Search results for: 'laminating'

- Related search terms

- Laminating m

- laminating machines

- laminating line

-

J-4756 EDGE SWEETS HT-140-ES-CC SEMI-AUTOMATIC PROFILE FOAM CUTTER, YEAR 2003 – REBUILT 2023J-4756 EDGE SWEETS HT-140-ES-CC SEMI-AUTOMATIC PROFILE FOAM CUTTER, YEAR 2003 – REBUILT 2023 - COMPLETELY REBUILT WITH NEW ELECTRICAL DRIVES AND NEW COMPUTER DESIGN SYSTEM -TO MAKE 3 DIMENSIONAL SHAPES FOR MANY USES INCLUDING FOR LAMINATING WITH FIBERGLASS TO MAKE SPECIAL PARTS QUANTITY: 1 Learn More

J-4756 EDGE SWEETS HT-140-ES-CC SEMI-AUTOMATIC PROFILE FOAM CUTTER, YEAR 2003 – REBUILT 2023J-4756 EDGE SWEETS HT-140-ES-CC SEMI-AUTOMATIC PROFILE FOAM CUTTER, YEAR 2003 – REBUILT 2023 - COMPLETELY REBUILT WITH NEW ELECTRICAL DRIVES AND NEW COMPUTER DESIGN SYSTEM -TO MAKE 3 DIMENSIONAL SHAPES FOR MANY USES INCLUDING FOR LAMINATING WITH FIBERGLASS TO MAKE SPECIAL PARTS QUANTITY: 1 Learn More -

TT-2703 SCHIAVI CONVERTING MACHINE, LAMINATORS AND COATERS, WORKING WIDTH 1350mm, YEAR 2003TT-2703 SCHIAVI CONVERTING MACHINE, LAMINATORS AND COATERS, WORKING WIDTH 1350mm, YEAR 2003 BRAND: SCHIAVI MODEL: ECOFLEX CL600 YEAR: 2003 QUANTITY: 1 Learn More

TT-2703 SCHIAVI CONVERTING MACHINE, LAMINATORS AND COATERS, WORKING WIDTH 1350mm, YEAR 2003TT-2703 SCHIAVI CONVERTING MACHINE, LAMINATORS AND COATERS, WORKING WIDTH 1350mm, YEAR 2003 BRAND: SCHIAVI MODEL: ECOFLEX CL600 YEAR: 2003 QUANTITY: 1 Learn More -

TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989 QUANTITY: 1 Learn More

TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989TT-2662 STORK COATING LINE ROLLER, WIDTH 2000mm, YEAR 1989 QUANTITY: 1 Learn More -

TT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mmTT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mm ITEM 001 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER IN 1980 STARTED PRODUCTION TEST POSSIBLE – IMMEDIATELY FREE FOR SALE ITEM 002 STAMPING AND EMBOSSING MACHINE HEIDEMANN ITEM 003 WAX-LAMINATOR KROENERT-PACK 850 THE MACHINE CAN BE DISMANTLED AS FROM NOW. Learn More

TT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mmTT-2113 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER, WORKING WIDTH 500 TO 1050mm ITEM 001 KROENERT TYPE PAK 600 WAXER / LAMINATOR / COATER IN 1980 STARTED PRODUCTION TEST POSSIBLE – IMMEDIATELY FREE FOR SALE ITEM 002 STAMPING AND EMBOSSING MACHINE HEIDEMANN ITEM 003 WAX-LAMINATOR KROENERT-PACK 850 THE MACHINE CAN BE DISMANTLED AS FROM NOW. Learn More -

TT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mmTT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mm RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210 APPLICATION: LAMINATING OF NONWOVEN FABRICS MATERIAL: PE MAXIMUM ROLL WIDTH: 2200mm QUANTITY: 1 Learn More

TT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mmTT-1739 RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210, WIDTH 2200mm RAMISCH KLEINEWEFERS 2 ROLL THERMOBOND CALENDAR TYPE RKK 210 APPLICATION: LAMINATING OF NONWOVEN FABRICS MATERIAL: PE MAXIMUM ROLL WIDTH: 2200mm QUANTITY: 1 Learn More -

TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR BRAND: NORDMECCANICA MODEL: SUPER SIMPLEX YEAR: 1995 AVAILABLE: NOW QUANTITY: 1 Learn More

TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995TT-1596 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR, WIDTH 1400mm, YEAR 1995 NORDMECCANICA SUPER SIMPLEX SOLVENTLESS LAMINATOR BRAND: NORDMECCANICA MODEL: SUPER SIMPLEX YEAR: 1995 AVAILABLE: NOW QUANTITY: 1 Learn More -

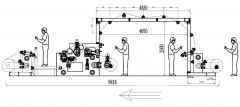

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAY

J-2172 COMPLETE MATTRESS PLANT AVAILABLE – 2000 TO 3000 MATTRESSES PER DAYSee all pictures: https://ibb.co/album/gpK9bF

#1 GRIBETZ MPLUS PATTERN LINK 90 TACK AND JUMP 3 BAR WITH PANEL CUTTER 4 POS CREEL

#2 GRIBETZ GI4300 TACK AND JUMP 90" 3 BAR WITH PANEL CUTTER 3 POS CREEL

# 3 EMCO 2 BAR 1X3 WITH PANEL CUTTER, YEAR 2001 (FOR PARTS)

#4 EMCO COMPUSTITCH 3 BAR

WITH JAMES CASH K-10 PANEL CUTTER#5 GRIBETZ GI2300 90" SET UP FOR BORDERS 4 POS CREEL

#6 EMCO 9000 COMPUSTITCH 1X3X6 BUT RUNNING 1X6

WITH BORDER CUTTER JAMES CASH K-10 1997#7 EMCO 9000 COMPUSTITCH 3 BAR 1 POSITION CREEL

WITH BORDER CUTTER JAMES CASH K-10#8 GRIBETZ 3 BAR 92"

WITH JAMES CASH K-12#9 TAPE EDGE WITH SINGER 300UX6 STEEL TABLE 55 X 81

#10 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#11 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX5 WITH STAINLESS STEEL TABLE 60 X 80

#12 ATLANTA ATTACHEMENT TAPE EDGE WITH PFAFF 5625 WITH STAINLESS STEEL TABLE 60 X 80

#13 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGER 300UX6 WITH STAINLESS STEEL TABLE 60 X 80

#14 PORTER TAPE EDGE PFAFF DISSASSEMBLED HEAD TABLE SIZE 60 X 82

#15 ATLANTA ATTACHMENT TAPE EDGE WITH PFAFF 5625 STAINLESS STEEL TABLE 59 X 79

#16 ATLANTA ATTACHEMENT TAPE EDGE WITH SINGERS 300UX5 STAINLESS STEEL TABLE 60 X 80 16"H

#17 BUILD UP TABLES MOSTLY 60 X 80 OF WHICH 15 ARE GLOBAL SYSTEMS AND 2 ARE HOME MADE

#19 ? SMALL BALER CONSOLIDATED MODEL STDS-2 36' WIDE X 18" FRONT TO BACK X 50"H

#20 SCREW UNBALER ATLANTA ATTACHMENT FOR 18 INNERSPRING CAPACITY

#21 PIQUA BALER 58 X 31 X 54" TALL 220 VOLT

#22 SCREW UNBALER WBSCO

#23 CART FOR INNERSPRING BALE

#24 GRIBETZ PANEL CUTTER ( I HAVE ALL THE INFO ALREADY)

#25 LAMINATOR GRIBETZ STRATA WITH HOT ROLL AND FELT BLANDET FOR LAMINATING WITH WEB SUBSTRATE (ROTARY HEAT PRESS) MODEL GLM011 220 VOLT , 2 POS CREEL

#26 HORIZONTAL FOAM CUTTER ESCO MODEL HTX 51-88 PU+

88" WIDE , X 118" LONG , KNIFE GRINDERS , SUCTION TABLE

TOUCH SCREEN PANEL , ELECTRICAL CONTROL PANEL

AUTOMATIC LUBRICATION BINKS MODEL 80-600 SG2 PLUS#27 VERTICAL FOAM CUTTER MODEL EL-4

112" WIDE

OUTSIDE TABLE 73"

INSIDE TABLE 74"

FENCE 8" PLUS 16 " EXTENSION

68" THROAT

112" OVERALL HEIGHT

194" TOTAL RAIL WIDTH#28 PORTER SERGER FLANGER MODEL 4000 WITH AIR FLOTATION TABLE

220 VOLT#29 ATLANTA ATTACHMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#30 ATLANTA ATTACHEMENT JUKI SERGER FLANGER MODEL MO6916G BELT DRIVE WITH AIR FLOTATION TABLE

#31 SINGER LONG ARM REPAIR 25"

#32 ATLANTA ATTACHEMENT RUFFLER

MODEL 13XXMF#33 ATLANTA ATTATCHMENT 9 NEEDLE SEWING MACHINE (MULTINEEDLE) MODEL 4000D

#34 SINGLE NEEDLE SIT DOWN MACHINES OF WHICH 3 ARE PORTER

#35 AVANCE EMBROIDERY MACHINE

#36 GALKIN "X" SEWING MACHINE FOR HANDLES

GAP5OBT-3 , JUKI MODEL LK1900CV#37 ATLANTA ATTACHMENT DOUBLE BORDER SERGER 25" OPENING , PEGASUS HEAD

MODEL E521-130 AND EX5203-M03#38 ATLANTA ATTACHMENT BINDER FOR HANDLE MAKING

#39 ANDERSON MULTISLITTER 10 BLADES 92" WIDE

#40 ANDERSON STAND ALONE PANEL CUTTER 103"WIDE WITH 2 EDGE SLITTERS AND ONE CROSS CUTTER

WITH 1049 HOURS ON THE CLOCK#41 CONVEYOR FOR SEW DEPARTMENTE 34" WIDE OVER 100 FEET LONG

#42 TOYOTA FORKLIFTS 6270 LBS CAPACITY MODEL 71CCUT5 (TWO)

ONE NISSAN FORKLIFT

ONE CATERPILLAR FORKLIFT#43 ONE GLUE STATION 4 GUNS , SABA GUNS , NOT THERE (BELONG TO SABA)

#44 240 FEET LONG CONVEYOR FEEDING MATTRESS WRAPPING DEPARTMENT

#45 TWO MERELLO WRAPPERS 20 INCH MAX HEIGHT X 88 " WIDE, YEAR 2016

#46 TECNOMAC (ITALY) MATTRESS ROLL AND PACK MACHINE MODEL TK381 YEAR 2015

Learn More

400 VOLT X 50HZ X 30 KW

8 BAR AIR PRESSURE -

C-4015 SCHLAFHORST OPEN END SPINNING FRAME ACO, YEAR 2004 TO 2007

C-4015 SCHLAFHORST OPEN END SPINNING FRAME ACO, YEAR 2004 TO 2007C-4015 SCHLAFHORST OPEN END SPINNING FRAME ACO, YEAR 2004 TO 2007

SCHLAFHORST OPEN END SPINNING FRAME

TYPE: ACO

19 MACHINES X YEAR: 2004

15 MACHINES X YEAR: 2007

360 POSITIONS

ROTOR DIAMETER: 28 + 33mmQUANTITY: 34

Learn More -

G-1322 5-LAYER BUBBLE FILM MAKING MACHINEREFERENCE NUMBER: G-1322 5-LAYER BUBBLE FILM MAKING MACHINE FEATURES: 1. ROBUST AND RELIABLE. 2. THIS MODEL CAN ALSO BE USED FOR 5 AND 4 LAYERS LAMINATING BUBBLE FILM WITH PURE ALUMINUM FOIL(PAPER) AND ALUMINUM FILM AND EPE FOAM, AND 3 AND 2 LAYERS BUBBLE FILM. 3. SUITABLE FOR A WIDE SPECTRUM OF MATERIALS, INCLUDING LDPE, LLDPE, AND RECYCLED PE. 4. CAN PRODUCE FILMS WITH VARIOUS BUBBLE SIZES FROM DIAMETER 6 TO DIAMETER 32, BY CHANGING THE ROLLER. 5. INDEX REVOLVING WINDER IS EASY TO OPERATE. 6. STRENGTHENED CHILLING FUNCTION WITH WATER AND WIND TOGETHER, WHICH GREATLY IMPROVED PRODUCTION EFFICIENCY. THE STRONG CHILLING FUNCTION MAKES THE BUBBLE MORE TRANSPARENT AND STEREOSCOPIC. THE WIND ALSO DRIES OUT THE FILM TO MAKE IT READY FOR THE NEXT STEP PROCESSING. 7. VARIABLE SPEED DRIVE CAN GREATLY REDUCE ENERGY CONSUMPTION. QUANTITY AVAILABLE: 1 Learn More

G-1322 5-LAYER BUBBLE FILM MAKING MACHINEREFERENCE NUMBER: G-1322 5-LAYER BUBBLE FILM MAKING MACHINE FEATURES: 1. ROBUST AND RELIABLE. 2. THIS MODEL CAN ALSO BE USED FOR 5 AND 4 LAYERS LAMINATING BUBBLE FILM WITH PURE ALUMINUM FOIL(PAPER) AND ALUMINUM FILM AND EPE FOAM, AND 3 AND 2 LAYERS BUBBLE FILM. 3. SUITABLE FOR A WIDE SPECTRUM OF MATERIALS, INCLUDING LDPE, LLDPE, AND RECYCLED PE. 4. CAN PRODUCE FILMS WITH VARIOUS BUBBLE SIZES FROM DIAMETER 6 TO DIAMETER 32, BY CHANGING THE ROLLER. 5. INDEX REVOLVING WINDER IS EASY TO OPERATE. 6. STRENGTHENED CHILLING FUNCTION WITH WATER AND WIND TOGETHER, WHICH GREATLY IMPROVED PRODUCTION EFFICIENCY. THE STRONG CHILLING FUNCTION MAKES THE BUBBLE MORE TRANSPARENT AND STEREOSCOPIC. THE WIND ALSO DRIES OUT THE FILM TO MAKE IT READY FOR THE NEXT STEP PROCESSING. 7. VARIABLE SPEED DRIVE CAN GREATLY REDUCE ENERGY CONSUMPTION. QUANTITY AVAILABLE: 1 Learn More