Search results for: 'Edge fol'

-

TT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURSTT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURS CATERPILLAR 988K XE CURRENT MACHINE HOURS: 6,200 VERY CLEAN, STRAIGHT LOADER RECENTLY REPLACED TIRES QUANTITY: 1 Learn More

TT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURSTT-2982 CATERPILLAR 988K XE WHEEL LOADER, YEAR 2019 WITH 6200 HOURS CATERPILLAR 988K XE CURRENT MACHINE HOURS: 6,200 VERY CLEAN, STRAIGHT LOADER RECENTLY REPLACED TIRES QUANTITY: 1 Learn More -

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More

J-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINEJ-4941 AUTOMATED INDUSTRIAL MACHINERY AFM 2 DG WIRE BENDING MACHINE MAKE: AIM (AUTOMATED INDUSTRIAL MACHINERY) MODEL: AFM 2 DG (ACCUFORM MODULAR 2DX) TILTING TABLE SINGLE STAGE BENDING HEAD OPTIONS: P8 F1 WE SERIAL NUMBER: C 3 F0701 2009 WIRING DIAGRAM: AFM 2D6 – P8WEF1 – 490 – V8 – 3 VOLTAGE: 460 VOLTS FREQUENCY: 50 / 60 Hz FULL LOAD: 40 KVA LARGEST LOAD: 9 KVA DIMENSIONS OF THE STAINLESS STEEL TABLE: WIDTH 15 FEET 1 INCH x LENGTH 10 FEET 5 inches LOWER STAINLESS STEEL TABLE EXPENSION DIMENSIONS: WIDTH 8 FEET x LENGTH 37.5 INCHES QUANTITY: 1 Learn More -

J-4903 PORTER SERGER FLANGER 4000 – EST-501 -WITH AUTOMATIC CONVEYOR FEEDJ-4903 PORTER SERGER FLANGER 4000 – EST-501 -WITH AUTOMATIC CONVEYOR FEED MODEL NUMBER: EST – 501 VOLTAGE: 220/240 VAC SINGLE NEEDLE SIZE : 6Z7027 135 x 7 #24 QUANTITY: 1 Learn More

J-4903 PORTER SERGER FLANGER 4000 – EST-501 -WITH AUTOMATIC CONVEYOR FEEDJ-4903 PORTER SERGER FLANGER 4000 – EST-501 -WITH AUTOMATIC CONVEYOR FEED MODEL NUMBER: EST – 501 VOLTAGE: 220/240 VAC SINGLE NEEDLE SIZE : 6Z7027 135 x 7 #24 QUANTITY: 1 Learn More -

TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000 ITEM 001 LAROCHE OPENING & BLENDING SET (COMPRISING OF 4 BALE HOPPER, SET OF FINE OPENER AND FIBRE CONVEYING SYSTEM) QUANTITY: 1 ITEM 002 THIBEAU CARD CA11, WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 ASSELIN CROSSLAPPER QUANTITY: 1 ITEM 004 RIETER- PERFOJET SPUNLACE MACHINE 3 CYLINDERS/7 INJECTORS WORKING WIDTH 3600mm QUANTITY: 1 ITEM 005 FLEISSNER DRUM DRYER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 006 BASTIAN AUTOMATIC WINDER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 007 THIBEAU CARD FEEDER QUANTITY: 1 ITEM 008 ASSELIN WEB-DRAFTER WORKING WIDTH 4400mm QUANTITY: 1 ITEM 009 LOT ELECTRICAL CONTROLS 380V/50Hz QUANTITY: 1 ITEM 010 LOT AUXILIARY EQUIPMENT FOR THE SPUNLACE UNIT QUANTITY: 1 YEAR 2000 DRYER: 8 TYPE, 2 DRUMS Learn More

TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000TT-1443 COMPLETE SPUNLACE LINE, WORKING WIDTH 3500mm, YEAR 2000 ITEM 001 LAROCHE OPENING & BLENDING SET (COMPRISING OF 4 BALE HOPPER, SET OF FINE OPENER AND FIBRE CONVEYING SYSTEM) QUANTITY: 1 ITEM 002 THIBEAU CARD CA11, WORKING WIDTH 3000mm QUANTITY: 1 ITEM 003 ASSELIN CROSSLAPPER QUANTITY: 1 ITEM 004 RIETER- PERFOJET SPUNLACE MACHINE 3 CYLINDERS/7 INJECTORS WORKING WIDTH 3600mm QUANTITY: 1 ITEM 005 FLEISSNER DRUM DRYER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 006 BASTIAN AUTOMATIC WINDER, WORKING WIDTH 3600mm QUANTITY: 1 ITEM 007 THIBEAU CARD FEEDER QUANTITY: 1 ITEM 008 ASSELIN WEB-DRAFTER WORKING WIDTH 4400mm QUANTITY: 1 ITEM 009 LOT ELECTRICAL CONTROLS 380V/50Hz QUANTITY: 1 ITEM 010 LOT AUXILIARY EQUIPMENT FOR THE SPUNLACE UNIT QUANTITY: 1 YEAR 2000 DRYER: 8 TYPE, 2 DRUMS Learn More -

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More

J-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY -FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLEJ-3249 AUTOMATIC NONWOVEN MACHINE TO CUT & SEW SHELLS 26 x 26” WIDE, AUTOMATICALLY-FOR 60 TO 160gsm FABRIC WE HAVE VIDEO AVAILABLE CAPACITY: 15 TO 36 PIECES PER MINUTE FABRIC WEIGHT: 60 TO 160gsm FOR NONWOVEN FABRIC BAG AUTOMATIC BOTTOM SEWING, SIDE SEWING, AUTOMATIC CUTTING PLC CONTROLLED SERVO MOTOR DRIVEN QUANTITY: 1 Learn More -

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More

SPINNBAU NONWOVEN LINE, YEAR 1994REFERENCE NUMBER: T-6843 SPINNBAU NONWOVEN LINE, YEAR 1994 BRAND: SPINNBAU SHORT DESCRIPTION: NONWOVEN LINE YEAR: 1994 NONWOVEN LINE CONSISTING OF 1. CARD FEEDING: CARD FEEDING R&S, NEW, IN 2500mm WORKING WIDTH, CONSISTING OF: ONE R&S MATERIAL BIN IN 2500mm WORKING WIDTH, 600mm DEPTH AND A COMPLETE HEIGHT OF 2500mm, WITH TOP AND BOTTOM WINDOW AT BOTH SIDES, FILLING LEVEL CONTROLLED BY IN HEIGHT ADJUSTABLE INFRARED DEVICES. ONE DOOR AT THE BACKSIDE FOR CLEANING, LOCKED BY SECURITY SWITCHES. THE VITIATED AIR ESCAPES THROUGH THE PERFORATED SHEETMETAL AT THE TOP. THESE AREAS ARE COMPLETELY COVERED, THE OUTGOING AIR CAN BE FILTERED BY AN EXCISTING FILTERSTATION OR OPTIONALLY BY FILTERBAGS, 2 DELIVERY ROLLERS. ONE R & S CHUTE FEEDER IN 2500mm WORKING WIDTH CONSISTING OF: ONE OPENING ROLLER DIAMETER 450mm, ONE VIBRATION CHUTE, FIBRELEVEL CONTROLLED BY ULTRASONIC, CHUTE ADJUSTABLE OVER TOOTH RAILS IN DEPTH FROM 80 TO 240mm, TWO DRAWING OFF ROLLERS, ONE FEEDING TABLE WITH TRANSILON BELT, PREPARED FOR SERVOLAP. DRIVES: DELIVERY ROLLERS: AC -GEARBOXMOTOR 0.55 KW, FC OPENING ROLLER: AC-MOTOR 2.2 KW VIBRATION: AC-GEARBOXMOTOR, 0.55 KW, FC FEEDING TABLE: AC-GEARBOXMOTOR, 0.55 KW, FC 2. CARDING; ONE SPINNBAU DOUBLE DOFFER CARD, IN 2500mm WORKING WIDTH, YEAR 1994: CARD, FOLLOWING EQUIPPED: 1 CYLINDER FEEDING DEVICE WITH FEED PLATE: 1 FEED ROLLER DIAMETER 159mm 1 LICKER-IN DIAMETER 292mm PRE-OPENING: 1 BREAST DIAMETER 412mm 1/1 WORKER/STRIPPER DIAMETER 213/118mm 1 INTERMETE ROLLER DIAMETER 412mm CARD: 1 MAIN CYLINDER DIAMETER 1500mm 5/5 WORKERS/STRIPPERS DIAMETER 213/118mm 1 DOFFER, TOP DIAMETER 550mm 1 DOFFER, BOTTOM DIAMETER 550mm 2 CONDENSING ROLLERS TOP DIAMETER 292mm TOP DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. BOTTOM DRAWING OFF DEVICE, NEW: 1 DRAWING OFF ROLLER/WIRED DIAMETER 159mm 1 DRAWING OFF ROLLER/STEEL RUBBER: DIAMETER 159mm 1 CLEANING ROLLER WITH INTEGRATED ELECTRONIC, WHEN DIAMETER OF CLEANING IS GETTING BIGGER, CARD WILL STOP. DRAWING OFF TABLES: TOP TRANSILON BELT BOTTOM: TRANSILON BELT COVERS: THE CARD HAS COVERS TO CLAP UP AND DOWN (SECURED WHEN CLAPPED UP), THE SIDES ARE FULLY COVERED AND ELECTRONICALLY LOCKED. RIGID WIRE: ONE COMPLETE SET OF RIGID WIRE, MOUNTED, FOR FIBRES 1.5 DTEX - 17 DTEX, CAPACITY UP TO 800 KG/H ELECTRIC: VOLTAGE: ~400 V AC, 3 PHASES CONTROL VOLTAGE: ~220 V AC, =24V DC FREQUENCY: 50 Hz COLOUR: MACHINE: RAL 5015/ 9001 (IF YOU LIKE WE CAN CHANGE) CONTROL CABINET: RAL 7032, GREY SWITCH BOARD: RAL 7032, GREY ELECTRICAL DRIVES: FEED ROLLER: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED LICKER-IN: MECHANICAL FROM BREAST BREAST: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED WORKERS BREAST: MECHANICALLY FROM BREAST INTERMEDIATE ROLLER: MECHANICALLY FROM MAINSWIFT MAIN SWIFT: 1 AC-MOTOR FREQUENCY CONTROLLED WORKERS: 1 AC GEARBOXMOTOR, FREQUENCY CONTROLLED DOFFERS: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED CONDENSING ROLLERS: 1 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF DEVICES: 2 AC GEARBOXMOTORS. FREQUENCY CONTROLLED DRAWING-OFF TABLES: 2 AC GEARBOXMOTORS, FREQUENCY CONTROLLED SWITCHBOARDS AND CONTROLS: SWITCHBOARDS RITTAL SERIES, COMPLETE WIRED. SWITCHBOARDS WITHOUT COOLING DEVICES. CONTROL CABINET OPERATION WITH COLOURED SCREEN, FITTED IN CONTROL CABINET OPERATED BY SIEMENS SPS S7-300 1 SET OF CABLE MATERIAL: FOR 20 MTR LENGTH BETWEEN MACHINERY AND SWITCHBOARD WITHOUT INSTALLATION MATERIAL ERECTION AND STARTING UP: IS NOT INCLUDED, SHOULD BE MADE BY US FOUNDATION: ONE FOUNDATION IN 750mm HEIGHT, WITH SIDEWALKS AROUND, TWO STEPS ON EACH SIDE. SUCTION: CONNECTION FOR THE DOFFER AND TOP OF CARD 3. CROSSLAPPING, NEW: ONE REISKY & SCHLESE CROSSLAPPER, TYPE RS 100 IN 2500mm WORKING WIDTH (BELT WIDTH 2800mm) AND 2500mm LAPPING WIDTH (BELT WIDTH 2700mm) MAX INFEEDING SPEED: 100 MTR/MIN, DELIVERY SPEED OF DRAWING OFF TABLE: FROM 0 TO 20 MTR/MIN, CONSISTING OF: ONE FEEDING TABLE IN 1000mm LENGTH MOUNTED IN IT'S OWN FRAME, ADJUSTABLE IN THE HEIGHT ACCORDING TO THE DOFFER, FURTHER THE COMPLETE FEEDING TABLE CAN BE MOVED UP IF THE DOFFER HAS TO BE DRAWN BACK. THE CROSSLAPPER ITSELF GUIDES THE WEB FROM THE INFEED DOWN TO THE OUTLET BETWEEN THE CONVEYORS, WHICH HAVE ANTISTATIC PROPERTIES. THE TENSION AND THE DISTANCES BETWEEN THEM CAN BE ADJUSTED ACCORDING TO THE DIFFERENT FIBRES. THE CONVEYORS ARE EQUIPPED WITH AUTOMATIC EDGE GUIDES, SO THAT THEY ARE RUNNING IN THE CENTRE. THE LAID WEB IS COVERED BY THEM. THE SERVO- DRIVES ARE RESPONSIBLE FOR THE PERFECT SYNCHRONISATION AND THE EXACT REVERSAL OF THE CARRIERS. THE SWITCHBOARD IS EQUIPPED WITH A COULOURED TOUCHSCREEEN, WHERE ALL NECESSARY PARAMETERS CAN BE PROGRAMMED, ALSO DIFFERENT CURVES FOR STORING THE WEB DURING REVERSALS. DRIVES: FEED TABLE: AC-SERVO-MOTOR BELT 1: AC-SERVO-MOTOR BELT 2: AC-SERVO-MOTOR TOP CARRIER: AC-SERVO-MOTOR BOTTOM CARRIER: AC-SERVO-MOTOR DRAWING OFF TABLE: AC-SERVO-MOTOR HEIGHT DRAWING OFF TABLE LEFT: AC-LINEARMOTOR HEIGHT DRAWING OFF TABLE RIGHT: AC-LINEARMOTOR OPERATION: BY COLOURED TOUCHSCREEN, SIEMENS IN CONTROL CABINET OF CARD. PARAMETERS: MANUEL / INLINE INFEED SPEED DRAFT (INFEED SPEED/LAYING SPEED) NUMBER OF LAPS LAPPING WIDTH FROM MIDDLE TO THE LEFT AND TO THE RIGHT DRAWING OFF SPEED AUTOMATICALLY SHOWN DEPENDING ON LAYERS DARWING OFF TABLE HEIGHT LEFT / RIGHT LAYING SPEED RECEIPES FAULT SHOWING SWITCHBOARD AND ELECTRONIC DEVICES: SWITCH BOAD RITTAL, COMPLETE WIRED. SWITCHBOARD WITHOUT COOLING DEVICE. CONTROL PANNEL RITTAL. CONTROLLED BY S7 SIEMENS 10000mm OF CABLES BETWEEN SWITHBOARD AND MACHINE/CONTROLPANEL QUANTITY: 1 Learn More -

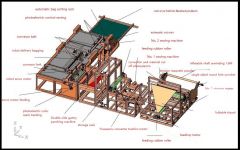

Y-2004 FACE MASK MACHINE, 120 MASKS PER MINUTE, FOR MASKS WITH 1 TO 4 LAYERS

Y-2004 FACE MASK MACHINE, 120 MASKS PER MINUTE, FOR MASKS WITH 1 TO 4 LAYERSCAPACITY: 100 TO 120 PER MINUTE

AUTOMATIC CONVEYING

CUT OFF THE BRIDGE OF THE NOSE

MASK EDGE WELDING

FOLDING

ULTRASONIC FUSION

WITH AUTOMATED MOLDING AND CUTTING

IT CAN BE USED AS A MASK WITH 1-4 LAYERS OF CLOTH ( THE ACTIVATED CARBON MATERIAL CAN BE

ADDED IN THE MIDDLE )

RATED POWER 10KW ( INCLUDING WELDING MACHINE)

DIMENSIONS: SIZE (L) 6500 x 3500 (W) x 1950 (H) mmQUANTITY: 1

Learn More -

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTE

J-2752 FACE MASK PRODUCTION MACHINE – 120 PIECES PER MINUTECOMPOSED OF

FACE MASK BLANK MAKING MACHINE

AUTOMATICALLY PRODUCES THE MAIN PART OF THE MASK

MACHINE HANDLES FEEDING, ALUMINUM STRIP INSERTION, CUTTING, FOLDING, ULTRASONIC WELDING, CUTTING

OUTPUT: 120 PIECES PER MINUTE

VOLTAGE: 220 VOLTS

POWER CONSUMPTION: 2.7 KW

DIMENSIONS: 3345 x 630 x 1830mm

CAN PRODUCE 3 TO 4 DIFFERENT MASK BLANKS ACCORDING TO PRODUCTION REQUIREMENTS

FOLDING LOCATION AND SIZE OF MASK IS ADJUSTABLE

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 1FACE MASK TRANSFERRING MACHINE

TRANSFERS THE MASKS TO THE ULTRASONIC EAR STRAP WELDING MACHINE

QUANTITY: 1ULTRASONIC EAR STRAP WELDING MACHINE

WELDS THE ELASTICS ON BOTH EDGES OF THE MASK

AUTOMATIC COUNTING

AUTOMATICALLY CONVEYS THE FINISHED MASKS TO PACKING PROCESS (PACKING BY HAND)

COMPUTER CONTROLS AND PHOTOELECTRIC DETECTION ENSURE LOW FAILURE RATE AND HIGH RELIABILITY

FRAME CONSTRUCTED OF ALUMINUM ALLOY

QUANTITY: 2PRODUCES MASKS WITH DIMENSIONS: 175mm x 95mm (ADULT SIZE)

FOR MASK TYPES: 2 LAYERS OF NONWOVEN CLOTH, 3 LAYERS OF NON-WOVEN FABRIC MASKS, 4 LAYERS OF ACTIVATED CARBON MASKS

• 2 LAYER FACIAL MASK: NONWOVEN, ALUMINUM STRIP, EAR STRAP WELDING

• 3 LAYER FACIAL MASK: NON-WOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER)

• ACTIVATED CARBON MASKS: NONWOVEN, ALUMINUM STRIP, EARLOOP WELDING, FILTER COTTON (FILTER PAPER), ACTIVATED CARBON CLOTHTECHNICAL PARAMETERS

OVERALL DIMENSIONS: 6500 L x 4000 W x 2000 H (mm)

PRODUCTION EFFICIENCY: 95%

PRODUCT SIZE: 175 x 95mm (ADULT SIZE)

FACIAL MASK LAYERS: 3 TO 4 LAYERS

POWER: 9 KW

AIR PRESSURE REQUIRED: 0.6 MPA

AIR CONSUMPTION: 300 LITERS PER MINUTE

WEIGHT: APPROXIMATELY 1800 KG

GROUND WEIGHT BEARING: ≤ 500KG/m2

ALL OF THE MAIN DRIVING PARTS ARE PROTECTED BY PROTECTIVE COVERQUANTITY: 1 COMPLETE LINE

Learn More -

L-5934 MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mm

L-5934 MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mmREFERENCE NUMBER: L-5934

MONFORTS 6-F TWIN AIR STENTER YEAR 2003 – WORKING WIDTH 2400mm

STENTER

RAMA MONFORTS

MAKE: MONFORTS

MODEL: 6-F TWIN

YEAR: 2003

440 VAC 60HZ

NATURAL GAS

AIR COMPRESSOR 7 BAR

QUANTITY: 1

Learn More -

C-3847 ALEA STENTER KNITS, WORKING WIDTH 2600mm YEAR 1998

C-3847 ALEA STENTER KNITS, WORKING WIDTH 2600mm YEAR 1998REFERENCE NUMBER: C-3847

ALEA STENTER FOR KNITS

WORKING WIDTH: 2600mm

6 CHAMBERS GAS HEATED

BETA TWO BOWL IMPREGNATION PADDER

WITH DOUBLE IMPREGNATION THROUGH

AND CORINO OPEN WIDTH SPREADERS

ROLLER WIDTH: 2400mm

YEAR: 1998

QUANTITY: 1

Learn More