Search results for: 'compo'[0]'

-

TT-7468 WORSTED WOOLLEN MACHINERIES FOR SALE, YEAR 1968 TO 1988TT-7468 WORSTED WOOLLEN MACHINERIES FOR SALE, YEAR 1968 TO 1988 1. ALL PRICES ARE EX-FLOOR (AS-IS, WHERE-IS). 2. DISMANTLING/LOADING FEES AVAILABLE ON REQUEST. 3. TRANSPORT FEES DEPEND ON THE NUMBER OF MACHINES TO BE SHIPPED. Learn More

TT-7468 WORSTED WOOLLEN MACHINERIES FOR SALE, YEAR 1968 TO 1988TT-7468 WORSTED WOOLLEN MACHINERIES FOR SALE, YEAR 1968 TO 1988 1. ALL PRICES ARE EX-FLOOR (AS-IS, WHERE-IS). 2. DISMANTLING/LOADING FEES AVAILABLE ON REQUEST. 3. TRANSPORT FEES DEPEND ON THE NUMBER OF MACHINES TO BE SHIPPED. Learn More -

TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000 1. USED 2. IN PRODUCTION 3. SPEED: 12000 BPH 4. CONTAINERS: PET 5. FORMATS: 0.50 L, 1.0 L, 1.5 L, 2 L 6. PRODUCT: WATER (SPARKLING), WATER (STILL) 7. FILL TYPE: ISOBARIC 8. NECK TYPE: 28 QUANTITY: 1 Learn More

TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000TT-6700 COMPLETE BOTTLING LINE PROCOMAC FOR STILL AND SPARKLING WATER, UP TO 12000 BPH, YEAR 2018 TO 2000 1. USED 2. IN PRODUCTION 3. SPEED: 12000 BPH 4. CONTAINERS: PET 5. FORMATS: 0.50 L, 1.0 L, 1.5 L, 2 L 6. PRODUCT: WATER (SPARKLING), WATER (STILL) 7. FILL TYPE: ISOBARIC 8. NECK TYPE: 28 QUANTITY: 1 Learn More -

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More

TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024TT-6598 MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET, 2.5 MW, 50 Hz, 1500 RPM, YEAR 2024 1. MTU 20V4000L64FNER TR OPEN TYPE NATURAL GAS GENSET 2. 1 UNIT 400 V 3. 2 UNITS 6.3 KV Learn More -

TT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINETT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINE CONDITION: NEW APPLICATION: LASER CUTTING APPLICABLE MATERIAL: LEATHER PAPER CRYSTAL LASER TYPE: FIBER LASER CUTTING AREA: 400mm X 600mm CNC OR NOT: YES Learn More

TT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINETT-4790 PP MICRO DANLINE TWISTED FIBER CUTTING MACHINE/MULTIFILAMENT YARN CHOPPING MACHINE CONDITION: NEW APPLICATION: LASER CUTTING APPLICABLE MATERIAL: LEATHER PAPER CRYSTAL LASER TYPE: FIBER LASER CUTTING AREA: 400mm X 600mm CNC OR NOT: YES Learn More -

TT-2077 GE FRAME 7EA 86.5MW POWER GENERATION SET – NEW, 60 Hz, YEAR 2014TT-2077 GE FRAME 7EA 86.5MW POWER GENERATION SET – NEW, 60 Hz, YEAR 2014 CONDITION: NEW NEVER USED MANUFACTURED: GENERAL ELECTRIC YEAR 2014 AVAILABILITY: DISCONNECTED / IMMEDIATE Learn More

TT-2077 GE FRAME 7EA 86.5MW POWER GENERATION SET – NEW, 60 Hz, YEAR 2014TT-2077 GE FRAME 7EA 86.5MW POWER GENERATION SET – NEW, 60 Hz, YEAR 2014 CONDITION: NEW NEVER USED MANUFACTURED: GENERAL ELECTRIC YEAR 2014 AVAILABILITY: DISCONNECTED / IMMEDIATE Learn More -

J-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTSJ-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTS MAKE: GE MODEL: LM6000 PA YEAR: 1993 42 MW 50 Hz DUAL FUEL 10,500 VOLTS CONDITION: USED, 12,000 HOURS QUANTITY: 1 Learn More

J-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTSJ-4722 GE LM6000 PA GAS TURBINE, 42 MW, 50 Hz, DUAL FUEL, 10,500 VOLTS MAKE: GE MODEL: LM6000 PA YEAR: 1993 42 MW 50 Hz DUAL FUEL 10,500 VOLTS CONDITION: USED, 12,000 HOURS QUANTITY: 1 Learn More -

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More

YY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mmYY-2251 AIRLAID PRODUCTION LINE, FINAL PRODUCT WIDTH 2200mm ITEM 001 BALE OPENER (2 SETS) AND SEALED BALE OPENER (1 SET) ITEM 002 FIBER OPENING MACHINE (FOR LOW MELT FIBER OR PP) - 1 SET ITEM 003 PRE-OPENER – 1 SET ITEM 004 BIG CHAMBER BLENDER – 1 SET ITEM 005 MAIN-OPENER – 1 SET ITEM 006 VIBRATING FEEDER – 1 SET ITEM 007 CONDENSER – 2 SETS ITEM 008 AUTO-LEVER - 1 SET ITEM 009 AIR LAID MACHINE – 1 SET ITEM 010 AUTO-LEVER – 1 SET ITEM 011 BATT FEEDER – 1 SET ITEM 012 HIGH SPEED SINGLE SHAFT SINGLE BOARD PRE NEEDLE LOOM – 1 SET ITEM 013 HIGH SPEED SINGLE SHAFT SINGLE BOARD MAIN NEEDLE LOOM – 1 SET ITEM 014 DOUBLE BELT THERMAL-BONDED OVEN – 1 SET ITEM 015 DOUBLE-ROLLER CALENDER MACHINE – 1 SET ITEM 016 COOLING UNIT – 1 SET Learn More -

J-4630 DOUBLE SHAFT SHREDDER, CHAMBER DIMENSIONS 1500mm LENGTH x 950mm WIDTHJ-4630 DOUBLE SHAFT SHREDDER, CHAMBER DIMENSIONS 1500mm LENGTH x 950mm WIDTH DOUBLE SHAFT SHREDDER KNIVES: 22 PIECES, SIZE Ø500mm x 70mm, MATERIAL 55SRCI SPACERS: 22 PIECES, SIZE Ø290mm x 70mm, MATERIAL 45C STEEL SHAFTS: 2 PIECES, SIZE Ø240mm x 2400mm, MATERIAL 42CRMO CHAMBER DIMENSIONS: 1500mm LENGTH x 950mm WIDTH SPEED: 10 RPM (SPEED IS FIXED AND CAN NOT BE ADJUSTED) DIAMETER OF BARE ROLL (WITHOUT TEETH): 420mm FROM INNER TO THE TEETH BOTTOM DIAMETER, TEETH DEPTH IS 40mm (TOTAL OUTER DIAMETER OF BLADE IS 500mm) SHAFT DIAMETER: 240mm MOTOR POWER: 37 KW (2 PIECES) REDUCER: K SERIES (2 PIECES) VOLTAGE: 480 VOLTS WEIGHT: 12,000 KGS QUANTITY: 1 Learn More

J-4630 DOUBLE SHAFT SHREDDER, CHAMBER DIMENSIONS 1500mm LENGTH x 950mm WIDTHJ-4630 DOUBLE SHAFT SHREDDER, CHAMBER DIMENSIONS 1500mm LENGTH x 950mm WIDTH DOUBLE SHAFT SHREDDER KNIVES: 22 PIECES, SIZE Ø500mm x 70mm, MATERIAL 55SRCI SPACERS: 22 PIECES, SIZE Ø290mm x 70mm, MATERIAL 45C STEEL SHAFTS: 2 PIECES, SIZE Ø240mm x 2400mm, MATERIAL 42CRMO CHAMBER DIMENSIONS: 1500mm LENGTH x 950mm WIDTH SPEED: 10 RPM (SPEED IS FIXED AND CAN NOT BE ADJUSTED) DIAMETER OF BARE ROLL (WITHOUT TEETH): 420mm FROM INNER TO THE TEETH BOTTOM DIAMETER, TEETH DEPTH IS 40mm (TOTAL OUTER DIAMETER OF BLADE IS 500mm) SHAFT DIAMETER: 240mm MOTOR POWER: 37 KW (2 PIECES) REDUCER: K SERIES (2 PIECES) VOLTAGE: 480 VOLTS WEIGHT: 12,000 KGS QUANTITY: 1 Learn More -

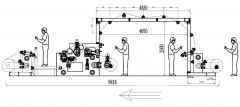

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More