Search results for: 'Steel'

- Related search terms

- steel wool

- steel bolt

- steel structure dimensions

- steel smart

- Steel+ta

-

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More

T-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mmT-7066 MELTBLOWN NON-WOVEN PRODUCTION LINE- 1600mm (1) EFFECTIVE WIDTH: 1600mm; (2) MAXIMUM COIL DIAMETER: 1200mm; (3) YIELD: 1.5 TO 2.0T /24 HOURS (20G/SQUARE); (4) FILAMENT SIZE: 2UM-5UM; (5) MAIN RAW MATERIALS: POLYPROPYLENE SLICING (MELTING AND SPRAYING SPECIAL MATERIALS) (6) PRODUCT WEIGHT: 15 TO 200G/M2. (7) MECHANICAL SPEED: 10 TO 80M/MIN; (8) INSTALLED CAPACITY: 450KW; (9) EQUIPMENT SIZE: 16000mm×6000mm×6000mm QUANTITY: 1 Learn More -

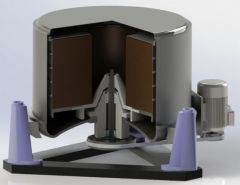

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More

AA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETERAA-1181 CENTRIFUGAL EXTRACTOR–1250mm/1500mm DIAMETER THIS CENTRIFUGAL EXTRACTOR IS USED TO PREDRY ALL KINDS OF FIBERS AFTER DYEING, HAS A MODULAR STRUCTURE TECHNICIAL SPECIFICATIONS: 1. BASKET DIAMETER: Ø500 TO Ø1800 mm 2. BASKET DEPTH: 750 mm 3. ROLLING BASKET: AISI304L STAINLESS PERFORATED STEEL 4. EXTERNAL BASKET: AISI304L STAINLESS STEEL 5. BASKET THICKNESS: 4mm 6. OUTER BASKET THICKNESS: 4mm 7. DRIVE MOTOR: 22 KW/H SPEED 1500 RPM 8. STRENGTH CIRCLE (USED TO INCREASE THE STRENGTH OF THE INNER BASKET (ROTATING PART) : 20 x 20 AISI304L STAINLESS PLATE (4 PIECES) 9. BEARING BLOCK: 3 PIECES, SKF/FAG BEARING 10. SPEED CONTROL: INVERTER CONTROL 11. BREAKING: INVERTER CONTROL EXTERNAL BREAKING SYSTEM Learn More -

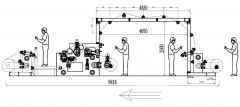

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More

YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES)YY-2409 SLOT DIE COATING MACHINE, MAXIMUM COATING WIDTH 1550mm (61 INCHES) APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, FOR COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. APPLICATION MATERIAL: PET, PVC, PAPER ETC. MACHINE FEATURES: 1. THIS MACHINE INCLUDES MICROCOMPUTER PLC, TOUCH SCREEN CONTROL, SIMPLE OPERATION AND HIGH AUTOMATION; 2. USING HIGH WEAR-RESISTANT ALLOY STEEL SLOT DIE, WITH COATING CONTROL ACCURACY AND GOOD SERVICE LIFE; 3. AN OVERALL COATING ADJUSTMENT BRACKET IS INCLUDED, AND THE REPEAT POSITIONING ACCURACY IS PRECISE; 4. AUTOMATICALLY TRACKS AND DISPLAYS AND STORES THE AMOUNT OF GLUE NEEDED, MAKING THE OPERATION AND USE CONVENIENT AND FAST; 5. THE FIRST UNWINDING IS EQUIPPED WITH A WEB GUIDING DEVICE, WITH A HIGH-PERFORMANCE INFRARED SENSOR AND ELECTRIC CONTROLLER TO ENSURE THE EVEN LET OFF OF THE MATERIAL ROLL; 6. THE HEATING TEMPERATURE IS ALL CENTRALLY CONTROLLED BY PLC; 7. THE AMOUNT OF GLUE SUPPLIED BY THE METERING PUMP FOR THE COATING WIDTH IS INPUT BY THE WORKER, AND THE AMOUNT OF GLUE SUPPLIED WILL BE AUTOMATICALLY CALCULATED AND SUPPLIED TO THE DIE SLOT. QUANTITY: 1 Learn More -

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More

YY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATIONYY-2761 SLOT DIE COATING MACHINE, WORKING WIDTH 1550mm, FOR HOT MELT PRESSURE SENSITIVE ADHESIVE COATING AND LAMINATION APPLICATION: 1. HOT MELT SENSITIVE PRESSURE ADHESIVE COATING AND LAMINATION LINE, IT HAS FUNCTIONS OF COATING, LAMINATION, PEELING, REWINDING FUNCTION. 2. MATERIAL APPLICATION: PET, PVC, PAPER ETC. QUANTITY: 1 Learn More -

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More

V-2042 WATER RECIRCULATION SYSTEM FOR WATERJETSV-2042 WATER RECIRCULATION SYSTEM FOR WATERJETS 6 LITERS PER MINUTE MAXIMUM JET HEAD USES 1 TO 2 LITERS PER MINUTE FILTRATION: FROM 5 TO 10 MICRONS Learn More -

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More

TT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mmTT-1431 SLOT DIE COATING MACHINE, COATING WIDTH 1600mm PARAMETERS 1. COATING METHOD: SLOT DIE COATING 2. MAX. COATING WIDTH: 1600mm 3. COATING WEIGHT: 50 TO 300 GSM 4. UNIFORMITY: ≤10% 5. MECHANICAL SPEED: 1 TO 20 METERS PER MINUTE 6. COATING SPEED: THE COATING SPEED IS DETERMINED ACCORDING TO THE COATING WEIGHT, QUANTITY, ADHESIVE VISCOSITY, THE TEMPERATURE AND THE SUBSTRATE. 7. ROLLER WIDTH: 1750mm (ACTUAL WORKING WIDTH OF PAPER ROLL IS 1600mm) 8. MAX. UNWINDING DIAMETER: 1250mm 9. MAX. REWINDING DIAMETER: 950mm 10. UNWINDING TENSION: ≤600N 11. FILM UNWINDING TENSION: ≤200N 12. WINDING TENSION: ≤600N 13. GLUE MELTING SPEED: 310 KG/HOUR 14. GLUE INPUT HOSE: TEFLON TUBE 15. GLUE MELTING TEMPERATURE: ABOUT 260°C MAXIMUM 16. MECHANICAL POWER: ABOUT 40 KW 17. INSTALLED POWER: ABOUT 110 KW 18. POWER SUPPLY: ABOUT 440 VOLTS, 60Hz 19. AIR SOURCE: 0.6 TO 0.8 MPA 20. WATER SOURCE: 0.15 TO 0.4 MPA CIRCULATING COOLING WATER 21. DIMENSIONS: 9000 (LENGTH) X 6600 (WIDTH) X 2300mm 22. THE AMOUNT OF GLUE AND THE GLUE SPEED ARE TRACKED SYNCHRONOUSLY, AND CAN ALSO BE ADJUSTED INDEPENDENTLY QUANTITY: 1 Learn More -

L-3886 CHICKEN FEED PRODUCTION LINE

L-3886 CHICKEN FEED PRODUCTION LINEREFERENCE NUMBER: L-3886

Learn More

1) RECEIVING PROCESS

HEIGHT: 12 METERS

POWER: 1.5 KW

2) GRINDING AND MIXING PROCESS

LENGTH: 1.5 METERS

POWER: 1.5 KW

3) PELLETIZING AND BAGGING PROCESS

CAPACITY: 2 TO 3 TONS PER HOUR, PER UNIT

POWER: 37 KW

4) AUXILIARY PROCESS

POWE: 1.5 KW

5) ELECTRIC CONTROL SYSTEM

POWER: 3 PHASE, 380 VOLTS, 50 Hz -

TT-6361 SIEMENS SGT 400 POWER PLANT – NEW, 12.9 MW, YEAR 2017, 50HzTT-6361 SIEMENS SGT 400 POWER PLANT – NEW, 12.9 MW, YEAR 2017, 50Hz 1. BRAND: SIEMENS TURBINES 2. MODEL: SIEMENS SGT400 3. CONDITION: NEW 4. YEAR: 2017 Learn More

TT-6361 SIEMENS SGT 400 POWER PLANT – NEW, 12.9 MW, YEAR 2017, 50HzTT-6361 SIEMENS SGT 400 POWER PLANT – NEW, 12.9 MW, YEAR 2017, 50Hz 1. BRAND: SIEMENS TURBINES 2. MODEL: SIEMENS SGT400 3. CONDITION: NEW 4. YEAR: 2017 Learn More -

YY-3241 SIEMENS SGT 400 GAS TURBINE, 12.9 MW, 11 KV, NATURAL GAS, YEAR 2017, 50 HzYY-3241 SIEMENS SGT 400 GAS TURBINE, 12.9 MW, 11 KV, NATURAL GAS, YEAR 2017, 50 Hz MW: 12.9 VOLTAGE: 11 KV FUEL TYPE: NATURAL GAS YEAR: 2017 50 Hz QUANTITY: 1 Learn More

YY-3241 SIEMENS SGT 400 GAS TURBINE, 12.9 MW, 11 KV, NATURAL GAS, YEAR 2017, 50 HzYY-3241 SIEMENS SGT 400 GAS TURBINE, 12.9 MW, 11 KV, NATURAL GAS, YEAR 2017, 50 Hz MW: 12.9 VOLTAGE: 11 KV FUEL TYPE: NATURAL GAS YEAR: 2017 50 Hz QUANTITY: 1 Learn More -

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More

YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATIONREFERENCE NUMBER: YY-1365 CONTINUOUS PRODUCTION LINE FOR IMPREGNATION, DRYING, ABRASIVE SPRAY, HEAT-SETTING OF SYNTHETIC FIBERS FOR ABRASIVE WADDINGS, WITH AIRLAY CARDING MACHINE AND FIBER PREPARATION DETAILS: MAIN FEATURES: - THREE LAYERS OVEN: TWO UPPER DRYING LAYERS WITH LENGTH OF 6+ 6 METERS; ONE LOWER CURING LAYER WITH A LENGTH OF 6 METERS; - HEATING: BY DIRECT HEATING WITH AUTOMATIC BURNERS; - CONVEYOR WIDTH: 2200mm; - WORKING WIDTH: 2000mm; - MAX DRYING AND POLYMERISATION TEMPERATURE: 230°C; - HEATING POWER: 4 BURNERS 350 KW EACH ONE, ABOUT TOTAL 1.400 KW; - VENTILATION: SEMI-CLOSED SYSTEM WITH 4 CENTRIFUGAL VENTILATORS; - ADJUSTABLE CONVEYOR SPEED BY A.C. MOTORS; - INSTALLED ELECTRIC POWER: 200 KW. APPROX.; - MECHANICAL SPEED: 2÷15 METERS PER MINUTE; - CONVEYOR DRIVING: BY A.C. MOTORS; - MANUFACTURED ARTICLE: SYNTHETIC FIBERS ABRASIVE WADDING. Learn More