Search results for: 'hot melt machine'

- Related search terms

- Machine fl

- machine''[0]''

- Machine+fe

- machine de''

- machines

-

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More

T-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACKT-8540 WET WIPES MACHINE, CAPACITY 30 TO 120 PIECES PER PACK WET WIPES MACHINE CAPACITY: 30 TO 120 PIECES PER PACK DRIVE MODE: AUTOMATIC STABLE SPEED: 3500 TO 4800 PIECES PER MINUTE (25 TO 60 BAGS) MACHINE SIZE (L X W X H): 12200 × 2400 × 2200mm QUANTITY: 1 Learn More -

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More

T-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLEST-7018 LINE FOR PRODUCING 70 TO 150 DENIER FROM RECYCLED BOTTLES EXTRUDER Φ 160/25 PRODUCT TYPE PET-POY END/POSITION 12 ENDS POSITIONS 24 POSITIONS POSITION/SPINNING BEAM 2 POSITIONS/SPINNING BEAM POSITION DISTANCE (mm) 1500mm SPINNING PACK CYLINDER TYPE, BOTTOM MOUNTED SPINNERET DIAMETER (mm) Φ 90mm CROSS BLOWING AREA 1430mm X 1380mm GEAR PUMP SPECIFICATIONS (CC/REV) 12X3.0CC/REV GEAR PUMP QUANTITY/POSITION 1 OIL PUMP SPECIFICATION (CC/REV) 12X0.12CC/REV OIL PUMP QUANTITY/ POSITION 1 DOWTHERM BOILER/LINE 600L/65KW GUIDE ROLLER SYSTEM (DIAMETER X WIDTH) 160mm X 160mm MIGRATION JET AWA. JAPAN WINDER TWA1800-12ENDS Learn More -

YY-2356 CHAMP DISTILLATE SPRAY GUNYY-2356 CHAMP DISTILLATE SPRAY GUN SPRAY HEATED MOLTEN DISTILLATE MATERIAL WITH SPEED, ACCURACY AND LOW MAINTENANCE. CHAMP DISTILLATE SPRAY GUN ELIMINATES THE NEED FOR ADDITIVES. CUSTOMER TO PROVIDE COMPRESSED AIR ( 3.5 SCFM AT 80PSI). QUANTITY: 1 Learn More

YY-2356 CHAMP DISTILLATE SPRAY GUNYY-2356 CHAMP DISTILLATE SPRAY GUN SPRAY HEATED MOLTEN DISTILLATE MATERIAL WITH SPEED, ACCURACY AND LOW MAINTENANCE. CHAMP DISTILLATE SPRAY GUN ELIMINATES THE NEED FOR ADDITIVES. CUSTOMER TO PROVIDE COMPRESSED AIR ( 3.5 SCFM AT 80PSI). QUANTITY: 1 Learn More -

YY-2338 MICRO MINI HIGH SPEED HOT MELT GUNYY-2338 MICRO MINI HIGH SPEED HOT MELT GUN PRODUCT DETAILS: • INTEGRATED NEEDLE AND SELF-CLEANING NOZZLE VIRTUALLY ELIMINATE ADHESIVE STRINGING. (MICRO OPTIMA MODULE). • DUAL-PORT PIVOTING MODULES SIMPLIFY SET-UP BY PROVIDING SIMPLE ADJUSTMENT OF BEAD PLACEMENT. • ADJUSTABLE NEEDLE STROKE SETS ADHESIVE FLOW FOR EXTREME ACCURACY. (MICRO ADJUSTABLE MODULE). • ON/OFF CYCLE SPEEDS OF 3.5 MILLISECONDS IS IDEAL FOR HIGH-SPEED APPLICATIONS. • COVER INCREASES SAFETY AND PROMOTES ENERGY EFFICIENCY. • INDUSTRY EXCLUSIVE BUILT-IN FILTER CAPTURES DEBRIS AND MINIMIZES NOZZLE CLOGGING. • COMPACT SIZE PROVIDES FOR EASY INSTALLATION INTO PACKAGING MACHINERY. • INSULATED THERMOPLASTIC COVER INCREASES SAFETY BY REDUCING OPERATOR EXPOSURE TO HOT SURFACES. • ENHANCED BUILT-IN FILTER CAPTURES DEBRIS AND REDUCES DOWNTIME DUE TO CLOGGED NOZZLES. QUANTITY: 1 Learn More

YY-2338 MICRO MINI HIGH SPEED HOT MELT GUNYY-2338 MICRO MINI HIGH SPEED HOT MELT GUN PRODUCT DETAILS: • INTEGRATED NEEDLE AND SELF-CLEANING NOZZLE VIRTUALLY ELIMINATE ADHESIVE STRINGING. (MICRO OPTIMA MODULE). • DUAL-PORT PIVOTING MODULES SIMPLIFY SET-UP BY PROVIDING SIMPLE ADJUSTMENT OF BEAD PLACEMENT. • ADJUSTABLE NEEDLE STROKE SETS ADHESIVE FLOW FOR EXTREME ACCURACY. (MICRO ADJUSTABLE MODULE). • ON/OFF CYCLE SPEEDS OF 3.5 MILLISECONDS IS IDEAL FOR HIGH-SPEED APPLICATIONS. • COVER INCREASES SAFETY AND PROMOTES ENERGY EFFICIENCY. • INDUSTRY EXCLUSIVE BUILT-IN FILTER CAPTURES DEBRIS AND MINIMIZES NOZZLE CLOGGING. • COMPACT SIZE PROVIDES FOR EASY INSTALLATION INTO PACKAGING MACHINERY. • INSULATED THERMOPLASTIC COVER INCREASES SAFETY BY REDUCING OPERATOR EXPOSURE TO HOT SURFACES. • ENHANCED BUILT-IN FILTER CAPTURES DEBRIS AND REDUCES DOWNTIME DUE TO CLOGGED NOZZLES. QUANTITY: 1 Learn More -

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More

M-4566 THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm)REFERENCE NUMBER: M-4566 (1111225RSJ10U) L THERMOPLASTIC HOTMELT COATING LINE MP ENGINEERING TYPE HM59-SD3 YEAR 2005 WIDTH 102” (2590mm) YEAR: 2005 TYPE: HM59-SD3 MATR: 404/04 ROLL FACE: 2600mm (102”) WORKING WIDTH: 2400mm (95”) VOLTAGE: 480/3/60 CONTROL VOLTAGE: 110/60 CONSISTING OF: CAROUSEL 3 POSITION LET-OFF, ENTRY ON ACCUMULATOR WITH HOT-WIRE SEAMING DEVICE, 8000 VOLT STATIC ELIMINATOR, PNEUMATICALLY OPERATED FABRIC HOLDING DEVICE FOR TENSION CONTROL, ACCUMULATOR WITH 8-ROLLS UP AND 9-ROLLS DOWN APPROX.. 80-YARD CAPACITY, COMPENSATING ARM ON EXIT SIDE. ROLLS ARE 4” DIA. X 102” FACE ALUMINUM, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. SECOND ACCUMULATOR WITH ROLL CRADLE FOR SECOND SUBSTRATE LET-OFF, ACCUMULATOR WITH 9-ROLLS UP AND 10 ROLLS DOWN, APPROX.. 54 YARD CAPACITY, ROLLS ARE 4’ DIA. X 102” FACE ALUMINUM, INCLUDES 8000 VOLT STATIC ELIMINATOR AND PNEUMATIC FABRIC HOLDING FOR TENSION, PENDULUM TYPE GUIDING DEVICE ON EXIT SIDE, CONTROL PANEL MOUNTED ONTO FRAMEWORK, FULLY ENCLOSED CAGE. OVERHEAD GANTRY WITH ACCESS STAIRS ON RIGHT SIDE OF FIRST ACCUMULATOR, EXTENDS OVER THE EXTRUDER WITH JIB MOUNTED FOR EASE IN REMOVING DIE FROM MACHINE, GUIDING/CENTERING DEVICE MOUNTED ONTO GANTRY FEEDING COATING HEAD. MP ENGINEERING EXTRUDER/APPLICATOR TYPE HM59-SD3, MATR. NO. 402/04, WITH 102” DIE, 98” RUBBER-BELT WITH PNEUMATIC CYLINDERS FOR BELT TENSION AND GUIDING, HEATED CYLINDER BACKING TO DIE, OPERATOR PLATFORM, CONTROLS MOUTNED IN DOOR AND OPERATOR TOUCH SCREEN PANEL. (NOTE: THESE ARE PRESENTLY MOUNTED ON PRODUCTION LINE AND WILL BE REMOVED AND PLACED BACK INTO/ONTO APPLICATOR. 480/3/60 COATEM SISTEMI C.R.L. IMBALLAGIO & HOT MELT EXTRUDER, S/N 50701, TYPE/MODEL CE-200, WITH DIGITAL MICROPROCESSOR AND INVERTER FOR SPEED VARIATION, DESIGNED TO WORK MAINLY WITH POLYESTER, POLYAMIDE AND POLYURETHANE BUT CAN ALSO EXTRUDE ABS, POLYTHENE, POLYPROPYLENE AND ADHESIVES LIKE EVA ADHESIVES. 480/3/60 CONAIR DRYER CD-300, PL-D-196-1, MODEL D03H4101310, S/N 9D0597, 480/3/60, AND HOPPER. THIRD ACCUMULATOR FOR BONDED PRODUCT WITH 6-ROLLS UP AND 7-ROLLS DOWN, APPROX…60-YARD CAPACITY, ROLLS ARE 6” DIA. X 102” FACE ALUMINUM, WITH DRAW-ROLL TENSION DEVICE MOUNTED ONTO EXIT, OVERHEAD CARRIER ROLLS AND FRAMEWORK DELIVERY TO ELECTRIC A-FRAME WINDER WITH 102” FACE LAY-ON ROLL, AND SEMI-AUTOMATIC BATCHER FOR INDIVIDUAL ROLLS, 2-ROLL SURFACE WINDING 102” FACE WIDTH, OVERHEAD CORE FEED, FABRIC CENTERING DEVICE, ELECTRIC SCISSOR CUT-OFF, KICK-OUT TO 2-ROLL BED, OPERATOR PLATFORM AND OPERATOR CONTROLS. ALL MACHINES PRODUCED BY MP CONFORMS TO EEC DIRECTORY 89/392 CEE (CE MARK) TECHNICAL FEATURES OF THE LINE, ACCORDING TO DWG 100-904/1C ROLLERS WIDTH 2600mm WORKING WIDTH 2400mm MAXIMUM DIAMTER OF THE ROLLS OF PU FOAM 1500mm MAXIMUM DIAMETER OF THE UNWOUND ROLLS OF FABRIC 600 ° 1500 MAXIMUM DIAMETER OF THE REWOUND ROLLS 500 ° 1500 (IN CASE YOU ARE REWINDING ROLLS OF FABRIC LAMINATED TO PU FOAM, THE MAXIMUM DIAMETER IS 1750mm) ADJUSTABLE MECHANIC SPEED: 5 TO 50 M/MIN MAIN POWER SUPPLY + NEUTRAL + EARTH 480+N+E/60 V/HZ VOLTAGE ON CONTROL PANELS 110/60 V/HZ INSTALLED POWER FOR MOTORS 22KW INSTALLED POWER FOR IR HEATER 14,25KW INSTALLED POWER TO HEAT THE SLOT-DIE 32KW INSTALLED POWER FOR THE THERMAL OIL HEATING UNIT FOR THE CALENDERING ROLLERS 32,2KW INSTALLED POWER FOR THE CHILLER 12,9KW A.C. MOTORS, DRIVER, ELECTRIC CABLES ARE ACCORDING TO CEI NORMS BACKGEAR ROLLERS, WITH PAINTED SURFACE OR ALUMINUM MADE WITH DIAMETER 100/120/150mm COMPRESSED AIR CONSUMPTION, AT 6 BAR 1500LT/H COOLING WATER CONSUMPTION (WATER MUST HAVE A TEMPERATURE NOT HIGHER THAN 10°C) 5500LT/H ADJUSTABLE TENSION ON THE REWOUND MATERIALS 5 A 35 KG. PAINTING GREEN RAL 6027 E BLUE MARINE RAL 5021 A.C. MOTORS CONTROL THE SPEED OF THE MACHINES, AND ARE AUTOMATICALLY SYNCHRONISED THROUGH ELECTRONIC DRIVES (INVERTER) AND PNEUMATIC DANCER UNITS (COMPENSTAORS) ESTRUDER: CAPACITY UP TO 200 KG/H (DEPENDING ON THE VISCOSITY OF THE ADHESIVE TO BE EXTRUDED) POWER OF THE MOTOR AND RESISTANCES: 90KW MAXIMUM MELTING TEMPERATURE: 220°C MATERIALS TO BE PROCESSED NONWOVENS 30:150 GR/M2 SYNTHETIC AND NATURAL FABRICS (EXCLUDING STRETCHY FABRICS) WITH WEIGHT 100:600 GR/M2 SCRIMS FOR BACKING FABRIC WITH WEIGHT 70:120 G/M2 MAXIMUM THICKNESS OF PU FOAM 15mm MINIMUM THICKNESS OF PU FOAM 2mm DENSITY OF PU FOAM 22/40 KG/M3 THERMOPLASTIC ADHESIVE TO BE COATED THERMOPLASTIC HOTMELTS (COPOLYAMMIDE, COPOLYESTER, EVA AND POLYURETHANE THERMOPLASTIC HOTMELT GRANULES) DATA REFERRING TO PRODUCTION THE PRODUCTION SPEED CAN CHANGE, DEPENDING ON THE KIND OF HOTMELTS, ON THEIR MELTING TEMPERATURE, ON THEIR VISCOSITY, AND ON THE GRAMS PER SQUARED METER TO BE COATED QUANTITY AVAILABLE: 1 Learn More -

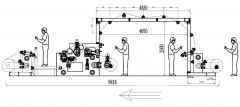

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

R-4395 SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOURREFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

REFERENCE NUMBER: R-4395

SQUARE (RECTANGLE) BUBBLE GUM PRODUCTION LINE, CAPACITY 80 KG/HOUR

MAIN TECHNICAL PARAMETERS:

PROFILES:

THIS LINE IS USED TO PRODUCE CANDIES IN VARIOUS COLORS AND DESIGNS, ESPECIALLY BUBBLE GUM IN X SHAPE, CUBIC, CORRUGATED, CHANNEL STYLE, AND OTHER KINDS.

IT IS DESIGNED TO FACILITATE THE OPERATION WITH RELIABLE PERFORMANCE AND CHANGEABLE CANDY STYLE.

A CORRUGATION-STYLE WRAPPING MACHINE OR A CUTTING/WRAPPING MACHINE CAN BE SUPPLIED IF REQUIRED.

ADVANTAGES:

1) RELIABILITY, EASY CLEANING AND MAINTENANCE

2) ACCURATE CUTTING AND SIMPLE CHANGEOVER

3) EASY OPERATION

4) AUTOMATIC BELT TENSIONING

Learn More -

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More

T-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTET-9895 FULLY AUTOMATIC MATTRESS (PET PAD) MAKING MACHINE, 120 TO 150 PIECES PER MINUTE TECHNICAL PARAMETERS FUNCTION: EMBOSSING, CUTTING, FOLDING OF PET PAD FOLDING METHOD: 1/3 IN THE WIDTH DIRECTION, 2 TIMES IN THE LENGTH DIRECTION RAW MATERIAL WIDTH: HYDROPHILIC CLOTH WIDTH ≦ 600mm (SLIGHTLY SMALLER THAN THE WIDTH OF THE CAST FILM) WATER ABSORPTION LAYER WIDTH = HYDROPHILIC CLOTH WIDTH: 50 TO 60mm CAST FILM WIDTH ≦ 600mm PRODUCT UNFOLDED SIZE: 400 X 600mm; 500 X 700mm; 600 X 900mm FOLDED SIZE: 135 X 200mm; 170 X 250mm; 200 X 300mm SPEED: 120 TO 150 PIECES PER MINUTE FINISHED PRODUCT LENGTH: LENGTH ERROR ≦ 5mm THE POSITION OF THE ABSORBENT LAYER: THE SAME LENGTH AS THE HYDROPHILIC CLOTH AND CAST FILM WATER-ABSORBING LAMINATED PATTERN: DIAMOND PATTERN (CUSTOMIZABLE) NUMBER OF FOLDING LAYERS: 3 LAYERS EACH FOLD WIDTH: 135 TO 200mm APPLICABLE RAW MATERIALS: HYDROPHILIC NON-WOVEN FABRIC ABOUT 20 GSM WATER ABSORPTION LAYER 0.5 TO 3mm CAST FILM ABOUT 25 GSM SSS SPUNBOND WEIGHT: 13 TO 15 GSM THE INNER DIAMETER OF THE RAW MATERIAL CORE: 3 INCHES (75mm) RAW MATERIAL DIAMETER: NON-WOVEN FABRIC ≦ 700mm WATER ABSORPTION LAYER ≦ 1200mm CAST FILM ≦ 400mm MACHINE SIZE (L X W X H) MACHINE: 15000 X 2000 X 1700mm VOLTAGE: 380V/50Hz POWER: 12KW (WITHOUT WOOD PULP SECTION) NET WEIGHT: 6T AIR COMPRESSOR: ≥ 0.6MPA 1.2m³/MINUTE, 15KW (CUSTOMER FURNISHES) NONWOVEN ROLL MAXIMUM DIAMETER: 650mm FILM ROLL DIAMETER: 450mm REQUIRES 2 40 FOOT HQ CONTAINERS Learn More -

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More

YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE)YY-2236 AUTOMATIC CARTONING MACHINE (MANUAL FEEDING), PACKING SPEED 30 TO 80 PCS PER MIN (CHANGES IN SPEED WITH RESPECT TO PRODUCT SIZE) DESCRIPTION: PACKING MACHINE WITH THE ADVANTAGES OF SMALL SIZE, LIGHT WEIGHT, HIGH EFFICIENCY, SEMI FUNCTIONAL, ETC., SUITABLE FOR PACKING COFFEE STICK, MEAT, BISCUIT, BLISTER, BOTTLES, VIALS, PILLOW BAGS, ETC. REMARK: SEALING: TWO SIDES WITH PLUG-IN. QUANTITY: 1 Learn More -

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

TT-3656 MASTER BAG DLS 200, WIDTH 150 TO 330mm, YEAR 2022TT-3656 MASTER BAG DLS 200, WIDTH 150 TO 330mm, YEAR 2022 CATEGORY: BAG MAKING MODEL: MASTER BAG DLS 200 YEAR: 2022 QUANTITY: 1 Learn More

TT-3656 MASTER BAG DLS 200, WIDTH 150 TO 330mm, YEAR 2022TT-3656 MASTER BAG DLS 200, WIDTH 150 TO 330mm, YEAR 2022 CATEGORY: BAG MAKING MODEL: MASTER BAG DLS 200 YEAR: 2022 QUANTITY: 1 Learn More