Search results for: 'heat t'

- Related search terms

- heat

- heat press

- heated

- heatin

- heating+w

-

KNITTING, DYEING, FINISHING MILL #1KNITTING, DYEING, FINISHING MILL #1 Learn More

KNITTING, DYEING, FINISHING MILL #1KNITTING, DYEING, FINISHING MILL #1 Learn More -

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More

E-4553INVENTORY NUMBER: E-4553 FOAM MACHINERY FOR SALE QUANTITY AVAILABLE: 33 LOTS Learn More -

M-3405 KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 WIDTH 1800mmREFERENCE NUMBER: M- 3405 (880160LMW7RM) K KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 WIDTH 1800mm KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 - TOTAL WIDTH 1800mm - FABRIC WIDTH 1600 mm - INITIAL DRYER 3 SECTIONS – ELECTRIC HEATING - DRYER 3 SECTIONS – STEAM HEATED ( 5 BARS) - THERMOSOL 2 SECTIONS – GAS HEATED QUANTITY AVAILABLE: 1 Learn More

M-3405 KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 WIDTH 1800mmREFERENCE NUMBER: M- 3405 (880160LMW7RM) K KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 WIDTH 1800mm KUSTERS THERMOSOL DYEING MACHINE YEAR 1993 - TOTAL WIDTH 1800mm - FABRIC WIDTH 1600 mm - INITIAL DRYER 3 SECTIONS – ELECTRIC HEATING - DRYER 3 SECTIONS – STEAM HEATED ( 5 BARS) - THERMOSOL 2 SECTIONS – GAS HEATED QUANTITY AVAILABLE: 1 Learn More -

C-4026 NUOVO PIGNONE GAS TURBINE, 11 MW AND CONDENSING TURBO GENERATOR SETS, 44.5 MW, YEAR 2002

C-4026 NUOVO PIGNONE GAS TURBINE, 11 MW AND CONDENSING TURBO GENERATOR SETS, 44.5 MW, YEAR 2002C-4026 NUOVO PIGNONE GAS TURBINE, 11 MW AND CONDENSING TURBO GENERATOR SETS, 44.5 MW, YEAR 2002

OFFER 001

11.7 MWE GAS TURBINE-GENERATOR SETS

GAS TURBINES

MANUFACTURER: NUOVO PIGNONE

MODEL: PGT10B-1

TYPE: MULTI-SHAFT, HEAVY DUTY GAS TURBINE

FUEL: NATURAL GASOFFER 002

ALTERNATOR

MANUFACTURER: ANSALDO

APPARENT POWER: 13,569 KVA

ACTIVE POWER: 11,000 KW

POWER FACTOR: 0.8

RATED SPEED: 1,500 RPMOFFER 003

65.7 TPH WASTE HEAT RECOVERY BOILERS

BOILERS

MANUFACTURER: MACCHI

THERMAL RATING: 55,330 KW

NET THERMAL EFFICIENCY. COP: 90.32%

NET THERMAL EFFICIENCY. COV: 92.48%OFFER 004

44.5 MW CONDENSING TURBO-GENERATOR SET

STEAM TURBINE

MANUFACTURER: NUOVO PIGNONE

MODEL NUMBER: HNK 50/3.2

CONFIGURATION: 1 IMPULSE STAGE 62 REACTION STAGES

RATED POWER: 44,500 KW

RATED INLET FLOW: 131,400 KG/HOFFER 005

GENERATOR

MANUFACTURER: JEUMONT INDUSTRIE

RATED APPARENT POWER: 51,500 KVA

POWER FACTOR: 0.8

ACTIVE POWER: 41,200 KWOFFER 006

CONDENSER

MANUFACTURER: CALDEMON

TYPE: SURFACE CONDENSERQUANTITY: 2

Learn More -

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More

TT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/HTT-1355 SPRAY DRYER, CAPACITY OF EVAPORATION 50L/H SPRAY DRYER CAPACITY OF EVAPORATION: 50L/H ELECTRICAL HEATING, 3 PHASE 380V 50Hz EQUIPMENT CHARACTERISTICS AND METHODS 1. ATOMIZATION METHOD: HIGH-SPEED CENTRIFUGAL ATOMIZATION. 2. FEEDING SYSTEM: FEEDING PUMP FEEDS. (FREQUENCY) 3. RECEIVING METHOD: COLLECT FROM THE BOTTOM OF THE TOWER TO THE NEXT POINT OF THE CYCLONE SEPARATOR. 4. HEATING METHOD: ELECTRIC HEATING. 5. TOTAL EQUIPMENT POWER: 72KW Learn More -

A-2573 TUBE FILLING SEALING MACHINE 2 KWA-2573 TUBE FILLING SEALING MACHINE 2 KW SPECIFICATIONS: SEALING TYPE: HEATING (PLASTIC), FOLDING (ALUMINUM) MAX POWER: 2 KW (PLASTIC), 3.3 KW (ALUMINUM) VOLTAGE: 220 VOLTZ AND 50/60 Hz PRODUCTIVITY: 30 TO 80 PCS/Min FILLING VOLUME: 5 TO 200 ML (CHANGE PUMP) TUBE DIAMETER: 10 TO 50 mm (CHANGE MOLDS) TUBE LENGTH: 210 mm (THE MAX.) FILLING ACCURACY: ≤±1% CONTROL: PLC CONTROL SYSTEM DISPLAY: TOUCH SCREEN DISPLAY FEATURE: NO TUBE NO FILLING DIMENSION (L X W X H): 1500 X 1100 X 1900 mm WEIGHT: ABOUT 850 KG Learn More

A-2573 TUBE FILLING SEALING MACHINE 2 KWA-2573 TUBE FILLING SEALING MACHINE 2 KW SPECIFICATIONS: SEALING TYPE: HEATING (PLASTIC), FOLDING (ALUMINUM) MAX POWER: 2 KW (PLASTIC), 3.3 KW (ALUMINUM) VOLTAGE: 220 VOLTZ AND 50/60 Hz PRODUCTIVITY: 30 TO 80 PCS/Min FILLING VOLUME: 5 TO 200 ML (CHANGE PUMP) TUBE DIAMETER: 10 TO 50 mm (CHANGE MOLDS) TUBE LENGTH: 210 mm (THE MAX.) FILLING ACCURACY: ≤±1% CONTROL: PLC CONTROL SYSTEM DISPLAY: TOUCH SCREEN DISPLAY FEATURE: NO TUBE NO FILLING DIMENSION (L X W X H): 1500 X 1100 X 1900 mm WEIGHT: ABOUT 850 KG Learn More -

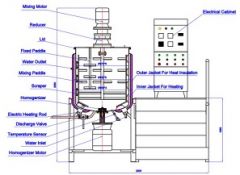

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More

Z-1564 500 L LIQUID WASHING HOMOGENIZER MIXERSZ-1564 500 L LIQUID WASHING HOMOGENIZER MIXERS MAIN STRUCTURE: MIXING POT, ELECTRIC CONTROL SYSTEM, OPERATION PLATFORM ESTIMATED PRODUCTION TIME AND CAPACITY FOR REF • MIXING + HOMOGENIZER + HEATING • REMARK: 2 TO 2.5 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 1500 IT’S TO 2000 DAY. • MIXING + HOMOGENIZER • REMARK: 2 HOURS PER BATCH, IF 8 HOURS PER DAY ABOUT 2000 IT’S DAY. • MIXING ONLY • REMARK: 1 TO 1.5 HOURS PER BATCH, IF 8 HOURS DAY, 2500 IT’S TO 4000 DAY. QUANTITY: 1 Learn More -

TT-5601 JENBACHER 612 GS F01 COMBINED HEAT AND POWER PLANT, 2,000 KW, YEAR 2008, 50 HzTT-5601 JENBACHER 612 GS F01 COMBINED HEAT AND POWER PLANT, 2,000 KW, YEAR 2008, 50 Hz JENBACHER J612 GS F01 GAS GENERATORS YEAR OF CONSTRUCTION 2008 CONDITION USED MACHINE TYPE: COMBINED HEAT AND POWER PLANT BRAND: JENBACHER MODEL: 612 GS F01 CONDITION: READY FOR OPERATION (USED) QUANTITY: 1 Learn More

TT-5601 JENBACHER 612 GS F01 COMBINED HEAT AND POWER PLANT, 2,000 KW, YEAR 2008, 50 HzTT-5601 JENBACHER 612 GS F01 COMBINED HEAT AND POWER PLANT, 2,000 KW, YEAR 2008, 50 Hz JENBACHER J612 GS F01 GAS GENERATORS YEAR OF CONSTRUCTION 2008 CONDITION USED MACHINE TYPE: COMBINED HEAT AND POWER PLANT BRAND: JENBACHER MODEL: 612 GS F01 CONDITION: READY FOR OPERATION (USED) QUANTITY: 1 Learn More -

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINE

V-1806 HALF AUTOMATIC FACE MASK WITH INNER EAR LOOP PACKING MACHINEI. FUNCTION

Learn More

THIS MACHINE IS USED TO PACK DISPOSABLE SURGICAL FACE MASK WITH THE SIZE OF 190 X 65mm. IT CAN ALSO BE USED TO PACK OTHER PRODUCTS SUCH AS WET TISSUE.

II. FEATURES:

1. ONE SET OF INK TO INJECT PRINTER IS INCLUDED; IT CAN BE USED TO PRINT THE DATA AND OTHER INFORMATION.

2. THE AIR COMPRESSOR EQUIPMENT IS OPTIONAL.

3. PACKING MATERIAL: SINGLE TO SIDE HEAT TO SEALING PACKAGING FILM MATERIALS, SUCH AS OPP, CPP, OPP COMPOSITE PE, PET COMPOSITE PE, SINGLE TO LAYER OR COMPOSITE PACKAGING FILM MATERIALS.

4. BAG FORM: BACK TO SEALED PACKING, CAN BE CUSTOMIZED.

5. VERTICAL/HORIZONTAL SEAL: RETICULATED PACKAGING/VERTICAL AND RETICULATED PACKAGING.

III. SPECIFICATION:

NAME: PILLOW PACKING MACHINE

TYPE KD TO 350

APPLICATION: FOR ALL KINDS OF OPP HEAT TO SEALING FILM, COMPOSITE FILM, SPRAY FILM PAPER, ALUMINUM FOIL FILM, ALUMINUM PLASTIC COMPOSITE FILM

MACHINE SIZE: 4600 X 850 X 1500

PACKING SPEED: 60 TO 220 BAG/MIN

MAX. PACKING SIZE: 330mm, 150mm, 80mm. LENGTH: 330mm, WIDTH: 150mm, HEIGHT: 80mm

MIN. PACKING SIZE: 50mm, 10mm, 5mm. LENGTH: 50mm, WIDTH: 10mm, HEIGHT: 5mm

ELECTRICAL: AC220V, 2.7KW

AIR PRESSURE 0.5 TO 0.7 MPA

AIR CONSUMPTION: >0.36 (M3/H)

(DB) NOISE: 60 TO 70DB

MACHINE WEIGHT: 550KG

MOTOR FREQUENCY ADJUST: 0 TO 50HZ

AUTOMATIC CONTROL

AUTOMATIC PRINTING

STANDARD: GMP STANDARD, PACKAGING MACHINE ENTERPRISE STANDARD

APPROVAL: ISO9001:2000, CE ISO:2000 -

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More

YY-2535 GE LM6000PA 42+7MW CHP PLANTYY-2535 GE LM6000PA 42+7MW CHP PLANT THE EXTENSIVE LIST OF ACCOMPANYING EQUIPMENT INCLUDES: 1. GE LM6000PA GAS TURBINE EQUIPPED WITH WATER INJECTION, PAIRED WITH A BRUSH ALTERNATOR WITH 42 MW OUTPUT CAPACITY. THIS GAS TURBINE SUPPORTS NATURAL GAS OR DISTILLATE FUEL. 2. GT MK V CONTROL UNIT WITH AUXILIARY SYSTEMS. 3. SIEMENS BACK PRESSURE STEAM TURBINE WITH 7MW OUTPUT CAPACITY. 4. NOOTER ERIKSON HRSG CAPABLE OF SUPPLEMENTARY FIRING WITH NATURAL GAS OR DISTILLATE FUEL. 5. DUAL BELLIS AND MORCOM THREE-STAGE RECIPROCATING NATURAL GAS COMPRESSORS. 6. WATER TREATMENT PLANT COMPOSED OF TWIN BED RESIN EXCHANGE UNITS AND MIXED BED UNITS. 7. MASSIVE STORAGE TANKS FOR DISTILLATE OIL AND HEAVY FUEL OIL, COMPLETE WITH NECESSARY PIPING AND PUMPS. 8. TWO 11/132 KV TRANSFORMERS RATED AT 40 MVA EACH. 9. STANDBY DIESEL GENERATOR FOR BACKUP POWER. 10. SERCK DISTRIBUTED CONTROL SYSTEM (DCS) FOR INTEGRATED CONTROL AND MONITORING. 11. THREE CONTROL AND GENERAL SERVICE AIR COMPRESSORS. 12. AN EXTENSIVE FIRE DETECTION AND SUPPRESSION SYSTEM, SECURITY CAMERAS, AND GAS DETECTION SYSTEM FOR SAFETY AND SECURITY. 13. A CBISS CONTINUOUS EMISSIONS MONITORING SYSTEM (CEMS) TO ENSURE ADHERENCE TO ENVIRONMENTAL STANDARDS. ALL THE NECESSARY CABLING, TRANSFORMERS, SWITCHGEAR, AND PRESSURE-REDUCING STATIONS ASSOCIATED WITH THE ABOVE-MENTIONED PLANT ARE INCLUDED. A BONUS OF UNIQUE SPARE PARTS, EXTENSIVE MANUALS, RECORDS, AND DRAWINGS ARE ALSO PART OF THE PACKAGE, ENSURING SMOOTH OPERATION AND MAINTENANCE. A GE LM6000PA CHP PLANT REPRESENTS A ROBUST, EFFICIENT SOLUTION TO YOUR POWER AND HEATING NEEDS, OFFERING THE RELIABILITY AND FLEXIBILITY NEEDED FOR YOUR OPERATIONS. QUANTITY: 1 UNIT AVAILABLE FOR PURCHASE Learn More