Search results for: 'rolling machine'

- Related search terms

- Machine+op

- Machine+fe

- Machine c''

- Machine fe'

- machine+de''

-

TT-3384 MASTER BAG 330, WIDTH 330mm, YEAR 2023TT-3384 MASTER BAG 330, WIDTH 330mm, YEAR 2023 CATEGORY BAG MAKING MODEL MASTER BAG 330 YEAR 2023 QUANTITY: 1 Learn More

TT-3384 MASTER BAG 330, WIDTH 330mm, YEAR 2023TT-3384 MASTER BAG 330, WIDTH 330mm, YEAR 2023 CATEGORY BAG MAKING MODEL MASTER BAG 330 YEAR 2023 QUANTITY: 1 Learn More -

NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015REFERENCE NUMBER: T-6868 NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015 NEEDLE PUNCH LINE EXIT WIDTH 2200/2500mm OVERHAULED AND UPDATED IN 2012/2015 TECHNOLOGY CONTROL BY S7 DESIGNED AND USED FOR NATURAL FIBRES, GLASS FIBRES, RECYCLED FIBRES 100% OR MIXED WITH PP FOR BASIC MATERIALS OF THE AUTOMOTIVE INDUSTRY CAPACITY: 400 KGS ITEM 001 2 BALE OPENER BRAND TEMAFA WORKING WIDTH: 1400mm WOODEN LATICE BELTS WOODEN TRANSPORT LATTICE VERY GOOD CONDITION INDIVIDUAL CONTROL OF OPENING AND MIXING ITEM 002 WILLOW BRAND TEMAFA 4 PAIRS STRIPPING AND WORKING ROLLERS WORKING WIDTH: 1400mm WITH VENTILATOR AND PIPE SYSTEM TO CHUTE FEED AND HOPPER FEEDER ITEM 003 CHUTE FEED BRAND TEMAFA WORKING WIDTH: 2700mm CONTROL OF FILLING HEIGHT BY ULTRASOUND SENSORS ITEM 004 HOPPER FEEDER BRAND OCTIR (RSP) GROUND BELT BY WOODEN LATTICE AND DRIVEN BY SEPARATE DRIVE VIA ECCENTRIC VIBRATION WALL MOBILE FRON WALL ITEM 005 CARDING MACHINE WORKING WIDTH: 2500mm 5 PAIRD STRIPPER AND WORKER INSTALLED 1 PAIR STRIPPER/WORKER SEPARATE DELIVERY INDIVIDUAL DRIVE SYSTEMS RIGID CARD CLOTHING MAIN DRUM 1600mm DIAMETER DOFFER DRUM 1200mm AND FLY COMB ITEM 006 CROSS LAPPER WEB FEEDING BY TRANSILON-BELTS EXIT BELT AS WOODEN LATTICE BELT ITEM 007 PRE-NEEDLE MACHINE BRAND DILO MODI DVM25 WORKING WIDTH: 2500mm ALL BELT SYSTEMS USE WOODEN LATTICE BELTS 1 NEEDLE BOARD NEEDLING FROM TOP TO BOTTOM ITEM 008 NEEDLE MACHINE BRAND ASSELIN WORKING WIDTH: 2200mm 4 NEEDLE BAR MACHINE (2 TOP/2 BOTTOM) ALTERNATING AND SIMULTANEOUS WORKING METHODS BY MODIFICATION OF DRIVING BELT WAYS PULL-OUT ROLLERS AT EXIT STROKE HEIGHT 40mm ITEM 009 ROLLING MACHINE 3 LONGITUDINAL CUTTER (TOP AND BOTTOM DRIVEN) 1 CROSS CUTTER CONTROL OF THE LINE: SEPARATE SYSTEM FOR BALE OPENING AND MIXING S7 CONTROL FOR COMPLETE LINE UPR TO DATE LEVEL, AIRCONDITIONED, CONTROL CABINETS CLOSE TO MACHINE OR SEPARATE MACHINES ARE IN VERY GOOD AND UPDATED CONDITION Learn More

NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015REFERENCE NUMBER: T-6868 NEEDLE PUNCH LINE, EXIT WIDTH 2200/2500mm, CAPACITY 400 KGS, OVERHAULED AND UPDATED 2012 AND 2015 NEEDLE PUNCH LINE EXIT WIDTH 2200/2500mm OVERHAULED AND UPDATED IN 2012/2015 TECHNOLOGY CONTROL BY S7 DESIGNED AND USED FOR NATURAL FIBRES, GLASS FIBRES, RECYCLED FIBRES 100% OR MIXED WITH PP FOR BASIC MATERIALS OF THE AUTOMOTIVE INDUSTRY CAPACITY: 400 KGS ITEM 001 2 BALE OPENER BRAND TEMAFA WORKING WIDTH: 1400mm WOODEN LATICE BELTS WOODEN TRANSPORT LATTICE VERY GOOD CONDITION INDIVIDUAL CONTROL OF OPENING AND MIXING ITEM 002 WILLOW BRAND TEMAFA 4 PAIRS STRIPPING AND WORKING ROLLERS WORKING WIDTH: 1400mm WITH VENTILATOR AND PIPE SYSTEM TO CHUTE FEED AND HOPPER FEEDER ITEM 003 CHUTE FEED BRAND TEMAFA WORKING WIDTH: 2700mm CONTROL OF FILLING HEIGHT BY ULTRASOUND SENSORS ITEM 004 HOPPER FEEDER BRAND OCTIR (RSP) GROUND BELT BY WOODEN LATTICE AND DRIVEN BY SEPARATE DRIVE VIA ECCENTRIC VIBRATION WALL MOBILE FRON WALL ITEM 005 CARDING MACHINE WORKING WIDTH: 2500mm 5 PAIRD STRIPPER AND WORKER INSTALLED 1 PAIR STRIPPER/WORKER SEPARATE DELIVERY INDIVIDUAL DRIVE SYSTEMS RIGID CARD CLOTHING MAIN DRUM 1600mm DIAMETER DOFFER DRUM 1200mm AND FLY COMB ITEM 006 CROSS LAPPER WEB FEEDING BY TRANSILON-BELTS EXIT BELT AS WOODEN LATTICE BELT ITEM 007 PRE-NEEDLE MACHINE BRAND DILO MODI DVM25 WORKING WIDTH: 2500mm ALL BELT SYSTEMS USE WOODEN LATTICE BELTS 1 NEEDLE BOARD NEEDLING FROM TOP TO BOTTOM ITEM 008 NEEDLE MACHINE BRAND ASSELIN WORKING WIDTH: 2200mm 4 NEEDLE BAR MACHINE (2 TOP/2 BOTTOM) ALTERNATING AND SIMULTANEOUS WORKING METHODS BY MODIFICATION OF DRIVING BELT WAYS PULL-OUT ROLLERS AT EXIT STROKE HEIGHT 40mm ITEM 009 ROLLING MACHINE 3 LONGITUDINAL CUTTER (TOP AND BOTTOM DRIVEN) 1 CROSS CUTTER CONTROL OF THE LINE: SEPARATE SYSTEM FOR BALE OPENING AND MIXING S7 CONTROL FOR COMPLETE LINE UPR TO DATE LEVEL, AIRCONDITIONED, CONTROL CABINETS CLOSE TO MACHINE OR SEPARATE MACHINES ARE IN VERY GOOD AND UPDATED CONDITION Learn More -

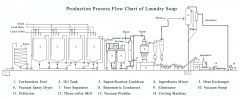

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR

K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HRREFERENCE NUMBER: K-3713 LAUNDRY SOAP PRODUCTION LINE-CAPACITY 1000 -1500 KG/HR THIS PRODUCT LINE IS A SOAP COMPLETE LINE STARTING FROM OIL MELTING, SAPONIFYING, VACUUM DRYING AND COOLING, MILLING SOAP NOODLES AND REFINING CONTINUOUSLY, THEN STAMPING INTO SOAPS. THIS PRODUCT LINE HAS ADVANCED TECHNOLOGY INCLUDING COVERING LESS FLOOR AREA, CONSUMING LESS ENERGY, SAVING HUMAN RESOURCES, AUTOMATING PROCESSES, PRODUCING HIGH QUALITY SOAPS WITH 50 TO 80% FATTY ACID CONTENT. QUANTITY AVAILABLE: 1

Learn More -

TT-7807 KUSTERS CONTINUOUS BLEACHING RANGE, WORKING WIDTH 3600 TO 3800mm, YEAR 1991TT-7807 KUSTERS CONTINUOUS BLEACHING RANGE, WORKING WIDTH 3600 TO 3800mm, YEAR 1991 1. KUSTERS CONTINUOUS BLEACHING RANGE 2. FOR FLAT AND TERRY COTTON AND COTTON BLENDED FABRIC 3. YEAR 1991 4. WORKING WIDTH: 3600 TO 3800mm 5. PRODUCTION SPEED: 120M/MIN QUANTITY: 1 Learn More

TT-7807 KUSTERS CONTINUOUS BLEACHING RANGE, WORKING WIDTH 3600 TO 3800mm, YEAR 1991TT-7807 KUSTERS CONTINUOUS BLEACHING RANGE, WORKING WIDTH 3600 TO 3800mm, YEAR 1991 1. KUSTERS CONTINUOUS BLEACHING RANGE 2. FOR FLAT AND TERRY COTTON AND COTTON BLENDED FABRIC 3. YEAR 1991 4. WORKING WIDTH: 3600 TO 3800mm 5. PRODUCTION SPEED: 120M/MIN QUANTITY: 1 Learn More -

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More

J-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mmJ-2125 COMPUTERIZED CHAIN-STITCH MULTI-NEEDLE QUILTING MACHINE & PANEL CUTTER (NEW) -WIDTH 2450mm QUILTING MACHINE QUILTING WIDTH: 2450mm QUANTITY: 1 PANEL CUTTER SPEED: 10 METERS PER MINUTE POWER: 3.2 KW AIR PRESSURE: 0.4 TO 0.8 Mpa VOLTAGE: 380 V / 50 Hz, 220 V / 60 Hz, 3-PHASE DIMENSIONS: 3500 x 1150 x 2300 (L x W x H mm) WEIGHT: 1150 KG QUANTITY: 1 Learn More -

Z-1616 AUTO MATTRESS COMPRESS AND ROLLZ-1616 AUTO MATTRESS COMPRESS AND ROLL THE COMPLETE PACKAGE LINE CONTAINS THE EQUIPMENT AUTO MATRESS COMPRESSING MACHINE AUTO MATRESS FOLDING AND ROTATING MACHINE MATRESS ROLL PACKING MACHINE MACHINE SIZE: L13100xW4200xH3300mm WEIGHT: 14000KG QUANTITY: 1 Learn More

Z-1616 AUTO MATTRESS COMPRESS AND ROLLZ-1616 AUTO MATTRESS COMPRESS AND ROLL THE COMPLETE PACKAGE LINE CONTAINS THE EQUIPMENT AUTO MATRESS COMPRESSING MACHINE AUTO MATRESS FOLDING AND ROTATING MACHINE MATRESS ROLL PACKING MACHINE MACHINE SIZE: L13100xW4200xH3300mm WEIGHT: 14000KG QUANTITY: 1 Learn More -

C-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mm

C-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mmC-4361 BABY WIPES FOLDING MACHINE Y-6, CAPACITY 40 TO 120 PCS/PACK (POP UP & NON POP UP), WIDTH 3000mm

Y-6 BABY WIPES FOLDING MACHINE

(POSSIBLE TO ADD ONE MORE RAW MATERIAL SHELF TO BE Y-12)

PS: Y-12 IS ADD ANOTHER RAW MATERIAL SHELF ON THE BASE OF Y-6

PRODUCTION FLOW: UNROLLING - SLITTING FABRIC INTO LANES - FOLDING - WETTING - CUTTING – PILE & COUNTING - DELIVERING

MAIN TECHNICAL PARAMETER (SUITABLE TO WET TISSUE FOR LARGE SIZE PACKING)

PRODUCT TYPE: BABY WIPES (NON CROSS FOLDING)

PRODUCT SPEED: 200 TO 270 CUTS/MIN (SET ON PLC)

SUITABLE RAW MATERIAL: AIR LAID PAPER, SPUNLACE/HOT-ROLLING NONWOVEN FABRIC

WEIGHT OF RAW MATERIAL: 40 TO 80 G/㎡

FOLDING WAY: “Z” SHAPE (NON-POP UP AND POP UP)

LENGTH OF WET TISSUE: 140 TO 185mm (SET ON PLC)

FREQUENCY OF RECEIVING PAPER: 14 TO 20 TIMES/MIN (SET ON PLC)

POWER SUPPLY: 380V 50HZ

POWER: 4KW

SIZE OF RAW MATERIAL: (1000 TO 1250) × Ø1000 (mm, W×DIA)

WET TISSUE UNFOLDED SIZE: (140 TO 185) × (150 TO 200) (mm, L×W)

WET TISSUE FOLDED SIZE: (140 TO 185) × (80 TO 110) (mm, L×W)

MATERIAL SUPPLY SYSTEM: SERVO MOTOR

CUTTING SYSTEM: CONVERTER MOTOR

PILING SYSTEM: SERVO MOTOR

POWER SUPPLY: 380V 50HZ

POWER: 6KW

SIZE OF MACHINE: 5200 × 3000 × 1800 (mm, L×W×H)

WEIGHT OF MACHINE: 1500 KG

OPTIONAL MAKING: Y-360 FULL AUTOMATIC RECIPROCATING TYPE PACKING MACHINE

CANISTER WET WIPES MACHINEQUANTITY: 1

Learn More -

P-4330 ROLL TYPE WET WIPES

P-4330 ROLL TYPE WET WIPESREFERENCE NUMBER: P-4330

ROLL TYPE WET WIPES

Model: WL-R

Machine Characteristic:

Control system: PLC

Drive element: inverter control

Operate interface: LCD touch screen

Packing style: end seal & rotary type

Detection online: raw material & film detect respectively

Moisture type: spray

SUS Agitate tank: 600L stainless steel agitate tank

Liquid level control: electronic detect control automatically

Specifications:

Raw material: spunlaced nonwoven, airlaid paper etc.

Raw material specification: max W300mm, φ1200mm

Diameter of ventilating shaft: 3"

Suitable packing material :BOPP CPP PET/PE PET/AL etc. heat-seal material

Packing Film specification: max W280mm, φ350mm

Diameter of ventilating shaft: 3"

Rolling type: V fold

Production size:L75-180mm max φ30mm

Open size: L150-300mm W150-300mm

Package size: L110-250mm W30-50mm

Production speed: up to packing material, design 200 bags/min

Machine space: L5000mm W3500mm H1900mm

Power: AC 380V 50/60Hz 4KW

Compressed air: 0.6-0.8Mpa 100L/min

Machine net weight : 2000kg

Option equipment: Production counting machine Coding machineQUANTITY: 1

Learn More -

P-2305 DOUBLE RASCHEL MACHINEREFERENCE NUMBER: P-2305 DOUBLE RASCHEL MACHINE DOUBLE RASCEL MACHINE 3 SETS MINK BLANKETS MANUFACTURING DUKSOO/WONIL 1 SET CUTTING (SLITTING) MACHINE WIDTH: 2600mm 2 SETS WARPING MACHINE 2 SETS ROLLING MACHINE WARP BEAM 14 INCHES x 19 INCHES QUANTITY AVAILABLE: 1 Learn More

P-2305 DOUBLE RASCHEL MACHINEREFERENCE NUMBER: P-2305 DOUBLE RASCHEL MACHINE DOUBLE RASCEL MACHINE 3 SETS MINK BLANKETS MANUFACTURING DUKSOO/WONIL 1 SET CUTTING (SLITTING) MACHINE WIDTH: 2600mm 2 SETS WARPING MACHINE 2 SETS ROLLING MACHINE WARP BEAM 14 INCHES x 19 INCHES QUANTITY AVAILABLE: 1 Learn More -

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More

C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992REFERENCE NUMBER: C-2459 FEHRER AIRLAY NONWOVEN LINE, WIDTH 2200mm, YEAR 1992 SPECIFICATIONS: 1 PC. AIRLAY NONWOVEN LINE FEHRER V 21 K 12 2200 MM WORKING WIDTH, YEAR OF CONSTRUCTION 1992, SECOND-HAND THE LINE IS CONSISTING OF: 1 PC. CHUTE FEEDER TEMAFA WITH CONDENSER. 1 PC. WEIGHTING UNIT KUKLA WITH CONTINUOUS BELT. 1 PC. FEEDING UNIT, CONTINUOUS BELT TYPE FEHRER - FEEDING V 21. 1 PC. WEB FORMING UNIT FEHRER V 21. 2200 mm WORKING WIDTH. 1 PC. AERODYNAMIC CARD FEHRER K 12, 2200 mm WORKING WIDTH. 1 PC. NEEDLE LOOM FEHRER NL 9 S, 2200 mm WORKING WIDTH. SINGLE BOARD DOWN STROKE MACHINE, 3000 NEEDLES/M. MAX. 1500 STROKES/MIN. WITH OUTLET ROLLERS. 1 PC. WINDER WITH LONGITUDINAL CUTTER. (NO CROSS CUTTER AVAILABLE.) 1 PC. COMPLETE DUST COLLECTION UNIT. THE V 21 K 12 LINE IS SUITABLE FOR A WEIGHT RANGE OF APPROX. 400 TO 2000 GR/SWM AND A CAPACITY OF UP TO 600 KG/H, DEPENDING ON FIBERS. THE CONTROL PANELS, FILTERS ETC. ARE IN A GOOD CONDITION. 1 PC. RANDOM CARDING MACHINE FEHRER K 12 (REF. NO. 2133817). 2300 mm WORKING WIDTH, YEAR OF CONSTRUCTION UNFORTUNATELY NOT KNOWN. WITH OPENING MACHINE K 12. WITH ONE ASSELIN NEEDLE LOOM MODEL 169, STROKE HEIGHT 0-30 MM. 2.800 mm WORKING WIDTH. WITH ONE FEHRER NEEDLE LOOM NL 12, 1200 STROKES/MIN. 60 mm STROKE HEIGHT, 2.400 mm WORKING WIDTH. INCL. CUTTING AND ROLLING SECTION. THE LINE CONSISTS OF K 12 SECTION ONLY. V 21 SECTION IS NOT INCLUDED. PREVIOUSLY USED FOR 200 TO 2000 GR/SQM. THE MINIMUM IS 200 GR/SQM. MAINLY USED TO PRODUCE HIGH QUALITY MATTRESS MATERIAL IN A SQM-RANGE OF 300-1200 G/SQM MADE FROM JUTE FIBRES. IN GENERAL ALMOST ALL TYPES OF FIBERS CAN BE PROCESSED. IT IS A GOOD MACHINE FOR NATURAL FIBERS. 1 PC. AIRLAY LINE ROLANDO / FEHRER V21/K12 (REF. NO. 2226950). 4400 MM WORKING WIDTH. THE LINE IS CONSISTING OF: - HOPPER FEEDER ROLANDO, CASTING IRON. - CHEMINEE FEEDER WITH AUTOMATIC REGULATED FEEDING ROLANDO. - SQUARE METER MEASURING UNIT AND CONTROL SYSTEM MADE BY FEHRER TYPE E-PW. - OPENER FEHRER V 21, 4400 MM WORKING WIDTH. - RANDOM CARDING MACHINE FEHRER K 12, 4400 MM WORKING WIDTH. THE LINE HAS WORKED ON 1000 GR / SQM AND UP. QUANTITY AVAILABLE: 1 Learn More