Search results for: 'cutting for'

- Related search terms

- Cutting+machine

- Cutting+m

- Cutting machin

- Cutting machi'

- Cutting fa

-

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

M-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mmM-6053 SPUNBOND PRODUCTION LINE, WORKING WIDTH 4040mm TO 4500mm

OFFER 001

SPUNBOND PRODUCTION LINE

WORKING WIDTH: 4040mm

WEIGHT: 130 TO 250 G/M2OFFER 002

POLYMER CLEANING GROUPOFFER 003

CRYSTALLIZING GROUPOFFER 004

DRYING GROUPOFFER 005

PNEUMATIC CONVEYING SYSTEMOFFER 006

EXTRUDER HOPPEROFFER 007

EXTRUDEROFFER 008

FILTERING UNITOFFER 009

MELT TRANSFER LINEOFFER 010

SPINNING BEAMOFFER 011

SPINNING PACKSOFFER 012

FILAMENTS QUENCHING SYSTEMOFFER 013

FILAMENTS DRAWING AND DISTRIBUTION SYSTEMOFFER 014

WEB FORMING CONVEYOR BELTOFFER 015

CREEL FOR APPLICATION OF REINFORCING FILAMENTSOFFER 016

PRE-NEEDLING MACHINEOFFER 017

NEEDLING MACHINEOFFER 018

THERMOSETTING UNITOFFER 019

OUTLET CALENDEROFFER 020

FOULARDOFFER 021

BINDER PREPARATION SYSTEMOFFER 022

DRYEROFFER 023

OUTLET CALENDEROFFER 024

AUTOMATIC WINDEROFFER 025

AIR COMPRESSORS (FOR FILAMENTS STRETCHING EJECTORS)OFFER 026

DIATHERMIC OIL HEATING SYSTEMOFFER 027

CHILLED WATER CIRCULATION AND GENERATION SYSTEMOFFER 028

EQUIPMENT FOR CLEANING CYCLE, SPECIAL TOOLSOFFER 029

FIBRE DUST RECOVERY SYSTEMOFFER 030

EDGES RECOVERY SYSTEMOFFER 031

SPINNING SECTION STEEL STRUCTUREOFFER 032

DISTRIBUTION ELECTRIC CABINETSOFFER 033

PROCESS ELECTRIC SYSTEM OF EXISTING MACHINES ACCORDING TO THE ACTUAL LAYOUTOFFER 034

CABLES AND CABLING MATERIALSQUANTITY: 1 LINE

Learn More -

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINE

M-0450 GPE1000 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1000MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:1000M/H ● OUTPUT:45KG/H ● TOTAL POWER:50KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:65MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 15KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : ONE-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:160MM (3) FILTER INSIDE DIA: 65MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1050MM (4) WIDTH ADJUSTMENT: UT-BLOCK TYPE, SINGLE SIDE IS 200MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1050MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT) AND 8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 1.5KW (6) THREE TRACTION ROLLER: 1050MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND15KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER. SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC

Learn More -

GPE1500 PE AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1500MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:800M/H ● OUTPUT:75KG/H ● TOTAL POWER:70KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T ● NEED ONE 20’ CONTAINER: EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:75MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 18.5KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:180MM (3) FILTER INSIDE DIA:75MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1550MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 13KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1550MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 3KW (6) THREE TRACTION ROLLER: 1550MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 18.5KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More

GPE1500 PE AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE ADOPTS ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. THIS MACHINE SET HAS SUCH FEATURES AS SCIENTIFIC AND REASONABLE STRUCTURE DESIGN, SMOOTH AND RELIABLE RUNNING AND CONVENIENT OPERATION AND MAINTENANCE. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVING VACUUM FORMING ROLL. FEATURE USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM CUSTOMIZED. ◆ APPLICATION OF AIR BUBBLE FILM ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE NEW MATERIAL, OR RECLAIMED MATERIALS. THE COLOR OF FILM MADE BY NEW MATERIAL IS GOOD. THE COLOR OF FILM MADE BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: ● PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL ● RAW MATERIAL : LDPE AND LLDPE ● WIDTH OF THE FILM :MAX IS 1500MM ● FILM THICKNESS:0.05MM-0.15MM ● LINEAR SPEED:800M/H ● OUTPUT:75KG/H ● TOTAL POWER:70KW ● POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) ● MACHINE WEIGHT:3T ● NEED ONE 20’ CONTAINER: EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:75MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFETIME. (3) HOPPER SEAT: CENTRAL FEEDING (4) MAIN MOTOR: 18.5KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:180MM (3) FILTER INSIDE DIA:75MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1550MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :THREE ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 13KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1550MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 3KW (6) THREE TRACTION ROLLER: 1550MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:2.2KW 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINT BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 18.5KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI NS BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS FREE: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More -

PE1800 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE INCLUDES ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVEN VACUUM FORMING ROLL. FEATURES USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM AND CUSTOMIZE WIDTHS. APPLICATIONS OF AIR BUBBLE FILMS: ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE VIRGIN POZYMER, OR RECLAIMED POLYMERS. CAN BE COLORED FILM WITH NEW POLYMER ( BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL RAW MATERIAL : LDPE AND LLDPE WIDTH OF THE FILM :MAX IS 1800MM FILM THICKNESS:0.05MM-0.15MM LINEAR SPEED:800M/H OUTPUT:90KG/H TOTAL POWER:86KW POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) MACHINE WEIGHT:3.5T NEED ONE 40’ CONTAINER EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:90MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFE TIME. (3) HOPPER: CENTRAL FEEDING (4) MAIN MOTOR: 30KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:200MM (3) FILTER INSIDE DIA:105MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1880MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :FOUR ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 25KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1880MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 2.2KW (6) THREE TRACTION FLAT ROLLER: Ф47MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:16NM 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINA BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 30KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI PARNIER BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS INCLUDED: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More

PE1800 AIR BUBBLE FILM MAKING MACHINEDESCRIPTION OF MACHINE THIS MACHINE INCLUDES ONCE-THROUGH SHAPING TECHNIQUE, THUS IT HAS HIGH EFFICIENCY AND EXCELLENT PRODUCT QUALITY. AIR BUBBLE SHEET EXTRUSION LINE PRODUCES CONTINUOUS ROLL OF AIR BUBBLE SHEET, AN IDEAL CUSHIONING-PACKAGING AND INSULATING MATERIALS, BY EXTRUDING POLYETHYLENE MELT THROUGH T-DIE OVER A DRIVEN VACUUM FORMING ROLL. FEATURES USER-FRIENDLY SYSTEM WITH AC VARIABLE SPEED DRIVES. PID TEMP. CONTROL & DIGITAL TEMP. DISPLAY. 2-LAYERS WIDTH 1000, 1200,1500, 1800, 2000,2500,3000MM AND CUSTOMIZE WIDTHS. APPLICATIONS OF AIR BUBBLE FILMS: ◆ EXCELLENT SHOCK ABSORBENCY. ◆ VERY LIGHT, TRANSPARENT BUFFER MATERIAL. ◆ HARMLESS AND RESISTANT TO ACID, ALKALI, OIL AND OTHER CHEMICALS. ◆ HIGHLY RESISTANT TO WATER AND MOISTURE. ◆ PRINTING AND LAMINATION WITH OTHER MATERIALS-IN ADDITION TO CUTTING, SLITTING, BAG-MAKING AND PUNCHING-ARE POSSIBLE. ◆ PACKAGE VOLUME REDUCTION PERMITS COST REDUCTION. ◆ EXCELLENT INSULATION EFFECTIVENESS. ◆ VARIED FROM PACKAGING OF FRAGILE ITEMS TO INSULATED COVER FOR SWIMMING POOLS. RAW MATERIAL IS LDPE : YOU CAN USE VIRGIN POZYMER, OR RECLAIMED POLYMERS. CAN BE COLORED FILM WITH NEW POLYMER ( BY RECLAIMED MATERIALS IS NOT VERY TRANSPARENT, MAYBE A LITTLE GRAY. IF YOU WANT TO PRODUCE COLOR FILM. YOU CAN ADD COLOR MASTER BATCH. TECHNICAL PARAMETERS: PRODUCTS PRODUCED: LDPE AIR BUBBLE FILM SHEET IN ROLL RAW MATERIAL : LDPE AND LLDPE WIDTH OF THE FILM :MAX IS 1800MM FILM THICKNESS:0.05MM-0.15MM LINEAR SPEED:800M/H OUTPUT:90KG/H TOTAL POWER:86KW POWER SUPPLY:380V/3PHASE,50HZ (IF THE VOLTAGE IS DIFFERENT PLEASE TELL US, AND THE PRICE MAYBE DIFFERENT) MACHINE WEIGHT:3.5T NEED ONE 40’ CONTAINER EQUIPMENT SPECIFICATIONS: 1. EXTRUDER (1) SCREW( ZHOU SHAN) DIAMETER OF SCREW:90MM L/D: 30:1 (2) SCREW AND BARREL MATERIAL: 38 CRMOAL AFTER NITROGEN TREATMENT WITH OPTIMUM HARDNESS, STRONG CORROSION RESISTANCE AND LONG SERVICE LIFE TIME. (3) HOPPER: CENTRAL FEEDING (4) MAIN MOTOR: 30KW, WITH FREQUENCY INVERTER CONTROL (5) HEATING METHOD: ALUMINUM-CASTED HEATER (6) HEATING ZONE : FOUR-ZONE DIGITAL TEMPERATURE CONTROL (7) GEAR BOX: HARD TOOTH GEAR BOX 2. FILTER PART: (1) LONG-LIFE NET TYPE MANUAL SCREEN CHANGING ( FAST NET CHANGER$800) (2) FILTER OUTSIDE DIA:200MM (3) FILTER INSIDE DIA:105MM 3. T-DIE: (1) WIDTH OF T-DIE: LIKE CLOTH-HANGER, ENABLE THE MELTING MATERIAL BE FLOWED EVENLY. WITH ALUMINUM-CASTED HEATER. (2) FILM STRUCTURE: 2LAYERS( FLAT FILM+ AIR BUBBLE FILM) (3) WIDTH:1880MM (4) WIDTH ADJUSTMENT: OUT-BLOCK TYPE, SINGLE SIDE IS 250MM (5) HEATING ZONE :FOUR ZONE, ALUMINUM-CASTED HEATER (6) HEATING POWER: 25KW 4. TRACTION PART: (1) AIR BUBBLE FORMING ROLLER 1PC:WIDTH 1880MM FORMING WAY: VACUUM SUBPRESSURE MOULD BUBBLE SPEC:10(DIAMETER)X4MM(HEIGHT),8MM*2.5MM ----------IT ALSO CAN BE DESIGNED WITH ACCORDING TO THE CUSTOMERS. (SCOPE: 6MM—32MM) (2) COOLING WAY: WATER COOLING (3) DRIVING WAY: LP MOTOR IN SHANGHAI (4) SPEED-ADJUSTING WAY: INVERTER ADJUSTMENT (5) DRIVING POWER: 2.2KW (6) THREE TRACTION FLAT ROLLER: Ф47MM 3PCS (7) EQUIPPED WITH CUTTING KNIFES AS CUSTOMER REQUEST. 5. WINDING PART: (1) WITH METER COUNTER, ALARM WARNING (2) TORQUE MOTOR (3) AUTOMATIC COLLECTION. AUTO CHANGER (4) MANUAL CUT FILM (5) WINDING MOTOR POWER:16NM 6.ELECTRICAL PARTS AND MOTORS:MADE IN CHINA ● ELECTRICAL PARTS:CHINA BRAND ● MAIN MOTOR:MADE IN SHANGHAI DED0NG BRAND 30KW( FREQUENCY INVERTER ADJUST SPEED) ● FREQUENCY INVERTER:MADE IN SHANGHAI PARNIER BRAND ● GEAR BOX : HARD TOOTH GEAR BOX ● ALUMINUM CASTING HEATING 7. COOLING SYSTEM: WATER RECYCLING COOLING SYSTEM. YOU CAN CHOOSE WATER TOWER OR CHILLER SPARE PARTS AS INCLUDED: 10 INCH WRENCH: 1 PC HEXAGEONIC WRENCH: 1 SET OIL GUN: 1 PC CROSS POINT SCREWDRIVER: 1 PC ELECTRICITY TESTING PEN: 1 PC MAIN SWITCH: 2 PCS TEMPERATURE CONTROLLER: 1 PC ELECTRIC-THERMAL COUPLE: 2 PCS TOOLS AND TOOL BOX: 1 SET SCREW HEATER: 1 PC CURRENT METER: 1 PC CJX1-22A/22V A.C CONTACTOR: 1 PC FILTER: 1 PC GLOVE: 2 PCS DZ47 1P 32A CIRCUITE BREAKER: 1 PC CUTTER: 5 PC OPERATION MANUAL: 1 PC HEAT PLATE: 1 PC Learn More -

TT-4756 VARGA FLEXO 800 TYPE HK68 FLEXO PRINTING MACHINE, 6 COLOR, CI, GEARLESS, YEAR 2008TT-4756 VARGA FLEXO 800 TYPE HK68 FLEXO PRINTING MACHINE, 6 COLOR, CI, GEARLESS, YEAR 2008 CHEAP VARGA 6 COLOR 800mm WIDE INCLUDING PLATE MOUNTER + BANANA CYLINDER AND POSSIBILITY OF LENGTH-SLITTING INLINE YEAR 2008 PRINTABLE MATERIALS: PRE-TREATED PLASTICS (PET, PE, BOPP) MULTILAYER FILMS PAPER LENZE SERVOMOTORS INSTALLED IN MACHINE- MAIN DRIVE, UNWINDING, WINDING PRESSURE CYLINDER: CENTRAL IMPRESSION CI PRESSURE CYLINDER MATERIAL: ST52–3 NUMBER OF PRINTING STATIONSS: 6 PCS PRINTING LENGTH: 300 TO 550mm PRINT LENGTH SCALE: 10mm PRINTING ACCURACY AT CONSTANT SPEED ± 0.2mm LENGTH REGISTER SETTING: MANUAL CROSS REGISTER SETTING: MANUAL MAXIMUM PRINT WIDTH: 800mm MAXIMUM ROLL WIDTH: 900mm UNWINDER: 1 PC CORE DIAMETER: 76mm MAXIMUM DIAMETER OF REELS: 1000mm MECHANICAL SPEED: 15 TO 120 M / MIN MACHINE WEIGHT: 7 TONS Learn More

TT-4756 VARGA FLEXO 800 TYPE HK68 FLEXO PRINTING MACHINE, 6 COLOR, CI, GEARLESS, YEAR 2008TT-4756 VARGA FLEXO 800 TYPE HK68 FLEXO PRINTING MACHINE, 6 COLOR, CI, GEARLESS, YEAR 2008 CHEAP VARGA 6 COLOR 800mm WIDE INCLUDING PLATE MOUNTER + BANANA CYLINDER AND POSSIBILITY OF LENGTH-SLITTING INLINE YEAR 2008 PRINTABLE MATERIALS: PRE-TREATED PLASTICS (PET, PE, BOPP) MULTILAYER FILMS PAPER LENZE SERVOMOTORS INSTALLED IN MACHINE- MAIN DRIVE, UNWINDING, WINDING PRESSURE CYLINDER: CENTRAL IMPRESSION CI PRESSURE CYLINDER MATERIAL: ST52–3 NUMBER OF PRINTING STATIONSS: 6 PCS PRINTING LENGTH: 300 TO 550mm PRINT LENGTH SCALE: 10mm PRINTING ACCURACY AT CONSTANT SPEED ± 0.2mm LENGTH REGISTER SETTING: MANUAL CROSS REGISTER SETTING: MANUAL MAXIMUM PRINT WIDTH: 800mm MAXIMUM ROLL WIDTH: 900mm UNWINDER: 1 PC CORE DIAMETER: 76mm MAXIMUM DIAMETER OF REELS: 1000mm MECHANICAL SPEED: 15 TO 120 M / MIN MACHINE WEIGHT: 7 TONS Learn More -

YY-2892 FANGBANG (CHINESE) PAPER BAG MAKING MACHINEYY-2892 FANGBANG (CHINESE) PAPER BAG MAKING MACHINE MAKE: FANGBANG (CHINESE) THIS MACHINE CAN PRODUCE PAPER BAGS OF WIDE-RANGE SIZES. IT CAN PRODUCE NOT ONLY SMALL-SIZE FOOD BAGS, BUT ALSO BIG-SIZE SHOPPING BAGS. THIS MACHINE CAN MAKE VARIOUS KINDS OF PAPER BAGS HAVING DIFFERENT BOTTOM STYLES. THIS MACHINE IS DESIGNED TO MANUFACTURE SQUARE BOTTOM PAPER BAGS WITHOUT HANDLES FROM PAPER ROLL, AND IT IS AN IDEAL EQUIPMENT FOR PRODUCING PRODUCING VARIOUS SIZED PAPER BAGS FAST. BY IMPLEMENTING STEPS INCLUDING PAPER FEEDING, TUBE FORMING, TUBE CUTTING AND BOTTOM FORMING INLINE, THIS MACHINE CAN EFFECTIVELY SAVE LABOR COSTS. THE EQUIPPED PHOTOELECTRIC DETECTOR CAN CORRECT CUTTING LENGTH, SO AS TO ENSURE CUTTING PRECISION. THE EQUIPPED SIEMENS PLC SYSTEM ENSURES THAT THE MACHINE CAN PERFORM QUICKLY AND STABLY. THIS MACHINE CAN PROCESS VERY THIN PAPER, AS WELL AS PRODUCE PAPER BAGS VERY FAST, THUS THIS MACHINE IS ESPECIALLY SUITABLE FOR BEING APPLIED IN FOOD INDUSTRIES. QUANTITY: 1 Learn More

YY-2892 FANGBANG (CHINESE) PAPER BAG MAKING MACHINEYY-2892 FANGBANG (CHINESE) PAPER BAG MAKING MACHINE MAKE: FANGBANG (CHINESE) THIS MACHINE CAN PRODUCE PAPER BAGS OF WIDE-RANGE SIZES. IT CAN PRODUCE NOT ONLY SMALL-SIZE FOOD BAGS, BUT ALSO BIG-SIZE SHOPPING BAGS. THIS MACHINE CAN MAKE VARIOUS KINDS OF PAPER BAGS HAVING DIFFERENT BOTTOM STYLES. THIS MACHINE IS DESIGNED TO MANUFACTURE SQUARE BOTTOM PAPER BAGS WITHOUT HANDLES FROM PAPER ROLL, AND IT IS AN IDEAL EQUIPMENT FOR PRODUCING PRODUCING VARIOUS SIZED PAPER BAGS FAST. BY IMPLEMENTING STEPS INCLUDING PAPER FEEDING, TUBE FORMING, TUBE CUTTING AND BOTTOM FORMING INLINE, THIS MACHINE CAN EFFECTIVELY SAVE LABOR COSTS. THE EQUIPPED PHOTOELECTRIC DETECTOR CAN CORRECT CUTTING LENGTH, SO AS TO ENSURE CUTTING PRECISION. THE EQUIPPED SIEMENS PLC SYSTEM ENSURES THAT THE MACHINE CAN PERFORM QUICKLY AND STABLY. THIS MACHINE CAN PROCESS VERY THIN PAPER, AS WELL AS PRODUCE PAPER BAGS VERY FAST, THUS THIS MACHINE IS ESPECIALLY SUITABLE FOR BEING APPLIED IN FOOD INDUSTRIES. QUANTITY: 1 Learn More -

YY-2891 FANGBANG (CHINESE) PAPER BAG MAKING MACHINEYY-2891 FANGBANG (CHINESE) PAPER BAG MAKING MACHINE MAKE: FANGBANG (CHINESE BRAND) THIS MACHINE CAN PRODUCE PAPER BAGS OF WIDE-RANGE SIZES. IT CAN PRODUCE NOT ONLY SMALL-SIZE FOOD BAGS, BUT ALSO BIG-SIZE SHOPPING BAGS. THIS MACHINE CAN MAKE VARIOUS KINDS OF PAPER BAGS HAVING DIFFERENT BOTTOM STYLES. THIS MACHINE IS DESIGNED TO MANUFACTURE SQUARE BOTTOM PAPER BAGS WITHOUT HANDLES FROM PAPER ROLL, AND IT IS AN IDEAL EQUIPMENT FOR PRODUCING PRODUCING VARIOUS SIZED PAPER BAGS FAST. PAPER BAGS FAST. BY IMPLEMENTING STEPS INCLUDING PAPER FEEDING, TUBE FORMING, TUBE CUTTING AND BOTTOM FORMING INLINE, THIS MACHINE CAN EFFECTIVELY SAVE LABOR COSTS. THE EQUIPPED PHOTOELECTRIC DETECTOR CAN CORRECT CUTTING LENGTH, SO AS TO ENSURE CUTTING PRECISION. THE EQUIPPED SIEMENS PLC SYSTEM ENSURES THAT THE MACHINE CAN PERFORM QUICKLY AND STABLY. THIS MACHINE CAN PROCESS VERY THIN PAPER, AS WELL AS PRODUCE PAPER BAGS VERY FAST, THUS THIS MACHINE IS ESPECIALLY SUITABLE FOR BEING APPLIED IN FOOD INDUSTRIES. QUANTITY: 1 Learn More

YY-2891 FANGBANG (CHINESE) PAPER BAG MAKING MACHINEYY-2891 FANGBANG (CHINESE) PAPER BAG MAKING MACHINE MAKE: FANGBANG (CHINESE BRAND) THIS MACHINE CAN PRODUCE PAPER BAGS OF WIDE-RANGE SIZES. IT CAN PRODUCE NOT ONLY SMALL-SIZE FOOD BAGS, BUT ALSO BIG-SIZE SHOPPING BAGS. THIS MACHINE CAN MAKE VARIOUS KINDS OF PAPER BAGS HAVING DIFFERENT BOTTOM STYLES. THIS MACHINE IS DESIGNED TO MANUFACTURE SQUARE BOTTOM PAPER BAGS WITHOUT HANDLES FROM PAPER ROLL, AND IT IS AN IDEAL EQUIPMENT FOR PRODUCING PRODUCING VARIOUS SIZED PAPER BAGS FAST. PAPER BAGS FAST. BY IMPLEMENTING STEPS INCLUDING PAPER FEEDING, TUBE FORMING, TUBE CUTTING AND BOTTOM FORMING INLINE, THIS MACHINE CAN EFFECTIVELY SAVE LABOR COSTS. THE EQUIPPED PHOTOELECTRIC DETECTOR CAN CORRECT CUTTING LENGTH, SO AS TO ENSURE CUTTING PRECISION. THE EQUIPPED SIEMENS PLC SYSTEM ENSURES THAT THE MACHINE CAN PERFORM QUICKLY AND STABLY. THIS MACHINE CAN PROCESS VERY THIN PAPER, AS WELL AS PRODUCE PAPER BAGS VERY FAST, THUS THIS MACHINE IS ESPECIALLY SUITABLE FOR BEING APPLIED IN FOOD INDUSTRIES. QUANTITY: 1 Learn More -

TT-2968 HEIDELBERG VARIMATRIX 105 CS AUTOPLATEN DIE CUTTER, YEAR 2011, 6999 HOURSTT-2968 HEIDELBERG VARIMATRIX 105 CS AUTOPLATEN DIE CUTTER, YEAR 2011, 6999 HOURS HEIDELBERG VARIMATRIX MODEL 105CS AUTOPLATEN DIE CUTTER YEAR 2011 QUANTITY: 1 Learn More

TT-2968 HEIDELBERG VARIMATRIX 105 CS AUTOPLATEN DIE CUTTER, YEAR 2011, 6999 HOURSTT-2968 HEIDELBERG VARIMATRIX 105 CS AUTOPLATEN DIE CUTTER, YEAR 2011, 6999 HOURS HEIDELBERG VARIMATRIX MODEL 105CS AUTOPLATEN DIE CUTTER YEAR 2011 QUANTITY: 1 Learn More -

L-2590 POLYETHYLENE FOAM SHEET PRODUCTION LINE MODEL 120-EPE 1100 TO 2000mm THICKNESS 8mm

L-2590 POLYETHYLENE FOAM SHEET PRODUCTION LINE MODEL 120-EPE 1100 TO 2000mm THICKNESS 8mmREFERENCE NUMBER: L-2590

Learn More

POLYETHYLENE FOAM SHEET PRODUCTION LINE

MODEL 120-EPE 1100 TO 2000mm THICKNESS 8mm -

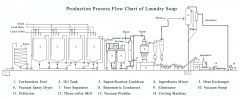

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More