Search results for: 'Mattress B'

- Related search terms

- mattress+s

- mattress mach

- mattress+machine

- mattress e

- Mattress mac

-

J-5331 MERT MAKINA M-1100 AUTOMATIC MATTRESS TAPE EDGE MACHINEJ-5331 MERT MAKINA M-1100 AUTOMATIC MATTRESS TAPE EDGE MACHINE -IN USED, LIKE NEW CONDITION (HAS RUN ONLY 20 MATTRESSES SINCE NEW) -FOR ALL SIZES (TWIN, FULL, QUEEN AND KING) -WITH AUTOMATIC MATTRESS FLIPPING AND TURNING -SPARE PARTS AND TECHNICAL SERVICE AVAILABLE FROM UNITED STATES QUANTITY: 1 Learn More

J-5331 MERT MAKINA M-1100 AUTOMATIC MATTRESS TAPE EDGE MACHINEJ-5331 MERT MAKINA M-1100 AUTOMATIC MATTRESS TAPE EDGE MACHINE -IN USED, LIKE NEW CONDITION (HAS RUN ONLY 20 MATTRESSES SINCE NEW) -FOR ALL SIZES (TWIN, FULL, QUEEN AND KING) -WITH AUTOMATIC MATTRESS FLIPPING AND TURNING -SPARE PARTS AND TECHNICAL SERVICE AVAILABLE FROM UNITED STATES QUANTITY: 1 Learn More -

YY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSESYY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSES HYDRAULIC PRESS FOR VACUUM MATTRESSES TECHNICAL SPECIFICATIONS: - WEIGHT: 1400 KG - CONSUMPTION: 10 KW - COMPRESSED AIR: 6 BAR - VOLTAGE: 400 V – 50 Hz THREE-PHASE QUANTITY: 1 Learn More

YY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSESYY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSES HYDRAULIC PRESS FOR VACUUM MATTRESSES TECHNICAL SPECIFICATIONS: - WEIGHT: 1400 KG - CONSUMPTION: 10 KW - COMPRESSED AIR: 6 BAR - VOLTAGE: 400 V – 50 Hz THREE-PHASE QUANTITY: 1 Learn More -

J-4802 TEKNOMAC MATTRESS ROLL PACKING MACHINE, YEAR 2018 - INCLUDES ENTRY CONVEYOR AND EXIT CONVEYORJ-4802 TEKNOMAC MATTRESS ROLL PACKING MACHINE, YEAR 2018 -INCLUDES ENTRY CONVEYOR AND EXIT CONVEYOR MAKE: TEKNOMAC MODEL: TK381/2+390 YEAR: 2018 QUANTITY: 1 Learn More

J-4802 TEKNOMAC MATTRESS ROLL PACKING MACHINE, YEAR 2018 - INCLUDES ENTRY CONVEYOR AND EXIT CONVEYORJ-4802 TEKNOMAC MATTRESS ROLL PACKING MACHINE, YEAR 2018 -INCLUDES ENTRY CONVEYOR AND EXIT CONVEYOR MAKE: TEKNOMAC MODEL: TK381/2+390 YEAR: 2018 QUANTITY: 1 Learn More -

J-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESSJ-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESS -MAXIMUM MATTRESS WIDTH: 2100mm -MAXIMUM MATTRESS HEIGHT: 500mm QUANTITY: 1 Learn More

J-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESSJ-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESS -MAXIMUM MATTRESS WIDTH: 2100mm -MAXIMUM MATTRESS HEIGHT: 500mm QUANTITY: 1 Learn More -

TT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATIONTT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATION A FULLY AUTOMATIC TUFTING SYSTEM COMPLETE WITH PLC CONTROL USING TOUCH SCREEN TECHNOLOGY. SUPPLIED WITH PRODUCT IN-FEED CONVEYOR AND EXIT CONVEYOR. MACHINE SPEED BASED ON FIRST TO LAST TUFT: 3FT IN 85 SECONDS 4’6 TO 5’ IN 105 SECONDS. 200+ MATTRESSES PER 8 HOUR SHIFT BASED ON 3’, 4’6’ & 5’ PRODUCTS. MACHINE FEATURES HORIZONTAL FEED SUITABLE FOR ALL SPRING TYPES INCLUDING POCKET UNITS LATEX AND FUTONS MATTRESSES HELICAL AVOIDANCE SYSTEM AUTOMATIC PRODUCT SIZING Learn More

TT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATIONTT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATION A FULLY AUTOMATIC TUFTING SYSTEM COMPLETE WITH PLC CONTROL USING TOUCH SCREEN TECHNOLOGY. SUPPLIED WITH PRODUCT IN-FEED CONVEYOR AND EXIT CONVEYOR. MACHINE SPEED BASED ON FIRST TO LAST TUFT: 3FT IN 85 SECONDS 4’6 TO 5’ IN 105 SECONDS. 200+ MATTRESSES PER 8 HOUR SHIFT BASED ON 3’, 4’6’ & 5’ PRODUCTS. MACHINE FEATURES HORIZONTAL FEED SUITABLE FOR ALL SPRING TYPES INCLUDING POCKET UNITS LATEX AND FUTONS MATTRESSES HELICAL AVOIDANCE SYSTEM AUTOMATIC PRODUCT SIZING Learn More -

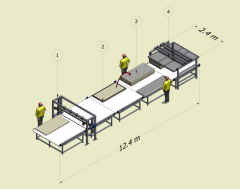

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More -

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINE

M-6042 VACUUM PRESSING AND ROLLING UP MATTRESSES LINEREFERENCE NUMBER: M-6042 (880699GY7RX) L

VACUUM PRESSING AND ROLLING UP MATTRESSES LINECOMPLETE LINE FOR VACUUM PRESSING AND ROLLING UP MATTRESSES

PRODUCTION: 3 MATTRESSES PER MINUTE

CAN WORK: VISCO / POLYURETHANE / LATEX / BONNELL SPRING / POCKET SPRING / ETC.QUANTITY: 1

Learn More -

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More

K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEWREFERENCE NUMBER: K-3774 LACOM HOT MELT COATING AND LAMINATING LINE FOR MATTRESS TICKING 2400mm YEAR 2002-LIKE NEW SUITABLE FOR MATTRESS TICKING LAMINATION MULTIROLLER SYSTEM WITH EXTRUDER AND DRUM MELTER (MELTING WITH BOTH SYSTEM IS POSSIBLE) POLIMERS TO BE USED ARE; EVA, PP, PE, REACTIVE PU QUANTITY AVAILABLE: 1 Learn More -

MERELLO MATTRESS PACKING MACHINE, MODEL ME-104, MAX. MATTRESS 2250 x 2250 x 500mmREFERENCE NUMBER: J-3756 MERELLO MATTRESS PACKING MACHINE, MODEL ME-104, MAX. MATTRESS 2250 x 2250 x 500mm MAKE: MERELLO MODEL: ME-104 BAG IS MADE OF PLASTIC ROLLS (PE), THICKNESS FROM 50 TO 200 MICROMETERS AUTOMATIC ADJUSTMENT OF THE WIDTH, HEIGHT AND THICKNESS OF THE MATTRESS MATTRESS DIMENSIONS: FROM 1700 x 700 x 100mm TO 2250 x 2250 x 500mm DETECTS THE THICKNESS OF THE MATTRESS AND APPLIES THE PROGRAMMED PRESSURE TO FURTHER TIGTHEN THE BAG PLASTIC CUTS WITH COLD KNIFE: MAINTENANCE-FREE, SMOKE OR ODOR FREE REINFORCEMENT COIL: MOTORIZED ROLLERS FOR PLACING ADDITIONAL PLASTIC ROLLERS TRANSISTORIZED PLC CONTROL AND TOUCH SCREEN THAT REPORTS THE STATUS OF HE MACHINE VARIABLE SPEED DRIVE IN ALL MOTORS TO EXTEND THEIR LIFE THE MACHINE CAN STORE 4 + 4 BOBBINS IN WORKING POSITION Learn More

MERELLO MATTRESS PACKING MACHINE, MODEL ME-104, MAX. MATTRESS 2250 x 2250 x 500mmREFERENCE NUMBER: J-3756 MERELLO MATTRESS PACKING MACHINE, MODEL ME-104, MAX. MATTRESS 2250 x 2250 x 500mm MAKE: MERELLO MODEL: ME-104 BAG IS MADE OF PLASTIC ROLLS (PE), THICKNESS FROM 50 TO 200 MICROMETERS AUTOMATIC ADJUSTMENT OF THE WIDTH, HEIGHT AND THICKNESS OF THE MATTRESS MATTRESS DIMENSIONS: FROM 1700 x 700 x 100mm TO 2250 x 2250 x 500mm DETECTS THE THICKNESS OF THE MATTRESS AND APPLIES THE PROGRAMMED PRESSURE TO FURTHER TIGTHEN THE BAG PLASTIC CUTS WITH COLD KNIFE: MAINTENANCE-FREE, SMOKE OR ODOR FREE REINFORCEMENT COIL: MOTORIZED ROLLERS FOR PLACING ADDITIONAL PLASTIC ROLLERS TRANSISTORIZED PLC CONTROL AND TOUCH SCREEN THAT REPORTS THE STATUS OF HE MACHINE VARIABLE SPEED DRIVE IN ALL MOTORS TO EXTEND THEIR LIFE THE MACHINE CAN STORE 4 + 4 BOBBINS IN WORKING POSITION Learn More