Search results for: 'Machine op'

- Related search terms

- Machine+f'

- MACHINE+S

- Machine c''

- machine+de'

- machine de''

-

TT-1753 COMPLETE OPEN END PLANT, 2688 ROTORS, YEAR 2017 TO 2018TT-1753 COMPLETE OPEN END PLANT, 2688 ROTORS, YEAR 2017 TO 2018 ITEM 001 TRUTZSCHLER BLOWROOM YEAR 2017 ITEM 002 TRUTZSCHLER CARDING QUANTITY: 6 ITEM 003 OPEN END SCHLAFHORST QUANTITY: 6 CONDITION: EXCELLENT Learn More

TT-1753 COMPLETE OPEN END PLANT, 2688 ROTORS, YEAR 2017 TO 2018TT-1753 COMPLETE OPEN END PLANT, 2688 ROTORS, YEAR 2017 TO 2018 ITEM 001 TRUTZSCHLER BLOWROOM YEAR 2017 ITEM 002 TRUTZSCHLER CARDING QUANTITY: 6 ITEM 003 OPEN END SCHLAFHORST QUANTITY: 6 CONDITION: EXCELLENT Learn More -

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More

TT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mmTT-1641 COMPLETE LINE FOR PROCESSING NON-WOVEN FABRIC, YEAR 1986 – 2200mm TRUTZSCHLER, SPINNBAU, RAMISCH KLEINEWEFERS, EDELMAN THERMOBOND LINE INTENDED USE: NONWOVEN PRODUCTION FROM ALL SYNTHETIC FIBRES AND MIXTURES WITH SYNTETIC FIBRES WHERE FIBRES SOFTENING POINT IS BELOW 250°C ROLLS WIDTH: 30mm TO MAX 2200mm ROLLS DIAMETER MAX 1000mm GRAMMAGES: 16GSM TO MAX 50GSM (DUPLEX 70GSM) EXIT TRIMMED WIDTH: 2000mm Learn More -

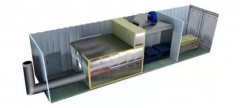

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More

YY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GASYY-2208 HUMAN CREMATION MACHINE, LIGHT DIESEL FUEL, GAS, NATURAL GAS, LIQUEFIED GAS DETAILS: 1. INCORPORATES EFFICIENT HEAT EXCHANGER AND SPECIAL AIR PATH STRUCTURE, MAKE FULL USE OF WASTE HEAT COMBUSTION FUEL GAS, IMPROVING HEAT UTILIZATION RATE, GOOD ENVIRONMENTAL PROTECTION INDEX, SAVES FUEL AND SHORTENS CREMATION TIME. 2. NEW REFRACTORY MATERIALS (EXCLUSIVE FORMULA) THAT ARE RESISTANT TO HIGH TEMPERATURE WITH LOW SPECIFIC HEAT. GREATLY EXTEND THE SERVICE LIFE. 3. SPECIAL CASTING MATERIAL, HIGH TEMPERATURE RESISTANCE, LONG SERVICE LIFE; SHORTENS THE COOLING CYCLE. THE BRICK STRUCTURE ON BOTH SIDES OF THE ASH PICKING FURNACE DOOR WILL NOT HAVE CRACKS CAUSED BY DESIGN OR QUALITY PROBLEMS GUARANTEED FOR ONE YEAR. REFRACTORY MATERIALS, THE FURNACE CONTACT ARE WITH FLAME HAS PHOSPHORIC ACID A CHARACTERISTIC COMBINATION BRICK WHICH CAN RESIST RAPID COOLING AND RAPID HEAT, AND THE ARCHED ROOF INCORPORATES HIGH ALUMINUM SINTERED MOLDING BRICK. THE FURNACE BODY IS SURROUNDED BY ALUMINUM SILICATE WOOL WITH GOOD HEAT INSULATION AND HEAT PRESERVATION PERFORMANCE. THE THICKNESS IS 180mm. 4. ALL OPERATING SYSTEMS OF THE EQUIPMENT HAVE THREE SETS OF OPERATION FUNCTIONS, NAMELY AUTOMATIC, SEMI-AUTOMATIC AND MANUAL, WHICH CAN BE SWITCH BETWEEN THEM WITHOUT INTERFERENCE. AUTOMATIC CONTROL, TELECOMMUNICATION OPERATION AND ANIMATION DISPLAY. KEEPING THE OPERATOR AWAY FROM THE CREMATION SITE AND PROTECTING THE OPERATOR. AT THE SAME TIME EQUIPPED WITH A STANDBY OPERATING SYSTEM. LOW NOISE MOTOR EQUIPMENT, THERMOCOUPLE RESISTANCE TO HIGH TEMPERATURE. ALL ELECTRICAL CABINETS OF THE EQUIPMENT ARE EXTERNAL. 5. THE OIL SUPPLY SYSTEM INCORPORATES AUTOMATIC CONTROL AND MANUAL CONTROL, AND INCORPORATES OIL PROTECTION TECHNOLOGY, WHICH CAN EFFECTIVELY PREVENT FUEL OIL FROM RUNNING, BUBBLING, LEAKING AND CAUSING FURNACE EXPLOSION ACCIDENTS INCLUDING ANTI-LEAKAGE TECHNOLOGY TO BETTER PROTECT THE PERSONAL SAFETY OF OPERATORS. 6. THE BLOWER, THE INDUCED DRAFT FAN, THE FURNACE DOOR MOTOR, THE BODY CART MOTOR, THE PREPARATORY DOOR MOTOR AND THE FLUE GATE MOTOR ARE ALL INSTALLED WITH AN INTEGRATED DEVICE FOR OVER-CURRENT AND SHORT-CIRCUIT PROTECTION. 7. SPECIAL DIESEL METERING DEVICE, ACCURATE METERING. QUANTITY: 1 Learn More -

YY-2072 AUTOMATIC HEMMING MACHINE, SEWING WIDTH 1000 TO 2400mm -OUTPUT: 2 TO 3 PIECES/MINUTEYY-2072 AUTOMATIC HEMMING MACHINE, SEWING WIDTH 1000 TO 2400mm -OUTPUT: 2 TO 3 PIECES/MINUTE TECHNICAL PARAMETERS: DIMENSIONS (L X W X H): 3235 X 4065 X 2035mm SEWING WIDTH: 1000 TO 2400mm MAXIMUM SEWING THICKNESS: 80mm STITCH: 3 TO 12mm POWER: 10 KW WEIGHT: 2800 KG VOLTAGE: 220 VOLTS 50/60Hz OR 380 VOLTS 50Hz OUTPUT: 2 TO 3 PIECES/MINUTE QUANTITY: 1 Learn More

YY-2072 AUTOMATIC HEMMING MACHINE, SEWING WIDTH 1000 TO 2400mm -OUTPUT: 2 TO 3 PIECES/MINUTEYY-2072 AUTOMATIC HEMMING MACHINE, SEWING WIDTH 1000 TO 2400mm -OUTPUT: 2 TO 3 PIECES/MINUTE TECHNICAL PARAMETERS: DIMENSIONS (L X W X H): 3235 X 4065 X 2035mm SEWING WIDTH: 1000 TO 2400mm MAXIMUM SEWING THICKNESS: 80mm STITCH: 3 TO 12mm POWER: 10 KW WEIGHT: 2800 KG VOLTAGE: 220 VOLTS 50/60Hz OR 380 VOLTS 50Hz OUTPUT: 2 TO 3 PIECES/MINUTE QUANTITY: 1 Learn More -

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More

T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003T-9753 BRUNO MODEL FH250-T TOGGLE DIE CUTTING PRESS BELT-FEED FOR SHEET AND ROLLED MATERIALS, 78” X 54”, 250 TON-YEAR 2003 78” X 54” BRUNO FH 250-T YEAR: 2003 QUANTITY: 1 Learn More -

YY-1792 ROLL WINDING MACHINE (AUTOMAT FOR FILM AND PAPER), WIDTH 1.200mm, YEAR 2006YY-1792 ROLL WINDING MACHINE (AUTOMAT FOR FILM AND PAPER), WIDTH 1.200mm, YEAR 2006 FILM THICKNESS: FROM 5 MICRONS TO 4 X 100 MICRONS MINIMUM WINDING WIDTH: 600mm / 23.3 IN MAXIMUM WINDING WIDTH: 1200mm / 47,2 IN MAXIMUM FILM SPEED: 220 M/MIN (720 FT/MIN) MAXIMUM ROLL CHANGES: 16/MIN MAXIMUM ROLL DIAMETER: 250mm / 9.8 IN CORES: WITH OR WITHOUT CORES PAPER CORE DIAMETER: FROM 38mm (1.5 IN) NUMBER OF LANES: 1 PERFORMANCE: MAXIMUM FILM SPEED: 220 M/MIN (720 FT/MIN) MAXIMUM ROLL CHANGES: 16/MIN QUANTITY: 1 Learn More

YY-1792 ROLL WINDING MACHINE (AUTOMAT FOR FILM AND PAPER), WIDTH 1.200mm, YEAR 2006YY-1792 ROLL WINDING MACHINE (AUTOMAT FOR FILM AND PAPER), WIDTH 1.200mm, YEAR 2006 FILM THICKNESS: FROM 5 MICRONS TO 4 X 100 MICRONS MINIMUM WINDING WIDTH: 600mm / 23.3 IN MAXIMUM WINDING WIDTH: 1200mm / 47,2 IN MAXIMUM FILM SPEED: 220 M/MIN (720 FT/MIN) MAXIMUM ROLL CHANGES: 16/MIN MAXIMUM ROLL DIAMETER: 250mm / 9.8 IN CORES: WITH OR WITHOUT CORES PAPER CORE DIAMETER: FROM 38mm (1.5 IN) NUMBER OF LANES: 1 PERFORMANCE: MAXIMUM FILM SPEED: 220 M/MIN (720 FT/MIN) MAXIMUM ROLL CHANGES: 16/MIN QUANTITY: 1 Learn More -

T-9185 BARMAG POY LINE 2, CAPACITY 11,500 TO 16,000 KG-DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER 6 END, 1200mm CHUCK = 192 THREAD LINESREFERENCE NUMBER: T-9185 BARMAG POY LINE 2, CAPACITY 11,500 TO 16,000 KG-DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER 6 END, 1200mm CHUCK = 192 THREAD LINES 70-100 DENIER MACHINE IS CAPACITY 11,500 TO 16,000 KG/DAY YEAR: 1998 Learn More

T-9185 BARMAG POY LINE 2, CAPACITY 11,500 TO 16,000 KG-DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER 6 END, 1200mm CHUCK = 192 THREAD LINESREFERENCE NUMBER: T-9185 BARMAG POY LINE 2, CAPACITY 11,500 TO 16,000 KG-DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER 6 END, 1200mm CHUCK = 192 THREAD LINES 70-100 DENIER MACHINE IS CAPACITY 11,500 TO 16,000 KG/DAY YEAR: 1998 Learn More -

T-9184 BARMAG POY LINE 1, CAPACITY 11,500 TO 16,000 KG/DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER, 6 END, 1200mm CHUCK = 192 THREAD LINEST-9184 BARMAG POY LINE 1, CAPACITY 11,500 TO 16,000 KG/DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER, 6 END, 1200mm CHUCK = 192 THREAD LINES 70-100 DENIER MACHINE IS CAPACITY 11,500 TO 16,000 KG/DAY YEAR 1998 Learn More

T-9184 BARMAG POY LINE 1, CAPACITY 11,500 TO 16,000 KG/DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER, 6 END, 1200mm CHUCK = 192 THREAD LINEST-9184 BARMAG POY LINE 1, CAPACITY 11,500 TO 16,000 KG/DAY, YEAR 1998 -WITH 32 SETS BARMAG CW WINDER, 6 END, 1200mm CHUCK = 192 THREAD LINES 70-100 DENIER MACHINE IS CAPACITY 11,500 TO 16,000 KG/DAY YEAR 1998 Learn More -

T-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINEST-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINES 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More

T-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINEST-9183 BARMAG FDY LINE 2, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 END, 920mm CHUCK = 102 THREAD LINES 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More -

T-9182 BARMAG FDY LINE 1, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 ENDS, 920mm CHUCK = 102 THREAD LINEST-9182 BARMAG FDY LINE 1, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 ENDS, 920mm CHUCK = 102 THREAD LINES FDY LINE 1 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More

T-9182 BARMAG FDY LINE 1, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 ENDS, 920mm CHUCK = 102 THREAD LINEST-9182 BARMAG FDY LINE 1, CAPACITY 3,250 TO 4,600 KG/DAY, YEAR 1998 -WITH 17 SETS BARMAG CW WINDER, 6 ENDS, 920mm CHUCK = 102 THREAD LINES FDY LINE 1 50-70 DENIER MACHINE IS CAPACITY 3,250 TO 4,600 KG/DAY YEAR 1998 Learn More