Search results for: 'Oper'

- Related search terms

- Opera

- Operating s

- Operating system

- Operating sy'A=0'

- operation system'

-

TT-3432 JAMES MACKIE & SONS LTD TEXTILE MACHINERY, SPINDLES 22 X 12 X 2TT-3432 JAMES MACKIE & SONS LTD TEXTILE MACHINERY, SPINDLES 22 X 12 X 2 JAMES MACKIE & SONS LTD TEXTILE MACHINERY SPINDLES 22 X 12 X 2 INTERNAL SPINDLE-Ø 56,7, INCL. SENSOR, MAKE ATEX, GAUGE MAX. NM 40, CONTROL CABINET, SPS-CONTROL, MAKE SIEMENS, OPERATOR TOUCHPANEL, TYPE COROS OP 25 Learn More

TT-3432 JAMES MACKIE & SONS LTD TEXTILE MACHINERY, SPINDLES 22 X 12 X 2TT-3432 JAMES MACKIE & SONS LTD TEXTILE MACHINERY, SPINDLES 22 X 12 X 2 JAMES MACKIE & SONS LTD TEXTILE MACHINERY SPINDLES 22 X 12 X 2 INTERNAL SPINDLE-Ø 56,7, INCL. SENSOR, MAKE ATEX, GAUGE MAX. NM 40, CONTROL CABINET, SPS-CONTROL, MAKE SIEMENS, OPERATOR TOUCHPANEL, TYPE COROS OP 25 Learn More -

TT-1592 ANGELUS INTEGRATED FILLER/SEAMER CANNING LINE, YEAR 2018TT-1592 ANGELUS INTEGRATED FILLER/SEAMER CANNING LINE, YEAR 2018 MANUFACTURED BY PNEMAUTIC SCALE ANGELUS MODEL CB50F FEATURES 6-HEAD INLINE FILLER WITH SINGLE HEAD CAN SEAMER YEAR: 2018 BRIEFLY USED IN BREWERY OPERATION BUT NEVER PUT INTO FULL PRODUCTION QUANTITY: 1 Learn More

TT-1592 ANGELUS INTEGRATED FILLER/SEAMER CANNING LINE, YEAR 2018TT-1592 ANGELUS INTEGRATED FILLER/SEAMER CANNING LINE, YEAR 2018 MANUFACTURED BY PNEMAUTIC SCALE ANGELUS MODEL CB50F FEATURES 6-HEAD INLINE FILLER WITH SINGLE HEAD CAN SEAMER YEAR: 2018 BRIEFLY USED IN BREWERY OPERATION BUT NEVER PUT INTO FULL PRODUCTION QUANTITY: 1 Learn More -

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More

YY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINEYY-2154 AUTOMATIC MATTRESS PROTECTOR SEWING MACHINE TECHNICAL DATA: 1. INCORPORATED PEGASUS OVERLOCK SEWING MACHINE, WITH HIGH SPEED AND STABLE PERFORMANCE. 2. DUAL MACHINE HEAD SYNCHRONOUS OPERATION, FREELY SWITCHABLE, INDEPENDENT OPERATION, OR RUN SYNCHRO - NOUSLY. 3. ELASTIC TENSION CONTROL STRUCTURE, AUTOMATIC GUIDE STRUCTURE, TO ENSURE ELASTIC SEWING AUTOMATION IS COMPLETED. 4. AUTOMATIC CORRECTION OF ALIGNMENT TO ENSURE THE SEWING PROCESS OF RUBBER BAND PERFECTLY & CONTINUOUS STITCHING. 5. PEDAL CONTROL SEWING SPEED, CUT AND STITCH TOGETHER, EXCESS EDGE MATERIAL CUT AND COLLECTED VIA ABSORPTION BIN. 6. SKIRT WIDTH SUPPORTS: 200 TO 500mm. 7. THREAD BREAKAGE DETECTION AND ALERT WITH ALARM. 8. THE MACHINE OCCUPIES SMALL SPACE, LOW POWER, AND SAVE ENERGY. 9. LARGE THREAD SPOOL HOLDER RACK IS OPTIONAL TO REDUCE FREQUENCY OF THREAT CHANGES. 10. CONSTANT TENSION CONTROL ENSURES THE STITCHING QUALITY OF ELASTIC SKIRT. APPLICATION: FOR MATTRESS PROTECTOR PRODUCTION, AUTOMATIC RUBBER BANDS SEWING, AUTO EDGE-ALIGNMENT, AUTO-FEEDING, DETECT MATERIAL, ETC. QUANTITY: 1 Learn More -

P-8875 INCLINED WHEELCHAIR LIFTSPLATFORM BASEBOARD ANTI-COLLISION FUNCTION: BASEPLATE AUTOMATICALLY DETECTS DISPLACEMENT AND SUSPENDS OPERATION TO ENSURE PASSENGER SAFETY. RAMPS ANTI-COLLISION FUNCTION: IF OBSTACLES CAN STOP AUTOMATICALLY, PERSONAL SAFETY OF PEDESTRIANS AND PASSENGERS CAN BE PROTECTED. RUNNING LIGHTS: WHEN RUNNING, THE OPERATION INDICATOR LIGHTS UP HELP BELL BUTTON: AT ANY TIME, YOU CAN PRESS THE BELL TO CALL THE OPERATOR QUANTITY: 1 Learn More

P-8875 INCLINED WHEELCHAIR LIFTSPLATFORM BASEBOARD ANTI-COLLISION FUNCTION: BASEPLATE AUTOMATICALLY DETECTS DISPLACEMENT AND SUSPENDS OPERATION TO ENSURE PASSENGER SAFETY. RAMPS ANTI-COLLISION FUNCTION: IF OBSTACLES CAN STOP AUTOMATICALLY, PERSONAL SAFETY OF PEDESTRIANS AND PASSENGERS CAN BE PROTECTED. RUNNING LIGHTS: WHEN RUNNING, THE OPERATION INDICATOR LIGHTS UP HELP BELL BUTTON: AT ANY TIME, YOU CAN PRESS THE BELL TO CALL THE OPERATOR QUANTITY: 1 Learn More -

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More

AA-1120 BASE SHOP COFFEE ROASTERAA-1120 –SALE BASE SHOP COFFEE ROASTER TECHNICAL SPECIFICATIONS: GREEN COFFEE BATCH CAPACITY (MAX): 1.2KG BATCH CAPACITY (MINIMUM ADVISED): 0.5KG CAPACITY PER HOUR: 4KG OPERATION CONTROL TYPE: MANUAL AIRFLOW CONTROL (DAMPER): MANUAL ROASTING TIME: 12 TO 15MIN TEMPERATURE SENSORS: 2 (BEAN AND EXHAUST AIR TEMPERATURE) COOLING TIME: 3MIN TYPE OF COOLING: AIR AMBIENT SAFETY DEVICE: YES OPERATION TYPE BURNER: MANUAL FUEL TYPE: NATURAL GAS(LNG)/PROPANE GAS(LPG) BURNER POWER LPG (G30): LPG 7 TO 23.885KW - BTU/H BURNER POWER LNG (G20): LNG 12 TO 40.945KW - BTU/H INLET PRESSURE LNG: 20MBAR INLET PRESSURE LPG: 37MBAR POWER: 2200W VOLTAGE: 220V/60HZ EXHAUST CHIMNEY (ROASTER CYCLONE): 100mm EXHAUST CHIMNEY (COOLER): 80mm ROASTER FAN MOTOR: 0.33HP COOLER FAN MOTOR: 0.33HP DRUM GEARBOX: 0.17HP COOLER GEARBOX: 170/374HP DIMENSIONS (L X W X H): 1465X940X1180mm NET WEIGHT (ROASTER + CYCLONE): 170KG SHIPPING BOX (L X W X H): 1560X1150X1410mm SHIPPING WEIGHT: 410KG Learn More -

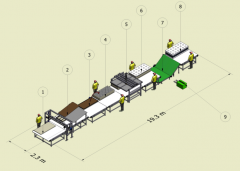

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More

K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5013 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 350 TO 400 MATTRESSES PER 8-HOUR SHIFT MAXIMUM WORKING WIDTH: 2200mm CAPACITY: AVERAGE OF 350 TO 400 MATTRESSES (IF OPERATORS WORK WITH AVERAGE EFFICIENCY); TWO LAYERS FOR EACH PANEL ARE GLUED. IN THE FIRST BRIDGE THERE ARE 5 HOTMELT GUNS IN TOTAL: 2 GUNS FOR THE EDGE GLUING 3 GUNS FOR THE CENTER GLUING ONE OF THE 2 EDGE GUNS HAS 8 NOZZLES (T-SHAPE) THE OTHER GUN HAS 4 NOZZLES THE THREE GUNS FOR CENTER GLUING CAN MOVE PNEUMATICALLY (ZIG-ZAG, ARC SHAPE) FELT-TO-FOAM BONDING THE MANUAL GLUING UNIT HAS 2 SPRAY GUNS WITH SEPARATE, 5-METER-LONG PIPES FLOOR SPACE DIMENSIONS: 19300mm X 2300mm ALL THE GLUING MACHINES ARE ABLE TO WORK WITH ANY KIND OF MATTRESS SIMPLY CHOOSE THE MATTRESS TYPE AND THE PARAMETERS ARE SET AUTOMATICALLY QUANTITY AVAILABLE: 1 Learn More -

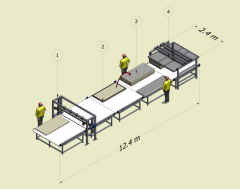

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More

K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFTREFERENCE NUMBER: K-5003 HOTMELT GLUING MATTRESS PRODUCTION LINE 2200mm 500 TO 600 MATTRESSES PER 8-HOUR SHIFT MAX WORKING WIDTH: 2200mm CAPACITY: AVERAGE 500 TO 600 MATTRESSES PER 8 HOUR SHIFT (DEPENDING ON THE OPERATOR PERFORMANCE), ASSUMING ONLY ONE FOAM LAYER IS USED. THE OVERALL SYSTEM IS CONTROLLED WITH ONE MAIN CONTROL PANEL INCLUDES TWO HOTMELT GLUE GUNS FOR THE EDGE: ONE GUN WITH 8 NOZZLES (T-SHAPED) ONE GUN WITH 4 NOZZLES LINE IS FOR BOTH POCKET AND BONNEL SPRINGS. ONE BUTTON PRESS TOGGLES BETWEEN THE TWO; ALL GLUING DIMENSIONS WILL BE SET AUTOMATICALLY WITHOUT ENTERING ANY DIMENSIONS. FLOORSPACE DIMENSIONS: 12400mm X 2400mm QUANTITY AVAILABLE: 1 Learn More -

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More

K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/HREFERENCE NUMBER: K-3842 BALL FIBER MACHINE CAPACITY 100-120KG/H ASSEMBLED WITH A BALL FIBER MACHINE AND A TRANSPORT BLOWER WHICH TRANSPORTS FINISHED BALL FIBER TO NEXT PROCESS FOR USE. SUITABLE RAW MATERIAL IS CONJUGATED HOLLOW SILICONIZED POLYESTER FIBER SHORTER THAN 100mm, SUCH AS 3D, 7D, 15D, 32mm, 51mm, 64mm ETC. BALL FIBER MACHINE INNER ASSEMBLY WITH AN OPENING ROLLER AND BALLING ROLLER. THIS MAKES THE PRODUCED BALL FIBER ELASTIC AND FLEXIBLE MACHINE WITH PLC CONTROL SYSTEM THAT KEY PARTS ARE FROM THE FAMOUS WORLD BRANDS SUCH LIKE SIEMENS, OMRON AND SCHNEIDER ETC. STABLE QUALITY AND WITH LOCAL SERVICE TO SUPPORT YOU. BALL FIBER SIZE ADJUSTABLE FAN MADE FROM ALUMINUM MATERIAL, SO CAN RUN FAST AND QUIET SIMPLE OPERATOR SKILL REQUIRED DIFFERENT POWER VOLTAGE AND SAFETY STANDARD CAN BE ORDERED ACCORDING TO THE CUSTOMER’S LOCAL REQUIREMENT CE CERTIFICATION DIMENSIONS: 4860 X 1630 X 1250mm QUANTITY AVAILABLE: 1 Learn More -

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More

E-9988 AUTOMATIC PILLOW MACHINEREFERENC ENUMBER: E-9988 AUTOMATIC PILLOW MACHINE MODEL: CF INSTALLATION AREA: 9000 X 5000 X 2100mm (29.5 FEET X 16.4 FEET X 82 INCHES) MIXING CHAMBER SIZE: AROUND 300KG (600 LBS) VOLTAGE: AS PER CUSTOMER REQUIREMENT POWER: 11.8KW CAPACITY: 6 PILLOWS PER MINUTE WEIGHING: ACCORDING TO THE TIME OF FILLING DISCHARGE. WEIGHT: 1.8MT (4000 LBS) LABOR: 1 OPERATOR CONTROL SYSTEM: COMPUTERIZED CONTROL SYSTEM QUANTITY AVAILABLE: 1 Learn More -

K-1291 INNOVATIVE SEWING TECHNOLOGY FOR HIGH QUALITY CUSHIONSREFERENCE NUMBER: K-1291 INNOVATIVE SEWING TECHNOLOGY FOR HIGH QUALITY CUSHIONS SPECIFIC FOR PRODUCING CUSHIONS OF SOFAS AND ARMCHAIRS, IN FOAM PARTIALLY OR TOTALLY COVERED WITH DACRON, EVEN WITH MECHANICAL PARTS, BABY MATTRESS, BEDSOFAS, CARAVAN BEDS WORKS WITH MANY KINDS OF MATERIALS: FOAM, DACRON (FOR FOAM THICKNESS: UP TO 20mm. ALSO HIGH DENSITY; FOR DACRON: UP TO 1000 GRAMS DENSITY), SYNTHETIC FIBER, COTTON, NON WOVEN, FEATHER, FIBRES, RECYCLED FIBRES AND FIBERBALLS. THE RESISTANT AND ELASTIC SEAM ALLOWS THE ELIMINATION OF THE USE OF GLUE, MAXIMIZING THE QUALITY OF THE PRODUCT AND GIVING ADDED VALUE TO THEIR PRODUCTION FACILITATES THE UPHOLSTERER OPERATIONS DURING THE SOFA CONSTRUCTION, GIVING ADVANTAGES THROUGHOUT ALL THE PRODUCTION PHASES QUANTITY AVAILABLE: 1 Learn More

K-1291 INNOVATIVE SEWING TECHNOLOGY FOR HIGH QUALITY CUSHIONSREFERENCE NUMBER: K-1291 INNOVATIVE SEWING TECHNOLOGY FOR HIGH QUALITY CUSHIONS SPECIFIC FOR PRODUCING CUSHIONS OF SOFAS AND ARMCHAIRS, IN FOAM PARTIALLY OR TOTALLY COVERED WITH DACRON, EVEN WITH MECHANICAL PARTS, BABY MATTRESS, BEDSOFAS, CARAVAN BEDS WORKS WITH MANY KINDS OF MATERIALS: FOAM, DACRON (FOR FOAM THICKNESS: UP TO 20mm. ALSO HIGH DENSITY; FOR DACRON: UP TO 1000 GRAMS DENSITY), SYNTHETIC FIBER, COTTON, NON WOVEN, FEATHER, FIBRES, RECYCLED FIBRES AND FIBERBALLS. THE RESISTANT AND ELASTIC SEAM ALLOWS THE ELIMINATION OF THE USE OF GLUE, MAXIMIZING THE QUALITY OF THE PRODUCT AND GIVING ADDED VALUE TO THEIR PRODUCTION FACILITATES THE UPHOLSTERER OPERATIONS DURING THE SOFA CONSTRUCTION, GIVING ADVANTAGES THROUGHOUT ALL THE PRODUCTION PHASES QUANTITY AVAILABLE: 1 Learn More