Search results for: 'hot g'

- Related search terms

- Hotm

- HOT MELT MACHINE

- HOT MELT GLUE MACHINE

- Hot w

- hot spray guns

-

YY-2326 ECONOMELT 10 GP INDUSTRIAL HOT MELT TANK, 10 LB CAPACITY TEFLON COATED MELT TANKYY-2326 ECONOMELT 10 GP INDUSTRIAL HOT MELT TANK, 10 LB CAPACITY TEFLON COATED MELT TANK SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 10 LB CAPACITY MELT TANK, PRECISION VARIABLE SPEED GEAR PUMP, ABILITY TO OPERATE WITH TWO HOSE AND GLUE GUNS. QUANTITY: 1 Learn More

YY-2326 ECONOMELT 10 GP INDUSTRIAL HOT MELT TANK, 10 LB CAPACITY TEFLON COATED MELT TANKYY-2326 ECONOMELT 10 GP INDUSTRIAL HOT MELT TANK, 10 LB CAPACITY TEFLON COATED MELT TANK SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 10 LB CAPACITY MELT TANK, PRECISION VARIABLE SPEED GEAR PUMP, ABILITY TO OPERATE WITH TWO HOSE AND GLUE GUNS. QUANTITY: 1 Learn More -

YY-2324 ECONOMELT 20-2/4 HOT MELT TANK, 20 LB TANK CAPACITYYY-2324 ECONOMELT 20-2/4 HOT MELT TANK, 20 LB TANK CAPACITY SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 20 LB CAPACITY, HIGH FLOW PISTON PUMP, ABILITY TO OPERATE WITH FOUR HOSES AND HANDGUNS OR AUTOMATIC GUNS. QUANTITY: 1 Learn More

YY-2324 ECONOMELT 20-2/4 HOT MELT TANK, 20 LB TANK CAPACITYYY-2324 ECONOMELT 20-2/4 HOT MELT TANK, 20 LB TANK CAPACITY SIMPLE, LOW COST INDUSTRIAL HOT MELT TANK WITH 20 LB CAPACITY, HIGH FLOW PISTON PUMP, ABILITY TO OPERATE WITH FOUR HOSES AND HANDGUNS OR AUTOMATIC GUNS. QUANTITY: 1 Learn More -

R-6856 FUTURA K AUTOMATIC ROASTING MACHINES

R-6856 FUTURA K AUTOMATIC ROASTING MACHINESR-6856 FUTURA K AUTOMATIC ROASTING MACHINES

AUTOMATIC ROASTING MACHINES RESULT OF LONG STUDIES AND LIVED EXPERIENCE.

THE ROASTING MACHINES SERIES FUTURA K ARE THE RESULT OF LONG STUDIES AND LIVED EXPERIENCE ALONGSIDE OUR CLIENTS COFFEE ROASTERS, FOR THE REALIZATION OF THE MOST ADVANCED MACHINERIES IN THE FIELD OF INDUSTRIAL COFFEE ROASTING.

THE COMPACT DIMENSIONS, RELIABILITY OF THE MATERIALS AND COMPONENTS, THERMAL MANAGEMENT WITH IMMEDIATE RESPONSE, CALIBRATED AND PARTICULARLY FUEL EFFICIENT, HIGH THERMAL AND ACOUSTIC INSULATION AND OTHER POSITIVE FEATURES, MAKE THESE MACHINES REFERENCEGUIDE IN PROFESSIONAL ROASTING FIELD.MAIN COMPONENTS:

FEEDING HOPPER INSULATED WITH PNEUMATIC FILLER DEVICE, MOVABLE INLET, ELECTROPNEUMATIC UNLOADING CONTROL.

ROASTING DRUM MADE BY A FIXED HOUSING WITH DOUBLE INSULATING WALLS FOR THERMAL PROTECTION AND SUPPORTING THE ROTARY CYCLINDER THAT MOVES THE PRODUCT. THE WHOLE CYCLINDER IS MADE OF COMPOUND STEEL TO WITHSTAND THERMAL SHOCKS, ABSOLUTELY ODOURLESS, WITH PERFORATED SHEET FOR PRODUCT CONTAINEMENT, RIGHT AND LEFT BLENDERS SETTLED AT DIFFERENT LEVELS TO OBTAIN PERFECT MIXTURE.

WHEN THE ROASTING PROCESS IS FINISHED, THE COFFEE IS UNLOADED THROUGH A LARGE DOOR WITH ELECTROPNEUMATIC CONTROL OF OPENING AND CLOSING.

THE HEATING GENERATOR IS SPECIFICALLY DESIGNED FOR ROASTING LINE APPLICATIONS. THE PRINCIPLE OF HEATING IS BASED ON HOT AIR FLOWS BY CONVECTION. GAS OR GASOIL BURNER TYPE MODULATING OR MULTI LEVEL- FLAMES ACCORDING THE APPLICATION.

COOLING TANK WITH LARGE STAINLESS STEEL SURFACE, SELF CLEANING, WHERE THE PRODUCT IS MOVED BY MEANS OF 4 CROSSED ARMS. TWO DISCHARGES: ONE IS ELECTROPNEUMATICALLY DRIVEN AND THE OTHER IS MANUAL FOR EMERGENCY. DOOR OF INSPECTION AND EASY CLEANING OF THE LOWER SIDE.

PELLICLES SEPARATOR WITH EXTRACTION, BY WORM CONVEYOR OR INCINERATOR FOR CONSTANT EFFICIENCY OF THE AIR CHAFFS SEPARATION SYSTEM.

SUPPORTING FRAME IN TUBULAR PROFILES, STEEL MADE, TO CONTAIN AND SUPPORT THE OPERATING DEVICES, SO TO OBTAIN A COMPACT MACHINE-LIMITED ENCUMBRANCE, COMPLETE WITH PANELS FOR HEATING AND NOISE CONTAINMENT.

INDEPENDENT ELECTRIC CONTROL BOARD WITH PLC + TOUCH SCREEN AND ALL DEVICES FOR MACHINE CONTROL AND

MANAGEMENT, CAREFULLY WIRED AND EQUIPPED WITH ALL SIGNALS USEFULL FOR ROASTING PROCESS.STANDARD EQUIPMENT:

AUTOMATIC ROASTING SYSTEM MANAGED BY PLC + TOUCH SCREEN WITH RECORDING FOR ROASTING CURVES – PROFILES.

VISUALIZATION BY MONITOR OF TEMPERATURES AND ROASTING FUNTIONS.

FIRE PREVENTION EQUIPMENT ON THE ROASTING DRUM AND COOLING TANK; ON THE CYCLONE-CHAFFS SEPARATOR IF EQUIPPED WITH WORM CONVEYOR FOR CHAFFS EXTRACTION.

ALARM SYSTEM BY BUZZER AND SIGNAL LAMP, UPON INTERVENTION OF THE OVERLOAD PROTECTION DEVICES ON THE ELECTRIC-MOTORS AND ON THE BURNER.

PROTECTING SAFETY SYSTEMS.

CYCLONE FOR COOLING TANK: STANDARD ON MOD. 240-300- 360-480.

OPTIONALS EQUIPMENTCOMPUTERIZED AUTOMATIC ROASTING PROCESS CARP MANAGED BY PC AND MONITOR.

Learn More

HEATING RECOVERY SYSTE

SMOKE BURNER TYPE THERMICAL AND/OR CATALYST

CLEAN AIR ROASTING SYSTEM

CHAFFS COMPACTOR. -

TT-8492 LAMINATING MACHINE, 51KW, WORKING WIDTH 2000mm – FOR LAMINATING FOAMTT-8492 LAMINATING MACHINE, 51KW, WORKING WIDTH 2000mm – FOR LAMINATING FOAM 1. DUST CLEANER: YES 2. PANEL PREHEATING: YES 3. PUR GLUE MACHINE: 55 GALLONS QUANTITY: 1 Learn More

TT-8492 LAMINATING MACHINE, 51KW, WORKING WIDTH 2000mm – FOR LAMINATING FOAMTT-8492 LAMINATING MACHINE, 51KW, WORKING WIDTH 2000mm – FOR LAMINATING FOAM 1. DUST CLEANER: YES 2. PANEL PREHEATING: YES 3. PUR GLUE MACHINE: 55 GALLONS QUANTITY: 1 Learn More -

YY-2359 DM55 HOT MELT DRUM UNLOADERYY-2359 DM55 HOT MELT DRUM UNLOADER DM55 HOT MELT DRUM UNLOADER MELTS AND PUMPS HOT MELT FROM 55 GALLON DRUMS WITH SPEED AND ACCURACY. THIS IS TRULY A “MELT ON DEMAND” MACHINE MELTING ONLY THE HOT MELT THAT IS NEEDED FOR THE APPLICATION. IT HAS PRECISION TEMPERATURE CONTROLS AND VARIABLE SPEED GEAR PUMP OR HIGH OUTPUT PISTON PUMP. QUANTITY: 1 Learn More

YY-2359 DM55 HOT MELT DRUM UNLOADERYY-2359 DM55 HOT MELT DRUM UNLOADER DM55 HOT MELT DRUM UNLOADER MELTS AND PUMPS HOT MELT FROM 55 GALLON DRUMS WITH SPEED AND ACCURACY. THIS IS TRULY A “MELT ON DEMAND” MACHINE MELTING ONLY THE HOT MELT THAT IS NEEDED FOR THE APPLICATION. IT HAS PRECISION TEMPERATURE CONTROLS AND VARIABLE SPEED GEAR PUMP OR HIGH OUTPUT PISTON PUMP. QUANTITY: 1 Learn More -

YY-2357 ECONOMELT HOT MELT PAIL UNLOADERYY-2357 ECONOMELT HOT MELT PAIL UNLOADER THIS HIGH QUALITY HOT MELT PAIL UNLOADER MACHINERY MELTS AND PUMPS HOT MELT ADHESIVE THROUGH HIGH PRESSURE FLEXIBLE HEATED HOSES TO MANUAL AND AUTOMATIC GUNS FOR THE PRECISE APPLICATION OF THE HOT MELT. QUANTITY: 1 Learn More

YY-2357 ECONOMELT HOT MELT PAIL UNLOADERYY-2357 ECONOMELT HOT MELT PAIL UNLOADER THIS HIGH QUALITY HOT MELT PAIL UNLOADER MACHINERY MELTS AND PUMPS HOT MELT ADHESIVE THROUGH HIGH PRESSURE FLEXIBLE HEATED HOSES TO MANUAL AND AUTOMATIC GUNS FOR THE PRECISE APPLICATION OF THE HOT MELT. QUANTITY: 1 Learn More -

YY-2355 DYNACHAMP S - HIGH FLOW SWIRL HANDGUNYY-2355 DYNACHAMP S - HIGH FLOW SWIRL HANDGUN HIGHEST QUALITY INDUSTRIAL HIGH FLOW HOT MELT HANDGUN FOR THE PRECISE APPLICATION OF HOT MELT ADHESIVE. THIS INDUSTRIAL HOT MELT GLUE GUN IS USED WITH THE N SERIES AND S SERIES HOT MELT TANKS IT REQUIRES A FLEXIBLE HEATED HOSE. QUANTITY: 1 Learn More

YY-2355 DYNACHAMP S - HIGH FLOW SWIRL HANDGUNYY-2355 DYNACHAMP S - HIGH FLOW SWIRL HANDGUN HIGHEST QUALITY INDUSTRIAL HIGH FLOW HOT MELT HANDGUN FOR THE PRECISE APPLICATION OF HOT MELT ADHESIVE. THIS INDUSTRIAL HOT MELT GLUE GUN IS USED WITH THE N SERIES AND S SERIES HOT MELT TANKS IT REQUIRES A FLEXIBLE HEATED HOSE. QUANTITY: 1 Learn More -

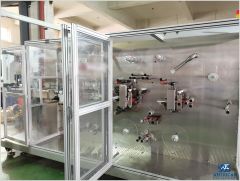

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More

J-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mmJ-4641 WOUND DRESSING MANUFACTURING AND PACKING LINE, WORKING WIDTH 100mm QUANTITY: 1 Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More

T-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINET-9483 FULLY AUTOMATIC FOUR EDGE-SEALING GAUZE PACKING MACHINE TECHNICAL PARAMETERS: BAG SIZE: BASED ON CUSTOMER'S REQUEST SPEED: 120~180 BAGS/MIN PACKING MATERIAL: PAPER+PAPER, PAPER+PLASTIC IT CAN HOT SEALING PACKING MATERIAL, PACKAGE MATERIAL DIAMETER Φ ≤ 350mm, WIDTH IS BASED ON CUSTOMER'S REQUEST; VOLTAGE: 3P 380V 50Hz SERVO MOTOR 1.5 KW+SERVO MOTOR: 1 KW+STEPPING MOTOR 110 + STEPPING MOTOR 130 + VARIABLE FREQUENCY MOTOR 0.37KW, TOTALLY 5 MOTORS ARE 4KW USING 28 VOLT SERIES CIRCUIT HEAT, 2 HEATING PANELS, EACH PANEL HAVE 8 PCS HEATING TUBE, EACH TUBE 300W, TOTALLY 4.8KW MACHINE WEIGHT: 800 KG MACHINE SIZE: LENGTH 5000 X WIDTH 1300 X HEIGHT 1600mm WOODEN CARTON SIZE: LENGTH 2600 X WIDTH 1900 X HEIGHT 1800mm Learn More