Search results for: 'Oper'

- Related search terms

- Opera

- Operating s

- Operating sy

- Operating sy'A=0'

- operation system'

-

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More

G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONSREFERENCE NUMBER: G-6926 SYSTEM FOR THE PRODUCTION OF PILLOWS AND FURNISHING CUSHIONS QUANTITY AVAILABLE: 1 Learn More -

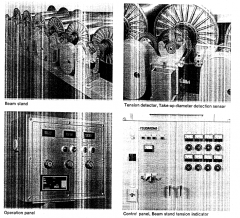

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More

M-5202 KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMAREFERENCE NUMBER: M-5202 (1313VTYFXX12) L KB10 REBEAMER FOR ACETATE WITH DISK BRAKES - TSUDAKOMA QUANTITY AVAILABLE: 1 Learn More -

M-3994 CONE DYEING MACHINE MASTER BM 300 400KG YEAR 300 400KG YEAR 1999

M-3994 CONE DYEING MACHINE MASTER BM 300 400KG YEAR 300 400KG YEAR 1999REFERENCE NUMBER: M-3994

CONE DYEING MACHINE MASTER BM 300 400KG YEAR 1999

CONE DYEING MACHINE

MASTER BM 300, 400 KG, RACK WITH 43 BARS.

MAX OPERATING PRESSURE MAIN BODY: 5

MAXIMUM OPERATING TEMPERATURE OF MAIN BODY:204C°

MAX OPERATING PRESSURE COIL :16

MAXIMUM OPERATING TEMPERATURE OF SERPENTINE:204C°

CAPACITY OF MAIN BODY :4085 LITERS

CAPACITY 65 LITERS SERPENTINE

YEAR 1999

Learn More -

M-3993 CONE DYEING MACHINE MASTER BM 100 HS 125K YEAR 2001 -125 KGS

M-3993 CONE DYEING MACHINE MASTER BM 100 HS 125K YEAR 2001 -125 KGSREFERENCE NUMBER: M-3993

CONE DYEING MACHINE MASTER BM 100 HS 125K YEAR 2001 -125 KGS

CONE DYEING MACHINE

MASTER BM 100 HS

125K

RACK WITH 12 BARS

MAX OPERATING PRESSURE MAIN BODY: 5

MAXIMUM OPERATING TEMPERATURE OF MAIN BODY: 158°C.

MAX OPERATING PRESSURE COIL: 16

MAXIMUM OPERATING TEMPERATURE OF SERPENTINE: 204°C

CAPACITY OF MAIN BODY: 1260 LITERS

CAPACITY OF SERPENTINE: 25 LITERS

YEAR: 2001

Learn More -

TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006 1. USED VECOPLAN SHREDDER, MODEL RG52-75 SPK 2. SINGLE-SHAFT DESIGN POWERED BY A 75 HP MOTOR AND IS EQUIPPED WITH 20 CUTTERS. 3. IT OFFERS A 52" X 58" FEED OPENING, 4. A 15" ROTOR, AND A 1.25" SCREEN. 5. BOTH THE FEED AND DISCHARGE CONVEYORS ARE INCLUDED. 6. YEAR 2006 7. REPORTEDLY LESS THAN 500 OPERATING HOURS. USED EXCLUSIVELY FOR SHREDDING 100% HARD DRIVES QUANTITY: 1 Learn More

TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006TT-7862 VECOPLAN RG52-75 SPK INDUSTRIAL SHREDDER, YEAR 2006 1. USED VECOPLAN SHREDDER, MODEL RG52-75 SPK 2. SINGLE-SHAFT DESIGN POWERED BY A 75 HP MOTOR AND IS EQUIPPED WITH 20 CUTTERS. 3. IT OFFERS A 52" X 58" FEED OPENING, 4. A 15" ROTOR, AND A 1.25" SCREEN. 5. BOTH THE FEED AND DISCHARGE CONVEYORS ARE INCLUDED. 6. YEAR 2006 7. REPORTEDLY LESS THAN 500 OPERATING HOURS. USED EXCLUSIVELY FOR SHREDDING 100% HARD DRIVES QUANTITY: 1 Learn More -

TT-4179 WARTSILA CHP W16V25SG ELECTRICITY AND HEAT GENERATOR WITH 61,000 HOURS, YEAR 1998TT-4179 WARTSILA CHP W16V25SG ELECTRICITY AND HEAT GENERATOR WITH 61,000 HOURS, YEAR 1998 ELECTRICITY AND HEAT GENERATOR YEAR 1998 WITH 61,000 OPERATING HOURS QUANTITY: 1 Learn More

TT-4179 WARTSILA CHP W16V25SG ELECTRICITY AND HEAT GENERATOR WITH 61,000 HOURS, YEAR 1998TT-4179 WARTSILA CHP W16V25SG ELECTRICITY AND HEAT GENERATOR WITH 61,000 HOURS, YEAR 1998 ELECTRICITY AND HEAT GENERATOR YEAR 1998 WITH 61,000 OPERATING HOURS QUANTITY: 1 Learn More -

YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS)YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS) AUTOMATICALLY REPLENISHES ADHESIVE TO THE DESIRED LEVEL IN HOT MELT EQUIPMENT. PRODUCT DETAILS: - AUTOMATIC "ON DEMAND" FILLING OF THE HOT MELT UNIT. - REMOVES AN OPERATOR FROM THE HOT MELT SUPPLY UNIT AREA. - NOZZLE PLUGGING AND SYSTEM CONTAMINATION IS VIRTUALLY ELIMINATED. - LESS THERMAL SHOCK TO THE HOT MELT SYSTEM. QUANTITY: 1 Learn More

YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS)YY-2332 AUTOMATIC HOT MELT TANK FILLING SYSTEM (ATFS) AUTOMATICALLY REPLENISHES ADHESIVE TO THE DESIRED LEVEL IN HOT MELT EQUIPMENT. PRODUCT DETAILS: - AUTOMATIC "ON DEMAND" FILLING OF THE HOT MELT UNIT. - REMOVES AN OPERATOR FROM THE HOT MELT SUPPLY UNIT AREA. - NOZZLE PLUGGING AND SYSTEM CONTAMINATION IS VIRTUALLY ELIMINATED. - LESS THERMAL SHOCK TO THE HOT MELT SYSTEM. QUANTITY: 1 Learn More -

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More

J-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mmJ-3004 FIBRILLATED RAFFIA TAPE EXTRUSION LINE – NEW, 120mm PP FIBRILLATED YARN EXTRUDER LINE MODEL: NOVASTAR-120 EXTRUSION LINE FOR PRODUCTION OF PP FIBRILLATED YARN RAW MATERIAL: PP GRANULE FINISHED PRODUCTS: NON-TWISTED TAPE YARN, FIBRILLATED YARN FOR TWINE RANGE OF PRODUCT: 10,000 TO 30,000 DENIER 10000 DENIER APPROXIMATELY 17 TO 19 YARN 16000 DENIER APPROXIMATELY 11 TO 12 YARN 22000 DENIER APPROXIMATELY 8 TO 9 YARN 28000 DENIER APPROXIMATELY 6 TO 7 YARN 32000 DENIER APPROXIMATELY 5 TO 6 YARN EXTRUSION THROUGHPUT: 300 KG PER HOUR EXTRUSION CAPACITY: 180 TO 250 KG PER HOUR (PRODUCT CAPACITY DEPEND ON FILAMENT SIZE) EXTRUDER SCREW DIAMETER: Ø 120mm T-DIE WIDTH: 1300mm TAKE-OFF ROLLER WIDTH: 1200mm TAKE-OFF LINE SPEED: 160 METERS PER MINUTE (MAXIMUM) OPERATION SIDE: RIGHT TO LEFT, OR LEFT TO RIGHT Learn More -

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014R-4533 MAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER, YEAR 2014

2 BAR , 150m DISTANCE BETWEEN BARS

WIDTH UP TO 2700mm = 106 INCHESMAMMUT VMK SELECT DOUBLE LOCK CHAINSTITCH MULTI-NEEDLE QUILTER

YEAR: 2014

96 SEPARATELY CONTROLLABLE NEEDLES

FULLY AUTOMATIC NEEDLE PLAN CHANGE

TOP AND BOTTOM THREAD CUTTER AT EACH SEWING POSITION

MATERIAL WIDTH UP TO 2700mm

TWO NEEDLE BARS

150mm SPACING

HANDWHEEL ADJUSTMENT OF HEIGHT OF PRESSER PLATE

ELECTRONIC THREAD BREAK DETECTOR FOR TOP AND BOTTOM THREADS

MATERIAL UNWIND DEVICE

RACKS FOR TOP AND BOTTOM THREAD

ONE CATWALK EACH ON FRONT AND REAR OPERATING SITE

TROUGH INFEED FOR UPPER MATERIAL WITH MOTOR-DRIVEN ROLLER SYSTEM

AUTOMATIC MARKING AND DETECTING UNIT FOR PATTERN CONFORM LATERAL CUT

ELECTRONICS AND MOTORS 400V, 3 PHASES

CONCRETE BASES AND VIBRATION DAMPERS

Learn More -

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More

TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006TT-8623 TETRA PAK® A3 FLEX 600V FILLING MACHINE 1000 EDGE 7000 BPH, YEAR 2006 1. TETRA PAK® A3 FLEX 600V FILLING MACHINE 2. YEAR OF CONSTRUCTION 2006 3. CONDITION USED 4. MACHINE TYPE: FILLING MACHINE 5. BRAND: TETRA PAK® 6. MODEL: A3 FLEX 600V 7. CONDITION: USED 8. OPERATING HOURS: 67,130 H Learn More