Search results for: 'storage ta'

- Related search terms

- storage

- storage tank

- storage sofa

- storage business for sale

- Storage Mart

-

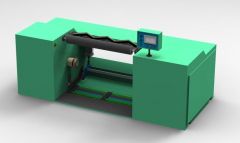

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More

AUTOMATIC HIGH-PRECISION COPY WARPING MACHINE FOR 30”×42” AND 21”X42” BEAM AND 1400-POSITION CREELMACHINE FEATURES: - WITH NC SERVICE ROLLER, AUTOMATIC ADDING OIL DEVICE, BACKING YARN STORAGE DEVICE, DEVICE YARN NEEDLE, YARN COLLECTING PLAT AND AUTO STOP DEVICE. -THE MAIN MOTOR IS CONTROLLED BY INVERTER AND PLC. -THE CREEL IS CONTROLLED BY PNEUMATIC, AND ITS POSITION IS ACCURACY CONTROLLED BY PHOTOELECTRIC SENSOR AND THE PLC AUTOMATICALLY. -THE MAIN BRAKE ADEPTS PNEUMATIC BUTTERFLY BRAKE. THE BREAKING TRAY WITH MIDDLE UNOCCUPIED HAS A NICE HEAT-DISSIPATED FUNCTION. ON THE OTHER HAND, THE USING OF BREAK PINCER WITH AUTO-COMPENSATION AND THE HOOFED PIECE MAKES THE BUTTERFLY BRAKE STABLE AND LAST A LONG LIFE. -THE BRAKE OF POSITIVE ROLLER AND SPEED ROLLER CAN MAKE DIFFERENT BRAKE PRESSURES ACCORDING TO DIFFERENT SPEEDS (MORE THAN 200 M/MIN). THESE DIFFERENT PRESSURES, TOGETHER WITH THE MAIN BEAM BREAK, GUARANTEES THE YARN TENSION IN THE BREAKING TIME IS THE SAME AS THE TENSION UNDER THE CONSTANT SPEED. -WITH TOUCH SCREEN. ALL THE ELECTRICAL TROUBLES AND WRONG OPERATION INFORMATION ARE DISPLAYED ON THE SCREEN. THE PNEUMATIC PART, AORTIC, IS MADE IN TAIWAN. -THE POSITIVE ROLLER IS COVERED BY HIGH-HARDNESS COATING, SO THE SMOOTH SURFACE IMPROVES THE ABSORPTION TO THE YARN. THE AC HIGH-SPEED SERVO SYSTEM PROVIDES A POWER TO THE ABOVE ROLLER, MATCHING WITH THE PLC, BOTH OF WHICH SERVICE FOR THE MAIN WINDING SYSTEM, TO ENSURE THE CONSTANT TENSION OF YARN. -WITH REMOTE DEBUGGING TO MONITOR THE CURRENT WORKING CONDITIONS. CONSISTS OF: (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER (1) COMPUTER CONTROLLED COPY WARPING MACHINE FOR 30”X42” INCH AND 21”X42” BEAM TECHNICAL DATA: LINE SPEED 0 TO 1000M/MIN MAX. TENSION OF LINE 1000N BRAKE TORQUE 3200NM UP AND DOWN OF BEAM PNEUMATIC CONTROL TIGHT AND RELEASE OF BEAM PNEUMATIC CONTROL DIAMETER OF SPEED ROLLER Ø120mm POWER OF MAIN MOTOR 15KW CONTROL TYPE OF MAIN MOTOR INVERTER CONTROL MONITORING WAY IMMEDIATE MONITOR BY MICROCOMPUTER CONTROLLED TOUCH SCREEN CONTROL TYPE OF POSITIVE YARN-SEND ROLLER AC HIGH-SPEED SERVO CONTROL SYSTEM OF MITSUBISHI DIAMETER OF POSITIVE YARN-SEND ROLLER Ø100mm PRESSURE OF PNEUMATIC SOURCE 6 BAR MAIN PARTS: MAIN MOTOR SIEMENS OF GERMANGY HIGH-SPEED SERVO SYSTEM MITSUBISHI OF JAPAN CONVERTER EMERSON OF USA TEST COMPONENTS A AUTONICS OF SOUTH KOREA TEST COMPONENTS B KOYO OF JAPAN PNEUMATIC COMPONENTS AIRTAC OF TAIWAN PLC OMRON OF JAPAN TOUCH SCREEN MCGS OF BEIJING OPERATING COMPONENTS SCHNEIDER OF FRANCE TERMINAL COMPONENTS PHOENIXCONTACT OF GERMANGY BEARING NSK OF JAPAN (2) ROTATION OPEN CREEL WITH 1400 POSITIONS AND KFD OIL HYDRAULIC TENSIONER MAJOR PARTS: 1. MOTOR 2. ROLLER SPEED DETECTOR 3. CONTROL PANEL 4. REED 5. SIZING PARTS 6. LUBRICATING DEVICE 7. YARN STORAGE 8. TENSION ROLLER 9. STATIC ELIMINATOR 10. NEEDLES 11. YARN COLLECTING BOARD DELIVERY TIME: 37-45 DAYS Learn More -

TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006 NATIONAL 110 UE 1500 HP SCR MAJOR REBUILD LIKE NEW (RIG BUILT NEW IN 2006) Learn More

TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006TT-2778 NATIONAL 110 UE 1500 HP SCR OIL RIG, YEAR 2006 NATIONAL 110 UE 1500 HP SCR MAJOR REBUILD LIKE NEW (RIG BUILT NEW IN 2006) Learn More -

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

T-7764 SOLAR TITAN T-70, 7.1MW ISO, 13,800 VOLTS, 60HzT-7764 SOLAR TITAN T-70, 7.1MW ISO, 13,800 VOLTS, 60Hz THIS PACKAGE WAS DELIVERED FULLY ENCLOSED AND SUITABLE FOR OUTDOOR INSTALLATION COMPLETE FIRE SYSTEM, WITH BOTTLES COMPLETE AIR FILTRATION SYSTEM (HUFF AND PUFF SELF-CLEANING) NEUTRAL GROUNDING RESISTOR QUANTITY: 1 Learn More

T-7764 SOLAR TITAN T-70, 7.1MW ISO, 13,800 VOLTS, 60HzT-7764 SOLAR TITAN T-70, 7.1MW ISO, 13,800 VOLTS, 60Hz THIS PACKAGE WAS DELIVERED FULLY ENCLOSED AND SUITABLE FOR OUTDOOR INSTALLATION COMPLETE FIRE SYSTEM, WITH BOTTLES COMPLETE AIR FILTRATION SYSTEM (HUFF AND PUFF SELF-CLEANING) NEUTRAL GROUNDING RESISTOR QUANTITY: 1 Learn More -

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

M-7873 CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINEREFERENCE NUMBER: M-7873

CHOCOLATE CEREAL AND GRANOLA BAR AUTOMATIC LINE

AUTOMATIC LINE

FOR CHOCOLATE CEREAL AND GRANOLA BARS

AUTOMATIC COMBINATION BETWEEN THE FREEZING, FORMING, AND PRESSING ROLLERS, AND THE SLITTING TECHNOLOGY.

THIS PRODUCING LINE IS A MULTI-FUNCTION LINE WHICH CONSISTS OF KITCHEN EQUIPMENTS, FORMING AND SHEETING SYSTEM, NUTS SPRINKLING SYSTEM, FORMING AND PRESSING ROLLER, REFRIGERATION SYSTEM, COOLING TUNNEL, CANDY BAR SLITTING, CUTTING AND CONVEYING SYSTEM, AND CHOCOLATE ENROBING MACHINE, ETC.

THIS LINE TAKES THE PLACE OF THE TRADITIONAL, MANUAL WORKSHOP PRODUCTION WITH FULL AUTOMATIC MACHINERY PRODUCTION. THIS LINE WILL BE IDEAL FOR THE CANDY BAR LEISURE FOOD INDUSTRY, WITH MODERN AND LARGE QUANTITY PRODUCTION.

Learn More -

L-3004 SIZING MACHINES FOR SALE

L-3004 SIZING MACHINES FOR SALELIST NUMBER: L-3004

Learn More

SIZING MACHINES FOR SALE

REFERENCE NUMBER: C-5212

BENNINGER SIZING MACHINE

TYPE BEN SIZETEC

YOM: 2004

WORKING WIDTH: 2400mm

BENINGER DIRECT WARPER

TYPE BEN DIRECT

YOM: 2005

WORKING WIDTH: 2400mm

QUANTITY: 1

REFERENCE NUMBER: P-4682

BENNINGER

SIZING MACHINE

YEAR: 2002

WIDTH: 2800mm

QUANTITY: 1 SET

REFERENCE NUMBER: P-7130

SUCKER MULLER

TYPE: HACOBA

SIZING MACHINE

YEAR: 1999

WORKING WIDTH: 1800mm

QUANTITY: 1

REFERENCE NUMBER: C-3650

OFFER 001

SUCKER MOENUS Z 14 SIZING MACHINE

WIDTH: 3400mm

YEAR: 2006

QUANTITY: 1

OFFER 002

BENNINGER BEN DIRECT WARPING MACHINE

YEAR: 2005

WIDTH: 2200mm

QUANTITY: 1

REFERENCE NUMBER: A-1197 (1212GHBXX11) A

MAKE: BENNINGER

MODEL: BEN SIZETEC

YEAR: 1998

Width - 2000mm

QUANTITY: 2

REFERENCE NUMBER: P-6712

SUCKER MULLER

SIZING MACHINE

YEAR: 2003

HEADSTOCK WIDTH: 3600mm

QUANTITY: 1

REFERENCE NUMBER: M-5040

(1 SET) BENNINGER SIZING MACHINES (SLASHERS), YEAR 2000

REFERENCE NUMBER: R-3746

ITEM 001

KARL MAYER DIRECT WARPING MACHINE

YEAR: 2006

WIDTH: 2000mm

QUANTITY: 1 SET

ITEM 002

KARL MAYER SIZING MACHINE

YEAR: 2011

QUANTITY: 1 SET -

R-3244 JABEZ BURNS ELECTRIC USED 2 BARREL SAMPLE ROASTER

R-3244 JABEZ BURNS ELECTRIC USED 2 BARREL SAMPLE ROASTERR-3244 JABEZ BURNS ELECTRIC USED 2 BARREL SAMPLE ROASTER

27" TALL X 15" WIDE X 30" DEEP

6 TO 20 OUNCES OF GREEN PER CYLINDER

122 POUNDS IN WEIGHT PLUS CRATING

ALLOW FOR 200 POUNDS SHIPPING

4" EXHAUST PIPE TO THE OUTSIDE WORLD

220 ELECTRIC SINGLE PHASE

RUNS REALLY GREAT

THIS IS A ONE-OWNER MACHINE - AND IS NO LONGER IN USE DUE TO MOVING TO A NEW BUILDING AND SWITCHING TO A ONE BARREL UNIT - AS THEIR NEED WAS NOT SO GREAT

THIS IS SITTING IN STORAGE.

NOW, THIS IS HISTORY - AS THIS IS THE LAST MACHINE MADE BY JABEZ BURNS AND HAS LOTS OF SENTIMENTAL VALUE DUE TO THAT. PARTS ARE OFF THE SHELF AND EVEN THE HEATING ELEMENTS ARE STANDARD STOVETOP ELEMENTS AVAILABLE AT ANY APPLIANCE PARTS STORE. THE ONLY DOWNSIDE TO THIS ROASTER IS A LONGER HEAT-UP TIME OR WARM-UP THAN A GAS VERSION, BUT THE SMOOTH ROAST IS WHAT MATTERS. THE CHAFF COLLECTION DRAWER IS LOCATED UNDER THE MACHINE AND FRONT REMOVABLE.

SHIPS FROM MIDWEST AS IT IS IN A STORAGE UNIT.QUANTITY: 1

Learn More -

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

M-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mmM-1696 MARGASA COMPLETE RECYCLING/TEARING LINE, YEAR 2012, WORKING WIDTH 1500mm

2 ROTARY CUTTERS TYPE CMT-900, WORKING WIDTH 900mm, INCLUDING FEEDING CONVEYORS.

Learn More

1 ELECTRONIC METAL DETECTOR, MOUNTED ON FEEDING CONVEYOR OF THE 1ST CUTTER.

1 PNEUMATIC MATERIAL TRANSPORT WITH SPECIAL FAN FOR RAGS ETC.

1 STATIONARY ZIG-ZAG HUMP MAGNET MOUNTED IN TUBE FOR MATERIAL TRANSPORT.

2 MIXING/ RELAXING STORAGE BINS FOR CUTTED RAGS WITH SPRAYING ROOM

IN FRONT OF:

1 FEEDING MACHINE TYPE CCS-1500, WORKING WIDTH 1500mm, AUTOMATIC PNEUMATIC FEEDING FROM STORAGE BINS, ELECTRONIC LEVEL CONTROL AND DOSING CONVEYOR TO TEARING LINE.

1 RAG TEARING LINE WITH 4 SECTIONS TYPE MASTER MCM-1550-DD, WORKING WIDTH 1500mm, TAMBOUR DIAM. 1000mm.

1 ELECTRONIC CONTROL PANEL FOR THE WHOLE LINE INCL. TOUCH SCREEN AND INVERTER DRIVER FOR SEVERAL MOTORS.

6 FILTER UNITS.

- ALL EQUIPMENT “AS NEW” SINCE RUNNING ONLY A FEW HOURS.

- CAPACITY UP TO 1000KG/HR. -

G-8448-C DUST-FREE AUTOMATIC FEATHER FILLING MACHINE MODEL S-6CLOSED TYPE WITH SMALL AIR-CONDITIONER (2) COMPUTER AND FILLING SETS RUN BY TWO OPERATORS DIAMETER OF FILLING NOZZLE: 12mm FILLING WEIGHT ≤2 GRAM, FILLING TIME ≤1 SECOND AN AIR COMPRESSOR (THREE-PHASE WITH 5.5KW) AND AN AIR STORAGE TANK (0.6 TO 1 M³) ARE NEEDED THE CAPACITY OF THE COMPRESSED AIR CAN BE USED BY (12) SETS OF FILLING NOZZLES (SIX FILLING MACHINES) DIAMETER OF COMPRESSED AIR PIPE: 1” (FROM AIR STORAGE TANK TO FILLING ROOM) DIAMETER OF COMPRESSED AIR PIPE: ½” (MAIN MACHINE TO FILLING NOZZLE) VOLTAGE: 220V POWER: AIR-CONDITION 500W, AIR-CIRCULATION FAN 370W, FILLING FAN 180W, VARIABLE SPEED MOTOR 200W, LIGHTS 60W AND COMPUTER 50W AIR PRESSURE: 6MPa FLOOR SPACE OF FILLING ROOM: ≥6M² FILLING ERROR RANGE: 1 GRAM FOR ONE PIECE DOWN CONTENT: 50% TO 95% STAINLESS STEEL MAIN FRAME TOUCH SCREEN WITH (1) PRECISE WEIGHING SCALE WITH AIR CIRCULATION SYSTEM AUTOMATICLLY RECYCLE FEATHERS THAT FALL TO THE FLOOR MOVABLE FILLING MACHINE CAN BE DISMOUNTED WITH SPOTLIGHT (2) WORKING TABLE DIMENSIONS OF THE MACHINE: 3000 X 1300 X 1800 (mm) Learn More

G-8448-C DUST-FREE AUTOMATIC FEATHER FILLING MACHINE MODEL S-6CLOSED TYPE WITH SMALL AIR-CONDITIONER (2) COMPUTER AND FILLING SETS RUN BY TWO OPERATORS DIAMETER OF FILLING NOZZLE: 12mm FILLING WEIGHT ≤2 GRAM, FILLING TIME ≤1 SECOND AN AIR COMPRESSOR (THREE-PHASE WITH 5.5KW) AND AN AIR STORAGE TANK (0.6 TO 1 M³) ARE NEEDED THE CAPACITY OF THE COMPRESSED AIR CAN BE USED BY (12) SETS OF FILLING NOZZLES (SIX FILLING MACHINES) DIAMETER OF COMPRESSED AIR PIPE: 1” (FROM AIR STORAGE TANK TO FILLING ROOM) DIAMETER OF COMPRESSED AIR PIPE: ½” (MAIN MACHINE TO FILLING NOZZLE) VOLTAGE: 220V POWER: AIR-CONDITION 500W, AIR-CIRCULATION FAN 370W, FILLING FAN 180W, VARIABLE SPEED MOTOR 200W, LIGHTS 60W AND COMPUTER 50W AIR PRESSURE: 6MPa FLOOR SPACE OF FILLING ROOM: ≥6M² FILLING ERROR RANGE: 1 GRAM FOR ONE PIECE DOWN CONTENT: 50% TO 95% STAINLESS STEEL MAIN FRAME TOUCH SCREEN WITH (1) PRECISE WEIGHING SCALE WITH AIR CIRCULATION SYSTEM AUTOMATICLLY RECYCLE FEATHERS THAT FALL TO THE FLOOR MOVABLE FILLING MACHINE CAN BE DISMOUNTED WITH SPOTLIGHT (2) WORKING TABLE DIMENSIONS OF THE MACHINE: 3000 X 1300 X 1800 (mm) Learn More -

TT-6753 WARTSILA HFO FIRED POWER PLANT, 119 MW, YEAR 2010TT-6753 WARTSILA HFO FIRED POWER PLANT, 119 MW, YEAR 2010 1. WARTSILA 2. 119 MW 3. YEAR 2010 4. BRAND HFO FIRED POWER PLANT 5. COMPRISING OF 7 X 17.55 MW EACH 6. W18V46 HFO FIRED GENERATOR SETS 7. THE ABOVE POWER PLANT IS IN EXCELLENT CONDITION 8. AND CAN BE INSPECTED ON FOUNDATION. 9. CURRENTLY THE PLANT IS BEING OPERATED ON “NO ENERGY, NO PAYMENT” BASIS. QUANTITY: 1 Learn More

TT-6753 WARTSILA HFO FIRED POWER PLANT, 119 MW, YEAR 2010TT-6753 WARTSILA HFO FIRED POWER PLANT, 119 MW, YEAR 2010 1. WARTSILA 2. 119 MW 3. YEAR 2010 4. BRAND HFO FIRED POWER PLANT 5. COMPRISING OF 7 X 17.55 MW EACH 6. W18V46 HFO FIRED GENERATOR SETS 7. THE ABOVE POWER PLANT IS IN EXCELLENT CONDITION 8. AND CAN BE INSPECTED ON FOUNDATION. 9. CURRENTLY THE PLANT IS BEING OPERATED ON “NO ENERGY, NO PAYMENT” BASIS. QUANTITY: 1 Learn More