Search results for: 'compression+machine'

- Related search terms

- compression+machine'[0]

- compression+machine'

-

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)

L-1502 DOUBLE COLUMN COMPUTER CONTROLLED ELECTRONIC UTM MODEL UE2410 TENSILE TESTER (FOR FOAM OR FABRIC)REFERENCE NUMBER: L-1502

Learn More

MODEL: UE2410

QUANTITY: 1 -

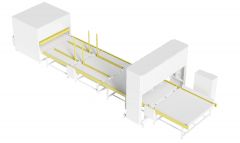

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

H-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mmH-1305 BATT FEEDING SYSTEM - WORKING WIDTH 3000mm

WORKING WIDTH: 3000mm

CONTROL SYSTEM INCLUDEDCOMPOSITION OF THE MACHINE:

- LOWER PVC INCLINED CONVEYOR BELT FOR THE TRANSPORT OF THE WEB FROM THE CROSS LAPPER TO THE ENTRANCE OF THE NEEDLE LOOM.

- UPPER PVC COMPRESSION BELT FOR THE PRE-COMPRESSION OF THE WEB BEFORE ENTERING THE FEEDING ROLLS.

- LOWER PVC CONVEYOR AND UPPER PVC BELT DRIVEN BY ONE GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- PAIR OF FEEDING ROLLS WITH PLASTIC FINGERS TO GUIDE THE COMPRESSED WEB CLOSE TO FIRST NEEDLE ZONE OF THE PRE-NEEDLE LOOM. ROLLER PAIR DRIVEN BY GEARBOX MOTOR WITH INDEPENDENT FREQUENCY INVERTER.

- BATT FEEDING SYSTEM INSTALLED ON RAIL SYSTEM AND EASY REMOVABLE FOR MAINTENANCE OF THE NEEDLE LOOMTECHNICAL DATA:

ELECTRICAL INFORMATION:

ELECTRIC: MAIN VOLTAGE 400 V, 50 HZ, 3 PH.

CONTROL VOLTAGE: DC - 24 V / AC - 230 V

OTHER INFORMATION:

AIR PRESSURE (CONSTANT): MIN. 6 BAR (AT SITE)

OPERATOR SIDE LEFT OR RIGHT (IN WEB RUNNING DIRECTION)

LACQUER COATING:

MAIN COLOR OF THE MACHINES: RAL 7035 (LIGHT GREY)

CONTROL CABINET AND CONTROL DESK RAL 7035 (LIGHT GREY)

LABELING: ENGLISH

TECHNICAL DOCUMENTATION: ONE TIME ON CD-ROM (FURTHER SETS AVAILABLE AT ADDITIONAL COST)

LANGUAGE FOR OPERATING INSTRUCTIONS: ENGLISH

LANGUAGE FOR FURTHER DOCUMENTATION (SPARE PART LISTS, WIRING DIAGRAM, ETC): ENGLISHENVIRONMENTAL CONDITIONS:

INSTALLATION HEIGHT ABOVE SEA LEVEL: LESS THAN OR EQUAL TO 1,000 METERS

TEMPERATURE: 24° C (±2° C)

RELATIVE HUMIDITY: 65% (±5%)

ABSOLUTE WATER CONTENT: 9 TO 12 G/KG DRY AIR

NOTE: PLEASE MAKE SURE THAT THE TEMPERATURE INSIDE THE CONTROL CABINET DOES NOT EXCEED 450 CENTIGRADE. IN CASE OF EXCESSIVE ROOM TEMPERATURES WE RECOMMEND AN AIR-CONDITIONING SYSTEM FOR THE CONTROL CABINETS TO AVOID MALFUNCTION OF ELECTRICAL COMPONENTSQUANTITY: 1

Learn More -

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

C-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MWC-3994 BARGEMOUNTED POWER PLANT, CAPACITY 220MW

A. ONCE THROUGH STEAM GENERATOR

B. BARGE

C. CHILLERS

D. AIR COMPRESSOR

E. GAS TURBINE

F. STEAM TURBINE

G. FEEDWATER SYSTEM

H. CLOSED COOLING WATER SYSTEM

I. AUXILIARY COOLING WATER SYSTEM

J. CONDENSATE POLISHING UNIT (CPU)

K. WASTE WATER SYSTEM

L. PLANT ELECTRICAL SYSTEM

M. BLACK START DG SET

N. PLANT CONTROLS AND INSTRUMENTATION

O. PLANT FIRE FIGHTING SYSTEM

P. START UP VACUUM SYSTEM

Q. STEAM TURBINE DEAERATING CONDENSERQUANTITY: 1 PLANT

Learn More -

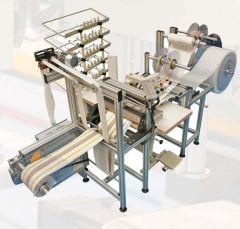

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More

G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERSREFERENCE NUMBER: G-7000 VERTICAL QUILTING MACHINES FOR MATTRESS BORDERS MODEL PM25 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 25 DISTANCE BETWEEN NEEDLES: 6.2mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST MODEL PM33 DIMENSIONS: 3000 x 1000 x 1600mm SEWING AREA: 152mm MAX FABRIC WIDTH: 400mm POWER: 1500kw NEEDLES: 33 DISTANCE BETWEEN NEEDLES: 406mm PNEUMATIC AIR COMPRESSION: 6kg DOUBLE CHAIN STITCH SPEED: UP TO 6 METERS PER MINUTE ULTRASONIC POWER: 150w VOLTAGE: PER CUSTOMER REQUEST QUANTITY AVAILABLE: 2 Learn More -

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More

TT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXITTT-2026 AUTOMATIC GLUE SPRAY MACHINE, WIDTH 850 TO 2200mm WITH BRIDGE AND CONVEYOR AND PRESS AT THE EXIT AUTOMATIC GLUE SPRAY MACHINE APPLICATION: THE AUTOMATIC GLUE SPRAY MACHINE IS HIGHLY AUTOMATED. THROUGH INFRARED MEASUREMENT, IT CAN AUTOMATICALLY IDENTIFY THE HEIGHT AND WIDTH OF THE MATERIAL, AND AUTOMATICALLY ADJUST THE POSITION OF THE GLUE NOZZLE FOR SPRAYING ACCORDING TO THE DETECTION HEIGHT. AUTOMATIC GLUE SPRAY MACHINE CAN COMPLETE SUCH PROCESSES AS AUTOMATICALLY GLUE SPRAYING, PNEUMATIC TURNING OVER OF THE UNIT AND AUTOMATICALLY PRESSING. WITH PLC CONTROL, HIGH PRODUCTION EFFICIENCY, SINGLE SPRAYING IS ABOUT 30 SECONDS PER SHEET. IT IS SUITABLE FOR SHEETS WITH WIDTH OF 850 TO 2200mm AND HEIGHT OF 5 TO 400mm THE GLUE SPRAYING MACHINE IS SUITABLE FOR FOAM, LATEX, MATTRESS AND HOME TEXTILE INDUSTRIES. Learn More -

J-5305 FINISHING PLANT FOR WORSTED AND WOOLENJ-5305 FINISHING PLANT FOR WORSTED AND WOOLEN SPLIT SALE POSSIBLE Learn More

J-5305 FINISHING PLANT FOR WORSTED AND WOOLENJ-5305 FINISHING PLANT FOR WORSTED AND WOOLEN SPLIT SALE POSSIBLE Learn More -

TT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mmTT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mm FILLMATIC STUFFING MACHINE WORKING WIDTH 2000mm TYPE OF MACHINE: FU 200/24 LENGTH: 65” 1650mm LENGTH WITH INFEED CONVEYOR: + +) 18.3” 4650mm 15’3” WIDTH: 114” 2900mm 9’6” HEIGHT: 57” 1450mm WEIGHT: 2100 KG INSTALLED LOAD: 6.05 KW 400 V 50 Hz THREE PHASE NUMBER OF FILLING ARMS: 8 LENGTH OF FILLING ARMS: 49” 1250mm MACHINE ADJUSTMENT: 24.4 - 78.74 WIDTH: 620 TO 2000mm MINIMUM WIDTH WITH 4 PISTOLS: 27.55 700mm HEIGHT: 5.51” - 9.44 - 140 TO 240mm MATTRESS WIDTH: 78.74” - 2000mm MATTRESS HEIGHT: 11.02” - 280mm TYPE OF MATTRESSES TO BE WRAPPED: INNER SPRING, ALL FOAM, LATEX WORKING SPEED: 30 M/MIN. +) MAXIMUM HEIGHT DEPENDS ON FOAM DENSITY AND COMPRESSABILITY. MINIMUM HEIGHT AND WIDTH MAY NOT BE ATTAINED AT THE SAME TIME. + +) CONTAINED WITHIN SCOPE OF DELIVERY. QUANTITY: 1 Learn More

TT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mmTT-1162 FILLMATIC FU 200/24 UNIVERSAL FILLING MACHINE, WORKING WIDTH 2000mm FILLMATIC STUFFING MACHINE WORKING WIDTH 2000mm TYPE OF MACHINE: FU 200/24 LENGTH: 65” 1650mm LENGTH WITH INFEED CONVEYOR: + +) 18.3” 4650mm 15’3” WIDTH: 114” 2900mm 9’6” HEIGHT: 57” 1450mm WEIGHT: 2100 KG INSTALLED LOAD: 6.05 KW 400 V 50 Hz THREE PHASE NUMBER OF FILLING ARMS: 8 LENGTH OF FILLING ARMS: 49” 1250mm MACHINE ADJUSTMENT: 24.4 - 78.74 WIDTH: 620 TO 2000mm MINIMUM WIDTH WITH 4 PISTOLS: 27.55 700mm HEIGHT: 5.51” - 9.44 - 140 TO 240mm MATTRESS WIDTH: 78.74” - 2000mm MATTRESS HEIGHT: 11.02” - 280mm TYPE OF MATTRESSES TO BE WRAPPED: INNER SPRING, ALL FOAM, LATEX WORKING SPEED: 30 M/MIN. +) MAXIMUM HEIGHT DEPENDS ON FOAM DENSITY AND COMPRESSABILITY. MINIMUM HEIGHT AND WIDTH MAY NOT BE ATTAINED AT THE SAME TIME. + +) CONTAINED WITHIN SCOPE OF DELIVERY. QUANTITY: 1 Learn More -

TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN)TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN) KEY SPECIFICATIONS MAX. CAPACITY: 5KN,10KN, 20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm EXTENSOMETER RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN, 0.001-1000mm/MIN WALKING SPACE: 1500mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER SUPPLY: AC 220V 50/60Hz 10A DIMENSIONS: 750 X 700 X 1700mm (W X D X H) WEIGHT: 170KG QUANTITY: 1 Learn More

TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN)TT-1039 RUBBER AND LEATHER UNIVERSAL TESTING MACHINE (DUAL COLUMN) KEY SPECIFICATIONS MAX. CAPACITY: 5KN,10KN, 20KN DISPLAY: COMPUTER DISPLAY MODE FORCE RESOLUTION: 1/100,000 FORCE ACCURACY: ≤+/-0.5% STROKE RESOLUTION: 0.001mm EXTENSOMETER RESOLUTION: 0.001mm TEST SPEED: 0.001-500mm/MIN, 0.001-1000mm/MIN WALKING SPACE: 1500mm (IT CAN BE CUSTOM-TAILOR ACCORDING TO THEIR REQUIREMENTS) FORCE UNIT SWITCH: KGF, N, IBF, G, TON, MPA STOP MODE: OVERLOAD STOP, EMERGENCY STOP BUTTON, SPECIMEN DAMAGE AUTOMATIC STOP, UPPER & LOWER LIMIT SET AUTOMATIC STOP, AUTOMATIC RESET FUNCTION MACHINE DRIVE: SERVO MOTOR DRIVE, SYNCHRONOUS WHEEL AND PRECISION BALL SCREW DRIVE POWER SUPPLY: AC 220V 50/60Hz 10A DIMENSIONS: 750 X 700 X 1700mm (W X D X H) WEIGHT: 170KG QUANTITY: 1 Learn More -

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More

YY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFFYY-2169 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE, PILLOW COVER PACKING MACHINE WITH CONVEYOR FEEED AND TAKE OFF DETAILS: ITEM 001 PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE THIS MACHINE IS USED FOR PILLOWS, CUSHIONS AUTOMATICALLY PACKAGE. QUANTITY: 1 ITEM 002 PILLOW COVER PACKING MACHINE QUANTITY: 1 NOTE: THE PILLOW COVER PACKING MACHINE IS USUALLY WORKED TOGETHER WITH THE PILLOW VACUUM COMPRESS AND ROLL PACKING MACHINE. Learn More -

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More

TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022TT-2175 ANTISLIP LAMINATING & PVC BACK-COATING LINE, WORKING WIDTH MINIMUM 1200mm, YEAR 2022 -FOR CARPET INDUSTRY WORKING WIDTH: MINIMUM 1200mm, MAXIMUM 4000mm WORKING SPEED: 7 METERS PER MINUTE PRIMARY GOODS: RUG AND BLANKET AND FABRIC COATING TYPE: PVC PLANT CAN BE USE FOR CARPET, FELT AND FABRIC FIRST FELT IS LAMINATED ON THE BACK FROM THE CARPET SECOND DOTTING FLEXIBLE PVC BACKING CARPET FELT PLANT IS BRAND NEW 2022 EXCLUSIVE TRANSPORT, FLIGHT TICKETS, HOTEL ACCOMODATION, FOOD & DRINKS QUANTITY: 1 Learn More