Search results for: 'needles/'

-

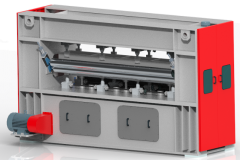

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More

J-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEWJ-3864-B NEEDLE PUNCHING LOOM, UPSTROKE, WORKING WIDTH 1000mm, STROKE 30mm - NEW TECHNICAL SPECIFICATIONS: a) WORKING WIDTH: 1000mm b) MAX INSTALLED FREQUENCY: 800RPM c) NEEDLE BEAM STROKE: 30mm d) NEEDLING TYPE: BOTTOM-TOP e) NEEDLE BOARDS: 2 f) NEEDLE DENSITY: TO BE CONFIRMED g) WEIGHTS/DENSITY CAPABILITY: 250 TO 560 gsm h) OUTPUT SPEED: 1 TO 10 METERS PER MINUTE i) VOLTAGE: 220 VOLTS 60Hz, 3 PHASE (ELECTRICAL SYSTEM IS BUILT SPECIFICALLY FOR US ELECTRICITY) j) NEEDLE BOARDS ARE DRILLED BY CNC DRAWING MACHINE, NEEDLE DIAMETER 1.83mm DOCUMENTATION: AVAILABLE IN ENGLISH LANGUAGE QUANTITY: 1 Learn More -

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More

YY-1366 (USERS MANUAL) BAG CLOSING MACHINE HEAD, INSTRUCTION MANUALYY-1366 BAG CLOSING MACHINE HEAD, INSTRUCTION MANUAL FOR OPENRATOR SAFETY: - THIS MANUAL BOOK CONTAINS INSTRUCTIONS AND PRECAUTIONS FOR USING THE BAG CLOSING MACHINE HEAD. BE SURE TO READ AND UNDERSTAND THE MANUAL BOOK BEFORE USING THE MACHINES. - KEEP THIS MANUAL BOOK NEAR THE SEWING MACHINE FOR REFERENCE. BE SURE TO ATTACH THIS MANUAL BOOK TO THE MACHINE WHEN LENDING OR TRANSFER IT TO ANOTHER PERSON OR COMPANY. - PLEASE CONTACT THIS MANUAL BOOK FROM US IF IT LOST. - THE CONTENTS OF THIS MANUAL BOOK ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE FOR IMPROVEMENT AND SAFETY PURPOSE. Learn More -

H-2386 ONE-PIECE MASK MANUFACTURING MACHINES

H-2386 ONE-PIECE MASK MANUFACTURING MACHINESONE-PIECE MASK MACHINERY, MADE ON HOSIERY MACHINES

REBUILT, RECONVERTED & UPDATED INTO MACHINES FOR ONE-PIECE MASKSSINGLE CYLINDER MACHINES

WITH FULLY ELECTRONIC CONTROL

DIAMETER: 4”

NEEDLES: 200 TO 400

FEEDS: 4KNITTING PRODUCTION:

• MASKS READY TO WEAR IN ANY SIZE & STYLE

• THEY ARE PRODUCED USING ANY NATURAL YARN,

ECOLOGICAL YARN, ANTIBACTERIAL FIBER, STRETCH FIBERS

• CAN BE CUSTOMIZED WITH DESIGNS, COLORS, LOGOS

• PRODUCTION TIME: FROM 45 SECONDS PER MASKPLAIN FABRIC, RUN PROOF, MICROMESH, NET, REINFORCED BAND, REINFORCED & FLOATED PATTERNS

SINKER CAP WITH STEPPING MOTOR

MASKS ARE COMPLETE WITH A TUBULAR POCKET FOR INSERTING FILTER OR ADDITIONAL FABRIC FOR BETTER PREVENTION

-TUBULAR POCKET DIMENSIONS: 50 X 100mm (FILTERS MAY ALSO BE ROUND SHAPE)

MACHINE WASHABLE AND REUSABLE

MOTORIZED DIAL ARM WITH VERTICAL MOVEMENT THROUGH STEPPING MOTOR FOR

UNLIMITED HEIGHT POSITIONSSTITCH CAMS WITH INDEPENDENT VARIABLE PROFILE SYSTEM

SYSTEM ON YARN FINGERS FOR PLATING CONTROL

ELECTRONIC NEEDLES & NEEDLES SELECTION ON 4 FEEDS

PROGRAMMABLE & VARIABLE STITCH CAM LOWERING IN DIFFERENT AREAS

BY STEPPING MOTOR ON EACH FEED

ALL FUNCTIONS ELECTRONICALLY CONTROLLED

PROGRAMMING STYLES & SIZE, PATTERNS EDITING & STITCH CAM LOWERING BY PERSONAL COMPUTER

AND POWERFUL GRAPHIC SOFTWARE FOR WINDOWS ENVIRONMENT.

KEYBOARD WITH GRAPHIC DISPLAY FOR SELECTION OF STYLE, SIZE , PATTERNS & OTHER FUNCTION

PRE-SETTING AND PROGRAMMING FOR DIFFERENT KINDS OF YARNS FEEDING DEVICEDIMENSIONS: 1000mm L x 1000mm W x 2500mm H

Learn More

SHIPPING WEIGHT: 350 KG, ON PALLETS

SHIPPING DIMENSIONS: 1000mm L x 1000mm W x 2000mm H

DELIVERY TIME FOR 1 TO 10 MACHINES: 3 TO 4 WEEKS FROM PAYMENT (3/27) -

L-6029 ARTIFICIAL GRASS CUT TUFTER, 5/8 GAUGE, 4100mm

L-6029 ARTIFICIAL GRASS CUT TUFTER, 5/8 GAUGE, 4100mmREFERENCE NUMBER: L-6029

ARTIFICIAL GRASS CUT TUFTER, 5/8 GAUGE, 4100mm

SEWING WIDTH: 4100mm

GAUGE: 5/8”

VARIABLE ELECTRONIC DRIVE

BRAND NEW GRASS-CUT PILE

SINGLE INLINE INDIVIDUAL NEEDLE BAR

QUANTITY: 1

Learn More -

M-7103 LIST OF DILO NEEDLE LOOMS – PRE-NEEDLE LOOM & FINISHING NEEDLE LOOMS, YEAR 1979 TO 1982

M-7103 LIST OF DILO NEEDLE LOOMS – PRE-NEEDLE LOOM & FINISHING NEEDLE LOOMS, YEAR 1979 TO 1982LIST NUMBER: M-7103

DILO NEEDLE LOOMS

REFERENCE NUMBER: P-4923

TYPE: DV25

YEAR: 1979

QUANTITY: 1REFERENCE NUMBER: P-4924

TYPE: NL32968

YEAR: 1979

QUANTITY: 1REFERENCE NUMBER: P-4925

Learn More

TYPE: OD II/25

YEAR: 1982

QUANTITY: 1 -

V-1388 COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINA

V-1388 COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINAREFERENCE NUMBER: V-1388

COMPUTERIZED AUTOMATIC MATTRESS BORDER QUILTING, NEW FROM CHINA

CONDITION: NEW

VOLTAGE: SINGLE PHASE, 220V, 50HZ, SINGLE PHASE, 220V, 50HZ

POWER(W):3.98KW

DIMENSION(L X W X H): 5.6 X 1.8 X 1.6M

WEIGHT: 450kg

CERTIFICATION: CE CERTIFICATE

WARRANTY: ONE YEAR

AFTER-SALES SERVICE PROVIDED:ENGINEERS AVAILABLE TO SERVICE MACHINERY OVERSEAS

SEWING SPEED: 5M/MIN

THICKNESS OF QUILTING:<1.5cm

MOTOR TYPE: PARASONIC

CHAIN STITCH HEADS:JUKI

MULTI-NEEDLE SEWING HEAD:52 NEEDLES

SPACE BETWEEN NEEDLES: 3/16,1/4

FABRIC WIDTH: 33cm

AIR PRESSURE:60PSI

1. AUTOMATIC PROGRAMMABLE BORDER WORKSTATION

2. STATE-TO-THE-ART SERVO DRIVES AND ADVANCED MOTION CONTROLLER

3. MULTI-NEEDLE SEWING HEAD WITH 52 NEEDLES 1/4" SPACING, 33cm MAX WIDTH

4. VIRTUALLY UNLIMITED PATTERN DESIGN STORAGE

5. ADJUSTABLE TENSION REWINDER

6. BORDER UP TO 33CM

7. PATTERNS MAY BE SCALED, SHIFTED OR OFFSET ON-THE-FLY

8. DUAL PATTERN STITCHING CHAIN STITCH HEADS(JUKI)

9. BORDER EDGES MAY BE HEMMED, ELIMINATING THE DOUBLE OVERLOCK OPERATION.

PACKAGING DETAILS:MACHINE BY WOODEN BOX

DELIVERY TIME: 35 DAYS

Learn More -

M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004

M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004M-6055 NONWOVEN NEEDLE FELT LINE, WIDTH 4300mm, YEAR 1970 TO 2004

OFFER 001

NONWOVEN NEEDLE FELT LINE – RENEWED 3 YEARS AGO

WORKING WIDTH: 4300mmOFFER 002

HERGETH BALE OPENER

YEAR: 1986

WORKING WIDTH: 1000mmOFFER 003

OILING UNIT

TANK CAPACITY: 250 LITRESOFFER 004

AUGUST PROTT FAN FOR FIBER TRANSPORT

POWER: 7.5 KWOFFER 005

TERMO GORING KERR METAL DETECTOR AND METAL SEPARATOR

YEAR: 2004OFFER 006

TEMAFA MIXING BINOFFER 007

FOR FAN FOR FIBER TRANSPORTATIONOFFER 008

FOR CHUTE FEED WITH MOVEABLE CONDENSOR

WORKING WIDTH: 2500mmOFFER 009

WEB DENSITY MEASURING AND AUTOMATIC ALIGNINGOFFER 010

FOR CARDING MACHINE

WORKING WIDTH: 2500mmOFFER 011

ASSELIN CROSSLAPPER

YEAR: 1984

INPUT WIDTH: 2500mmOFFER 012

FEHRER FIRST NEEDLE LOOM

YEAR: 1973

WORKING WIDTH: 4800mmOFFER 013

UNWINDING FOR PRELIMINARY WEBOFFER 014

CONVEYOR SYSTEM FOR WEB TRANSPORTATION TO SECOND NEEDLE LOOMOFFER 015

FEHRER SECOND NEEDLE LOOM

YEAR: 1970

WORKING WIDTH: 4400mmOFFER 016

FEHRER THIRD NEEDLE LOOM

YEAR: 1973

WORKING WIDTH: 4800mmOFFER 017

BENEDETTI & CALAMAI TRIMMING AND WINDING UNIT

YEAR: 1995

TABLE WIDTH: 5500mmOFFER 018

LAROCHE EDGE TRIM OPENERQUANTITY: 1 LINE

Learn More -

M-4398 STRUCTURING NEEDLE LOOM PUNCH MACHINE YEAR 1974 WIDTH 4880mmREFERENCE NUMBER: M-4398 (101048QEU9RX) K STRUCTURING NEEDLE LOOM PUNCH MACHINE YEAR 1974 WIDTH 4880mm STRUCTURING NEEDLE LOOM PUNCH MACHINE DR. ERNST FEHRER AG TYPE NL 11 WORKING WIDTH 4880mm YEAR 1974 LAMELLA GAUGE 4.7mm THE CONTROLS AND ELECTRIC BOARDS ARE NOT INCLUDED BECAUSE THE MACHINE WAS CONTROLLED BY A CENTRAL CONTROL FOR THE ENTIRE LINE TOTALLY 2 OR 3 SETS OF NEEDLE BOARDS CAN BE SUPPLIED WITH THE MACHINE THE MACHINE WAS PURCHASED AS SECOND-HAND APPROXIMATELY 7 YEARS AGO AND WAS USED FOR MAKING CARPETS SINCE THEN AS PER OPINION OF THE PLANT TECHNICIAN, THE MAIN BEARING IN THE HOUSING SHOULD BE OKAY. THE MACHINE WAS PURCHASED FROM A MULTINATIONAL COMPANY 7 YEARS AGO AND WAS IN GREAT CONDITION WHEN THE USED MACHINE CHANGED OWNER THE TOTAL INSIDE WIDTH IS 5178mm THE WIDTH ON WHICH THE NEEDLE BOARDS ARE DRILLED WITH HOLES FOR THE NEEDLES IS 4920mm. SO THIS IS THE TOTAL MAXIMUM WIDTH ON WHICH THE MATERIAL WOULD BE NEEDLE PUNCHED. NEEDLE BOARDS INSIDE THE MACHINE: 4 BOARDS ON ONE LINE. NUMBER OF NEEDLES PER METER: ESTIMATED TO BE 5,000 NEEDLES/M, BUT NEEDS TO BE CHECKED. QUANTITY AVAILABLE: 1 Learn More

M-4398 STRUCTURING NEEDLE LOOM PUNCH MACHINE YEAR 1974 WIDTH 4880mmREFERENCE NUMBER: M-4398 (101048QEU9RX) K STRUCTURING NEEDLE LOOM PUNCH MACHINE YEAR 1974 WIDTH 4880mm STRUCTURING NEEDLE LOOM PUNCH MACHINE DR. ERNST FEHRER AG TYPE NL 11 WORKING WIDTH 4880mm YEAR 1974 LAMELLA GAUGE 4.7mm THE CONTROLS AND ELECTRIC BOARDS ARE NOT INCLUDED BECAUSE THE MACHINE WAS CONTROLLED BY A CENTRAL CONTROL FOR THE ENTIRE LINE TOTALLY 2 OR 3 SETS OF NEEDLE BOARDS CAN BE SUPPLIED WITH THE MACHINE THE MACHINE WAS PURCHASED AS SECOND-HAND APPROXIMATELY 7 YEARS AGO AND WAS USED FOR MAKING CARPETS SINCE THEN AS PER OPINION OF THE PLANT TECHNICIAN, THE MAIN BEARING IN THE HOUSING SHOULD BE OKAY. THE MACHINE WAS PURCHASED FROM A MULTINATIONAL COMPANY 7 YEARS AGO AND WAS IN GREAT CONDITION WHEN THE USED MACHINE CHANGED OWNER THE TOTAL INSIDE WIDTH IS 5178mm THE WIDTH ON WHICH THE NEEDLE BOARDS ARE DRILLED WITH HOLES FOR THE NEEDLES IS 4920mm. SO THIS IS THE TOTAL MAXIMUM WIDTH ON WHICH THE MATERIAL WOULD BE NEEDLE PUNCHED. NEEDLE BOARDS INSIDE THE MACHINE: 4 BOARDS ON ONE LINE. NUMBER OF NEEDLES PER METER: ESTIMATED TO BE 5,000 NEEDLES/M, BUT NEEDS TO BE CHECKED. QUANTITY AVAILABLE: 1 Learn More -

G-8636 LONATI FL 626 KNITTING MACHINES YEAR 2004 TO 2005REFERENCE NUMBER: G-8636 LONATI FL 626 KNITTING MACHINES YEAR 2004 TO 2005 A) LONATI FL 626 KNITTING MACHINE YEAR 2005 NEEDLES : 156 DIAMETER 3 ¾" QUANTITY: 2 B) LONATI FL 626 KNITTING MACHINE YEAR 2004 NEEDLES: 200 DIAMETER 3 ¾" QUANTITY: 1 C) LONATI FL 626 KNITTING MACHINE (SMOOTH AND TERRY PRODUCTS) YEAR OCTOBER 2004 NEEDLES : 168 DIAMETER 3 ¾" QUANTITY: 1 ALL RUNNING AND IN EXCELLENT CONDITION QUANTITY AVAILABLE: 3 Learn More

G-8636 LONATI FL 626 KNITTING MACHINES YEAR 2004 TO 2005REFERENCE NUMBER: G-8636 LONATI FL 626 KNITTING MACHINES YEAR 2004 TO 2005 A) LONATI FL 626 KNITTING MACHINE YEAR 2005 NEEDLES : 156 DIAMETER 3 ¾" QUANTITY: 2 B) LONATI FL 626 KNITTING MACHINE YEAR 2004 NEEDLES: 200 DIAMETER 3 ¾" QUANTITY: 1 C) LONATI FL 626 KNITTING MACHINE (SMOOTH AND TERRY PRODUCTS) YEAR OCTOBER 2004 NEEDLES : 168 DIAMETER 3 ¾" QUANTITY: 1 ALL RUNNING AND IN EXCELLENT CONDITION QUANTITY AVAILABLE: 3 Learn More -

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More

TT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mmTT-1316 NONWOVEN MIDDLE SPEED NEEDLE LOOM, WORKING WIDTH 3200mm MACHINE STRUCTURE FEATURES: 1. SPLICING TYPE STRUCTURE, IT IS MADE BY HIGH QUALITY Q235 STEEL PLATE WELDING, THEN FINE TEMPERING QUALITATIVELY WITH SUFFICIENT COMPLETENESS AND STABILITY. UPPER AND DOWN MACHINE GIRDERS BOTH PRECISELY PROCESSING MACHINED. 2. ECCENTRIC BEARINGS ADOPT TORRINGTON FAMOUS BRAND 3. MAIN SHAFT IS USING 42CROMO MATERIAL. AFTER CONDITIONING TREATMENT FINE FINISHING AND GRINDING. 4. NEEDLE GIRDER HIGH SPEED TURBINE ELECTRIC LIFTING, STRIPPER PLATE TURBINE ELECTRIC LIFTING, NEEDLE GIRDER ROLLER SCALE DISPLAY. AIR LOCKED THE NEEDLE PLATE TIGHTLY. 5. NEEDLE PLATE LUOYANG MADE BY MAGNESIUM ALLOY DIE CASTING PLATE COMPOSITE PU, RADON ARRANGE NEEDLES HOLE φ1.82mm 6. INPUT PVC LATTICE, OUTPUT ROLLER ADOPTS φ155mm, HIGH QUALITY SEAMLESS STEEL PIPE, AFTER FINISHING GRINDING, THE SURFACE IS PLATED WITH HARD CHROME, UPPER ROLLER ADJUSTABLE HEIGHT AIR CYLINDER. 7. MAIN MOTOR, OUTPUT ROLLER ALL FREQUENCY CONTROL. 8. INSTALLED POWER: AROUND 15.5KW, MAIN MOTOR 11 KW. QUANTITY: 1 SET Learn More