 2150mmREFERENCE NUMBER: V-1035 YQ-2150A FOAM PEELING CUTTING MACHINE – 2150mm 1.CUTTING SIZE: DIA 2000 X 2150mm. 2.CUTTING THICKNESS: 3~25mm. 3.BLADE LENGTH: 9350mm. 4.TURNING SPEED: 5M~30M/MIN. 5.TOTAL POWER: 6.59KW. 6.MACHINE WEIGHT: 1800KG. 7.MACHINE EXTERNAL SIZE: L 4560mm X W 1650mm X H 1950mm. 8.SPARE PARTS: 3PCS OF BLADES, 4PCS OF GRINDING WHEELS, 1 SET OF MAINTAIN TOOLS. 9.GUARANTEE: CE CERTIFICATE, MAINTAIN FOR ONE YEAR. OPTION: SERVO SYSTEM & BALL SCREW QUANTITY AVAILABLE: 1 SET Learn More -

M-5393 TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATIONREFERENCE NUMBER: M-5393 (2206YBJL1UM) L TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATION TUFTO COATING LINE FOR EMBOSSED UNITARY BACKED RUGS USING WASHABLE LATEX FOR EMBOSSED WASHABLE RUGS – SET UP FOR 12’ WIDTH AND INCLUDES THE FOLLOWING: TISI MODEL 38500 BUTT SEAMER WITH TRIMMER ON RAIL ENTRANCE J-BOX VERTICAL KEYON PIN TENTER DIRECT COAT APPLICATOR, ROLL OVER ROLL WITH TRAVERSING SYSTEM DAY TANK TO FEED LATEX TO FROTH MACHINE EASE TYPE FROTH MACHINE PRE-STEAMER BANK OF ELECTRIC INFRAREDS TWO BASKET-WEAVE EMBOSSING ROLLERS FOR 12’ WIDTHS FOUR MODULE NATURAL GAS HEATED TUFTCO CURING OVEN COOL OUT SECTION SLITTING SECTION WITH EIGHT SLITTING HEADS AND A CAMERA GUIDING SYSTEM 10 LOOP ACCUMULATOR ROLLUP ELECTRICAL CONTROL SYSTEM BY TUFTCO SPEED RANGE: LINE SPEED FOR COATING 50 OUNCE/SQUARE YARD FACE WEIGHT WITH 24 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 35FPM, LINE SPEED FOR COATING 30 OZ/SQUARE YARD FACE WEIGHT WITH 20 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 45 FPM. TOILET SEAT CONVERS ARE COATED WITH APPROXIMATELY 7 OZ/SQUARE YARD AT 70 FPM. NOTE THE MAXIMUM MECHANICAL SPEED OF THE COATING LINE IS 70 FPM. QUANTITY AVAILABLE: 1 Learn More

M-5393 TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATIONREFERENCE NUMBER: M-5393 (2206YBJL1UM) L TUFTCO COATING LINE WITH FOAM MACHINE AND SLITTING OPERATION TUFTO COATING LINE FOR EMBOSSED UNITARY BACKED RUGS USING WASHABLE LATEX FOR EMBOSSED WASHABLE RUGS – SET UP FOR 12’ WIDTH AND INCLUDES THE FOLLOWING: TISI MODEL 38500 BUTT SEAMER WITH TRIMMER ON RAIL ENTRANCE J-BOX VERTICAL KEYON PIN TENTER DIRECT COAT APPLICATOR, ROLL OVER ROLL WITH TRAVERSING SYSTEM DAY TANK TO FEED LATEX TO FROTH MACHINE EASE TYPE FROTH MACHINE PRE-STEAMER BANK OF ELECTRIC INFRAREDS TWO BASKET-WEAVE EMBOSSING ROLLERS FOR 12’ WIDTHS FOUR MODULE NATURAL GAS HEATED TUFTCO CURING OVEN COOL OUT SECTION SLITTING SECTION WITH EIGHT SLITTING HEADS AND A CAMERA GUIDING SYSTEM 10 LOOP ACCUMULATOR ROLLUP ELECTRICAL CONTROL SYSTEM BY TUFTCO SPEED RANGE: LINE SPEED FOR COATING 50 OUNCE/SQUARE YARD FACE WEIGHT WITH 24 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 35FPM, LINE SPEED FOR COATING 30 OZ/SQUARE YARD FACE WEIGHT WITH 20 OZ/SQUARE YARD OF EMBOSSIBLE LATEX IS 45 FPM. TOILET SEAT CONVERS ARE COATED WITH APPROXIMATELY 7 OZ/SQUARE YARD AT 70 FPM. NOTE THE MAXIMUM MECHANICAL SPEED OF THE COATING LINE IS 70 FPM. QUANTITY AVAILABLE: 1 Learn More -

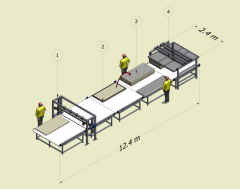

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More