Search results for: 'Continuous+fi'

-

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More

M-1487 CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mmREFERENCE NUMBER: M-1487 (660125KJH5RXM) CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC YEAR 2000 WIDTH 3600mm CONTINUOUS WASHING LINE IN OPEN WIDTH FOR WOVEN FABRIC MEZZERA BIANCO ROLLERS WIDTH: 3800 mm WORKING WIDTH: 3600 mm YEAR OF CONSTRUCTION: 2000 COMPOSED OF: - DOUBLE INTRODUCTION, FRAME MANUFACTURED IN PAINTED FE PROFILES , SLINGING BY ADJUSTABLE FLYWHEELS, 2 GROUPS OF WIDENING-CENTRING ROLLERS E+L KF20, FABRIC GUIDING ROLLERS IN AISI 316, DRAGGING CALANDER WITH 3 ROLLERS. - BY-PASS AND SYNCHRONIZATION BRIDGE COMPOSED OF : FRAME IN CARBON STEEL FE37, GROUP OF GUIDING ROLLERS IN STAINLESS STEEL COMPLETE WITH SELF-ALIGNED BEARINGS TO GUIDE THE FABRIC TO THE FOLLOWING SECTION . - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH , MOD. ACTIVA 30, WITH DOUBLE FABRIC DWELLING. - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - SQUEEZING SYSTEM WITH : 2 ROLLERS COATED RUBBER/EBONITE, RUBBER HARDNESS 75-80 SHA, WORKING PRESSURE 3000 KG, A.C. MOTOR GEARBOX, INVERTER, PNEUMATIC DRIVE. - ROLLER WASHING UNIT IN OPEN WIDTH, MOD. ACTIVA 20, WITH SIMPLE FABRIC DWELLING - INTERMEDIATE SEPARATOR FOR TANK SPLITTING - 5 INTERMEDIATE SQUEEZERS - SLAT WIDENING UNIT FOR DOUBLE ROW - DELIVERY GROUP WITH PNEUMATIC FOULARD OF 10 TON RUBBER/EBONITE, COMPLETE WITH BEARING FRAME AND PROTECTION CASING. RUBBER ROLLER WITH HIGH SQUEEZING EFFECT ROLLIN - SECOND DISCHARGING STACK - PUMP FOR THE BATH RECYCLING IN THE NEUTRALIZATION PART - PH-METER WITH DOSING PUMP TO NEUTRALIZE IN THE FIRST SECTION OF THE LAST TANK - BIG BATCHER, ADHERING TYPE, DRIVEN BY MOTOR WITH VARIABLE SPEED. - SLAT WIDENING UNIT FOR DOUBLE ROW - 2 DUCTING FOR THE WATER RECOVERY BETWEEN THE 2 WASHING UNITS IN OPEN WIDTH - 3 TEMPERATURE AUTOMATIC CONTROLS PER EACH WASHING UNIT - 4 SETS OF PROPORTIONAL VALVES WITH LITER COUNTER - COMPLETE MOTORIZATION OF THE LINE WITH MOTORS GROUP, ELECTRIC CONTROL CABINET AND SYNOPTICAL PANEL. - VERTICAL DRYER RAMALLUMIN COMPOSED OF 2 COLUMNS WITH 8 ROLLERS, IN ORDER TO DRY BOTH FACES OF THE FABRIC, FOR A TOTAL OF 16 DRYING ROLLERS. O MAX. WORKING WIDTH: 3600 mm. O MAX. MECHANICAL SPEED: 80 MT./MIN. O MAX. WEIGHT OF THE FABRIC, IN WIDTH 3400 mm 900 GR./LINEAR METER O FORESEEN WORKING SPEED WITH FABRIC W=3400mm W=850 GR. 40/45 MT./MIN. O FORESEEN WORKING SPEED WITH FABRIC W=3400 W=425 GR. 80 MT./MIN. O MODIFIED, AS FOLLOWS, WITH ADDITIONS OF : 2 COOLING ROLLERS, 1 SET OF ACCESSORIES FOR THE FEEDING AND RETURN OF THE COOLING WATER, SET OF COMPONENTS FOR THE CONTROL, 4 RETURN CYLINDERS, COMPENSATING GROUP ON THE INTRODUCTION SIDE, 3 SUCTIONING HOODS, 1 EXHAUSTER. Learn More -

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More

TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006TT-8694 A1 TETRA PAK ASEPTIC 16400 BPH FILLING MACHINE, YEAR 2006 1. FILLING MACHINE 2. BRAND: TETRA PAK® 3. MODEL: A1-TETRA CLASSIC ASEPTIC (TCA) 4. YEAR: 2006 5. SPEED: 16400 BOXES/HOUR 6. PRODUCTS: DAIRY, JUICE Learn More -

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mm

L-4682 BALE BREAKER SYSTEM FOR MICRO FIBER MIXING, WIDTH 1200mmREFERENCE NUMBER: L-4682

Learn More

WIDTH: 1200mm

CAPACITY: 200-600KG/H

QUANTITY: 1 -

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More

TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003TT-6302 TETRA PAK FILLING LINE TBA 19 200ML SLIM 10V, YEAR 2003 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2003 3. CONDITION USED 4. OPERATING HOURS: 38,750 H QUANTITY: 1 Learn More -

TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED QUANTITY: 1 Learn More

TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6295 TETRA PAK BOTTLING PLANT BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. TETRA PAK BOTTLING PLANT 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED QUANTITY: 1 Learn More -

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More

TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020TT-6207 TETRA PAK BOTTLING PLANT A3 FLEX SLIM 5500 BPH 1.5L, YEAR 2020 1. BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 2. YEAR OF CONSTRUCTION 2020 3. CONDITION USED 4. MACHINE TYPE: BOTTLING LINE TETRA PAK A3 FLEX SLIM 5500 BPH 1.5L 5. BRAND: TETRA PAK 6. MODEL: BOTTLING PLANT 7. CONDITION: USED 8. OPERATING HOURS: 500 H QUANTITY: 1 Learn More -

YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2 WATERMAKER PRODUCES DRINKING WATER FROM SEA WATER BASED UPON THE REVERSE OSMOSIS MEMBRANE TECHNIQUE. THE CAPACITY IS 50M3/24H FROM SEAWATER (25OC). THE QUALITY OF THE DRINKING WATER IS CONTINUOUSLY MONITORED BY A SALINITY METER. THE DESIGN IS IDEAL FOR SIMPLE SERVICE AND MAINTENANCE. THE UNIT IS SUITABLE FOR: - DRILLING PLATFORMS; - OFFSHORE RIGS AND ACCOMMODATION PLATFORMS; - COMMERCIAL VESSELS; - MILITARY VESSELS; - RESORTS, HOTELS AND COMMUNITIES; - GOLF COURSES. QUANTITY: 2 Learn More

YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2YY-2370 UNUSED WATERMAKERS, CAPACITY 50 M3 PER 24H, QUANTITY 2 WATERMAKER PRODUCES DRINKING WATER FROM SEA WATER BASED UPON THE REVERSE OSMOSIS MEMBRANE TECHNIQUE. THE CAPACITY IS 50M3/24H FROM SEAWATER (25OC). THE QUALITY OF THE DRINKING WATER IS CONTINUOUSLY MONITORED BY A SALINITY METER. THE DESIGN IS IDEAL FOR SIMPLE SERVICE AND MAINTENANCE. THE UNIT IS SUITABLE FOR: - DRILLING PLATFORMS; - OFFSHORE RIGS AND ACCOMMODATION PLATFORMS; - COMMERCIAL VESSELS; - MILITARY VESSELS; - RESORTS, HOTELS AND COMMUNITIES; - GOLF COURSES. QUANTITY: 2 Learn More -

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More

YY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINEYY-3145 BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGH-CAPACITY POLYESTER STAPLE FIBER LINE HIGH-CAPACITY POLYESTER STAPLE FIBER LINE BARMAG/NEUMAG/FLEISSNER/AUTEFA HIGHLY VERSATILE COMPLETE STAPLE FIBER LINE, HIGH PRODUCTIVITY AND COULD BE RUN SEPARATELY FROM VIRGIN PET OR AS WELL PET BOTTLE FLAKES, CHIPS AND R-PET. QUANTITY: 1 Learn More -

TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018 CHROMOJET PRINTING MACHINE YEAR 2018 CHR800 16X512 AND SAMPLING EQUIPMENT FULL LINE, ENTRY, STEAMER, WASHER, DRYER, ROLL UP FULL AUTOMATIC DYE KITCHEN CARPET WIDTH: 2000 TO 4200mm CARPET PILE WEIGHT: 300 TO 2500 G/M² CARPET HEIGHT: 3mm TO 20mm VOLTAGE 380 VOLTS / 3 PHASES / 50 CYCLES; +/- 5% QUANTITY: 1 Learn More

TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018TT-4315 CHROMOJET PRINTING MACHINE, WIDTH 4200mm, YEAR 2018 CHROMOJET PRINTING MACHINE YEAR 2018 CHR800 16X512 AND SAMPLING EQUIPMENT FULL LINE, ENTRY, STEAMER, WASHER, DRYER, ROLL UP FULL AUTOMATIC DYE KITCHEN CARPET WIDTH: 2000 TO 4200mm CARPET PILE WEIGHT: 300 TO 2500 G/M² CARPET HEIGHT: 3mm TO 20mm VOLTAGE 380 VOLTS / 3 PHASES / 50 CYCLES; +/- 5% QUANTITY: 1 Learn More -

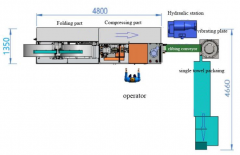

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More

YY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINSYY-2994 AUTOMATIC MACHINE TO PRODUCE COMPRESSED FACE PAD, FACE TOWELS AND NAPKINS ASK FOR MORE DETAILS! PRODUCTION PROCESS: AUTOMATIC FEEDING→CUTTING→FOLDING→COMPRESSING→FORMING→DELIVERY→PACKING→OUTPUT Learn More