Search results for: 'pillow c'

- Related search terms

- pillow

- pillow f

- pillow fi

- pillow fillin

- pillow filli

-

TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998 QUANTITY: 1 Learn More

TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998TT-7364 GRAUFF WWK-500 POLYURETHANE-FOAM CUTTING/GRINDING, AND FILLING MACHINE FOR PILLOWS AND CUSHIONS, DOG BEDS, ETC, WORKING WIDTH 500mm, YEAR 1998 QUANTITY: 1 Learn More -

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More

YY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOURYY-2308 AUTOMATIC PILLOW PACKING MACHINE (HYDRAULIC SYSTEM), CAPACITY 300 TO 350 PCS PER HOUR FEATURES: - WITH WATER CIRCULATION COOLING SYSTEM. - PLC PROGRAMMED CONTROL SYSTEM, DISPLAY SCREEN FOR SETTING PARAMETERS. - OPERATOR: 1 PERSON. QUANTITY: 1 Learn More -

YY-2176 AUTOMATIC PILLOW VACUUM PACKING MACHINE (HYDRAULIC SYSTEM) WITH FRONT AND BACK FEED CONVEYORYY-2176 AUTOMATIC PILLOW VACUUM PACKING MACHINE (HYDRAULIC SYSTEM) WITH FRONT AND BACK FEED CONVEYOR POWER: 7.5KW SEALING WIDTH: 800mm TABLE AREA: 800 X 800mm COMPRESSION STROKE: 350mm THE COMPRESSION HEIGHT CAN BE ADJUSTED AIR PRESSURE: <0.8MPA CAPACITY: 300 TO 350 PCS/H MAXIMUM PRESSURE: 5 TONS (OIL HYDRAULIC SYSTEM) OVERALL DIMENSIONS: 4100 X 1250 X 2030mm QUANTITY: 1 Learn More

YY-2176 AUTOMATIC PILLOW VACUUM PACKING MACHINE (HYDRAULIC SYSTEM) WITH FRONT AND BACK FEED CONVEYORYY-2176 AUTOMATIC PILLOW VACUUM PACKING MACHINE (HYDRAULIC SYSTEM) WITH FRONT AND BACK FEED CONVEYOR POWER: 7.5KW SEALING WIDTH: 800mm TABLE AREA: 800 X 800mm COMPRESSION STROKE: 350mm THE COMPRESSION HEIGHT CAN BE ADJUSTED AIR PRESSURE: <0.8MPA CAPACITY: 300 TO 350 PCS/H MAXIMUM PRESSURE: 5 TONS (OIL HYDRAULIC SYSTEM) OVERALL DIMENSIONS: 4100 X 1250 X 2030mm QUANTITY: 1 Learn More -

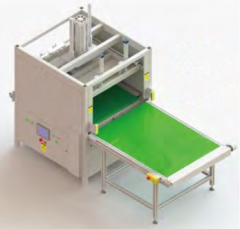

YY-2175 AUTOMATIC PILLOW, CUSHION PACKING MACHINE (AIR PRESSURE SYSTEM) WITH FRONT FEED CONVEYORYY-2175 AUTOMATIC PILLOW, CUSHION PACKING MACHINE (AIR PRESSURE SYSTEM) WITH FRONT FEED CONVEYOR SEALING WIDTH: 800mm WORKING TABLE AREA: 800 X 800mm OVERALL DIMENSIONS: 3260 X 1250 X 1850mm QUANTITY: 1 Learn More

YY-2175 AUTOMATIC PILLOW, CUSHION PACKING MACHINE (AIR PRESSURE SYSTEM) WITH FRONT FEED CONVEYORYY-2175 AUTOMATIC PILLOW, CUSHION PACKING MACHINE (AIR PRESSURE SYSTEM) WITH FRONT FEED CONVEYOR SEALING WIDTH: 800mm WORKING TABLE AREA: 800 X 800mm OVERALL DIMENSIONS: 3260 X 1250 X 1850mm QUANTITY: 1 Learn More -

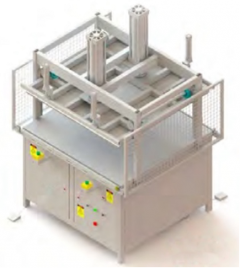

YY-2174 PILLOW CUSHION VACUUM PACKING MACHINE (CAN PRESS TWO PILLOWS AT A TIME)YY-2174 PILLOW CUSHION VACUUM PACKING MACHINE (CAN PRESS TWO PILLOWS AT A TIME) OPERATE: 1 TO 2 PERSONS OVERALL DIMENSIONS: 1430 X 1310 X 2020mm QUANTITY: 1 Learn More

YY-2174 PILLOW CUSHION VACUUM PACKING MACHINE (CAN PRESS TWO PILLOWS AT A TIME)YY-2174 PILLOW CUSHION VACUUM PACKING MACHINE (CAN PRESS TWO PILLOWS AT A TIME) OPERATE: 1 TO 2 PERSONS OVERALL DIMENSIONS: 1430 X 1310 X 2020mm QUANTITY: 1 Learn More -

J-4460 SEWING MACHINE FOR PILLOWS AND CUSHIONSJ-4460 SEWING MACHINE FOR PILLOWS AND CUSHIONS STITCH LENGTH: 9mm MAXIMUM PRESSER FOOT LIFT HEIGHT: 16mm STITCHES PER MINUTE: 2000 TABLE SIZE: 1200 x 600mm 750 WATT NEEDLE POSITION MOTOR MOTOR SPEED: 3900 RPM 110 VOLTS MOTOR KW: 0.75 KW, BOTH 110 VOLT AND 220 VOLT SINGLE PHASE AVAILABLE QUANTITY: 1 Learn More

J-4460 SEWING MACHINE FOR PILLOWS AND CUSHIONSJ-4460 SEWING MACHINE FOR PILLOWS AND CUSHIONS STITCH LENGTH: 9mm MAXIMUM PRESSER FOOT LIFT HEIGHT: 16mm STITCHES PER MINUTE: 2000 TABLE SIZE: 1200 x 600mm 750 WATT NEEDLE POSITION MOTOR MOTOR SPEED: 3900 RPM 110 VOLTS MOTOR KW: 0.75 KW, BOTH 110 VOLT AND 220 VOLT SINGLE PHASE AVAILABLE QUANTITY: 1 Learn More -

V-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONSV-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONS A. MICROFIBER OPENER B. OPENING DRUM 900mm WORKING WIDTH C. FEED SUCTION FAN D. RECEIVING BOX – METAL FABRICATION E. FILLING FANS AT EXIT (FAN-1112) QUANTITY: 1 SET Learn More

V-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONSV-1996 MICROFIBER OPENER WITH 4 FILLING FANS FOR PILLOWS AND CUSHIONS A. MICROFIBER OPENER B. OPENING DRUM 900mm WORKING WIDTH C. FEED SUCTION FAN D. RECEIVING BOX – METAL FABRICATION E. FILLING FANS AT EXIT (FAN-1112) QUANTITY: 1 SET Learn More -

J-1948-B PILLOW & CUSHION COMPRESSION PACKING MACHINE NEW -AUTOMATIC, 12 PILLOWS PER MINUTE - PRESS BOARD SIZE: 1270 x 1016mmJ-1948-B PILLOW & CUSHION COMPRESSION PACKING MACHINE NEW -AUTOMATIC, 12 PILLOWS PER MINUTE - PRESS BOARD SIZE: 1270 x 1016mm VOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz AIR PRESSURE: 0.4 – 0.8 MPA AT 0.5Mpa pressing board has a force of 12,272 Newtons (about 2,700 lbs) PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE PRESS BOARD SIZE: 1270 x 1016mm MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL) MAIN SHAFT DIAMETER 30mm OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm POWER: 1.5 KW NET WEIGHT: 350 KG GROSS WEIGHT: 400 KG QUANTITY: 1 Learn More

J-1948-B PILLOW & CUSHION COMPRESSION PACKING MACHINE NEW -AUTOMATIC, 12 PILLOWS PER MINUTE - PRESS BOARD SIZE: 1270 x 1016mmJ-1948-B PILLOW & CUSHION COMPRESSION PACKING MACHINE NEW -AUTOMATIC, 12 PILLOWS PER MINUTE - PRESS BOARD SIZE: 1270 x 1016mm VOLTAGE AND POWER: 220 V SINGLE-PHASE, 0.5 KW, 50 Hz AIR PRESSURE: 0.4 – 0.8 MPA AT 0.5Mpa pressing board has a force of 12,272 Newtons (about 2,700 lbs) PACKING CAPACITY: : 8 TO 12 ITEMS PER MINUTE PRESS BOARD SIZE: 1270 x 1016mm MAXIMUM COMPRESSION THICKNESS: 500mm (AIR CYLINDER TRAVEL) MAIN SHAFT DIAMETER 30mm OVERALL DIMENSIONS: LENGTH 3390mm x WIDTH 940mm x HEIGHT 2010mm POWER: 1.5 KW NET WEIGHT: 350 KG GROSS WEIGHT: 400 KG QUANTITY: 1 Learn More -

J-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIXJ-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIX POWER SUPPLY: 380 VOLTS, 60 OR 50 Hz (or as per clients need) TOTAL POWER: 12 KW AIR COMPRESSOR POWER REQUIRED: >/= 15 KW WORKING PRESSURE: 0.6 TO 0.8 Mpa MAIN MIXING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 2250mm HEIGHT WEIGHING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 1600mm HEIGHT TOTAL FLOORSPACE: >12 SQUARE METERS MIXING BOX WEIGHT: 412 KG WEIGHING BOX WEIGHT: 364 KG QUANTITY: 1 Learn More

J-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIXJ-3489 PILLOW FILLING MACHINE FOR FEATHER AND FIBER MIX, TWO NOZZLES -FOR FEATHER/DOWN & FIBER COTTON MIX POWER SUPPLY: 380 VOLTS, 60 OR 50 Hz (or as per clients need) TOTAL POWER: 12 KW AIR COMPRESSOR POWER REQUIRED: >/= 15 KW WORKING PRESSURE: 0.6 TO 0.8 Mpa MAIN MIXING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 2250mm HEIGHT WEIGHING BOX DIMENSIONS: 2200mm LENGTH x 900mm WIDTH x 1600mm HEIGHT TOTAL FLOORSPACE: >12 SQUARE METERS MIXING BOX WEIGHT: 412 KG WEIGHING BOX WEIGHT: 364 KG QUANTITY: 1 Learn More -

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More

FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60HzREFERENCE NUMBER: T-6869 FIBER OPENING AND PILLOW FILLING MACHINE, WORKING WIDTH 1500mm, CAPACITY 800KG/H, 60Hz FEED HOPPER WITH LONG EXTENDED APRON 1500mm FEED HOPPER MODEL: OP-B POWER: 3.6KW FILLING CAPACITY: 800KG/H LAYOUT: 5940 X 1600 X 2200mm WEIGHT: 3200KG WORKING WIDTH: 1500mm VOLTAGE: 440V 60Hz 3 PHASES (AS PER ORDER) AIR PRESSURE: 0.6 TO 0.8MPA MAIN STRUCTURE: MADE BY COMPUTERIZED LASER CUTTING MACHINE ELECTRICITY: KEY PARTS ARE WORLD FAMOUS BRAND, OMRON, SCHNEIDER. BEARING: SKF SPRAY: RUST-PROOF PRETREATMENT AND ELECTROSTATIC COATING. ROLLERS: WITH DYNAMIC BALANCE PROCESSING. DESCRIPTION: • MACHINE IS MAINLY USED TO LOAD A BALE OF FIBER AND SEND IT TO NEXT PROGRAM AUTOMATICALLY. • THE SUITABLE MATERIAL CAN BE CONJUGATE SILICON POLYESTER FIBER THAT SHORTER THAN 100mm. POLYESTER FIBER: RECYCLE AND VIRGIN POLYESTER STAPLE FIBER. 0.6 TO 15D, 32mm TO 64mm, MICROFIBER ALSO POSSIBLE. • ANTI-DEVIATION DEVICE, CONVEYOR BELT TRACK PROTECTION, TO ENSURE THAT BELT ALWAYS RUNNING STRAIGHT. • ONE OPERATOR • WORKING PROCESS: 1. USE FORKLIFT TO PUT BALE OF FIBER ON THE CONVEYOR. 2. THE FIRST CONVEYOR WILL SEND FIBER TO THE SECOND CONVEYOR 3. THEN THE SPIKED INCLINE BELT LIFTS THE FIBER, THE EVENING ROLLER TAKES THE EXCESSIVE FIBER OFF AND THE STRIPPING ROLLER STRIP THE FIBER OFF AND FIBER FALLS DOWN TO NEXT PROCESS. 4. THERE ARE PHOTO CELLS TO CONTROL THE MATERIAL FIBER LEVEL, FEEDING AND SUPPLY SPEED. • ELECTRICAL KEY PARTS ARE WORLD FAMOUS BRANDS, SUCH AS SCHNEIDER ETC. AVAILABLE WORLDWIDE. • ELECTRICAL WITH OVERLOAD PROTECTION. Learn More