Search results for: 'heating+e'

- Related search terms

- heating+el

- heating+eleme

- heating+ele

- heating+elemen

- heating+elem

-

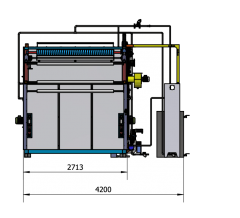

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986V-1360 SANTEX THERMOBONDING COMPRESSION OVEN FOR NONWOVENS ON ROLL, 80 TO 400 G/M, YEAR 1986

WORKING WIDTH: 2500mm

ROLL FACE WIDTH: WORKING WIDTH + 50mm

MATERIAL FIBERS: NONWOVEN WEB OF POLYESTER OR DIFFERENT FIBERS MIXED WITH 10 TO 25% POLYESTER BI-COMPONENT BINDER FIBERS OR DIFFERENT BINDER FIBERS

MACHINE SPEED: 1 TO 20 M/MIN. (OTHERS UPON REQUEST)

COMPOSITION OVEN: 2 HEATING ZONES OF 2 M EACH + 1 COOLING SECTIONQUANTITY: 1

Learn More -

T-9598 TEXTILE COLOR FASTNESS TO WASHING TESTERT-9598 TEXTILE COLOR FASTNESS TO WASHING TESTER KEY SPECIFICATION: CUP COMPOSITE MODE: 2A+2B, 4A+4B, 6A+6B, 8A+8B, 8A+12B, 12A, 8B, CUSTOMIZED AATCC CUP VOLUME (A): 1200ML ISO CUP VOLUME (B): 550ML CONTROL MODE: LCD COUNTER DISPLAY ROTATION SPEED: 40±2 RPM TEMPERATURE CONTROL RANGE: RT TO 100℃ HEATING METHODS: ELECTRICAL HEATING STAINLESS STEEL BALLS:¢6mm STAINLESS STEEL DRY CLEANING DISCS:¢30mm, THICKNESS: 3mm, MASS: 20G POWER SUPPLY: 3∮AC 380V 50/60Hz PACKED DIMENSIONS: 890 x 690 x 1200mm PACKED WEIGHT: 130 KG Learn More

T-9598 TEXTILE COLOR FASTNESS TO WASHING TESTERT-9598 TEXTILE COLOR FASTNESS TO WASHING TESTER KEY SPECIFICATION: CUP COMPOSITE MODE: 2A+2B, 4A+4B, 6A+6B, 8A+8B, 8A+12B, 12A, 8B, CUSTOMIZED AATCC CUP VOLUME (A): 1200ML ISO CUP VOLUME (B): 550ML CONTROL MODE: LCD COUNTER DISPLAY ROTATION SPEED: 40±2 RPM TEMPERATURE CONTROL RANGE: RT TO 100℃ HEATING METHODS: ELECTRICAL HEATING STAINLESS STEEL BALLS:¢6mm STAINLESS STEEL DRY CLEANING DISCS:¢30mm, THICKNESS: 3mm, MASS: 20G POWER SUPPLY: 3∮AC 380V 50/60Hz PACKED DIMENSIONS: 890 x 690 x 1200mm PACKED WEIGHT: 130 KG Learn More -

YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm)YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm) EFFECTIVE WIDTH: 1800mm (ROLL SURFACE 2000mm); CAPACITY: 45M; QUANTITY: 1 Learn More

YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm)YY-2846 NEW STEAMER, EFFECTIVE WIDTH 1800mm (ROLL SURFACE 2000mm) EFFECTIVE WIDTH: 1800mm (ROLL SURFACE 2000mm); CAPACITY: 45M; QUANTITY: 1 Learn More -

TT-6739 FULTON HOT OIL HEATING SYSTEM, YEAR 2014TT-6739 FULTON HOT OIL HEATING SYSTEM, YEAR 2014 1. PREVIOUSLY USED WITH HOLOFLITE DRYERS 2. THERMAL FLUID HEATER 3. MODEL FT-0800C 4. RATED FOR UP TO 8,000,000 BTU/HR OUTPUT AND 9,195,000 BTU/HR INPUT. 5. FEATURES 700.2 SQUARE FEET HEATING SURFACE AREA, QUANTITY: 1 Learn More

TT-6739 FULTON HOT OIL HEATING SYSTEM, YEAR 2014TT-6739 FULTON HOT OIL HEATING SYSTEM, YEAR 2014 1. PREVIOUSLY USED WITH HOLOFLITE DRYERS 2. THERMAL FLUID HEATER 3. MODEL FT-0800C 4. RATED FOR UP TO 8,000,000 BTU/HR OUTPUT AND 9,195,000 BTU/HR INPUT. 5. FEATURES 700.2 SQUARE FEET HEATING SURFACE AREA, QUANTITY: 1 Learn More -

TT-6645 GE FRAME 6B GAS TURBINE, YEAR 1981TT-6645 GE FRAME 6B GAS TURBINE, YEAR 1981 1. 2X GE FRAME 6B GAS TURBINES 2. TECHNICAL SUMMARY 3. GAS TURBINES: TWO GE MS 6001 B GAS TURBINES PAIRED WITH AEG GENERATORS (TYPE S7102/2). QUANTITY: 2 Learn More

TT-6645 GE FRAME 6B GAS TURBINE, YEAR 1981TT-6645 GE FRAME 6B GAS TURBINE, YEAR 1981 1. 2X GE FRAME 6B GAS TURBINES 2. TECHNICAL SUMMARY 3. GAS TURBINES: TWO GE MS 6001 B GAS TURBINES PAIRED WITH AEG GENERATORS (TYPE S7102/2). QUANTITY: 2 Learn More -

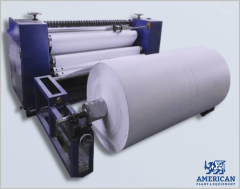

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More

YY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDEYY-2703 SLITTER REWINDER FOR PLASTIC FILMS LABEL MATERIAL, ETC., UP TO 1600mm WIDE FEATURES: HOT BLADE CUTTING SYSTEM FOR WOVEN LABELS COLD BLADE CUTTING SYSTEM FOR NON-WOVEN LABELS EASY OPERATION STABLE WORKING AND LONG LIFE QUANTITY: 1 Learn More -

YY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER HYY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER H OVERCONSUMPTION: 500 KW OUTPUT: 1000 KGS PER HOUR INTENDED FOR THE FOLLOWING WASTE: OUTPUT; BOPP FILM, FLUFF, LUMPS, MDO WASTE: 900 TO 1000 KG/H; CPP FILM, FLUFF, LUMPS: 900 TO 1000 KG/H; PERFORMANCE IS PROVIDED FOR REFERENCE ONLY. THE CAPACITY OF THE DEVICE DEPENDS ON THE PROPERTIES OF THE MATERIAL, E.G. MOISTURE CONTENT, PRINTING, WEIGHT, MELT INDEX, CONTAMINATION AND DEGREE OF FILTRATION. AVERAGE POWER CONSUMPTION: 500 KW; AVERAGE COOLING WATER DEMAND: 668 L/MIN; AVERAGE FRESH WATER CONSUMPTION: 34 L/H; MAXIMUM COMPRESSED AIR CONSUMPTION: 100 L/MIN. THE VALUES GIVEN ABOVE ARE ONLY REFERENCE VALUES AND MAY DIFFER FROM THE VALUES FINAL VALUES OBTAINED AFTER CALIBRATION OF THE DEVICE. THIS DATA SHOULD NOT BE USED FOR PLANNING. Learn More

YY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER HYY-2424 USED NGR REGRANULATION LINE for BOPP FILM, FLUFF, LUMPS, MDO WASTE 900 TO 1000 KG PER H OVERCONSUMPTION: 500 KW OUTPUT: 1000 KGS PER HOUR INTENDED FOR THE FOLLOWING WASTE: OUTPUT; BOPP FILM, FLUFF, LUMPS, MDO WASTE: 900 TO 1000 KG/H; CPP FILM, FLUFF, LUMPS: 900 TO 1000 KG/H; PERFORMANCE IS PROVIDED FOR REFERENCE ONLY. THE CAPACITY OF THE DEVICE DEPENDS ON THE PROPERTIES OF THE MATERIAL, E.G. MOISTURE CONTENT, PRINTING, WEIGHT, MELT INDEX, CONTAMINATION AND DEGREE OF FILTRATION. AVERAGE POWER CONSUMPTION: 500 KW; AVERAGE COOLING WATER DEMAND: 668 L/MIN; AVERAGE FRESH WATER CONSUMPTION: 34 L/H; MAXIMUM COMPRESSED AIR CONSUMPTION: 100 L/MIN. THE VALUES GIVEN ABOVE ARE ONLY REFERENCE VALUES AND MAY DIFFER FROM THE VALUES FINAL VALUES OBTAINED AFTER CALIBRATION OF THE DEVICE. THIS DATA SHOULD NOT BE USED FOR PLANNING. Learn More -

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More

TT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDEDTT-1112 EXTRUSION LAMINATOR, UP TO 2200mm, ONE SIDED LAMINATING MACHINE (480 VOLTS, 3-PHASE, 60Hz) MAIN PROCESS AND PARAMETERS TECHNOLOGICAL PROCESS MAIN UNWINDING, RECTIFYING, EXTRUDING, COMPOUND CUTTING AND REWINDING. MAIN TECHNICAL PARAMETERS 1. RAW MATERIAL: SUITABLE FOR COATING RESIN LDPE, PP AND OTHER COATING BASE MATERIAL. 2. AUXILIARY BASE MATERIAL: PAPER, NON-WOVEN FABRIC, ALUMINUM FILM, WOVEN CLOTH AND OTHER APPLICABLE MATERIALS MECHANICAL SPEED: 60 TO 150 METERS/MINUTE (ACTUAL SPEED DEPENDS ON FILM MATERIAL, FILM WIDTH AND THICKNESS, ETC.) EFFECTIVE WIDTH OF LAMINATING: 1200 TO 2000mm LAMINATING THICKNESS: 0.008 TO 0.080mm LAMINATING THICKNESS ERROR ±5% TENSION SETTING RANGE: 20 TO 200 KG/FULL WIDTH CONSTANT TENSION MAXIMUM EXTRUSION: 200 KG/HOUR INNER DIAMETER OF BASE MATERIAL ROLL CORE: 76mm MACHINE POWER: 100 KW ACTUAL OPERATING POWER IS 50 KW TO 60 KW CONTROL TYPE OF COMPOUND SPEED AND LAMINATING THICKNESS: PLC COMPUTER, FULLY AUTOMATIC ELECTRICAL CONTROL LAMINATING WITH EMBOSSING: SINGLE-LAYER Learn More -

M-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mm

M-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mmM-5175 OLBRICH COATING LINE FOR MANUFACTURING TARPAULIN AND BANNER PVC COATED FABRICS 3300mm

KNIFE OVER ROLL COATING

LIST OF EQUIPMENT FOR MANUFACTURING OF PVC COATED FABRICS, LINE CAN APPLY ANY TYPE OF COATING INCLUDING WATER BASED OR SOLVENT BASED AND EITHER CLEAR COAT THE FABRIC OR SATURATE COAT ANY WOVEN FABRIC , CAN ALSO DO SUNBRELLA TYPE TECHNICAL TEXTILES

FOR ONE SIDE COATING WITH KISS COATERMANUFACTURED BY OLBRICH GMBH (ERECTED IN 2005) 3400mm (SCRIM CAN BE 3400mm WIDTH)

CAN MAKE 3350mm COATED FABRIC AND AFTER TRIMMED EDGES HAVE A FINISHED PRODUCT OF 3300mm (BEGINNING WITH A 3400mm SCRIM , THERE ARE INBUILT CUTTING BLADES FOR TRIMMING .

MANUFACTURED IN GERMANY BEGINNING 2003 AND 2004COATING LINE

UNWINDER

PENDULUM

WEB CONTROL UNIT

PULLING STATION

PENDULUM

HEATING ROLLER (DIAMETER 570 mm)

PLATFORM

SAWING GAUGE

DOUBLE-KNIFE (DOCTOR) VERTICAL COATING MACHINE

VERTICAL DRIER

COOLING STATION WITH ROLLER LOCK

PENDULUM

SMOOTHING ROLL

MACHINE FRAME

IDLER ROLLER BRIDGE

PULLING STATION

PLATFORM

COATING MACHINE (KNIFE-OVER-ROLL)

HORIZONTAL DRIER

COOLING STATION

IDLER ROLLER BRIDGE

PLATFORM

SMOOTHING CALENDER

SUCTION HOOD

LACQUERING MACHINE (ZIMMER)

TEMPERATURE CONTROL UNIT

DRYER

ACCUMULATOR OF FABRIC

COMPUTER WITH SOFTWARE CONTROL

(SIEMENS)

ELECTRICAL CONTROL PLANT

WEIGHT-PER-UNIT-AREA

MEASURING GAUGE (2 UNITS MAHLO)-ISOTOPE NOT INCLUDED

REWINDER

FREE STANDING SLITTER-REWINDER (SEE PHOTO ATTACHED)

TRIMMING GOUGE

PERIPHERAL EQUIPMENT

LIQUIFIED GAS EQUIPMENT RH80 (RANSOME MANUFACTURING USA)

EVAPORATOR-RANSOME (USA)

CHILLER (ITALY) WITH EXPANSION TANK

BOILER ERENSAN MODEL 2000 (ISI SANAYI A.S. TURKEY) FOR HEATING OIL WITH EXPANSION TANK.

\BOILER FOR HEATING BUILDING, NOT INCLUDED

REGENERATIVE THERMAL OXIDIZER (RTO) ENVIROLOGIC USA

12 STAINLESS STEEL CONTAINERS FOR PLASTISOL VOLUME -1 M3

VACUUM DISSOLVER (SRUGO)-2 UNITS

PIPING, EXHAUST VENT PIPES (NO BUILDING HEATING PIPES )

OVERHEAD CRANE NOT INCLUDEDFLOORSPACE OCCUPIED BY THE LINE:

LENGTH 67,125mm

WIDTH 6200mm

HEIGHT 8100mmSPEED 3 TO 30 M/MIN

HEATING SYSTEM: OIL

QUANTITY: 1 LINE

Learn More -

M-6092 ETHYLENE OXIDE STERILIZER

M-6092 ETHYLENE OXIDE STERILIZERREFERENCE NUMBER: M-6092

ETHYLENE OXIDE STERILIZERSTERILIZING TEMPERATURE: 0~100°C, PID ADJUSTABLE

Learn More

STERILIZING PRESSURE: -95~+80KPA

STERILIZING HUMIDITY: 20~100% RH, ADJUSTABLE

EO CONCENTRATION: 300~1,000 MG/L

STERILIZING TIME: 3~12 HRS