Search results for: 'Manual coun'

- Related search terms

- Manual ri

- Manual de par

- manual pre

- Manual con

- Manual c

-

T-9498 SSM SCHARER SCHWEITER METTLER MODEL PW 1– F WITH 6 SPINDLES, YEAR 2001T-9498 SSM SCHARER SCHWEITER METTLER MODEL PW 1– F WITH 6 SPINDLES, YEAR 2001 CONDITION: DISMANTLED QUANTITY: 1 Learn More

T-9498 SSM SCHARER SCHWEITER METTLER MODEL PW 1– F WITH 6 SPINDLES, YEAR 2001T-9498 SSM SCHARER SCHWEITER METTLER MODEL PW 1– F WITH 6 SPINDLES, YEAR 2001 CONDITION: DISMANTLED QUANTITY: 1 Learn More -

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More

YY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINEYY-1521COMPUTERIZED SINGLE HEAD QUILTING MACHINE QUANTITY: 1 Learn More -

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More

T-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACKT-8541 WET WIPES MACHINE, CAPACITY 5 TO 30 PIECES PER PACK WET WIPES MACHINE CAPACITY: 5 TO 30 PIECES PER PACK DRIVE MODE: AUTOMATIC FOLDING: 300 TO 400 PIECES PER MINUTE (STABLE SPEED) PACKAGING: 40 BAGS PER MINUTE (STABLE SPEED) MACHINE SIZE (L X W X H): 5000mm X 1200mm X 2100mm QUANTITY: 1 Learn More -

Z-1565 HORIZONTAL LIQUID FILLING MACHINEZ-1565 HORIZONTAL LIQUID FILLING MACHINE MATERIAL: SS316L FOR ALL CONTACT PRODUCTS PART, OTHER PARTS SS304 FILLING RANGE: 100 TO 1000ML FILING SPEED: 0 TO 30BPM (ADJUSTABLE) AIR PRESSURE: 0.5 TO 0.8MPA WORKING PRESSURE: S0.2 TO 0.5MPA AIR CONSUMPTION: 50000mm WEIGHT: 45KG QUANTITY: 1 Learn More

Z-1565 HORIZONTAL LIQUID FILLING MACHINEZ-1565 HORIZONTAL LIQUID FILLING MACHINE MATERIAL: SS316L FOR ALL CONTACT PRODUCTS PART, OTHER PARTS SS304 FILLING RANGE: 100 TO 1000ML FILING SPEED: 0 TO 30BPM (ADJUSTABLE) AIR PRESSURE: 0.5 TO 0.8MPA WORKING PRESSURE: S0.2 TO 0.5MPA AIR CONSUMPTION: 50000mm WEIGHT: 45KG QUANTITY: 1 Learn More -

GRAUTE AND SCHOTT & MEISSNER AIRLAY PRODUCTION LINE – NEW, WORKING WIDTH 3200mmREFERENCE NUMBER: T-6756 GRAUTE AND SCHOTT & MEISSNER AIRLAY PRODUCTION LINE – NEW, WORKING WIDTH 3200mm BRAND: GRAUTE (GERMANY) AND SCHOTT & MEISSNER YEAR: 2012, HAS NEVER BEEN INSTALLED WORKING WIDTH: 3200mm (AFTER EDGE TRIM) CAPACITY: 1400 KG/H (BEFORE EDGE TRIM) RANGE OF WEIGHTS: 80 TO 3500 G/M2 THICKNESS: MAX. 250mm WEB DENSITY: 5 TO 80 KG/M3 WEIQHT [G/M2] PRODUCTION [KG/H] SPEED [M/MIN] 80 298 18.0 100 370 18.0 500 1375 13.3 2000 1375 6.7 3500 1375 1.9 CONSISTING OF: • BALE OPENING BRAND: GRAUTE 3X BALE OPENER (BO 150) 1X FINE OPENER (FO 125) 2X TRANSPORT FAN (TFF 30) 2X FILLING CAGE (FC 150) 3X WEIGHTING PLATE SYSTEM (WPS 150) 2X CONTINUOUS MIXING OPENER • BLENDING AND FEEDING BRAND: GRAUTE 1X LARGE VOLUME BLENDER (LVB 150) 2X TRANSPORT FAN (TFF 30) 1X METAL DETECTOR (DMX) 1X BUFFER EQUIPMENT (PO 175) • AIRLAY-CARDING BRAND: GRAUTE 1X CARD FEEDING UNIT (CFV 344) 1X WEIGHTING PLATE SYSTEM (WPS 344) 1X AIR-WEB FORMER (AWF 344) 1X HIGH LOFT OUTLET 2X TRANSPORT FAN (TFF 30) 1X DUST FAN (DF 25) 1X FILTER STATION 1X CONTINUOUS MISSING OPENER (CMO 80) 1X CONVEYOR BELT (CB 80) • TOPCON DOUBLE BELT OVEN BRAND: SCHOTT & MEISSNER 2X 3M TOPCON HEATING SECTIONS 2X DIRECT HEATING BY GAS BLOWER BURNER 300KW 2X CIRCULATING AIR BLOWER 25000M3/H; 15KW 1X EXHAUST AIR FAN 6000M3/H; 3KW 2X TOPCON COOLING SECTIONS 1X EXHAUST AIR BLOWER 28000M3/H; 15KW 1X FRESH AIR BLOWER 28000M3/H; 15KW TOPCON CONVEYING SYSTEM WITH BELT GUIDING AND TENSIONING SYSTEM MAGNETIC SYSTEM FOR KEEPING THE TOP BELT SUSPENDED • CUTTING MACHINE BRAND: SCHOTT & MEISSNER 1X INLET BELT CONVEYOR, LENGTH APPROX. 1000mm 7X LONGITUDINAL CUTTING HEAD, CIRCULATING KNIFE Ø 810mm 1X SHARPENING DEVICE FOR LONGITUDINAL CUTTING 1X FLYING CROSS CUTTING HEAD, CIRCULATING KNIFE Ø 810mm TRANSPORT BELT FOR CROSS CUTTING UNIT SAFETY FENCES ON THE CUTTING MACHINE • WINDER BRAND: SCHOTT & MEISSNER OUTLET TRANSPORT BELT, LENGTH APPROX. 3000mm 1X ASCENDING BATCH WINDER, MAX. Ø 1500mm • ADDITIONAL MULTI-MOTOR AC DRIVES CONTROL PANEL AND COMMAND PANEL MACHINE IS AVAILABLE FOR IMMEDIATE SALE COMPLETE PRODUCTION LINE IS ORIGINAL PACKED AND HAS NEVER BEEN INSTALLED SPECIFICATION OF NONWOVEN LINE SCHOTT & MEISSNER NONWOVEN LINE FOR CONTINUOUSE THERMOBONDING OF PES / BICO WEBS USEFUL WORKING WIDTH: 3400mm, SIMILAR TO DRAWING NO. 60.71X.086 CONSISTING OF: PARAGRAPH §1 1. BALE OPENING EXECUTED AS FOLLOWS • 1X BALE OPENER (BO 150) • 1X FINE OPENER (FO 125) • 1X TRANSPORT FAN (TFF 30) • 2X FILLING CAGE (FC 150) • 2X BALE OPENER (BO 150) • 3X WEIGHING PLATE SYSTEM WPS 150 • 2X CONTINUES MIXING OPENER (CMO 150) • 1X TRANSPORT FAN (TFF 30) 2. BLENDING AND FEEDING EXECUTED AS FOLLOWS • 1X LARGE VOLUME BLENDER (LVB 150) • 1X TRANSPORT FAN (TFF 30) • 1X METAL DETECTOR DMX • 1X BUFFER EQUIPMENT (PO 175) • 1XTRANSPORT FAN (TFF 30) 3. AIRLAY-CARDING EXECUTED AS FOLLOWS • 1X CARD FEEDING UNIT CFV 344 • 1X WEIGHING PLATE SYSTEM WPS 344 • 1X AIR-WEB FORMER AWF 344 • 1X HIGH LOFT OUTLET • 1X TRANSPORT FAN (TFF 35) • 1X DUST FAN (DF 25) • 1X FILTER STATION • 1X CONTINUES MIXING OPENER (CMO 80) • 1X CONVEYOR BELT (CB 80) • 1X TRANSPORT FAN (TFF 30) 4. TOPCON®LP DOUBLE BELT OVEN - AIR-THROUGH EXECUTED AS FOLLOWS • 2X 3M TOPCON®LP HEATING SECTIONS • 2X DIRECT HEATING BY GAS BLOWER BURNER 300 KW • 2X CIRCULATING AIR BLOWER, 25,000 M3/H. 15 KW • 1X EXHAUST AIR FAN 6,000 M3/H; 3 KW • 2X 2M TOPCON®LP INTEGRATED COOLING SECTIONS • 1X EXHAUST AIR BLOWER 28,000 M3/H; 15KW • 1X FRESH AIR BLOWER 28,000 M3/H; 15KW • TOPCON®LP CONVEYING SYSTEM INCLUDING BELT GUIDING SYSTEM AND BELT TENSIONING SYSTEM • MAGENTIC SYSTEM FOR KEEPING THE TOP BELT SUSPENDED 5. SCHOTT & MEISSNER CUTTING MACHINE EXECUTED AS FOLLOWS • 1X INLET BELT CONVEYOR, LENGTH APPROX 1000mm • 7X LONGITUDINAL CUTTING HEAD, CIRCULATING KNIFE, Ø 810mm • 1X SHARPENING DEVICE FOR LONGITUDINAL CUTTING KNIFES • 1X FLYING CROSS CUTTING HEAD, CIRCULATING KNIFE, Ø 810mm • TRANSPORT BELT FOR CROSS CUTTING UNIT • SAFETY FENCE FOR CUTTING MACHINE 6. SCHOTT & MEISSNER ASCENDING BATCH WINDER INCL. TRANSPORT BELT EXECUTED AS FOLLOWS • OUTLET TRANSPORT BELT; LENTH APPROX. 3000mm • 1X ASCENDING BATCH WINDER, MAX. 0 1500mm 7. MULTI-MOTOR AC DRLVE(S) 8. CONTROL PANEL AND COMMAND PANEL 9. SUPERVISION OF FINAL ASSEMBLY AND START-UP ENVIRONMENTAL DETAILS SITE ALTITUDE ≤ 1000 MUNN TEMPERATURE 10 °C... ≤35 °C RELATIVE AIR HUMIDITY 65% ± 5% ABSOLUTE WATER CONTENT 9-12 G/KG DRY AIR DESIGN DATA MATERIAL IN USE CARDED AND AIRTAID NONWOVEN FIBRES PES + BICO MIXTURE OF FIBRES MUST BE CONFIRMED BY THE CUSTOMER FIBRE FINESS 3.3...6.7 DTEX FIBRE LENGTH 38 TO 60mm METTING POINT BICO FIBRE 110°C .... 140°C (DEPENDING ON FIBRES IN USE) PRODUCTION TEMPERATURE MAX. 190°C (DEPENDING ON MELTING FIBRE) END PRODUCT WADDINGS / INSULATION RANGE OF WEIGHTS 80...3500 G/M2 FINAL PRODUCT THICKNESS MAX. 250mm WEB DENSITY MAX. 80 KG/M3 (DEPENDING ON FIBRE) FIBRE THROUGHPUT MAX. 1400 KG/H (DEPENDING ON WEB WEIGHT AND FIBRE IN USE) WORKING WIDTH / VENTILATED WIDTH MAX. 3400mm FINISH PRODUCT WIDTH MAX. 3200mm PRODUCTION SPEED MAX 18 M/MIN (DEPENDING ON PRODUCT REQUIREMENTS, FIBERS IN USE. BASIC WEIGHTS) MECHANICAL SPEED 1....20 M/MIN (RATIO 1:20) REFERENCE PRODUCT MUST BE CONFIRMED BY THE CUSTOMER ENERGY CONSUMPTION 1 KG/FIBRE = APPROX. 0.3 KW (10 KW = 1 M’/NATURAL GAS) TECHNICAL SPECIFICATION 1. BALE OPENING 1X BALE OPENER TYPE: BO 150 FIBRE IN USE: BICO WORKING WIDTH 1500mm WITH FREQUENCY REGULATED DRIVES AND 2 M FEED TABLE POWER INSTALLED: EACH APPROX. 5 KW 1X FINE OPENER TYPE: FO 125 FIBRE: BICO WORKING WIDTH: 1250mm MODE OF DRIVES: AC, ACF POWER INSTALLED: APPROX. 9 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 5500 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 2X FILLING CAGE TYPE: FC 150 WORKING WIDTH: 1500mm WITH BLOW-IN-HOOD AND TWO TAKE-OFF-ROLLS MODE OF DRIVES: ACF POWER INSTALLED: APPROX. 1.0 KW 2X BALE OPENER TYPE: BO 150 FIBRE IN USE: PES WORKING WIDTH 1500mm WITH FREQUENCY REGULATED DRIVES, 2 M FEED TABLE AND FIBER OUTLET THROUGH TWO TAKE-OFF-ROLLS. POWER INSTALLED EACH APPROX. 5.6 KW 3X WEIGHING PLATE SYSTEM TYPE: WPS 150 WORKING WIDTH 1500mm FOR AUTOMATIC SETTING AND REGULATION OF FIBER BLENDING, TO BE INSTALLED BETWEEN BALE OPENER AND CONTINUES MIXING OPENER 2X CONTINUES MIXING OPENER TYPE: CMO 150 WORKING WIDTH 1500mm WITH DOUBLE-SIDED FEEDING THROUGH A PAIR OF FEED ROLLS AND A TRAY PLATE FEEDING POWER INSTALLED: APPROX. 13 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX 6,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 7.5 KW 2. BLENDING AND FEEDING 1X LARGE VOLUME BLENDER TYPE: LVB 150 WORKING WIDTH: 1500mm FILLING LENGTH: 4000mm FILLING HEIGHT: APPROX 2000mm TOTAL HEIGHT: APPROX. 5200mm FILLING CAPACITY: APPROX 12 M3 FEED BY 1 CYCLON CYC 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 5500 M3/H MODE OF DRIVES: ACF POWER INSTALLED EACH 4 KW 1X METAL DETECTOR TYPE: DMX WITH REMOVING DEVICE (BAC) FOR FERROUS PARTS DETECTOR WITH ELECTRONIC APPARATUS SPECIAL PVC PIPE WITH CONNECTIONS ELECTRIC-PNEUMATIC VALVE BOX COLLECTING SILO 1X BUFFER EQUIPMENT TYPE: PO 175 WORKING WIDTH: 1750mm WITH BLOW-IN-HOOD, FILLING CAGE, PRE OPENER AND SUCTION CHANNEL MODE OF DRIVES: AC, ACF POWER INSTALLED: APPROX. 3 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 6,00 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 3. AIRLAY-CARDING TX CARD FEEDING UNIT TYPE: CFV 344 WORKING WIDTH 3440mm WITH BLOW-IN-HOOD, FILLING CAGE, FIBER COMPACTION BY VIBRATION WALL AND MATERIAL OUTLET ON GLIDING PLATE MODE OF DRIVES: AC. ACF POWER INSTALLED: APPROX 7 KW 1X WEIGHING PLATE SYSTEM TYPE: WPS 344 WORKING WIDTH 3440mm FOR AUTOMATIC SETTING AND REGULATION OF WEB WEIGHT DURING PRODUCTION, TO BE INSTALLED BETWEEN CARD-FEEDER AND AIR-WEB-FORMER AIR-WEB FORMER TYPE: AWF 344 WORKING WIDTH 3440mm WITH MOVABLE PRE-CARD AND WITH AN AIR-LAY TAKE OFF DEVICE FOR RANDOMISED WEB. KIND OF INLET OVERHEAD INLET WITH FEED ROLL 2 TRANSFER ROLLS Ø 413mm AND Ø 550mm 2 WORKER ROLLS Ø 260mm 1 STRIPPER ROLL Ø 180mm COVERED TURBO ROLL Ø 600mm ADJUSTABLE AIR-LAY FORMING CHANNEL METALLIC WIRE FOR ALL ROLLS BLOWING FAN FOR FIBRE DOFFING WITH A MESH BELT CONVEYOR INCLUDED A AUTOMATIC GUIDING SYSTEM AND SUCTION DEVICE FOR REMOVING FIBER ACCUMULATIONS FROM THE MESH CONVEYOR THE MESH CONVEYOR, WITH ADJUSTABLE CHANNEL, MOUNTED ON MOVABLE FRAME AND WITH A SUCTION FAN APPROX. 42,000 M3/H OF EXHAUST AIR TO ERECT NEAR TO THE AIR-WEB-FORMER AND TO BE LED TO THE CUSTOMERS FILTER INSTALLATION CARD PREPARED FOR CONNECTION TO CUSTOMERS FILLER UNIT FOR DUST ASPIRATION ETC. INCL ALL NECESSARY ACF DRIVES AND GEARBOXES, POWER INSTALLED: ABOUT 150 KW 1X HIGH LOFT OUTLET ADJUSTABLE SUCTION ROLL SYSTEM INDUCTED THE FLEXIBLE TUBE FROM SUCTION ROLL TO THE FAN 1 X T RANSPORT FAN TYPE: TFF 35 AIR CAPACITY: MAX. 7,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 2X DUST FAN TYPE: DF 25 AIR CAPACITY: MAX. 3,600 M3/H MODE OF DRIVES: ACF / POWER INSTALLED: EACH 4 KW 1X FILTER STATION FOR THE SUCTION FANS OF THE AWF 344 AIR CAPACITY: APPROX. 40,000 M3/H 1X CONTINUES MIXING OPENER TYPE: CMO 80 WORKING WIDTH 800mm WITH FEED TABLE AND SPRING LOADED PAIR OF FEED ROLLS POWER INSTALLED: APPROX 6 KW CONVEYOR BELT TYPE: CB 80 WORKING WIDTH 800mm FOR 2 EDGE STRIPS, LENGTH APPROX 5.0 M TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY, MAX. 6,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED EACH 4 KW ELECTRICAL CABINET WITH COMPLETE INSTALLATION SUCH AS INVERTER FOR VARIABLE SPEED MOTORS, CONTROL BASED ON SIEMENS S7 PLC, CONTROL ELEMENTS, PROGRAMMING AND WIRING DIAGRAM, WITH PLC CONTROL TOUCH PANEL 2X OP17 FOR THE AFOREMENTIONED MACHINERY 4. TOPCON®/LP DOUBLE BELT OVEN - AIR-THROUGH TOPCON®LP - HEATING SECTION TYPE 1-PASS AIR-THROUGH OVEN HOUSING INSULATING PANEL DESIGN, FILLED WITH MINERAL WOOL, THICKNESS 120mm: INSIDE SHEETS AND PLENUMS MADE OF HOT-GALVANISED STEEL HEATED LENGTH 2 SECTIONS OF 3M HEATED LENGTH, EACH = 6M LENGTH IN TOTAL VENTILATION AIR-THROUGH TREATMENT WITH VERTICALLY AIR-FLOW DIRECTION: DIFFUSOR SYSTEM FOR CAREFULLY FIBRE TREATMENT BY LOWER FLOW VELOCITY (LOW PRESSURE) AND HIGHER AIR VOLUME: REVERSING THE AIR-FLOW DIRECTION METER BY METER VENTILATED WIDTH MAX. 3400mm CIRCULATING AIR BLOWER 2X MAX 25,000 M3/H, 15 KW. ΔP 1,600 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER EXHAUST AIR BLOWER 1X MAX. 6,000 M3/H. 3 KW, ΔP 900 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER HEATING SYSTEM DIRECT HEATING BY GAS BLOWER BURNER (INCL. GOST CERTIFICATE) (1 HEATING SYSTEM EACH SECTION) HEATING MEDIUM NATURAL GAS INSTALLED HEATING CAPACITY 300 KW PER SECTION, IN TOTAL 2 X 300 KW = 600 KW EACH HEATING SECTION INFINITELY ADJUSTABLE IN THE RANGE OF 10...300 KW (1:30 RATIO) MAX. CIRCULATING AIR TEMPERATURE 190°C (DEPENDING ON BELTS) TEMPERATURE CONTROL BY ELECTRONIC PID-CONTROLLER TEMPERATURE ACCURACY ±1.5% (180°C AND 80% BLOWER CAPACITY) TOPCON®LP INTEGRATED AIR-THROUGH COOLING ZONE KIND OF TREATMENT AIR THROUGH TREATMENT BY FRESH AIR COOLED LENGTH 2 SECTIONS OF 2 M COOLED LENGTH = 4 M LENGTH IN TOTAL AIR FLOW SENSE FROM THE BOTTOM TO THE TOP COOLING MEDIUM FRESH AIR EXHAUST AIR BLOWER 1X MAX. 28,000 M3/H, 15 KW. ΔP 1,200 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER FRESH AIR BLOWER 1 X MAX 28,000 M3/H. 15 KW. ΔP 1,200 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER TOPCON®LP CONVEYING SYSTEM TYPE TOPCON CONVEYING SYSTEM WITH TWO FREE-WHEELING CONVEYOR BELTS INCL. AUTOMATIC BELT TRACKING MECHANISM: THE UPPER CONVEYOR BELT IS VERTICALLY ADJUSTABLE BY MOTOR DRIVEN WORM GEAR JACKS TOP BELT QUALITY BRONZE / STEEL BOTTOM BELT QUALITY BRONZE / STAINLESS STEEL BELT WIDTH USEFUL WORKING WIDTH + 200mm BELT TENSIONING PNEUMATICALLY WITH AUTOAMTIC PARALLEL TRACKING MECHANISM MAGNETIC SYSTEM FOR TOP BELT INCLUDED FREE PASSAGE HEIGHT 5...300mm, DIGITAL READOUT AT THE COMMAND PANEL 5. SCHOTT & MEISSNER CUTTING MACHINE LONGITUDINAL CUTTER OPERATING PRINCIPLE "SAW CUT MODE" WEB CONVEYANCE BY MEANS OF FEED AND DRAW-OFF BELTS, MOTOR DRIVEN SLITTING MODE MOTOR-DRIVEN CIRCULAR BLADES EACH SLITTING HEAD CAN BE INDEPENDENDLY LOADED BY MEANS OF PNEUMATIC CYLINDER A) FOR SLITTING MODE B) OR LIFTED UP IF OUT OF USE MOTOR DRIVE A.C. MOTOR DRIVE, FREQUENCY CONTROLLED, (1 INDEPENDED DRIVE MOTOR EACH SLITTING HEAD) BLADE DIAMETER 0 810mm BLADE QUALITY CUTTING STEEL NUMBER OF SLITTING STATIONS 7X; (2 X EDGE TRIMS, 5 X CENTER CUT) AUTOMATIC SLITTING HEAD ADJUSTMENT BY A.C. MOTOR DRIVE WITH BRAKE IN COMBINATION WITH A MAGNET LINEAR LENGTH MEASURING SYSTEM (EACH SLITTING STATION CONTAINS ITS OWN A C. MOTOR DRIVE, MAGNET SENSOR AND MAGNET TAPE), 1 CENTRAL MEASUREMENT ACTUATING DEVICE MIN. SLITTING HEAD DISTANCE MIN. 300mm MAX MATERIAL THICKNESS TO BE PROCESSED 300mm BLADE SHARPENING UNIT 1 X SHARPENING UNIT SHARPENING PROCESS TWO GRINDSTONES ARE LATERALLY POSITIONED NEXT TO THE BLADE SHARPENING PROCESS ONLY WITHOUT PRODUCT WHILE LINE STOP PNEUMATICALLY ACTIVATED VIA OPERATOR PANEL MIN DISTANCE BETWEEN THE SLITTING HEADS MIN. 300mm EDGE TRIM REMOVAL INCLUDED SAFETY GUARDS IND. SAFETY DOOR SWITCH ON ACCESS DOOR ABOVE THE MOTOR DRIVEN BLADES INDUDING THE SAFETY GUARDS AND LIMIT SWITCH FOR THE FEED AND DELIVERY SIDE CROSS CUTTER OPERATING PRINCIPLE "FLYING WHEEL" THE CUTTING HEAD IS MOVED ACROSS THE WEB WIDTH BY MEANS OF A LINEAR DRIVE AND THE CUTTING UNIT MOVES FORWARD IN PRODUCTION SPEED FOR RECTANGULAR CUT WITHOUT STOP TYPE DRIVEN ROTARY BLADE MOTOR DRIVE A.C. MOTOR DRIVE, FREQUENCY CONTROLLED, BLADE DIAMETER Ø 810mm SPECIFICATION ADDITIONAL OPERATOR GUARD ONTO BLADE, DETACHABLE FOR SERVICING AND MAINTENANCE WORK BLADE QUALITY CUTTING STEEL NUMBER OF ROTARY BLADES 1X WEB WIDTH / CUTTING WIDTH MAX. 3400mm WEB THICKNESS MAX. 300mm CUTTING FREQUENCY MAX. 6 CUTS/MIN (DEPENDING ON PRODUCT, WEB THICKNESS, BLANKET LENGTH, PRODUCTION SPEED) LENGTH MEASUREMENT BY MEASUREMENT WHEEL, COUNTER, AND ELECTRONIC PULSE GENERATOR TRANSPORT BELT POSITION BETWEEN CROSS CUTTER AND WIND-UP STATION FUNCTION CONTINUOUS WEB CONVEYANCE TOWARDS THE WINDER QUALITY SYNTHETIC WEAVE BELT GUIDING RESTRICTED GUIDANCE BY MEANS OF DOUBLE SIDED WEDGE GUIDE BELT TENSION MECHANICALLY BY SPRING FORCE BELT WIDTH USEFUL WORKING WIDTH + 200mm DISTANCE BETWEEN THE ROLLER AXIS APPROX. 2500mm EXTENDED FROM CROSS CUTTER HEIGHT DOWN TO 900mm 6. ASCENDING BATCH WINDER WINDING MODE WINDING MODE IS PROCESSED BY MEANS OF TWO MOTOR DRIVEN WINDING ROLLS THE MANDREL IS POSITIONED IN BETWEEN THE ROLLER NIP AND IS CAUGHT BY LATERAL BRACKETS TENSILE STRENGTH CONTROL BY MEANS OF A PNEUMATIC BRAKE WHICH IMPACTS / CONTROLS THE VERTICAL UPWARDS MOVEMENT OF THE BRACKETS AND GIVES MORE OR LESS DENSITY TO THE BATCH USEFUL WORKING WIDTH 3400mm ROLLER DIAMETER 300mm ROLLER QUALITY STEEL ROLLER, WRAPPED WITH FRICTION TAPE MAX. BATCH DIAMETER 1500mm MAX. BATCH WEIGHT TO BE ADVISED 7. MULTI - MOTOR A.C. DRIVE(S) TYPE GEARED MOTOR DRIVE(S) SPEED ADJUSTMENT INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER, MANUALLY ADJUSTABLE AT THE COMMAND PANEL OR AUTOMATICALLY BY THE GIVEN REFERENCE VALUE OF THE PRE-MACHINE MECHANICAL LINE SPEED 1 .....20 M/MM (1:20 RATIO) NUMBER OF DRIVING STATIONS WILL BE CONFIRMEND REFERENCE INPUT TO BE GIVEN 0...10 V 8. CONTROL PANEL AND COMMAND PANEL SUPPLY VOLTAGE 400 V: 3 PHASES; 60 CYCLES CONTROL VOLTAGE 24 V DC INSTALLED ELECTRICAL POWER APPROX. 475 KW / 950 A CURRENT FLUCTUATION 5...10 % CONTROL PANEL BRAND “RITTAL”. INCLUDING ALL ELECTRICAL EQUIPMENT EXCEPTING OPERATING AND INDICATING ELEMENTS OF THE LINE CONTROL PANEL SIZE: 4800 X 2000 X 500mm (+200mm SOCKET) NUMBER OF FIELDS: 10 (IN TOTAL) PROTECTION LEVEL: IP 54 CABLE INLET: FROM BOTTOM COOLING UNIT NOT INCLUDED COMMAND PANEL BRAND "RITTAR. INCLUDING ALL OPERATING AND INDICATING ELEMENTS, LINE'S OPERATION BY SIEMENS OPERATOR PANEL MP 277 10” AND OP 177 6” OPERATOR PANEL MP 277 10” / OP 177 6” TO SET ALL DRIVES INTO OPERATION, TO GIVE ALL REFERENCE SETTINGS AND TO INDICATE ALL ACTUAL VALUES TO LOG ALL OPERATION VALUES AND FAULT INDICATIONS (DATE/TIME), PASSWORD AVAILABLE CONTROL BY PLC BRAND “SIEMENS” SIMATIC S7-300 USER INTERFACE RUSSIAN LANGUAGE SPS PROGRAMMING, CIRCUIT DIAGRAMS ENGLISH LANGUAGE MODEM LINK THE PLC SIEMENS S7 CONTAINS A TS-ADAPTER AND MODEM LINK FOR ASSISTANCE IN MAINTENANCE, TECHNICAL SERVICE, FAULT ANALYSIS'S OR TROUBLE SHOOTING) WIRING ACCORDING TO THE MOST MODEM EN-STANDARDS PRE-WIRING OF THE SENSORS OF THE LINE ON TERMINALS IS MADE BY SCHOTT & MEISSNER; THE JUNCTION BOXES (TERMINALS) ARE POSITIONED INSIDE THE INLET AND EXIT STANDS OF THE LINE SPECIFICATION OUR QUOTE CONTAINS 30 M WIRE CABLES BETWEEN CONTROL PANEL, COMMAND PANEL AND END-USER POINTS OF THE LINE GENERAL DATA SERVICE SIDE (OVEN ACCESS DOORS) LEFT HAND SIDE IN MATERIAL TRANSPORT DIRECTION OVEN EXTERIOR LACQUER COATING ACCORDING TO YOUR CHOICE (RAL COLORING) CONTROL PANEL AND COMMAND PANEL RAL 7035 LIGHT GREY OVEN INTERIOR NO LACQUER COATING, HOT-GALVANIZED STEEL OPERATING MANUAL 2- FOLD RUSSIAN LANGUAGE 2- FOLD ENGLISH LANGUAGE TECHNICAL DOCUMENTATION 2- FOLD ENGLISH LANGUAGE SPARE PART LIST 2- FOLD ENGLISH LANGUAGE TECHNICAL AND TECHNOLOGICAL PARAMETERS OF THE OVERALL SYSTEM FIBRE SPECIFICATIONS TYPE OF FIBRE PES – 3.3 - 15 DTEX (PET) FIBRE FINENESS PES - BIKO - 4.4 DTEX FIBRE LENGTH 38 TO 51mm MIXING RATIO BICO PERCENTAGE 15 - 30 % PRODUCTION RANGE OF WEIGHTS 80 TO 3500 G/M3 FIBRE THROUGHPUT 1400KG/H (BEFORE EDGE CUTTING) THICKNESS OF WEB - FINISHED PRODUCT MAX 250mm WIDTH OF END PRODUCT AFTER EDGE CUTTING MAX. 3200mm WEB DENSITY 5 TO 80 KG/M1 (DEPENDING ON WEIGHT AND FIBRE MIX) WEIGHT (G/M2) PRODUCTION (KG/H) LINE SPEED (MJMIN) 80 298 18 100 370 18 500 1375 13.3 2000 1375 6.7 3500 1375 1.9 FOR THE TECHNOLOGICAL COMMISSIONING OF THE MACHINES IN ACCORDANCE WITH ANNEX NO. 6, THE TWO UNDERLINED PRODUCTS ARE RUN FOR 6 HOURS EACH FIBRE MIX: 20% BICO 4.4 DTEX; 60% PES 6.7 DTEX; 20% PES 15 DTEX LACQUERING MACHINES RAJ. COLOR AS DESIRED CONTROL CABINETS RAJ. 7035, LIGHT GREY CONTROL PANELS RAL 7035, LIGHT GREY MOTORS ORIGINAL MANUFACTURER'S COLOR ELECTRICAL DATA SUPPLY VOLTAGE 3 X 400 V (+/-10%) 50Hz CONTROL VOLTAGE 230 V- AC / 24 V - DC TEMPERATURE IN CONTROL CABINETS = 35°C HEIGHT < 1000 M ABOVE SEA LEVEL PRODUCTION CLIMATE TEMPERATURE 24°C +/- 5°C REL HUMIDITY 70% +/- 5% BUILDING REQUIREMENTS THE REQUIRED CLEARANCE HEIGHT 6000mm SMOOTH AND EVEN FLOOR RELEVANT FOUNDATION LOADS CLIMATIC CONDITIONS MUST BE OBSERVED Learn More

GRAUTE AND SCHOTT & MEISSNER AIRLAY PRODUCTION LINE – NEW, WORKING WIDTH 3200mmREFERENCE NUMBER: T-6756 GRAUTE AND SCHOTT & MEISSNER AIRLAY PRODUCTION LINE – NEW, WORKING WIDTH 3200mm BRAND: GRAUTE (GERMANY) AND SCHOTT & MEISSNER YEAR: 2012, HAS NEVER BEEN INSTALLED WORKING WIDTH: 3200mm (AFTER EDGE TRIM) CAPACITY: 1400 KG/H (BEFORE EDGE TRIM) RANGE OF WEIGHTS: 80 TO 3500 G/M2 THICKNESS: MAX. 250mm WEB DENSITY: 5 TO 80 KG/M3 WEIQHT [G/M2] PRODUCTION [KG/H] SPEED [M/MIN] 80 298 18.0 100 370 18.0 500 1375 13.3 2000 1375 6.7 3500 1375 1.9 CONSISTING OF: • BALE OPENING BRAND: GRAUTE 3X BALE OPENER (BO 150) 1X FINE OPENER (FO 125) 2X TRANSPORT FAN (TFF 30) 2X FILLING CAGE (FC 150) 3X WEIGHTING PLATE SYSTEM (WPS 150) 2X CONTINUOUS MIXING OPENER • BLENDING AND FEEDING BRAND: GRAUTE 1X LARGE VOLUME BLENDER (LVB 150) 2X TRANSPORT FAN (TFF 30) 1X METAL DETECTOR (DMX) 1X BUFFER EQUIPMENT (PO 175) • AIRLAY-CARDING BRAND: GRAUTE 1X CARD FEEDING UNIT (CFV 344) 1X WEIGHTING PLATE SYSTEM (WPS 344) 1X AIR-WEB FORMER (AWF 344) 1X HIGH LOFT OUTLET 2X TRANSPORT FAN (TFF 30) 1X DUST FAN (DF 25) 1X FILTER STATION 1X CONTINUOUS MISSING OPENER (CMO 80) 1X CONVEYOR BELT (CB 80) • TOPCON DOUBLE BELT OVEN BRAND: SCHOTT & MEISSNER 2X 3M TOPCON HEATING SECTIONS 2X DIRECT HEATING BY GAS BLOWER BURNER 300KW 2X CIRCULATING AIR BLOWER 25000M3/H; 15KW 1X EXHAUST AIR FAN 6000M3/H; 3KW 2X TOPCON COOLING SECTIONS 1X EXHAUST AIR BLOWER 28000M3/H; 15KW 1X FRESH AIR BLOWER 28000M3/H; 15KW TOPCON CONVEYING SYSTEM WITH BELT GUIDING AND TENSIONING SYSTEM MAGNETIC SYSTEM FOR KEEPING THE TOP BELT SUSPENDED • CUTTING MACHINE BRAND: SCHOTT & MEISSNER 1X INLET BELT CONVEYOR, LENGTH APPROX. 1000mm 7X LONGITUDINAL CUTTING HEAD, CIRCULATING KNIFE Ø 810mm 1X SHARPENING DEVICE FOR LONGITUDINAL CUTTING 1X FLYING CROSS CUTTING HEAD, CIRCULATING KNIFE Ø 810mm TRANSPORT BELT FOR CROSS CUTTING UNIT SAFETY FENCES ON THE CUTTING MACHINE • WINDER BRAND: SCHOTT & MEISSNER OUTLET TRANSPORT BELT, LENGTH APPROX. 3000mm 1X ASCENDING BATCH WINDER, MAX. Ø 1500mm • ADDITIONAL MULTI-MOTOR AC DRIVES CONTROL PANEL AND COMMAND PANEL MACHINE IS AVAILABLE FOR IMMEDIATE SALE COMPLETE PRODUCTION LINE IS ORIGINAL PACKED AND HAS NEVER BEEN INSTALLED SPECIFICATION OF NONWOVEN LINE SCHOTT & MEISSNER NONWOVEN LINE FOR CONTINUOUSE THERMOBONDING OF PES / BICO WEBS USEFUL WORKING WIDTH: 3400mm, SIMILAR TO DRAWING NO. 60.71X.086 CONSISTING OF: PARAGRAPH §1 1. BALE OPENING EXECUTED AS FOLLOWS • 1X BALE OPENER (BO 150) • 1X FINE OPENER (FO 125) • 1X TRANSPORT FAN (TFF 30) • 2X FILLING CAGE (FC 150) • 2X BALE OPENER (BO 150) • 3X WEIGHING PLATE SYSTEM WPS 150 • 2X CONTINUES MIXING OPENER (CMO 150) • 1X TRANSPORT FAN (TFF 30) 2. BLENDING AND FEEDING EXECUTED AS FOLLOWS • 1X LARGE VOLUME BLENDER (LVB 150) • 1X TRANSPORT FAN (TFF 30) • 1X METAL DETECTOR DMX • 1X BUFFER EQUIPMENT (PO 175) • 1XTRANSPORT FAN (TFF 30) 3. AIRLAY-CARDING EXECUTED AS FOLLOWS • 1X CARD FEEDING UNIT CFV 344 • 1X WEIGHING PLATE SYSTEM WPS 344 • 1X AIR-WEB FORMER AWF 344 • 1X HIGH LOFT OUTLET • 1X TRANSPORT FAN (TFF 35) • 1X DUST FAN (DF 25) • 1X FILTER STATION • 1X CONTINUES MIXING OPENER (CMO 80) • 1X CONVEYOR BELT (CB 80) • 1X TRANSPORT FAN (TFF 30) 4. TOPCON®LP DOUBLE BELT OVEN - AIR-THROUGH EXECUTED AS FOLLOWS • 2X 3M TOPCON®LP HEATING SECTIONS • 2X DIRECT HEATING BY GAS BLOWER BURNER 300 KW • 2X CIRCULATING AIR BLOWER, 25,000 M3/H. 15 KW • 1X EXHAUST AIR FAN 6,000 M3/H; 3 KW • 2X 2M TOPCON®LP INTEGRATED COOLING SECTIONS • 1X EXHAUST AIR BLOWER 28,000 M3/H; 15KW • 1X FRESH AIR BLOWER 28,000 M3/H; 15KW • TOPCON®LP CONVEYING SYSTEM INCLUDING BELT GUIDING SYSTEM AND BELT TENSIONING SYSTEM • MAGENTIC SYSTEM FOR KEEPING THE TOP BELT SUSPENDED 5. SCHOTT & MEISSNER CUTTING MACHINE EXECUTED AS FOLLOWS • 1X INLET BELT CONVEYOR, LENGTH APPROX 1000mm • 7X LONGITUDINAL CUTTING HEAD, CIRCULATING KNIFE, Ø 810mm • 1X SHARPENING DEVICE FOR LONGITUDINAL CUTTING KNIFES • 1X FLYING CROSS CUTTING HEAD, CIRCULATING KNIFE, Ø 810mm • TRANSPORT BELT FOR CROSS CUTTING UNIT • SAFETY FENCE FOR CUTTING MACHINE 6. SCHOTT & MEISSNER ASCENDING BATCH WINDER INCL. TRANSPORT BELT EXECUTED AS FOLLOWS • OUTLET TRANSPORT BELT; LENTH APPROX. 3000mm • 1X ASCENDING BATCH WINDER, MAX. 0 1500mm 7. MULTI-MOTOR AC DRLVE(S) 8. CONTROL PANEL AND COMMAND PANEL 9. SUPERVISION OF FINAL ASSEMBLY AND START-UP ENVIRONMENTAL DETAILS SITE ALTITUDE ≤ 1000 MUNN TEMPERATURE 10 °C... ≤35 °C RELATIVE AIR HUMIDITY 65% ± 5% ABSOLUTE WATER CONTENT 9-12 G/KG DRY AIR DESIGN DATA MATERIAL IN USE CARDED AND AIRTAID NONWOVEN FIBRES PES + BICO MIXTURE OF FIBRES MUST BE CONFIRMED BY THE CUSTOMER FIBRE FINESS 3.3...6.7 DTEX FIBRE LENGTH 38 TO 60mm METTING POINT BICO FIBRE 110°C .... 140°C (DEPENDING ON FIBRES IN USE) PRODUCTION TEMPERATURE MAX. 190°C (DEPENDING ON MELTING FIBRE) END PRODUCT WADDINGS / INSULATION RANGE OF WEIGHTS 80...3500 G/M2 FINAL PRODUCT THICKNESS MAX. 250mm WEB DENSITY MAX. 80 KG/M3 (DEPENDING ON FIBRE) FIBRE THROUGHPUT MAX. 1400 KG/H (DEPENDING ON WEB WEIGHT AND FIBRE IN USE) WORKING WIDTH / VENTILATED WIDTH MAX. 3400mm FINISH PRODUCT WIDTH MAX. 3200mm PRODUCTION SPEED MAX 18 M/MIN (DEPENDING ON PRODUCT REQUIREMENTS, FIBERS IN USE. BASIC WEIGHTS) MECHANICAL SPEED 1....20 M/MIN (RATIO 1:20) REFERENCE PRODUCT MUST BE CONFIRMED BY THE CUSTOMER ENERGY CONSUMPTION 1 KG/FIBRE = APPROX. 0.3 KW (10 KW = 1 M’/NATURAL GAS) TECHNICAL SPECIFICATION 1. BALE OPENING 1X BALE OPENER TYPE: BO 150 FIBRE IN USE: BICO WORKING WIDTH 1500mm WITH FREQUENCY REGULATED DRIVES AND 2 M FEED TABLE POWER INSTALLED: EACH APPROX. 5 KW 1X FINE OPENER TYPE: FO 125 FIBRE: BICO WORKING WIDTH: 1250mm MODE OF DRIVES: AC, ACF POWER INSTALLED: APPROX. 9 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 5500 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 2X FILLING CAGE TYPE: FC 150 WORKING WIDTH: 1500mm WITH BLOW-IN-HOOD AND TWO TAKE-OFF-ROLLS MODE OF DRIVES: ACF POWER INSTALLED: APPROX. 1.0 KW 2X BALE OPENER TYPE: BO 150 FIBRE IN USE: PES WORKING WIDTH 1500mm WITH FREQUENCY REGULATED DRIVES, 2 M FEED TABLE AND FIBER OUTLET THROUGH TWO TAKE-OFF-ROLLS. POWER INSTALLED EACH APPROX. 5.6 KW 3X WEIGHING PLATE SYSTEM TYPE: WPS 150 WORKING WIDTH 1500mm FOR AUTOMATIC SETTING AND REGULATION OF FIBER BLENDING, TO BE INSTALLED BETWEEN BALE OPENER AND CONTINUES MIXING OPENER 2X CONTINUES MIXING OPENER TYPE: CMO 150 WORKING WIDTH 1500mm WITH DOUBLE-SIDED FEEDING THROUGH A PAIR OF FEED ROLLS AND A TRAY PLATE FEEDING POWER INSTALLED: APPROX. 13 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX 6,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 7.5 KW 2. BLENDING AND FEEDING 1X LARGE VOLUME BLENDER TYPE: LVB 150 WORKING WIDTH: 1500mm FILLING LENGTH: 4000mm FILLING HEIGHT: APPROX 2000mm TOTAL HEIGHT: APPROX. 5200mm FILLING CAPACITY: APPROX 12 M3 FEED BY 1 CYCLON CYC 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 5500 M3/H MODE OF DRIVES: ACF POWER INSTALLED EACH 4 KW 1X METAL DETECTOR TYPE: DMX WITH REMOVING DEVICE (BAC) FOR FERROUS PARTS DETECTOR WITH ELECTRONIC APPARATUS SPECIAL PVC PIPE WITH CONNECTIONS ELECTRIC-PNEUMATIC VALVE BOX COLLECTING SILO 1X BUFFER EQUIPMENT TYPE: PO 175 WORKING WIDTH: 1750mm WITH BLOW-IN-HOOD, FILLING CAGE, PRE OPENER AND SUCTION CHANNEL MODE OF DRIVES: AC, ACF POWER INSTALLED: APPROX. 3 KW 1X TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY: MAX. 6,00 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 3. AIRLAY-CARDING TX CARD FEEDING UNIT TYPE: CFV 344 WORKING WIDTH 3440mm WITH BLOW-IN-HOOD, FILLING CAGE, FIBER COMPACTION BY VIBRATION WALL AND MATERIAL OUTLET ON GLIDING PLATE MODE OF DRIVES: AC. ACF POWER INSTALLED: APPROX 7 KW 1X WEIGHING PLATE SYSTEM TYPE: WPS 344 WORKING WIDTH 3440mm FOR AUTOMATIC SETTING AND REGULATION OF WEB WEIGHT DURING PRODUCTION, TO BE INSTALLED BETWEEN CARD-FEEDER AND AIR-WEB-FORMER AIR-WEB FORMER TYPE: AWF 344 WORKING WIDTH 3440mm WITH MOVABLE PRE-CARD AND WITH AN AIR-LAY TAKE OFF DEVICE FOR RANDOMISED WEB. KIND OF INLET OVERHEAD INLET WITH FEED ROLL 2 TRANSFER ROLLS Ø 413mm AND Ø 550mm 2 WORKER ROLLS Ø 260mm 1 STRIPPER ROLL Ø 180mm COVERED TURBO ROLL Ø 600mm ADJUSTABLE AIR-LAY FORMING CHANNEL METALLIC WIRE FOR ALL ROLLS BLOWING FAN FOR FIBRE DOFFING WITH A MESH BELT CONVEYOR INCLUDED A AUTOMATIC GUIDING SYSTEM AND SUCTION DEVICE FOR REMOVING FIBER ACCUMULATIONS FROM THE MESH CONVEYOR THE MESH CONVEYOR, WITH ADJUSTABLE CHANNEL, MOUNTED ON MOVABLE FRAME AND WITH A SUCTION FAN APPROX. 42,000 M3/H OF EXHAUST AIR TO ERECT NEAR TO THE AIR-WEB-FORMER AND TO BE LED TO THE CUSTOMERS FILTER INSTALLATION CARD PREPARED FOR CONNECTION TO CUSTOMERS FILLER UNIT FOR DUST ASPIRATION ETC. INCL ALL NECESSARY ACF DRIVES AND GEARBOXES, POWER INSTALLED: ABOUT 150 KW 1X HIGH LOFT OUTLET ADJUSTABLE SUCTION ROLL SYSTEM INDUCTED THE FLEXIBLE TUBE FROM SUCTION ROLL TO THE FAN 1 X T RANSPORT FAN TYPE: TFF 35 AIR CAPACITY: MAX. 7,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED: EACH 4 KW 2X DUST FAN TYPE: DF 25 AIR CAPACITY: MAX. 3,600 M3/H MODE OF DRIVES: ACF / POWER INSTALLED: EACH 4 KW 1X FILTER STATION FOR THE SUCTION FANS OF THE AWF 344 AIR CAPACITY: APPROX. 40,000 M3/H 1X CONTINUES MIXING OPENER TYPE: CMO 80 WORKING WIDTH 800mm WITH FEED TABLE AND SPRING LOADED PAIR OF FEED ROLLS POWER INSTALLED: APPROX 6 KW CONVEYOR BELT TYPE: CB 80 WORKING WIDTH 800mm FOR 2 EDGE STRIPS, LENGTH APPROX 5.0 M TRANSPORT FAN TYPE: TFF 30 AIR CAPACITY, MAX. 6,000 M3/H MODE OF DRIVES: ACF POWER INSTALLED EACH 4 KW ELECTRICAL CABINET WITH COMPLETE INSTALLATION SUCH AS INVERTER FOR VARIABLE SPEED MOTORS, CONTROL BASED ON SIEMENS S7 PLC, CONTROL ELEMENTS, PROGRAMMING AND WIRING DIAGRAM, WITH PLC CONTROL TOUCH PANEL 2X OP17 FOR THE AFOREMENTIONED MACHINERY 4. TOPCON®/LP DOUBLE BELT OVEN - AIR-THROUGH TOPCON®LP - HEATING SECTION TYPE 1-PASS AIR-THROUGH OVEN HOUSING INSULATING PANEL DESIGN, FILLED WITH MINERAL WOOL, THICKNESS 120mm: INSIDE SHEETS AND PLENUMS MADE OF HOT-GALVANISED STEEL HEATED LENGTH 2 SECTIONS OF 3M HEATED LENGTH, EACH = 6M LENGTH IN TOTAL VENTILATION AIR-THROUGH TREATMENT WITH VERTICALLY AIR-FLOW DIRECTION: DIFFUSOR SYSTEM FOR CAREFULLY FIBRE TREATMENT BY LOWER FLOW VELOCITY (LOW PRESSURE) AND HIGHER AIR VOLUME: REVERSING THE AIR-FLOW DIRECTION METER BY METER VENTILATED WIDTH MAX. 3400mm CIRCULATING AIR BLOWER 2X MAX 25,000 M3/H, 15 KW. ΔP 1,600 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER EXHAUST AIR BLOWER 1X MAX. 6,000 M3/H. 3 KW, ΔP 900 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER HEATING SYSTEM DIRECT HEATING BY GAS BLOWER BURNER (INCL. GOST CERTIFICATE) (1 HEATING SYSTEM EACH SECTION) HEATING MEDIUM NATURAL GAS INSTALLED HEATING CAPACITY 300 KW PER SECTION, IN TOTAL 2 X 300 KW = 600 KW EACH HEATING SECTION INFINITELY ADJUSTABLE IN THE RANGE OF 10...300 KW (1:30 RATIO) MAX. CIRCULATING AIR TEMPERATURE 190°C (DEPENDING ON BELTS) TEMPERATURE CONTROL BY ELECTRONIC PID-CONTROLLER TEMPERATURE ACCURACY ±1.5% (180°C AND 80% BLOWER CAPACITY) TOPCON®LP INTEGRATED AIR-THROUGH COOLING ZONE KIND OF TREATMENT AIR THROUGH TREATMENT BY FRESH AIR COOLED LENGTH 2 SECTIONS OF 2 M COOLED LENGTH = 4 M LENGTH IN TOTAL AIR FLOW SENSE FROM THE BOTTOM TO THE TOP COOLING MEDIUM FRESH AIR EXHAUST AIR BLOWER 1X MAX. 28,000 M3/H, 15 KW. ΔP 1,200 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER FRESH AIR BLOWER 1 X MAX 28,000 M3/H. 15 KW. ΔP 1,200 PA INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER TOPCON®LP CONVEYING SYSTEM TYPE TOPCON CONVEYING SYSTEM WITH TWO FREE-WHEELING CONVEYOR BELTS INCL. AUTOMATIC BELT TRACKING MECHANISM: THE UPPER CONVEYOR BELT IS VERTICALLY ADJUSTABLE BY MOTOR DRIVEN WORM GEAR JACKS TOP BELT QUALITY BRONZE / STEEL BOTTOM BELT QUALITY BRONZE / STAINLESS STEEL BELT WIDTH USEFUL WORKING WIDTH + 200mm BELT TENSIONING PNEUMATICALLY WITH AUTOAMTIC PARALLEL TRACKING MECHANISM MAGNETIC SYSTEM FOR TOP BELT INCLUDED FREE PASSAGE HEIGHT 5...300mm, DIGITAL READOUT AT THE COMMAND PANEL 5. SCHOTT & MEISSNER CUTTING MACHINE LONGITUDINAL CUTTER OPERATING PRINCIPLE "SAW CUT MODE" WEB CONVEYANCE BY MEANS OF FEED AND DRAW-OFF BELTS, MOTOR DRIVEN SLITTING MODE MOTOR-DRIVEN CIRCULAR BLADES EACH SLITTING HEAD CAN BE INDEPENDENDLY LOADED BY MEANS OF PNEUMATIC CYLINDER A) FOR SLITTING MODE B) OR LIFTED UP IF OUT OF USE MOTOR DRIVE A.C. MOTOR DRIVE, FREQUENCY CONTROLLED, (1 INDEPENDED DRIVE MOTOR EACH SLITTING HEAD) BLADE DIAMETER 0 810mm BLADE QUALITY CUTTING STEEL NUMBER OF SLITTING STATIONS 7X; (2 X EDGE TRIMS, 5 X CENTER CUT) AUTOMATIC SLITTING HEAD ADJUSTMENT BY A.C. MOTOR DRIVE WITH BRAKE IN COMBINATION WITH A MAGNET LINEAR LENGTH MEASURING SYSTEM (EACH SLITTING STATION CONTAINS ITS OWN A C. MOTOR DRIVE, MAGNET SENSOR AND MAGNET TAPE), 1 CENTRAL MEASUREMENT ACTUATING DEVICE MIN. SLITTING HEAD DISTANCE MIN. 300mm MAX MATERIAL THICKNESS TO BE PROCESSED 300mm BLADE SHARPENING UNIT 1 X SHARPENING UNIT SHARPENING PROCESS TWO GRINDSTONES ARE LATERALLY POSITIONED NEXT TO THE BLADE SHARPENING PROCESS ONLY WITHOUT PRODUCT WHILE LINE STOP PNEUMATICALLY ACTIVATED VIA OPERATOR PANEL MIN DISTANCE BETWEEN THE SLITTING HEADS MIN. 300mm EDGE TRIM REMOVAL INCLUDED SAFETY GUARDS IND. SAFETY DOOR SWITCH ON ACCESS DOOR ABOVE THE MOTOR DRIVEN BLADES INDUDING THE SAFETY GUARDS AND LIMIT SWITCH FOR THE FEED AND DELIVERY SIDE CROSS CUTTER OPERATING PRINCIPLE "FLYING WHEEL" THE CUTTING HEAD IS MOVED ACROSS THE WEB WIDTH BY MEANS OF A LINEAR DRIVE AND THE CUTTING UNIT MOVES FORWARD IN PRODUCTION SPEED FOR RECTANGULAR CUT WITHOUT STOP TYPE DRIVEN ROTARY BLADE MOTOR DRIVE A.C. MOTOR DRIVE, FREQUENCY CONTROLLED, BLADE DIAMETER Ø 810mm SPECIFICATION ADDITIONAL OPERATOR GUARD ONTO BLADE, DETACHABLE FOR SERVICING AND MAINTENANCE WORK BLADE QUALITY CUTTING STEEL NUMBER OF ROTARY BLADES 1X WEB WIDTH / CUTTING WIDTH MAX. 3400mm WEB THICKNESS MAX. 300mm CUTTING FREQUENCY MAX. 6 CUTS/MIN (DEPENDING ON PRODUCT, WEB THICKNESS, BLANKET LENGTH, PRODUCTION SPEED) LENGTH MEASUREMENT BY MEASUREMENT WHEEL, COUNTER, AND ELECTRONIC PULSE GENERATOR TRANSPORT BELT POSITION BETWEEN CROSS CUTTER AND WIND-UP STATION FUNCTION CONTINUOUS WEB CONVEYANCE TOWARDS THE WINDER QUALITY SYNTHETIC WEAVE BELT GUIDING RESTRICTED GUIDANCE BY MEANS OF DOUBLE SIDED WEDGE GUIDE BELT TENSION MECHANICALLY BY SPRING FORCE BELT WIDTH USEFUL WORKING WIDTH + 200mm DISTANCE BETWEEN THE ROLLER AXIS APPROX. 2500mm EXTENDED FROM CROSS CUTTER HEIGHT DOWN TO 900mm 6. ASCENDING BATCH WINDER WINDING MODE WINDING MODE IS PROCESSED BY MEANS OF TWO MOTOR DRIVEN WINDING ROLLS THE MANDREL IS POSITIONED IN BETWEEN THE ROLLER NIP AND IS CAUGHT BY LATERAL BRACKETS TENSILE STRENGTH CONTROL BY MEANS OF A PNEUMATIC BRAKE WHICH IMPACTS / CONTROLS THE VERTICAL UPWARDS MOVEMENT OF THE BRACKETS AND GIVES MORE OR LESS DENSITY TO THE BATCH USEFUL WORKING WIDTH 3400mm ROLLER DIAMETER 300mm ROLLER QUALITY STEEL ROLLER, WRAPPED WITH FRICTION TAPE MAX. BATCH DIAMETER 1500mm MAX. BATCH WEIGHT TO BE ADVISED 7. MULTI - MOTOR A.C. DRIVE(S) TYPE GEARED MOTOR DRIVE(S) SPEED ADJUSTMENT INFINITELY ADJUSTABLE BY FREQUENCY CONVERTER, MANUALLY ADJUSTABLE AT THE COMMAND PANEL OR AUTOMATICALLY BY THE GIVEN REFERENCE VALUE OF THE PRE-MACHINE MECHANICAL LINE SPEED 1 .....20 M/MM (1:20 RATIO) NUMBER OF DRIVING STATIONS WILL BE CONFIRMEND REFERENCE INPUT TO BE GIVEN 0...10 V 8. CONTROL PANEL AND COMMAND PANEL SUPPLY VOLTAGE 400 V: 3 PHASES; 60 CYCLES CONTROL VOLTAGE 24 V DC INSTALLED ELECTRICAL POWER APPROX. 475 KW / 950 A CURRENT FLUCTUATION 5...10 % CONTROL PANEL BRAND “RITTAL”. INCLUDING ALL ELECTRICAL EQUIPMENT EXCEPTING OPERATING AND INDICATING ELEMENTS OF THE LINE CONTROL PANEL SIZE: 4800 X 2000 X 500mm (+200mm SOCKET) NUMBER OF FIELDS: 10 (IN TOTAL) PROTECTION LEVEL: IP 54 CABLE INLET: FROM BOTTOM COOLING UNIT NOT INCLUDED COMMAND PANEL BRAND "RITTAR. INCLUDING ALL OPERATING AND INDICATING ELEMENTS, LINE'S OPERATION BY SIEMENS OPERATOR PANEL MP 277 10” AND OP 177 6” OPERATOR PANEL MP 277 10” / OP 177 6” TO SET ALL DRIVES INTO OPERATION, TO GIVE ALL REFERENCE SETTINGS AND TO INDICATE ALL ACTUAL VALUES TO LOG ALL OPERATION VALUES AND FAULT INDICATIONS (DATE/TIME), PASSWORD AVAILABLE CONTROL BY PLC BRAND “SIEMENS” SIMATIC S7-300 USER INTERFACE RUSSIAN LANGUAGE SPS PROGRAMMING, CIRCUIT DIAGRAMS ENGLISH LANGUAGE MODEM LINK THE PLC SIEMENS S7 CONTAINS A TS-ADAPTER AND MODEM LINK FOR ASSISTANCE IN MAINTENANCE, TECHNICAL SERVICE, FAULT ANALYSIS'S OR TROUBLE SHOOTING) WIRING ACCORDING TO THE MOST MODEM EN-STANDARDS PRE-WIRING OF THE SENSORS OF THE LINE ON TERMINALS IS MADE BY SCHOTT & MEISSNER; THE JUNCTION BOXES (TERMINALS) ARE POSITIONED INSIDE THE INLET AND EXIT STANDS OF THE LINE SPECIFICATION OUR QUOTE CONTAINS 30 M WIRE CABLES BETWEEN CONTROL PANEL, COMMAND PANEL AND END-USER POINTS OF THE LINE GENERAL DATA SERVICE SIDE (OVEN ACCESS DOORS) LEFT HAND SIDE IN MATERIAL TRANSPORT DIRECTION OVEN EXTERIOR LACQUER COATING ACCORDING TO YOUR CHOICE (RAL COLORING) CONTROL PANEL AND COMMAND PANEL RAL 7035 LIGHT GREY OVEN INTERIOR NO LACQUER COATING, HOT-GALVANIZED STEEL OPERATING MANUAL 2- FOLD RUSSIAN LANGUAGE 2- FOLD ENGLISH LANGUAGE TECHNICAL DOCUMENTATION 2- FOLD ENGLISH LANGUAGE SPARE PART LIST 2- FOLD ENGLISH LANGUAGE TECHNICAL AND TECHNOLOGICAL PARAMETERS OF THE OVERALL SYSTEM FIBRE SPECIFICATIONS TYPE OF FIBRE PES – 3.3 - 15 DTEX (PET) FIBRE FINENESS PES - BIKO - 4.4 DTEX FIBRE LENGTH 38 TO 51mm MIXING RATIO BICO PERCENTAGE 15 - 30 % PRODUCTION RANGE OF WEIGHTS 80 TO 3500 G/M3 FIBRE THROUGHPUT 1400KG/H (BEFORE EDGE CUTTING) THICKNESS OF WEB - FINISHED PRODUCT MAX 250mm WIDTH OF END PRODUCT AFTER EDGE CUTTING MAX. 3200mm WEB DENSITY 5 TO 80 KG/M1 (DEPENDING ON WEIGHT AND FIBRE MIX) WEIGHT (G/M2) PRODUCTION (KG/H) LINE SPEED (MJMIN) 80 298 18 100 370 18 500 1375 13.3 2000 1375 6.7 3500 1375 1.9 FOR THE TECHNOLOGICAL COMMISSIONING OF THE MACHINES IN ACCORDANCE WITH ANNEX NO. 6, THE TWO UNDERLINED PRODUCTS ARE RUN FOR 6 HOURS EACH FIBRE MIX: 20% BICO 4.4 DTEX; 60% PES 6.7 DTEX; 20% PES 15 DTEX LACQUERING MACHINES RAJ. COLOR AS DESIRED CONTROL CABINETS RAJ. 7035, LIGHT GREY CONTROL PANELS RAL 7035, LIGHT GREY MOTORS ORIGINAL MANUFACTURER'S COLOR ELECTRICAL DATA SUPPLY VOLTAGE 3 X 400 V (+/-10%) 50Hz CONTROL VOLTAGE 230 V- AC / 24 V - DC TEMPERATURE IN CONTROL CABINETS = 35°C HEIGHT < 1000 M ABOVE SEA LEVEL PRODUCTION CLIMATE TEMPERATURE 24°C +/- 5°C REL HUMIDITY 70% +/- 5% BUILDING REQUIREMENTS THE REQUIRED CLEARANCE HEIGHT 6000mm SMOOTH AND EVEN FLOOR RELEVANT FOUNDATION LOADS CLIMATIC CONDITIONS MUST BE OBSERVED Learn More -

T-6552 MASK AIR TIGHTNESS TESTER

T-6552 MASK AIR TIGHTNESS TESTERREFERENCE NUMBER: T-6552

MASK AIR TIGHTNESS TESTER

MASK AIR TIGHTNESS TESTER

HOW TO CHOOSE A HIGH-QUALITY MASK NOT ONLY DEPENDS ON THE FILTERING EFFICIENCY OF THEMASK, BUT ALSO TO CONFIRM WHETHER THE MASK IS COMPLETELY IN CONTACT WITH THE FACE, OTHERWISE AEROSOL PARTICLES SUCH AS GERMS THAT HAVE NOT BEEN FILTERED BY THE MASK WILL BE INHALED FROM THE INADEQUATE ADHESION. THEREFORE, IT IS VERY IMPORTANT TO CHECK THE WEARING STATUS OF THE MASK. THE EUROPEAN AND AMERICAN COUNTRIES HAVE LISTED THE APPLICATION TEST OF THE MASK AS A STRONG INSPECTION ITEM.

FOR EXAMPLE, THE N95 MASK IS ONE OF 9 TYPES OF PARTICULATE PROTECTIVE MASKS CERTIFIED BY NIOSH (NATIONAL INSTITUTE OF OCCUPATIONAL SAFETY AND HEALTH). "N" INDICATES OIL RESISTANCE."95" INDICATES THAT THE PARTICLE CONCENTRATION IN THE MASK IS MORE THAN 95% LOWER THAN THAT OF THE PARTICLES OUTSIDE THE MASK WHEN EXPOSED TO THE SPECIFIED NUMBER OF SPECIAL TEST PARTICLES. N95 IS NOT A SPECIFIC PRODUCT NAME, AS LONG AS IT MEETS THE N95 STANDARD AND PASSES THE NIOSH REVIEW, IT CAN BE CALLED "N95 MASK".

N95 TYPE MASKS, IN ADDITION TO THE FILTERING EFFICIENCY OF THE MASKS, THE CLOSENESS OF THE MASKS TO THE FACE IS ONE OF THE IMPORTANT FACTORS THAT DETERMINE THE EFFECTIVENESS OF THE USE OF THE MASKS. THE SUITABILITY OF DIFFERENT TYPES OF MASKS FOR THE HUMAN FACE VARIES GREATLY.

THEREFORE, BEFORE USING A MASK, THE SUITABILITY OF THE MASK SHOULD BE CHECKED FIRST. DURING THETIGHTNESS TEST OF THE WEARER'S FACE, ENSURE THAT AIR CAN PASS IN AND OUT THROUGH THE MASK WHEN IT IS CLOSE TO THE EDGE OF THE FACE. THE MASK TIGHTNESS TESTER CAN QUICKLY COMPLETE THE TIGHTNESS TEST OF RESPIRATORS SUCH AS MASKS TO ENSURE THAT IT PROVIDES GOOD PROTECTION PERFORMANCE. IT CONFORMS TO THE CHINESE RESPIRATOR STANDARD GB2626-2019 STANDARD, OSHA / CSA STANDARD AND CHINA GENERAL ADMINISTRATION OF QUALITY SUPERVISION, INSPECTION AND QUARANTINE "GB 19083-2010 TECHNICAL REQUIREMENTS FOR MEDICAL PROTECTIVE MASKS" JOINTLY ISSUED BY THE CHINA NATIONAL STANDARDIZATION ADMINISTRATION COMMITTEE.

ADHESION (SUITABILITY TEST): THE MASK DESIGN SHOULD PROVIDE GOOD ADHESION. THE OVERALL FIT FACTOR OF THE MASK SHOULD NOT BE LESS THAN 100. THIS TEST THE REQUIREMENTS WERE FORMALLY IMPLEMENTED ON AUGUST 1, 2011.

Learn MoreMASK TIGHTNESS TESTER USES CNC TECHNOLOGY, SUITABLE FOR 100 / 99 / P3 / HEPASERIES MASKS DISPOSABLE FILTER MASK TIGHTNESS TEST (INCLUDING DISPOSABLE DUST MASKS SUCH ASN95 / N90 / KN95), GAS MASKS / BREATHING MASKS, ADHESIVENESS TEST OF HALF-MASK AND FULL FACE MASK, INDEPENDENT OR COMPUTER CONTROL, FIVE LANGUAGES SWITCH DISPLAY, EQUIPPED WITH MULTIPLE COMMUNICATION INTERFACES (USB, ETHERNET), WIFI CAN ALSO BE ENABLED, ONE COMPUTERCAN CONTROL FOUR INSTRUMENTS AT THE SAME TIME.PARAMETER:CONCENTRATION RANGE: 0 ~ 100,000 / CM3GRAIN DIAMETER: 0.02 ~ 1.0^MFLOW: SAMPLING FLOW: 100CM3 / MINTOTAL FLOW: 700CM3 / MINCLOSENESS COEFFICIENT TEST: DIRECT TEST (COUT/ CIN)LIQUOR: 99.5% + ISOPROPANOL (ANALYTICAL GRADE)DISPLAY: 7INCH TRUE COLOR TOUCH SCREENCOMMUNICATION INTERFACE: USB X 3 (HOST X 2,DEVICE X 1) ETHERNET INTERFACE X1CONNECTION PORT: ENVIRONMENT PORT, SAMPLING PORTWIFI: EQUIPPEDLANGUAGES: ENGLISH, FRENCH, SPANISH, PORTUGUESE, CHINESEFLOW CONTROL: SENSOR CONTROLPC CONTROLLABLE OPERATION: ONE COMPUTER CAN CONTROL 4 INSTRUMENTS AT THE SAME TIMEDATA OUTPUT FORMAT: MICROSOFT EXCELWORKING TEMPERATURE: 15 ~ 35 °CPOWER SOURCE: AC 110 —240V 50 / 60HZAPPEARANCE SIZE: 208 X 117 X 262MMWEIGHT: 2.1KGACCESSORIES: ALCOHOL REAGENT BOTTLE, PROTECTIVE CAP, REAGENT STICK, ZERO-COUNT FILTER, STRAINER, SAMPLING TUBE, INSTRUCTION MANUAL, AC ADAPTER, TOUCH SCREEN PEN, OPTIONAL COMPUTER.OPTIONAL: TEST KIT FOR TIGHTNESS COEFFICIENTIN ORDER TO PREVENT INFECTION AT THE MEDICAL SITE AND DURING LABOR WORK, WORKERS MUST BE PROTECTED FROM INHALABLE HAZARDOUS SUBSTANCES IN THE WORKPLACE, AND RESPIRATORS SUCH AS MASKS MUST BE WORN DURING WORK.SELECT A RESPIRATOR, SUCH AS A MASK, BASED ON YOUR FACIAL FEATURES, AND EVALUATE THE TIGHTNESS BETWEEN THE RESPIRATOR, SUCH AS A MASK AND THE FACE, TO CHECK WHETHER THERE ARE GAPS OR LEAKS THAT PUT WORKERS AT RISK. THE MASK TIGHTNESS TESTER CAN QUICKLY COMPLETE THE TIGHTNESS TEST OF RESPIRATORS SUCH AS MASKS TO ENSURE THAT IT PROVIDES GOOD PROTECTIVE PERFORMANCE. SECURITY EXPERTS WILL ALSO DEVELOP PROTECTION SCHEMES AND STANDARD REGULATIONS BASED ON THE RESULTS OF THE TIGHTNESS TEST. WIDELY USED IN HOSPITALS, MANUFACTURING PLANTS, PRODUCTION SITES, FIREFIGHTING WORKPLACES AND OTHER OFFICIAL TESTING AGENCIES.MASK TIGHTNESS TESTER FEATURES:• QUANTITATIVE TIGHTNESS TEST FOR RESPIRATORS SUCH AS MASKS (QNFT)• APPLICABLE TO 100/99 / P3 / HEPA SERIES MASK DISPOSABLE FILTER MASK TIGHTNESS TEST (INCLUDING N95 / N90 / KN95 AND OTHER DISPOSABLE DUST MASKS)• ADHESION TEST OF HALF MASK AND FULL FACE MASK• GAS MASK TIGHTNESS TEST• PAPR MASK TIGHTNESS TEST• SCBA RESPIRATOR MASK TIGHTNESS TEST• 7INCH TRUE COLOR TOUCH SCREEN• INDEPENDENT OR COMPUTER CONTROLLED• USING CNC TECHNOLOGY• ENGLISH, FRENCH, SPANISH, PORTUGUESE, CHINESE LANGUAGE SWITCHING DISPLAY• COMPLIES WITH US OSHA STANDARDS, CANADIAN STANDARDS ASSOCIATION (CSA) GUIDELINES, INCLUDING N95• EQUIPPED WITH A VARIETY OF COMMUNICATION INTERFACES (USB, ETHERNET), AND CAN ALSO ENABLE WIFI• ONE COMPUTER CAN CONTROL FOUR INSTRUMENTS AT THE SAME TIMEQUANTITY: 1 -

J-2813 HANDHELD AIRBORNE PARTICLE COUNTER, MODEL 3000

J-2813 HANDHELD AIRBORNE PARTICLE COUNTER, MODEL 3000FEATURES

0.3 - 25 µm SENSITIVITY

FLOW RATE: 1.0 CFM (28.3 LPM)

UP TO 8 CHANNELS OF SIMULTANEOUS COUNT DATA

21 CFR PART 11 COMPLIANT SECURE USB FLASH TRANSFER

EXTREME LIFE LASER DIODE TECHNOLOGY >20-YEAR MTTF

5.7 INCH COLOR TOUCH SCREEN DISPLAY

THERMAL PRINTER

STAINLESS STEEL CONSTRUCTION

ETHERNET/RS485/MODBUS, 4x 4-20mA ANALOG INPUTS

3,000 RECORD DATA STORAGE

50-RECORD CONFIGURABLE RECIPE DATABASE

REPORT WIZARD: FS-209E, ISO-14644-1 & EU GMP ANNEX 1

2 YEAR WARRANTYSTANDARD 6 CHANNELS: 0.3, 0.5, 1.0, 3.0, 5.0, 10.0 µm , 0.3, 0.5, 1.0, 5.0, 10.0, 25.0 µm

STANDARD 8 CHANNELS: 0.3,0.5,0.7,1.0,3.0,5.0,7.0,10.0 µm

OPTIONAL 8 CHANNELS: OPTIONAL BETWEEN 0.3 AND 25.0 µm

COUNTING EFFICIENCY: 50%@0.3µm; 100% FOR PARTICLES > 0.45 µm (PER ISO 21501-4)

CONCETRATION LIMITS: 1,000,000 PARTICLES/FT3, (35,300,000/M3) @ 10% COINCIDENCE LOSS SUITABLE FOR ISO CLASSES 1-8 CLEANROOMS

DIMENSIONS: 9.5”(L) x 8.0”(W) x 10.2”(H) (24.13 x 20.32 x 25.9 cm)

WEIGHT: WITH BATTERY: 13.95 LBS (6.33 KG), WITHOUT BATTERY 12.35 LBS (5.6 KG)INCLUDES

OPERATING MANUAL WITH CD, LMS EXPRESS TRANSFER SOFTWARE DOWNLOAD INSTRUCTIONS, ISOKINETIC SAMPLE PROBE, TRIPOD, TUBING, PURGE FILTER, POWER CABLES, SPARE FUSE, PRINTER, PRINTER PAPERLEAD TIME: 1 TO 2 WEEKS FROM RECEIPT OF ORDER

QUANTITY: 1

Learn More -

J-2811 AIRBORNE PARTICLE COUNTER

J-2811 AIRBORNE PARTICLE COUNTERAIRBORNE PARTICLE COUNTER

PORTABLE PARTICLE COUNTER WITH 0.10 MICRON SENSITITIVITY AND 1.0 CFM (28.3 LPM) FLOW RATE USING LONG LIFE LASER DIODE TECHNOLOGY.

DESIGNED TO OPERATE IN ISO CLASS 1 TO CLASS 7 CLEANROOMS WITHOUT CONCERNS OF IT DEGRADING ITS ENVIRONMENT OR EXCEEDING CONCENTRATION LIMITS

USES AN OPTICS AND PHOTODIODE SYSTEM DESIGNED TO REDUCE OR ELIMINATE THE TEMPERATURE ISSUES ASSOCIATED WITH HIGH POWER LASER DIODE SENSORS

WITH THERMALLY CONTROLLED EXHAUST SYSTEM AND HEPA FILTER OPTION TO PREVENT ANY EXTERNAL CONTAMINATIONFEATURES

0.1- 1.0 µm SENSITIVITY

1.0 CFM (28.3 LPM)

UP TO 8 CHANNELS OF SIMULTANEOUS COUNT DATA

21 CFR PART 11 COMPLIANT SECURE USB FLASH TRANSFER

LASER DIODE SENSOR TECHNOLOGY

5.7 INCH COLOR TOUCH SCREEN DISPLAY

THERMAL PRINTER

STAINLESS STEEL CONSTRUCTION

ETHERNET/RS485/MODBUS, 4X 4-20MA ANALOG OUTPUTS

3,000 RECORD DATA STORAGE

50-RECORD CONFIGURABLE RECIPE DATABASE

Report wizard: ISO-14644-1, EU GMP Annex 1, FS-209ESTANDARD CHANNEL SIZES: 0.10, 0.15, 0.2, 0.25, 0.3, 0.5, 0.7, 1.0 µm

INCLUDES

OPERATING MANUAL ON CD; ISOKINETIC SAMPLE PROBE WITH TRIPOD AND TUBING; PURGE FILTER; POWER CABLE AND SPARE FUSE; LMS XCHANGE AND EXPRESS SOFTWARE; PRINTER; PRINTER PAPERQUANTITY: 1

Learn More -

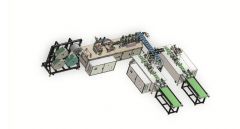

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTE

J-2730 AUTOMATIC DISPOSABLE SURGICAL MASK (N95) PRODUCTION LINE WITH PACKAGING -PRODUCES SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% -CAPACITY: 50 MASKS (N95) PER MINUTEITEM 001 - MASK PRODUCTION MACHINE WITH (2) ULTRASONIC EAR STRAP WELDING DEVICES

FOR THE PRODUCTION OF SURGICAL MASKS WITH FILTRATION EFFICIENCY OF NO LESS THAN 95% (N95)

CAPACITY: 50 FOLDED N95 MASKS PER MINUTE

MASK DIMENSIONS: 175mm x 95mm

MATERIAL TYPE: 3 LAYERS OF POLYPROPYLENE NONWOVEN COMPOSITE FIBER

OPERATION CONTROLLED BY LCD TOUCH SCREEN

AUTOMATICALLY ALIGNS 3 ROLLS OF MATERIAL TO FEED IN (OUTER, FILTER AND INNER LAYERS)

PRESSES BOTH SIDES TOGETHER SYMMETRICALLY WHILE WELDING WITH ULTRASONIC HEAD

SPLITS TO 2 SERPATE WELDING DEVICES FOR EARLOOPS AND SENDS TO DIGITAL COUNTER

EARLOOPS ARE FINISHED WITH ULTRASONIC CUTTING AND WELDING

NOSE BRIDGE CAN BE PRODUCED WITH AUTOMATIC FEEDING, CUTTING AND ULTRASONIC WELDING

ULTRASONIC HEADS

VOLTAGE: 220 VOLTS

WATTS CAPACITY: 1500 WATT

FREQUENCY (KHZ): 20 KHZ

WARRANTY PERIOD FOR HEADS: 1 YEAR

COMPONENT MANUFACTURERS

SERVO MOTOR: PANASONIC / SCHNEIDER

CONTROL SYSTEM: PROPRIETARY

ULTRASONIC GENERATOR: PROPRIETARY, 220 VOLTS, 1.5 KW, 20 KHZ

SENSOR: OMRON / SICK

PNEUMATIC COMPONENT: SMC / FESTO

BELT: SAMSUNG / BANDO

MAIN BODY: PRE-MADE MATERIAL, WELDED ASSEMBLY

BEARINGS: NSK

BALL SCREWS: HIWIN

SECURITY DEVICE: SICK (SAFETY DEVICES TO PROTECT WORKERS)

TOTAL POWER: 4 KW

MACHINE MUST BE STOPPED TO FEED NEW ROLL OF MATERIAL

END OF ROLL DETECTOR INCLUDED: WHEN FABRIC IS FINISHED THE MACHINE WILL ALARM AND STOP

AIR PRESSURE: 0.6 MPa

VOLTAGE: 220 VOLTS, 60 Hz

DIMENSIONS: 6400mm x 4700mm x 1700mm

INCLUDES ELECTRONIC MANUAL BOOK (STORED ON USB MEMORY) AND WARRANTY CARD

OPTIONS (INQUIRE FOR PRICING): EAR STRAP FOLDER

ITEM 001 QUANTITY: 1 MASK PRODUCTION MACHINE AND 2 ULTRASONIC WELDING DEVICES FOR EAR STRAPS

ITEM 002 AUTOMATIC BAGGING MACHINE

SUITABLE FOR AUTOMATIC BAGGING OPERATIONS FOR VARIOUS MASK TYPES

MOTOR CONTROL SYSTEM: SERVO (3), AUTOMATICALLY SETS BAG LENGTH (UP TO 400mm) FOR SPECIFIED BAGGING LENGTH, WITH ANTI-AIR BAG , AUTOMATICALLY DETECTS PRODUCT BASE POINT AND MATERIAL POSITION, AUTOMATIC STOP WHEN OUT OF MATERIAL & STARTS WHEN MATERIAL IS PRESENT

FAST & CONVENIENT SETTING OF PARAMETERS, STORES SETS OF PARAMETERS FOR MULTIPLE PRODUCTS, OPERATOR CAN CHOOSE PARAMETERS ACCORDING TO PRODUCT SIZES

DIAGNOSTICS SYSTEM CLEARS ERROR & RESETS IN SINGLE STEP

HIGHLY SENSITIVE PHOTOELECTRIC EYE COLOR MARK TRACKER, DIGITAL INPUT SEAL/CUT POSITION MAKES SEAL & CUT POSITIONS MORE ACCURATE

TEMPERATURE CONTROLLED WITH INDEPENDENT PID, ALLOWS FOR VARIOUS MATERIALS IN PACKAGING

SIMPLE TRANSMISSION SYSTEM ALLOWS FOR EASY MAINTENANCE AND RELIABILITY

ALL CONTROLS SET BY SOFTWARE ALLOWING FOR ADJUSTING OF FUNCTIONS AND UPGRADES

MATERIALS

PVC FILM (HEAT SEALING), BOPP, OPP, CPP, ALUMINIZED PET FILM, ALUMINUM-PLASTIC FILM, PAPER FILM, PAPER GLUE, OTHER SINGLE- OR MULTIPLE-LAYERED HEAT-SEALED DIALYZABLE MATERIALS, ETC.

LENGTH OF PACKAGE BAGS: ≤400mm

WIDTH OF PACKAGE BAGS: 100 TO 165mm

HEIGHT OF PRODUCT: 55mm MAXIMUM

LENGTH OF FILM: 360mm MAXIMUM

DIAMETER OF FILM ROLL: 320mm MAXIMUM

CAPACITY/SPEED OF PACKAGING: 40 TO 230 BAGS PER MINUTE (1 TO 20 PIECES PER BAG)

POWER: 220 VOLTS, 50 OR 60 Hz, 2.4 KW

DIMENSIONS: 4050mm x 750mm x 1450mm

WEIGHT: APPROXIMATELY 300 KGS

COMPONENT MANUFACTURERS

TOUCH SCREEN: WEINVIEW

SERVO MOTOR: DORNA / WEIDE

SERVO CONTROLLER: DORNA / WEIDE

PROXIMITY SWITCH: OMRON

PHOTOELECTRIC SWITCH: OETAI

TEMPERATURE CONTROLLER: YATAI

SOLID STATE RELAY: SCHNEIDER

INTERMEDIATE RELAY: WEIDMUELLER

OPTIONS, INQUIRE FOR PRICING: STRAIGHT GRAIN SEALING, STAINLESS STEEL FRAME, CODE STAMPER (PRODUCTION DATE), EXHAUST (PINHOLE EXHAUST FEATURE)

ITEM 002 QUANTITY: 1 BAGGING MACHINE

ENTIRE LINE COMPOSED OF ITEM 001 AND ITEM 002

Learn More -

J-2640 DYEING AND FINISHING PLANT FOR SALE

J-2640 DYEING AND FINISHING PLANT FOR SALEREFERENCE NUMBER: J-2640

DYEING AND FINISHING PLANT FOR SALEITEM 001

THIES SAMPLE DYEING MACHINE

MODEL: MINISOFT SAMPLE

CAPACITY: 50 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 002

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

3 PORT SPLIT/SPLIT

CAPACITY: 900 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 003

THIES DYEING MACHINE

MODEL: ECOSOFT PLUS

2 PORT SPLIT/SPLIT

CAPACITY: 600 KGS

YEAR: 1999

MICROPROCESSOR CONTROL

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 004

THIES DYEING MACHINE

MODEL ECOSOFT PLUS

1 PORT SPLIT/SPLIT

CAPACITY: 300 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: A460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 005

GASTON COUNTY DYEING MACHINE

MODEL: AQUAFLOW

2 PORT

CAPACITY; 250 KGS

YEAR: 1987

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING AND UNLOADING REEL

QUANTITY: 1ITEM 006

THIES DYEING MACHINE

MODEL: SOFT TRD

2 TUBE

CAPACITY: 700 KGS

YEAR: 1999

MICROPROCESSOR CONTROLLED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

SINGLE ADD TANK WITH MIXER

HEAT EXCHANGER

ALL PUMPS AND MOTORS

LOADING REEL AND FABRIC EXIT PLAITOR

QUANTITY: 1ITEM 007 (also our J-2647)

LAFER OPEN WIDTH COMPACTOR MACHINE

MODEL: KSA 500 2400/2200

YEAR: 1998

LAFER TEXEN CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY, VERTICAL PIN CHAIN, WITH PLATE GUIDES, RAIL OPENING, PINNING BRUSHES, PINS ONLY, WITH SUPPORT SECTION FOR THE FABRIC IN THE CENTER, AT 10’ THERE IS A STEAMING SECTION, TOTAL LENGTH OF THE TENTER IS 30’, WITH AUTOMATIC LUBRICATION FOR THE CHAIN

• KSA 500 COMPACTOR BENCH WITH TEXEN CONTROLS

• TENSIONLESS FABRIC CONVEYOR

• PLAITOR AND FABRIC SCRAY WITH OPTICAL LOAD SENSOR

• INLINE INSPECTION BATCHER MACHINE, WITHH A BACK LIGHTED BOARD, MANUAL CUT

• SCALE TO WEIGHT THE FABRIC

QUANTITY: 1ITEM 008 (also our J-2648)

SANTEX TUBULAR 4-ROLL EXTRACTION PAD

MODEL: SANTASTRETCH PLUS 140

YEAR: 1998

COMPOSED OF TURNTABLE, DETWISTER, TUBULAR 4-ROLL PAD WITH WET SPREADERS, PLAITOR

WITH ADDITION TANKS FOR SOFTENER

REEL FABRIC PLAITOR EXIT

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 009

SANTEX CONVEYOR DRYER FOR OPEN WIDTH AND TUBULAR FABRIC

MODEL: SANTASHRINK 4/5240

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION BAR ENTRY TO LATTICE ROLL GUIDER TO

• (2) SANTEX 2-ROLL PADS, RUBBER OVER RUBBER, 102” WIDE x 12” DIAMETER, STAINLESS STEEL PAN, 10-TON PAD, SWING-AWAY PAN, TENSION BAR WITH 2 STAINLESS STEEL MIXING TANKS, 75 GALLONS EACH

• DRIVEN SCROLL ROLLS WITH EDGE GUIDE CONTROL, WIDTH 95”

• OPERATOR’S PLATFORM

• PUP TENTER WITH KNIT ENTRY 45°, YEAR 1998, VERTICAL PIN CHAIN, 30’ LONG WITH TANDEMATIC PLATE GUIDES, RAIL GUIDES, PINNING BRUSHES, GUIDE SUPPORT FOR THE FABRIC, FABRIC CONVEYOR TO ENTER BOTH TUBULAR OR OPEN WIDTH FABRIC TO

• CONVEYOR DRYER 100” WIDE, 5 ZONES, 3-PASS WITH MAXON BURNERS, 5 CIRCULATING FANS TO CONVEYOR BELT TO PLAITOR

• ALL MOTORS AND SANTEX CONTROLS AND MONITORS

QUANTITY: 1ITEM 010

SANTEX AG TUBULAR COMPACTOR MACHINE

MODEL: SANTASPREAD 140

YEAR: 1998

SANTEX CONTROLS

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSIONS BAR ENTRY

• OPERATOR’S PLATFORM

• TENSION DEVICE

• DRIVEN SPREADER BARS

• STEAMING DEVICE

• TUBULAR COMPACTING BENCH

• FELT BLANKET ONTO THE CONVEYOR BELT

• PRECISION PLAITOR

• TABELTOP ELECTRONIC SCALE

QUANTITY: 1ITEM 011

COMET NAPPER

MODEL: PEGSO-X4

YEAR: 1998

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

24 ROLLS WITH TURNING BARS FOR TUBULAR 90” WIDE

XYCOM CONTROLS

12-BAG COLLECTION SYSTEM AND PLAITOR

YEAR: 1996

QUANTITY: 1ITEM 012

STENTEX TENTER FRAME

MODEL: STENTOTHERM 3300

YEAR: 1999

STENTEX CONTROLS

VOLTAGE: 480 VOLTS, 3-PHASE, 60 Hz

COMPOSED OF:

• TENSION ENTRY TO TEXT-STAR TYPE GUIDER TO 2 ROLL PAD

• ADDITION TANK TOP SCRAY PAD TO TEXT-STAR TYPE GUIDER

• TWO ROLL PAD R/R 10 TON

• OPERATOR’S PLATFORM

• WORKING WIDTH 1800mm

• HORIZONTAL PIN CHAIN, KNIT ENTRY

• TANDEMATIC SPLITLEVEL DECURLERS

• OVERFEED

• PINNING BRUSHES

• STEAM BOX

• RAIL GUIDERS, 20 FEET ENTRY, 8 ZONES

• 80 FEET HOUSING

• SCREEN MONITORS

• GAS FIRED, MAXON OVEPAK 408 BURNERS

• HONEYWELL CONTROLS

• 3 FEET COOLING ZONE

• 2 COOLING CANS, SELVEDGE TRIMMERS

• PLIATOR, SCRAY

• ZONE IN LINE INSPECTION BATCHER

QUANTITY: 1ITEM 013

ZIMMER ROTARY SCREEN PRINTING MACHINE

MODEL: R92-S153

YEAR: 1993

COMPOSED OF:

• TENSION BAR SKY ENTRY

• SCRAY

• CORINO BRUSH

• CORINO PRINT GUIDER

• ZIMMER PRINTER, 8 COLOR, 86” BLANEKT

• PRINT CONVEYOR DRYER, 30’ LONG, 3-ZONE, GAS FIRED

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1ITEM 014

Learn More

SAFETY SWITCH BULLET NOSE SLITTER

MODEL: CUTTING

WITH REEL FABRIC PLIATOR

VOLTAGE: 460 VOLTS, 3-PHASE, 60 Hz

QUANTITY: 1