Search results for: 'foam con'

- Related search terms

- contr'

- contr''

- Control pa'||'

- cond''

- Control pa'"'

-

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More

K-5243 AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDESREFERENCE NUMBER: K-5243 (YOU MUST LOOK AT THE VIDEO, IT’S AMAZING) AUTOMATIC TRIMMING MACHINE FOR FOAM BLOCKS OR FOAM MATTRESSES, FOUR SIDES DESCRIPTION: PU SLABS CUT FROM FOAM BLOCK BY HORIZONTAL CUTTING UNDERGO PERIMETRICAL STRETCHING, (SOMETIMES A FEW CENTIMETERS STRETCHING). IN ORDER TO ACHIEVE SATISFACTORY SIZES (±1MM EACH SIDE) THE REMOVING OF IRREGULAR EDGES IS REQUIRED. THIS MACHINE TRIMS FOAM SLABS AND ALSO COUPLED SLABS. IT CAN BE PLACED AT THE END OF THE MATTRESS GLUING PLANT (MANUAL OR AUTOMATIC) OR BEYOND THE HORIZONTAL CUTTING MACHINE. THE COUPLED FOAM SHEETS ARE NOT ALIGNED AND NEED TO BE TRIMMED. OFTEN THE COUPLED MATTRESSES ARE TRIMMED ONE BY ONE ALONG THE FOUR SIDES WITH A MANUAL VERTICAL CUTTING MACHINE WASTING A LARGE AMOUNT OF TIME. THIS MACHINE AUTOMATICALLY TRIMS THE FOUR SIDES OF FOAM MATTRESSES WITHOUT ANY HANDLING; THAT MEANS AN ACCURATE TRIM AND SHORT PROCESSING TIME. QUANTITY AVAILABLE: 1 Learn More -

TT-8151 AUTO FOAM GENERATOR, YEAR 2023TT-8151 AUTO FOAM GENERATOR, YEAR 2023 1. AUTO FOAM GENERATOR 2. YEAR 2023 3. AUTO FOAM UNIT 200Mm DIAMETER MIXING HEAD SHAFT DRIVEN BY 4.0 KWATT, 960 RPM, 3 PHASE, AC MOTOR, 3½ TO 1 REDUCTION REQUIRED, BY PULLEY/BELT OR BY GEARBOX. QUANTITY: 1 Learn More

TT-8151 AUTO FOAM GENERATOR, YEAR 2023TT-8151 AUTO FOAM GENERATOR, YEAR 2023 1. AUTO FOAM GENERATOR 2. YEAR 2023 3. AUTO FOAM UNIT 200Mm DIAMETER MIXING HEAD SHAFT DRIVEN BY 4.0 KWATT, 960 RPM, 3 PHASE, AC MOTOR, 3½ TO 1 REDUCTION REQUIRED, BY PULLEY/BELT OR BY GEARBOX. QUANTITY: 1 Learn More -

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More

V-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTINGV-2197 VERTICAL FAST WIRE CONTOUR CUTTER – WITH NESTING For Max. Block Size: Length 2440 mm (96 in), Width 1220 mm (48 in), Height 600 mm (23.6 in) Machine for cutting pipe insulation A programmed-control cutting machine which runs on AutoCAD, controlled by computer. Main Features of Contour Cutter: 1. Integrated design & cutting program. Simply design and cut; 2. Big cost savings by automatically arranging the product; 3. Support numeric instrument; 4. Higher material utilization resulting from computer aided nesting of shapes; 5. Cut speed can be set to achieve the best-cut speed for different foam material; 6. Can pre-cut on the computer to check cutting course; 7. With Nesting System Learn More -

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More

J-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEETJ-5033 FOAM SHEET TRI-FOLD ROLL PACKING LINE, 15 SECONDS PER SHEET SUITABLE FOR FOAM ROLL WRAP FOAM DENSITY: 25 KGS/m3 TO 45 KGS/m3 CAPACITY: 15 SECONDS PER SHEET, CONTINUOUS OPERATION MAXIMUM MATTRESS SIZE: 2200 x 1500 x 150mm ROLL DIAMETER: 50 TO 300mm VOLTAGE: 380 VOLTS, 50 Hz OR 220 VOLTS, 60 Hz TOTAL POWER: 25 KW WEIGHT: 6.5 TONS QUANTITY: 1 Learn More -

TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE YEAR OF CONSTRUCTION 1986 CONDITION USED QUANTITY: 1 Learn More

TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986TT-3371 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE, YEAR 1986 ALBRECHT BAEUMER BSL-D HORIZONTAL FOAM SPLITTING MACHINE YEAR OF CONSTRUCTION 1986 CONDITION USED QUANTITY: 1 Learn More -

TT-2777 ALBRECHT BAUMER OFS-HE CNC HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE, WIDTH 2300mm, YEAR 2001TT-2777 ALBRECHT BAUMER OFS-HE CNC HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE, WIDTH 2300mm, YEAR 2001 HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE YEAR: 2001 CONDITION USED QUANTITY: 1 Learn More

TT-2777 ALBRECHT BAUMER OFS-HE CNC HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE, WIDTH 2300mm, YEAR 2001TT-2777 ALBRECHT BAUMER OFS-HE CNC HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE, WIDTH 2300mm, YEAR 2001 HORIZONTAL CONTOUR CUTTING MACHINE WITH ROTATING KNIFE YEAR: 2001 CONDITION USED QUANTITY: 1 Learn More -

YY-2095 POLYURETHANE FOAM CUTTING MACHINEYY-2095 POLYURETHANE FOAM CUTTING MACHINE POWER: 13KW WEIGHT: 1000 KG QUANTITY: 1 Learn More

YY-2095 POLYURETHANE FOAM CUTTING MACHINEYY-2095 POLYURETHANE FOAM CUTTING MACHINE POWER: 13KW WEIGHT: 1000 KG QUANTITY: 1 Learn More -

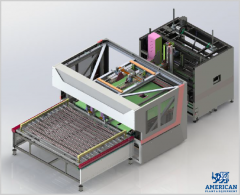

YY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEMYY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEM THE FOAM BLOCK RACK STORAGE SYSTEM IS FOR THE STORAGE OF THE UNCURED FOAM BLOCK AFTER FOAMING AND CUTTING OFF, AND THE SUPER SOFT FOAM WHICH CAN NOT BE LIFTED BY CRANE. EQUIPPED WITH THE AUTOMATIC MOVABLE CONVEYOR LINE, WHICH CAN MOVE WITH LEFT & RIGHT, UP & DOWN DIRECTION TO CONNECT TO EACH CONVEYOR RACK OF THE SYSTEM. WITH THE TOUCH SCREEN AND PLC AUTO CONTROL, THE FOAM BLOCKS IN THE STORAGE SYSTEM WILL BE MOVED IN AND OUT OF THE STORAGE SYSTEM AUTOMATICALLY. THIS STORAGE SYSTEM WILL HELP THE FOAM CURING PROCESS, AND UTILIZE MORE STORAGE SPACE EFFECTIVELY UNDER LIMITED WORKSHOP, AND SAVE A LOT OF TIME AND LABOR COST. Learn More

YY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEMYY-1829 FOAM BUN, BLOCK RACK STORAGE SYSTEM THE FOAM BLOCK RACK STORAGE SYSTEM IS FOR THE STORAGE OF THE UNCURED FOAM BLOCK AFTER FOAMING AND CUTTING OFF, AND THE SUPER SOFT FOAM WHICH CAN NOT BE LIFTED BY CRANE. EQUIPPED WITH THE AUTOMATIC MOVABLE CONVEYOR LINE, WHICH CAN MOVE WITH LEFT & RIGHT, UP & DOWN DIRECTION TO CONNECT TO EACH CONVEYOR RACK OF THE SYSTEM. WITH THE TOUCH SCREEN AND PLC AUTO CONTROL, THE FOAM BLOCKS IN THE STORAGE SYSTEM WILL BE MOVED IN AND OUT OF THE STORAGE SYSTEM AUTOMATICALLY. THIS STORAGE SYSTEM WILL HELP THE FOAM CURING PROCESS, AND UTILIZE MORE STORAGE SPACE EFFECTIVELY UNDER LIMITED WORKSHOP, AND SAVE A LOT OF TIME AND LABOR COST. Learn More -

L-1656 FOAM CASTING PROCESS / LFC MOLDING MACHINE FOR 10 TONS

L-1656 FOAM CASTING PROCESS / LFC MOLDING MACHINE FOR 10 TONSREFERENCE NUMBER: L-1656

Learn More

LOST FOAM CASTING PROCESS FOUNDRY MACHINERY

QUANTITY: 1 -

G-7287 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXING WITH SHREDDED FOAMPRODUCT INTRODUCTION : SPECIALLY DESIGNED FOR THE STUFFING PRODUCTS SUCH AS SOFA, SEAT CUSHION, PILLOW ETC. ITS GREASTEST ADVANTAGE IS THAT THE MIX OF COTTON FIBER WON'T FORM GRANULES. THE PRODUCTS HAVE A PLAIN & TIDY APPEARANCE WITH GOOD FLEXIBILITY (ESPECIALLY IMPORTANT TO PILLOWS AND SOFAS) Learn More

G-7287 PILLOW FILLING LINE 1400mm COMBINATION FOAM SHREDDER, COTTON OPENING AND MIXING WITH SHREDDED FOAMPRODUCT INTRODUCTION : SPECIALLY DESIGNED FOR THE STUFFING PRODUCTS SUCH AS SOFA, SEAT CUSHION, PILLOW ETC. ITS GREASTEST ADVANTAGE IS THAT THE MIX OF COTTON FIBER WON'T FORM GRANULES. THE PRODUCTS HAVE A PLAIN & TIDY APPEARANCE WITH GOOD FLEXIBILITY (ESPECIALLY IMPORTANT TO PILLOWS AND SOFAS) Learn More