Search results for: 'Mattress t'

- Related search terms

- mattress

- Mattress q

- Mattress r

- Mattress f

- Mattress co

-

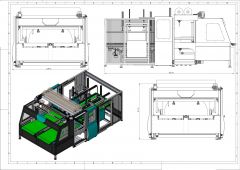

YY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSESYY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSES HYDRAULIC PRESS FOR VACUUM MATTRESSES TECHNICAL SPECIFICATIONS: - WEIGHT: 1400 KG - CONSUMPTION: 10 KW - COMPRESSED AIR: 6 BAR - VOLTAGE: 400 V – 50 Hz THREE-PHASE QUANTITY: 1 Learn More

YY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSESYY-3078 RESTA H227 GP HYDRAULIC PRESS FOR THE VACUUM SEALING OF MATTRESSES HYDRAULIC PRESS FOR VACUUM MATTRESSES TECHNICAL SPECIFICATIONS: - WEIGHT: 1400 KG - CONSUMPTION: 10 KW - COMPRESSED AIR: 6 BAR - VOLTAGE: 400 V – 50 Hz THREE-PHASE QUANTITY: 1 Learn More -

K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSINGREFERENCE NUMBER: K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSING WITH SELP-ADJUSTMENT FOR PACKING DIFFERENT SIZES OF PRODUCTS IT ALLOWS UP TO 2 WRAPS PER MINUTE WITH EXCELLENT QUALITY THANKS TO 2 TONS PRESS AND TIGHTENING MECHANISMS MAX. PRESS LOAD CAPACITY: 2 TONS MAX. MATTRESS SIZE: 210 CM X 210 CM SETUP AREA: 3.5 M X 6.5 M QUANTITY AVAILABLE: 1 Learn More

K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSINGREFERENCE NUMBER: K-8622 MATTRESS WRAPPER -FULLY AUTOMATIC HIGH CAPACITY-WITH PRESSING WITH SELP-ADJUSTMENT FOR PACKING DIFFERENT SIZES OF PRODUCTS IT ALLOWS UP TO 2 WRAPS PER MINUTE WITH EXCELLENT QUALITY THANKS TO 2 TONS PRESS AND TIGHTENING MECHANISMS MAX. PRESS LOAD CAPACITY: 2 TONS MAX. MATTRESS SIZE: 210 CM X 210 CM SETUP AREA: 3.5 M X 6.5 M QUANTITY AVAILABLE: 1 Learn More -

J-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESSJ-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESS -MAXIMUM MATTRESS WIDTH: 2100mm -MAXIMUM MATTRESS HEIGHT: 500mm QUANTITY: 1 Learn More

J-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESSJ-4765 AUTOMATIC HOT MELT GLUE MACHINE FOR MATTRESSES, 20 SECONDS PER MATTRESS -MAXIMUM MATTRESS WIDTH: 2100mm -MAXIMUM MATTRESS HEIGHT: 500mm QUANTITY: 1 Learn More -

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More

J-3671 AUTOMATIC MATTRESS PACKING MACHINEJ-3671 AUTOMATIC MATTRESS PACKING MACHINE PRODUCTION CAPACITY: 30 SECONDS PER MATTRESS WITH PNEUMATIC PRESS WITH AUTOMATIC SIZING SYSTEM WITH AUTOMATIC WATER-COOLING SYSTEM (GIVES A BETTER SEAL) POWER REQUIREMENT: 6.5 KW / 380 VOLTS QUANTITY: 1 Learn More -

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More

J-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEWJ-3030 AUTOMATIC COMPRESSION, FOLD & ROLL PACKING MACHINE FOR MATTRESSES – NEW TOTAL POWER: 45 KW VOLTAGE: PER CUSTOMER REQUIREMENT, SPECIFY WHEN ORDERING TOTAL WEIGHT: 15000 KGS OVERALL DIMENSIONS: 12300 x 3400 x 3000mm WITH CE CERTIFICATE REQUIRES (2) 40-FOOT HIGH CUBE CONTAINERS TO SHIP QUANTITY: 1 Learn More -

TT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATIONTT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATION A FULLY AUTOMATIC TUFTING SYSTEM COMPLETE WITH PLC CONTROL USING TOUCH SCREEN TECHNOLOGY. SUPPLIED WITH PRODUCT IN-FEED CONVEYOR AND EXIT CONVEYOR. MACHINE SPEED BASED ON FIRST TO LAST TUFT: 3FT IN 85 SECONDS 4’6 TO 5’ IN 105 SECONDS. 200+ MATTRESSES PER 8 HOUR SHIFT BASED ON 3’, 4’6’ & 5’ PRODUCTS. MACHINE FEATURES HORIZONTAL FEED SUITABLE FOR ALL SPRING TYPES INCLUDING POCKET UNITS LATEX AND FUTONS MATTRESSES HELICAL AVOIDANCE SYSTEM AUTOMATIC PRODUCT SIZING Learn More

TT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATIONTT-2144 MPT AUTO-TUFT SYSTEM, COMPLETELY AUTOMATION A FULLY AUTOMATIC TUFTING SYSTEM COMPLETE WITH PLC CONTROL USING TOUCH SCREEN TECHNOLOGY. SUPPLIED WITH PRODUCT IN-FEED CONVEYOR AND EXIT CONVEYOR. MACHINE SPEED BASED ON FIRST TO LAST TUFT: 3FT IN 85 SECONDS 4’6 TO 5’ IN 105 SECONDS. 200+ MATTRESSES PER 8 HOUR SHIFT BASED ON 3’, 4’6’ & 5’ PRODUCTS. MACHINE FEATURES HORIZONTAL FEED SUITABLE FOR ALL SPRING TYPES INCLUDING POCKET UNITS LATEX AND FUTONS MATTRESSES HELICAL AVOIDANCE SYSTEM AUTOMATIC PRODUCT SIZING Learn More -

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More

T-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINET-8404 AUTOMATIC MATTRESS HOTMELT GLUE LINE CONTENT OF LINE HOT MELT SITATION UNIT - WITH HOT MELT UNIT (CORNER AND CENTER GLUING) TRANSPORTATION CONVEYOR WITH ANTISTATIC SILICON BELT (2 SETS) MATTRESS FLIPPING CONVEYOR (1 SET) AUTOMATIC PRESSING SYSTEM (1 SET) Learn More -

J-3325 SEMI-AUTOMATIC MATTRESS COMPRESSING MACHINE WITHOUT CONVEYORJ-3325 SEMI-AUTOMATIC MATTRESS COMPRESSING MACHINE WITHOUT CONVEYOR MAXIMUM PRESSURE : 60 TONS TOTAL POWER : 15 KW DIMENSIONS: LENGTH 2650 x WIDTH 2250 x HEIGHT 2700mm TOTAL WEIGHT: 3500KG QUANTITY : 1 Learn More

J-3325 SEMI-AUTOMATIC MATTRESS COMPRESSING MACHINE WITHOUT CONVEYORJ-3325 SEMI-AUTOMATIC MATTRESS COMPRESSING MACHINE WITHOUT CONVEYOR MAXIMUM PRESSURE : 60 TONS TOTAL POWER : 15 KW DIMENSIONS: LENGTH 2650 x WIDTH 2250 x HEIGHT 2700mm TOTAL WEIGHT: 3500KG QUANTITY : 1 Learn More -

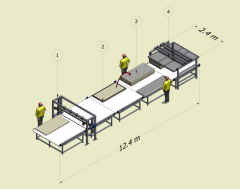

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

YY-2861 UNIVERSAL FILLING MACHINE FU 200/30SYY-2861 UNIVERSAL FILLING MACHINE FU 200/30S THE UNIVERSAL FILLING MACHINE FOR ALL TYPES OF MATTRESSES. - INNER SPRING MATTRESSES; - ALL FOAM MATTRESSES; - LATEX MATTRESSES; - COMPOUND MATTRESSES OF FOAM OR LATEX LAYERS WITH LAYERS OF NATURAL FIBRES. Learn More

YY-2861 UNIVERSAL FILLING MACHINE FU 200/30SYY-2861 UNIVERSAL FILLING MACHINE FU 200/30S THE UNIVERSAL FILLING MACHINE FOR ALL TYPES OF MATTRESSES. - INNER SPRING MATTRESSES; - ALL FOAM MATTRESSES; - LATEX MATTRESSES; - COMPOUND MATTRESSES OF FOAM OR LATEX LAYERS WITH LAYERS OF NATURAL FIBRES. Learn More