Search results for: 'fabric p'

- Related search terms

- Fabric cu

- fabrics

- fabric d

- fabric cutting machine

- fabric roll

-

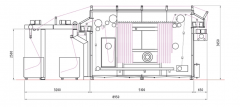

MELTBLOWN FABRIC PRODUCTION MACHINE, 600 mmREFERENCE NUMBER: A-2484 MELTBLOWN FABRIC PRODUCTION MACHINE, 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600 mm PRODUCTION SPEED: 300 KG/24 HOURS EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 18.5 KW PRODUCT WEIGHT RANGE:25 TO 30 GSM MAX OUTPUT: 350 KG/24HOURS DIMENSION: 7500 X 1800 X 2550 mm WEIGHT: 3.3 TONS POWER (TOTAL KW): 2.2 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 25 DAYS Learn More

MELTBLOWN FABRIC PRODUCTION MACHINE, 600 mmREFERENCE NUMBER: A-2484 MELTBLOWN FABRIC PRODUCTION MACHINE, 600 mm MACHINE TYPE: MELTBLOWN WORKING WIDTH: 600 mm PRODUCTION SPEED: 300 KG/24 HOURS EXTRUDER DIAMETER IN mm: 65mm EXTRUDER MOTOR IN KW: 18.5 KW PRODUCT WEIGHT RANGE:25 TO 30 GSM MAX OUTPUT: 350 KG/24HOURS DIMENSION: 7500 X 1800 X 2550 mm WEIGHT: 3.3 TONS POWER (TOTAL KW): 2.2 KW VOLTAGE: 220 VOLTS AND 50/60 Hz QUANTITY OF CONTAINERS NEEDED: 1 X 40 PRODUCTION TIME: 25 DAYS Learn More -

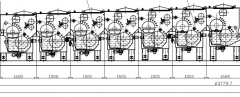

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWN

L-7134 PP NONWOVEN FABRIC PRODUCTION LINE, SPUNBONDED, MELT BLOWNEFFECTIVE WIDTH: 1600mm

DAILY OUTPUT: 10,000 KGS PER DAY

WEIGHT RANGE: 10 TO 150 GSM

FILAMENT DIAMETER: 1.6 TO 2.0 DENIER

SPEED: 350 TO 400 METERS PER MINUTE

RAW MATERIAL: POLYPROPYLENE (PP)

DIMENSIONS: 35,000 X 15,000 X 11,000mm

VOLTAGE: 380 VOLTS, 3 PHASECONSISTING OF:

SPUNBOND EQUIPMENT

PP VACUUM SUCTION MACHINE (2)

7800 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS PER HOUR

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

ACCURACY: 0.01%EXTRUDER (2)

DIAMETER: 130mm

SINGLE SCREW (2)

HEATING SYSTEM: ELECTRICITY

MOTOR: 75 KWMELT FILTRATION MACHINE (2)

PIPE SIZE: 50mm

FILTER AREA: 3.5 SQUARE METERS

MELT FLOW: 650 KGS PER HOUR

DOUBLE FILTRATION CHAMBERMELTING PUMP (2)

40 RPM

FLOW CAPACITY: 400 KGS PER HOUR

POWER: 7.5 KWSPINNING BEAM (2)

DIMENSIONS: 1900 X 256mm

HANGER TYPE MELT DISTRIBUTION

HEATING SYSTEM: OIL

WORKING TEMPERATURE: 200 TO 260 CELSIUSSPINNERET (4)

HARDNESS: 30

SIZE: 1900mm LONG X 256mm WIDE

HOLE DIAMETER 0.45mm

HOLE QUANTITY: 6500 HOLE PER METERQUENCHING UNIT (2)

WORKING TEMP: 20 CELSIUS

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

AIR PRESSURE: 6500

FILTER SIZE: 80#FILAMENT DRAFT UNITS (2)

AIR PRESSURE: 5020PA

AIR FLOW CAPACITY: 12,000 CUBIC METERS/H

INSIDE TEMP: 10 TO 25 CELSIUS

FILAMENT FINENESS: 1.6 TO 2.0 DENIERMELT BLOWN EQUIPMENT

VACUUM SUCTION MACHINE (2)

LOAD CAPACITY: 700 TO 900 KGS PER HOUR

AIR CAPACITY: 300 CUBIC METERS/H

POWER: 7.5 KWMASTER BATCH DOSING UNIT (2)

4 HOPPERS

200 KGS HOPPER LOADEXTRUDER

DIAMETER: 105mm

SINGLE SCREW

MOTOR: 18.5 KWMELT FILTER

DOUBLE CYLINDER

HYDRAULIC

MELT FLOW CAPACITY: 450 KGS/HR

FILTER SIZE: 150mm DIAMETER

ELECTRIC HEATINGMELTING PUMP

SPEED: 40 RPM

MELT FLOW CAPACITY: 450 KGS PER HOUR

POWER: 7.5 KWMELT BLOWN DIE SPINNARET

SPINNERET HOLE SIZE: 0.32 TO 0.35mm

HOLE DISTANCE: 40 TO 42 PER INCH

FABRIC WEIGHT: 2 TO 200 GSMHIGH PRESSURE AIR BLOWER

AIR FLOW CAPACITY: 70 TO 100 CUBIC METERS PER MINUTE

AIR PRESSURE: 100 KPA

POWER: 200 KWWEB FORMING MACHINE

SPEED: 100 METERS PER MINUTEELECTRIC TREATMENT

VOLTAGE: 220 VOLTS, 50 Hz

INPUT CURRENT: 3A

OUTPUT VOLTAGE: 60 KV

TREAT WEB WIDTH: 1.6 METERSHOT AIR HEATING MACHINE

WORKING TEMP: 350 CELSIUS

PRESSURE: 0.8 KPA

HEATING: ELECTRIC

POWER: 200 KWTHERMAL CALENDER

PROCESSING SPEED: 400 METERS PER MINUTE

ROLLER SIZE: 2000mm LONG, 520mm DIAMETER

EMBOSSING ROLLER: 1

LINEAR PRESSURE: 30 TO 125 N/mm

HEATING SYSTEM: OILHYDROPHILIC MACHINE

SPEED: 400 METERS PER MINUTE

FEEDING SYSTEM: DOUBLE KISSING ROLLER

KISS ROLLER DIAMETER: 215mm

LIQUID TANK: 200 KGS WITH HEAT/WARM AND MIXDRYING SYSTEM:

INFRARED + HOT AIR

DRIVE ROLL SIZE: 150mm

HEATING EQUIPMENT: QUARTZ HEATER, HOT AIR BLOWER, EXHAUST AIR BLOWERINSPECTION MACHINE

EFFECTIVE WIDTH: 1600mm

INSPECTION SPEED: 400 METERS PER MINUTE

INSPECT GSM: 10 TO 40 GSMAUTOMATIC WINDING MACHINE

SPEED: 400 METERS PER MINUTE

ROLLER DIAMETER: 2000mm

ROLLER EXCHANGE SYSTEM: AUTOMATIC

FABRIC INSPECTOR: ONLINE

POWER: 15 KWHIGH SPEED SLITTING MACHINE

PROCESS SPEED: 800 METERS PER MIN

ROLL DIAMETER: MAX 1500mm

SLITTING WIDTH: 80mm

PAPER TUBE SIZE: 76mm DIAMETER

AUTO TENSILE CONTROL: AVAILABLE ONLINE

METER COUNTING: AVAILABLE ONLINEOIL HEATER (4)

HEATING POWER: 60 KW

MOTOR POWER: 7.5 KW

OIL PUMP FLOW: 30 CUBIC METERS PER SECOND

PRESSURE: 0.4 KPAWATER CHILLER

DRIVE SYSTEM: SCREW

COOLING CAPACITY: 300,000 CALORIES

TEMP: 0 TO 20 CELSIUS

POWER: 110 KWAIR BLOWER

SPEED: 1450 RPM

AIR BLOW CAPACITY: 12,000 CUBIC METERS PER HOUR

PRESSURE: 5200 PA

POWER: 30 KW x 3, 45 KW x 1AIR COMPRESSOR

DRIVE SYSTEM: SCREW

PRESSURE: 0.8 KPA

POWER: 15 KWHEATING SYSTEM: ELECTRIC

TEMP: 350 CELSIUS

HEATING TIME: 6 TO 8 HOURS

POWER: 4 KWULTRASONIC CLEANING MACHINE

3mm THICK

SIZE: 2000 X 500mm

FREQUENCY VIBRATION: 100 KHZ

TEMP: 40 CELSIUSELECTRONIC PANEL BOARD

PLATFORM

Learn More -

PP-1141 MISCELLANEOUS RAW MATERIALS, FABRIC, INNERSPRINGS, ETC. FROM MATTRESS PLANT

PP-1141 MISCELLANEOUS RAW MATERIALS, FABRIC, INNERSPRINGS, ETC. FROM MATTRESS PLANTMISCELLANEOUS RAW MATERIALS, FABRIC, INNERSPRINGS, ETC. FROM MATTRESS PLANT

Learn More -

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNIT

J-1590 CIBITEX EASYCOAT-DRY FABRIC DYEING PRE-TREATMENT UNITMAKE: CIBITEX

COMPACT UNIT FOR PRE-TREATMENT AND DRYING OF FABRICS PRINTED USING BOTH ACID, REACTIVE OR PIGMENTED INKS

MAXIMUM WORKING WIDTH: 1800mm

POWER INSTALLED: 82 Kw

VOLTAGE: 400 V 50Hz

MAXIMUM CYLINDERS TEMPERATURE: 210 °C

INTERNAL CONTENT (DEPENDING ON FABRIC): 300 M

MAX LOAD: 280 KG

COATING BASIC CAPACITY: 40 L

DIMENSIONS: 3500 X 4600 X 1890mm

WEIGHT: 4,935 KGQUANTITY: 1

Click here to watch the videos of this machine on YouTube.

Learn More -

J-1589 MS PRINTING SOLUTIONS ECOVAPOR 110 FABRIC STEAMER, 110 METER CAPACITY – YEAR 2016

J-1589 MS PRINTING SOLUTIONS ECOVAPOR 110 FABRIC STEAMER, 110 METER CAPACITY – YEAR 2016MAKE: MS PRINTING SOLUTIONS

MODEL: ECOVAPOR 110

FABRIC CAPACITY: 110 M

ROLLER WIDTH: 2200mm

SATURATED STEAM OPERATION: 102 TO 106 ⁰C

STEAM CONSUMPTION: 400 TO 600 KG/H

HIGH TEMPERATURE OPERATION: 180 ⁰C

TEMPERATURE DIATHERMIC OIL: 260 ⁰C

INSTALLED THERMIC POWER: 64,000 KCAL/H

WORKING SPEED: 2 TO 20 METERS/MINUTE

DWELL TIME: 5,5 TO 55 MINUTES

INSTALLED ELECTRIC POWER: 16 kVA

AIR COMPRESSED CONSUMPTION: 2 L/MIN

AIR COMPRESSED SUPPLY: 2 BAR

VOLTAGE: 400V 50/60HzQUANTITY: 1

Click here to watch the videos of this machine on YouTube.

Learn More -

L-4085 HIGH-SPEED CNC FOAM AND NONWOVEN TRAVELLING HEAD CUTTING PRESS- 30 TONS – AMAZING!! 1500 mm FABRIC CUT WIDTH , 500 X500mm CUTTING HEAD

L-4085 HIGH-SPEED CNC FOAM AND NONWOVEN TRAVELLING HEAD CUTTING PRESS- 30 TONS – AMAZING!! 1500 mm FABRIC CUT WIDTH , 500 X500mm CUTTING HEADREFERENCE NUMBER: L-4085

Learn More

STANDARD MODEL

CUTTING WIDTH: 1500mm

BELT WIDTH: 1600mm

AXES MOTOR POWER: 7.5 nm BRUSHLESS

PUMP MOTOR POWER: 4 KW TO 5.5 HP

AIR PRESSURE: 7 TO 10 BAR, 200 lt/min

TOTAL POWER: 10 KW

DIMENSIONS: 3120mm WIDE X 5220 DEEP x 2390mm HIGH

WEIGHT: 4460 KGS -

V-1177 GEOTEXTIL NEEDLE PUNCH PRODUCTION LINE, FINAL FABRIC WIDTH 6000mm

V-1177 GEOTEXTIL NEEDLE PUNCH PRODUCTION LINE, FINAL FABRIC WIDTH 6000mmV-1177 GEOTEXTIL NEEDLE PUNCH PRODUCTION LINE, WORKING WIDTH 2500mm TO 7400mm, YEAR 1992 TO 1994

OFFER 001

PRODUCTION SPEED: 20 M/MIN

WEIGHT: 130 TO 600 G/M²COMPOSED OF:

OFFER 002

HERGETH CARDINGOFFER 003

ASSELIN CROSSLAPPEROFFER 004

FEHRER PRE-NEEDLINGOFFER 005

FEHRER NEEDLINGOFFER 006

ACCUMULATORQUANTITY: 1 LINE

Learn More -

P7300 SULZER LOOM 3300mm YEAR 2005-FOR HEAVY DUTY INDUSTRIAL FABRICS-WITH CREELP7300 SULZER LOOM WIDTH 3300mm (130") WORKS FROM CREEL (NO WARP BEAMS) INCLUDES SPECIAL WARP DELIVERY UNITS INTEGRATED IN THE LOOM 2 COLORS CAM MOTION YEAR 2005 LOOM WERE WEAVING CONVEYOR FABRIC WITH 500 AND 1000 DENIER YARN AVAILABLE FOR EACH LOOM: -CLOTH TENSION WHILE MACHINE RUNNING, CLOTH TENSION WHILE MACHINE STOPPED, CLOTH TAKE UP SPEED -CREEL WITH 3456 POSITIONS; CREEL HELD 5 AND 10 KGS BOBBINS -TWO CENTRAL TUCK IN UNITS 40mm SELVAGE; ULTRASONIC CUTTERS FOR THE EDGES -TWO WEFT FEEDERS ROJ HD10 ONE AUTOMATIC BATCHER (CLOTH WINDER) CREEL RECEIVED CONES EITHETR 5 OR 10 KGS THE 5 KGS BOBBINS HAVE A DIAMETER OF 250mm THE HORIZONTAL GAUGE OF THE CREEL IS 265mm TO PLACE THE 10 KG BOBBINS YOU SKIP ONE POSITION THEY USED POLYESTER HIGH TENACITY FROM KOSA AND INVISTA THE CREEL COMES IN MODULES OF 1152 POSITIONS AND YOU CAN HAVE A CREEL OF 2304 OR 3456 POSITIONS THE CREEL COMES FURTHER DIVIDED IN SECTIONS OF 288 POSITIONS , ONE 1152 MODULE HAS 4 X 288 SECTIONS Learn More

P7300 SULZER LOOM 3300mm YEAR 2005-FOR HEAVY DUTY INDUSTRIAL FABRICS-WITH CREELP7300 SULZER LOOM WIDTH 3300mm (130") WORKS FROM CREEL (NO WARP BEAMS) INCLUDES SPECIAL WARP DELIVERY UNITS INTEGRATED IN THE LOOM 2 COLORS CAM MOTION YEAR 2005 LOOM WERE WEAVING CONVEYOR FABRIC WITH 500 AND 1000 DENIER YARN AVAILABLE FOR EACH LOOM: -CLOTH TENSION WHILE MACHINE RUNNING, CLOTH TENSION WHILE MACHINE STOPPED, CLOTH TAKE UP SPEED -CREEL WITH 3456 POSITIONS; CREEL HELD 5 AND 10 KGS BOBBINS -TWO CENTRAL TUCK IN UNITS 40mm SELVAGE; ULTRASONIC CUTTERS FOR THE EDGES -TWO WEFT FEEDERS ROJ HD10 ONE AUTOMATIC BATCHER (CLOTH WINDER) CREEL RECEIVED CONES EITHETR 5 OR 10 KGS THE 5 KGS BOBBINS HAVE A DIAMETER OF 250mm THE HORIZONTAL GAUGE OF THE CREEL IS 265mm TO PLACE THE 10 KG BOBBINS YOU SKIP ONE POSITION THEY USED POLYESTER HIGH TENACITY FROM KOSA AND INVISTA THE CREEL COMES IN MODULES OF 1152 POSITIONS AND YOU CAN HAVE A CREEL OF 2304 OR 3456 POSITIONS THE CREEL COMES FURTHER DIVIDED IN SECTIONS OF 288 POSITIONS , ONE 1152 MODULE HAS 4 X 288 SECTIONS Learn More -

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More

TT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBERTT-8645 OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC, WORKING WIDTH 1800mm, 5 WASHING CHAMBERS, 2 WASHING DRUMS IN EACH CHAMBER 1. OPEN WIDTH WASHING MACHINE FOR WOVEN FABRIC 2. WORKING WIDTH: 1800mm 3. 5 WASHING CHAMBERS 4. 2 WASHING DRUM IN EACH CHAMBER 5. DRIVING SIDE: (PLEASE SPECIFY) Learn More